by Fronetics | Feb 19, 2015 | Blog, Strategy, Supply Chain, Warehousing & Materials Handling

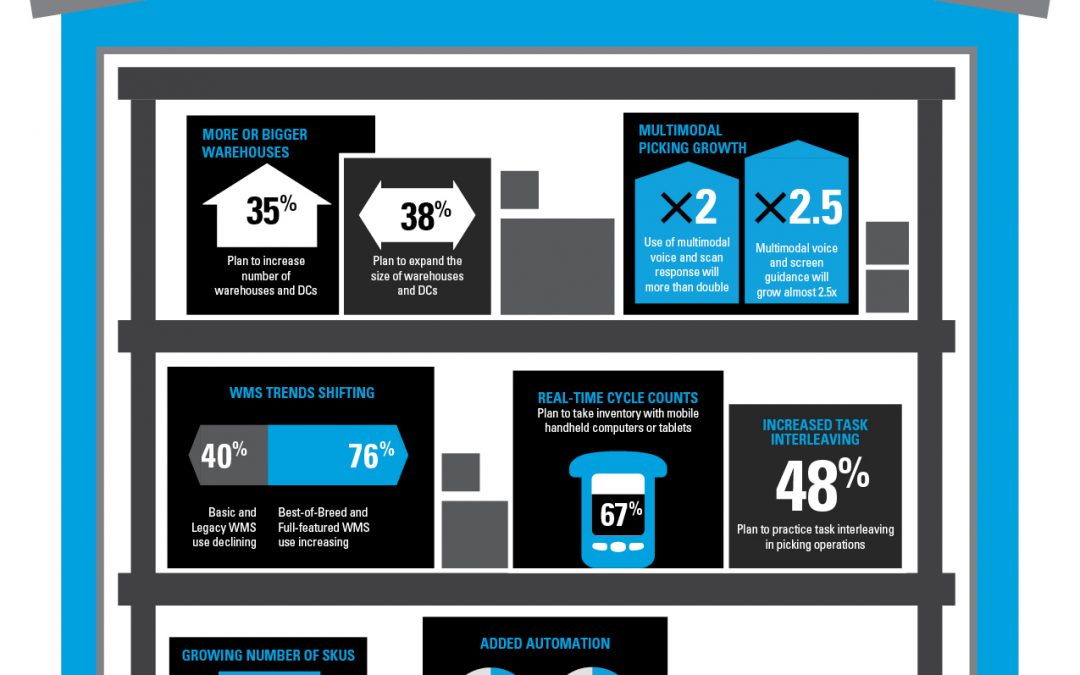

Source: Motorola

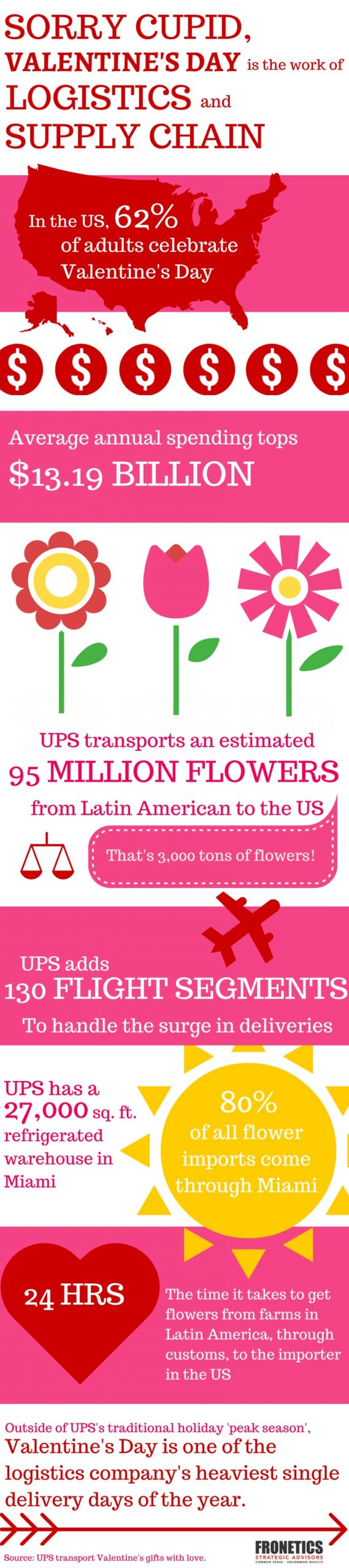

Growing in concert with consumer demand, distribution centers are getting bigger. In fact, a 2013 Motorola Warehouse Vision Survey reported that a full thirty-eight percent of respondents would be increasing the size of their warehouses and distribution centers over the next five years. And while there are certainly potential benefits, there are also plenty of potential problems. With good planning, though, organizations can successfully navigate around the pitfalls of distribution center growth.

Here’s how to achieve success when growing the size of your distribution center.

Streamline operations and processes

Increasing the square footage of your distribution center requires extensive strategy pre-planning. This means taking stock of your entire logistics and distribution process and strategically thinking about how these processes can be made more efficient. Areas where many companies can increase efficiencies include: decreasing reliance on paper, cross-docking, incorporating multi-modal wireless solutions, and revamping the pick strategy.

Optimize communication across departments

Communication is essential when growing your distribution center. Communicating across departments will enable your company to be able to effectively plan for both current capacity requirements as well as capacity requirements that are forecasted in the near-, mid-, and long-term. Building a larger distribution center only to outgrow it five years later is a costly mistake. Furthermore, communication across departments will allow for the right-sizing of both equipment and labor.

Be flexible

Allowing for flexibility is a key factor of successful growth. A large distribution center that can process a limited number of SKUs is, well, limited. A distribution center that is designed to be able to process a wide variety of goods and SKUs can reduce operating costs and enable your company to be more nimble. When designing your distribution center, keep flexibility at the forefront.

Invest and utilize technology

A larger distribution center requires more automation and more technology than a smaller distribution center. Similarly, a larger distribution benefits from mobile solutions. As more specific and sophisticated technology emerges, implementing smart technologies can aid in your efforts to achieve optimization of communications and streamline your operations more efficiently.

When the square footage of your distribution center grows, it is important to remember that you are dealing with a different beast. It’s one that requires extra careful thought. Taking the time to consider potential problems and preparing a solid plan of implementation before you begin will increase your odds of successful growth.

by Fronetics | Feb 9, 2015 | Blog, Logistics, Strategy, Supply Chain

Reducing paper in the distribution center is good for business (and trees).

Paper isn’t a thing of the past in workplaces, but it probably should be. The reasons go well beyond simply saving trees to an even more compelling argument: it’s just better business. A 2014 survey conducted by the Association for Information and Image Management (AIIM) found that more than half of responding businesses posited that the single largest way they could improve productivity would be to remove paper from their organizational processes.

The study’s implications for companies in the supply chain industry echo a 2005 Inbound Logistics article in which Leslie Hansen Harps wrote that the speed through the distribution center is critical. “Effective operations use best practices within the four walls of the facility — and beyond.” One of the best-practices discussed in the article: reducing reliance on paper. Specifically, the article referenced moving to hands-free solutions. Denny McKnight of Tompkins Associates Inc. told Harps: “People writing numbers on pads of paper or keying strings of numbers into a keyboard is a bad sign.”

Of the companies reporting superfluous paper use as an impediment to greater productivity in the 2014 AIIM study, less than 20% have paper-reducing policies in place. This finding highlights the fact that many companies have identified the need to reduce their use of paper, but most lack a clear vision for doing so. While the shift to a paper-free distribution center can seem overwhelming and cost prohibitive, small efforts to eliminate unnecessary paper can dramatically improve efficiencies. To start, consider the identification of one organizational process where it would make sense to introduce a paper-free method and spend an hour researching how other companies have transformed similar processes and which solutions have proved to be the most successful.

No doubt, as faster, more sophisticated technology couples with a more computer literate workforce, distribution centers will see an organic shift to a paper-less work environment. Including regular reviews of ways your company could implement paperless processes ensures paper doesn’t slow you down. After all, finding ways to eliminate paper is akin to finding gains in operational efficiency.

Here are 10 (more!) reasons why your company should tame its paper tiger:

- Increased inventory visibility

- Increased fulfillment accuracy

- Fewer lost sales

- Fewer out-of-stock situations

- Reduced search time

- Increased communication with customers

- Waste reduction

- Overhead cost cuts

- Document storage cost cuts

- A safer work environment

Has your company reduced its reliance on paper? If so, what benefits have you realized? If not, what barriers to the implementation of paperless processes have you experienced?

by Fronetics | Feb 9, 2015 | Blog, Logistics, Strategy, Supply Chain

Reducing paper in the distribution center is good for business (and trees).

Paper isn’t a thing of the past in workplaces, but it probably should be. The reasons go well beyond simply saving trees to an even more compelling argument: it’s just better business. A 2014 survey conducted by the Association for Information and Image Management (AIIM) found that more than half of responding businesses posited that the single largest way they could improve productivity would be to remove paper from their organizational processes.

The study’s implications for companies in the supply chain industry echo a 2005 Inbound Logistics article in which Leslie Hansen Harps wrote that the speed through the distribution center is critical. “Effective operations use best practices within the four walls of the facility — and beyond.” One of the best-practices discussed in the article: reducing reliance on paper. Specifically, the article referenced moving to hands-free solutions. Denny McKnight of Tompkins Associates Inc. told Harps: “People writing numbers on pads of paper or keying strings of numbers into a keyboard is a bad sign.”

Of the companies reporting superfluous paper use as an impediment to greater productivity in the 2014 AIIM study, less than 20% have paper-reducing policies in place. This finding highlights the fact that many companies have identified the need to reduce their use of paper, but most lack a clear vision for doing so. While the shift to a paper-free distribution center can seem overwhelming and cost prohibitive, small efforts to eliminate unnecessary paper can dramatically improve efficiencies. To start, consider the identification of one organizational process where it would make sense to introduce a paper-free method and spend an hour researching how other companies have transformed similar processes and which solutions have proved to be the most successful.

No doubt, as faster, more sophisticated technology couples with a more computer literate workforce, distribution centers will see an organic shift to a paper-less work environment. Including regular reviews of ways your company could implement paperless processes ensures paper doesn’t slow you down. After all, finding ways to eliminate paper is akin to finding gains in operational efficiency.

Here are 10 (more!) reasons why your company should tame its paper tiger:

- Increased inventory visibility

- Increased fulfillment accuracy

- Fewer lost sales

- Fewer out-of-stock situations

- Reduced search time

- Increased communication with customers

- Waste reduction

- Overhead cost cuts

- Document storage cost cuts

- A safer work environment

Has your company reduced its reliance on paper? If so, what benefits have you realized? If not, what barriers to the implementation of paperless processes have you experienced?

by Fronetics | Feb 5, 2015 | Blog, Logistics, Strategy, Supply Chain

Think inbound marketing isn’t for the supply chain and logistics industries? Guess again. Here are 5 reasons companies in the supply chain and logistics industries need inbound marketing.

Companies within the supply chain and logistics industries tend to disregard inbound marketing. The reason being they do not think inbound marketing will prove successful. The common objection is that prospects and customers for these industries are not online.

The reality, however, is that inbound marketing can be wildly successful for companies within the supply chain and logistics industries.

Here are five reasons why companies in these industries should use inbound marketing:

1. Customers are online.

B2B buyers are online. 93% of B2B buyers report that they use search engines to research purchase decisions. These buyers go online for a number of reasons including to:

- Learn about new market developments and industry practices;

- Discover new solutions to address a specific problem;

- Address a project or a program being undertaken by their company.

2. 60% of the sales process takes place before they engage your sales rep.

The average customer progresses nearly 60% of the way through the purchase decision-making process before engaging with a sales rep.

Before engaging with a sales rep, customers are turning to the internet and to social media for information. The 2014 UPS B2B Buyers Insight Study found that 68% percent of buyers research supply purchases via supplier website, and 52% use search engines.

3. You can present solutions to your prospects’ problems via social media and content.

When prospects go online they are looking for information and for answers. By creating valuable content and leveraging social media you can attract and engage prospects, and convert these prospects to customers.

4. Inbound marketing is more effective than traditional marketing.

Research conducted by HubSpot found that inbound marketing is more effective than outbound marketing:

- 200% average ROI;

- 62% lower cost head;

- 15% increase in top line revenue.

5. The proof is in the pudding.

Freight logistics company Cerasis decided to make the switch from outbound marketing to inbound marketing. Within 25 months the company gained 98 new customers and increased revenue by 14%.

Fronetics Strategic Advisors is a management consulting firm with a focus on inbound marketing. We create and execute successful strategies for growth and value creation. Unlike other firms, our approach is data driven. We know ROI is important, so we track and measure results to drive success. Read about our approach to inbound marketing, or get in touch.

by Fronetics | Feb 5, 2015 | Blog, Logistics, Strategy, Supply Chain

Think inbound marketing isn’t for the supply chain and logistics industries? Guess again. Here are 5 reasons companies in the supply chain and logistics industries need inbound marketing.

Companies within the supply chain and logistics industries tend to disregard inbound marketing. The reason being they do not think inbound marketing will prove successful. The common objection is that prospects and customers for these industries are not online.

The reality, however, is that inbound marketing can be wildly successful for companies within the supply chain and logistics industries.

Here are five reasons why companies in these industries should use inbound marketing:

1. Customers are online.

B2B buyers are online. 93% of B2B buyers report that they use search engines to research purchase decisions. These buyers go online for a number of reasons including to:

- Learn about new market developments and industry practices;

- Discover new solutions to address a specific problem;

- Address a project or a program being undertaken by their company.

2. 60% of the sales process takes place before they engage your sales rep.

The average customer progresses nearly 60% of the way through the purchase decision-making process before engaging with a sales rep.

Before engaging with a sales rep, customers are turning to the internet and to social media for information. The 2014 UPS B2B Buyers Insight Study found that 68% percent of buyers research supply purchases via supplier website, and 52% use search engines.

3. You can present solutions to your prospects’ problems via social media and content.

When prospects go online they are looking for information and for answers. By creating valuable content and leveraging social media you can attract and engage prospects, and convert these prospects to customers.

4. Inbound marketing is more effective than traditional marketing.

Research conducted by HubSpot found that inbound marketing is more effective than outbound marketing:

- 200% average ROI;

- 62% lower cost head;

- 15% increase in top line revenue.

5. The proof is in the pudding.

Freight logistics company Cerasis decided to make the switch from outbound marketing to inbound marketing. Within 25 months the company gained 98 new customers and increased revenue by 14%.

Fronetics Strategic Advisors is a management consulting firm with a focus on inbound marketing. We create and execute successful strategies for growth and value creation. Unlike other firms, our approach is data driven. We know ROI is important, so we track and measure results to drive success. Read about our approach to inbound marketing, or get in touch.

![The Valentine’s Day Supply Chain [Infographic]](https://fronetics.com/wp-content/uploads/2024/10/Valentines-Day-Supply-Chain1-800x675.jpg)

by Fronetics | Feb 3, 2015 | Blog, Strategy, Supply Chain

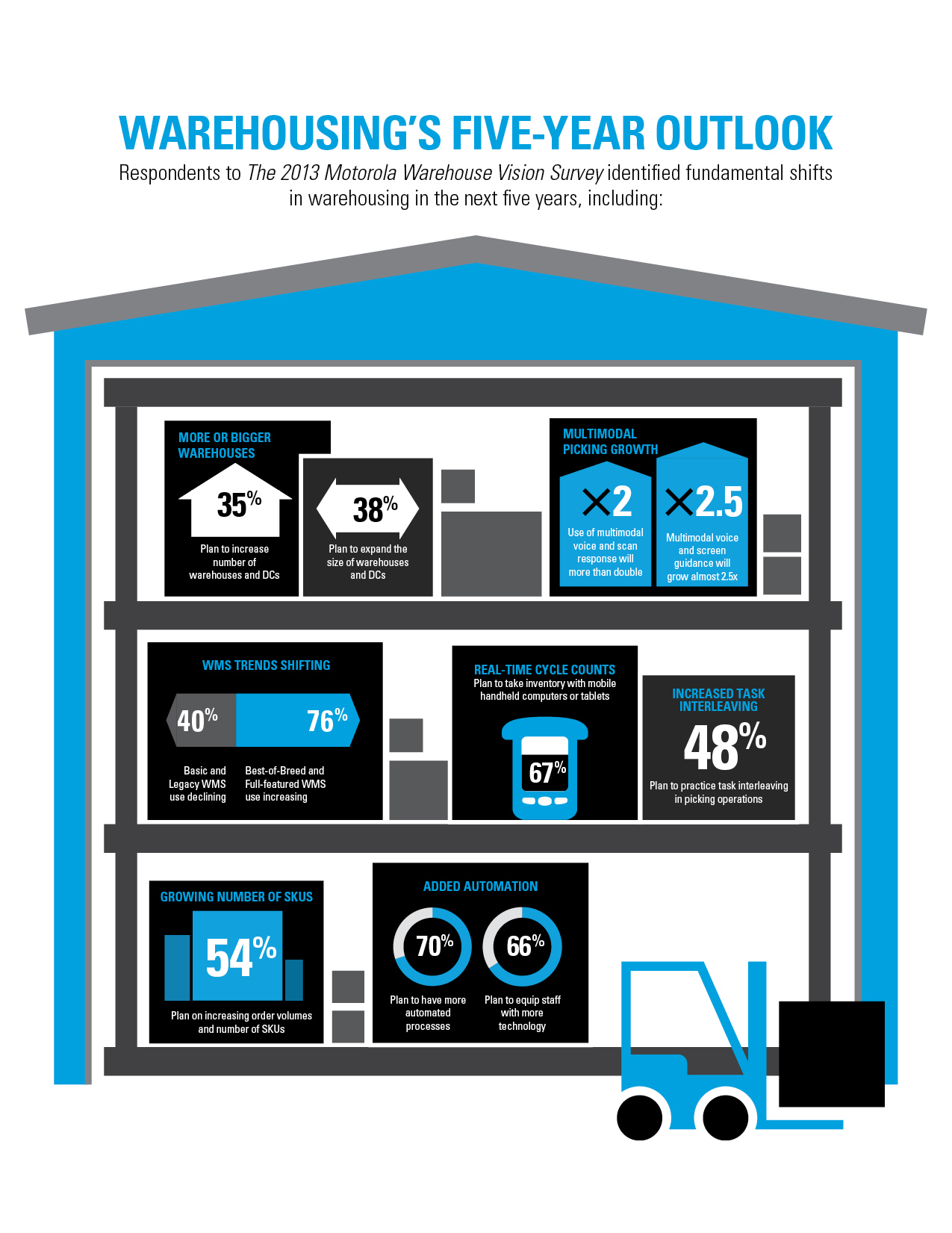

The Valentine’s Day supply chain by the numbers.

In the late 400s Gelasius declared February 14th as a day for honoring Saint Valentine. Over the years February 14th became associated with love and romance (1300s) and the exchange of cards (1600s). In the 1840s the first mass produced Valentine’s Day cards were sold in the US.

Over the years Valentine’s Day has become big business. 62% of adults in the US say that they celebrate the holiday. Spending for Valentine’s Day tops $13.9 billion. $8.9 billion is spent on sparkling wine (174,000 gallons are sold during the holiday week alone). The number of cards and gifts exchanged totals 150 million.

Cupid gets the credit for the holiday, but really Valentine’s Day is the work of logistics and supply chain. UPS alone transports more than 3,000 tons of flowers for Valentine’s Day – requiring the company to add an additional 130 flight segments.

Check out our infographic. You’ll see that Cupid really doesn’t play much of a role (sorry Cupid).

![The Valentine’s Day Supply Chain [Infographic]](https://fronetics.com/wp-content/uploads/2024/10/Valentines-Day-Supply-Chain1-800x675.jpg)