by Jennifer Hart Yim | May 20, 2015 | Blog, Manufacturing & Distribution, Strategy, Supply Chain, Warehousing & Materials Handling

This article is part of a series of articles written by MBA students and graduates from the University of New Hampshire Peter T. Paul College of Business and Economics.

David Chadwick is an MBA student at the University of New Hampshire with a background in retail store management and electrical engineering.

If technology continues to advance, humans may be obsolete in the supply chain as a result of both automation and RFID utilization. Both technologies have been introduced into the supply chain over the past decade, resulting in a major shift in performance and costs. While automation is a process which can navigate product throughout facilities, RFID can improve efficiency dramatically as well as being the major driver for the elimination of human involvement in the supply chain.

If technology continues to advance, humans may be obsolete in the supply chain as a result of both automation and RFID utilization. Both technologies have been introduced into the supply chain over the past decade, resulting in a major shift in performance and costs. While automation is a process which can navigate product throughout facilities, RFID can improve efficiency dramatically as well as being the major driver for the elimination of human involvement in the supply chain.

RFID (Radio Frequency Identification) is a form of extremely low-power data communication between a RFID scanner and an RFID tag. The tags are placed on any number of items, ranging from individual parts to shipping labels. The RFID tag itself consists of a microchip and antennae, usually without a battery to power it. The tags can be printed using special printers, which wirelessly load the identifying information to the tags. The information on the tags can be used for a wide variety of tasks. When an item goes through the RFID scanners, information is read from the tag, which could include any amount of information, such as:

- Order ID number

- Product bin location

- Order status

- Serial numbers for individual product components

- Location logs

The information is not limited to just holding ID and serial numbers. Since the information can be updated and transferred through any RFID receiver when in range, it can be joined with other software to update databases, send information online, and more. The amount of information that RFID can provide can be matched with order management systems to track shipment and stock locations automatically as the products move through warehouses and trucks. Powerful receivers can also track the exact location of products within a warehouse in real time, instead of relying on time and location logs to determine the location. This has been a major benefit to UPS, who’ve had RFID tracking chips in their warehouses for over ten years.

The largest problem facing supply chain management today is the potential for the occurrence of devastating errors. These errors could lead to trucks leaving product behind, not stocking to capacity, losing product, or delivering to the wrong locations. There are numerous reasons for such errors to occur, but the most common factor in their inception is human error. Much of the errors faced result from manual inspection and control over product flow in warehouses by humans. Many systems still operate using written data tables and checklists, which can be written incorrectly. Despite major advancements in technology over the past decade, the digital world is being sourced by analog supply chains. This is an aspect which RFID control can create beneficial change.

RFID can lead to completely autonomous warehouses and distribution centers. This can be seen in current warehouses with high levels of automation, where picking machines transport bins of product to a central sorting area to be boxed, before returning to their location. Zebra uses this technique to ensure product location accuracy as a means of reducing lost merchandise. Zebra places a great deal of importance on product visibility and transparency as well as accuracy in locations. Implementation of RFID into this system can ensure that both the correct product and the correct quantities of product are collected at both points, thereby eliminating errors seen in traditional analog supply networks. Coupled with the potential for self-driving trucks and the ever expanding internet of things in the cloud, product information can be tracked at all stages of shipment and storage, increasing accuracy, efficiency, and accountability. Where warehouses and receiving departments had to endure a certain amount of shrinkage of products in the past, a fully utilized RFID-enabled supply network can determine exactly where product is at all times, ensuring that theft is discovered immediately and enforced.

While the reduction of human interaction in the supply chain and warehouses in general can be eliminated with enough technology, it is uncertain to what degree this technology will be implemented in all aspects of supply chain management. While there are huge benefits to operating in such a system, the major negatives include high initial costs and restructuring costs associated with implementing this network into existing, analog networks. Humanity may not be completely removed from the supply chain in the future, but this technology, as well as more advanced techniques for automation, will increase the efficiency and reduce the costs required to operate these newer supply chains dramatically while significantly reducing errors and inefficiencies.

by Jennifer Hart Yim | May 20, 2015 | Blog, Manufacturing & Distribution, Strategy, Supply Chain, Warehousing & Materials Handling

This article is part of a series of articles written by MBA students and graduates from the University of New Hampshire Peter T. Paul College of Business and Economics.

David Chadwick is an MBA student at the University of New Hampshire with a background in retail store management and electrical engineering.

If technology continues to advance, humans may be obsolete in the supply chain as a result of both automation and RFID utilization. Both technologies have been introduced into the supply chain over the past decade, resulting in a major shift in performance and costs. While automation is a process which can navigate product throughout facilities, RFID can improve efficiency dramatically as well as being the major driver for the elimination of human involvement in the supply chain.

If technology continues to advance, humans may be obsolete in the supply chain as a result of both automation and RFID utilization. Both technologies have been introduced into the supply chain over the past decade, resulting in a major shift in performance and costs. While automation is a process which can navigate product throughout facilities, RFID can improve efficiency dramatically as well as being the major driver for the elimination of human involvement in the supply chain.

RFID (Radio Frequency Identification) is a form of extremely low-power data communication between a RFID scanner and an RFID tag. The tags are placed on any number of items, ranging from individual parts to shipping labels. The RFID tag itself consists of a microchip and antennae, usually without a battery to power it. The tags can be printed using special printers, which wirelessly load the identifying information to the tags. The information on the tags can be used for a wide variety of tasks. When an item goes through the RFID scanners, information is read from the tag, which could include any amount of information, such as:

- Order ID number

- Product bin location

- Order status

- Serial numbers for individual product components

- Location logs

The information is not limited to just holding ID and serial numbers. Since the information can be updated and transferred through any RFID receiver when in range, it can be joined with other software to update databases, send information online, and more. The amount of information that RFID can provide can be matched with order management systems to track shipment and stock locations automatically as the products move through warehouses and trucks. Powerful receivers can also track the exact location of products within a warehouse in real time, instead of relying on time and location logs to determine the location. This has been a major benefit to UPS, who’ve had RFID tracking chips in their warehouses for over ten years.

The largest problem facing supply chain management today is the potential for the occurrence of devastating errors. These errors could lead to trucks leaving product behind, not stocking to capacity, losing product, or delivering to the wrong locations. There are numerous reasons for such errors to occur, but the most common factor in their inception is human error. Much of the errors faced result from manual inspection and control over product flow in warehouses by humans. Many systems still operate using written data tables and checklists, which can be written incorrectly. Despite major advancements in technology over the past decade, the digital world is being sourced by analog supply chains. This is an aspect which RFID control can create beneficial change.

RFID can lead to completely autonomous warehouses and distribution centers. This can be seen in current warehouses with high levels of automation, where picking machines transport bins of product to a central sorting area to be boxed, before returning to their location. Zebra uses this technique to ensure product location accuracy as a means of reducing lost merchandise. Zebra places a great deal of importance on product visibility and transparency as well as accuracy in locations. Implementation of RFID into this system can ensure that both the correct product and the correct quantities of product are collected at both points, thereby eliminating errors seen in traditional analog supply networks. Coupled with the potential for self-driving trucks and the ever expanding internet of things in the cloud, product information can be tracked at all stages of shipment and storage, increasing accuracy, efficiency, and accountability. Where warehouses and receiving departments had to endure a certain amount of shrinkage of products in the past, a fully utilized RFID-enabled supply network can determine exactly where product is at all times, ensuring that theft is discovered immediately and enforced.

While the reduction of human interaction in the supply chain and warehouses in general can be eliminated with enough technology, it is uncertain to what degree this technology will be implemented in all aspects of supply chain management. While there are huge benefits to operating in such a system, the major negatives include high initial costs and restructuring costs associated with implementing this network into existing, analog networks. Humanity may not be completely removed from the supply chain in the future, but this technology, as well as more advanced techniques for automation, will increase the efficiency and reduce the costs required to operate these newer supply chains dramatically while significantly reducing errors and inefficiencies.

by Jennifer Hart Yim | Jun 26, 2014 | Blog, Internet of Things, Logistics, Manufacturing & Distribution, Marketing, Social Media, Strategy, Supply Chain

This article is part of a series of articles written by MBA students and graduates from the University of New Hampshire Peter T. Paul College of Business and Economics.

Supply Chain Management will use the Internet of Things to improve factory workflow, increase material tracking, and optimize distribution to maximize revenues.

“Clap on “(clap, clap), “Clap off” (clap, clap), “the Clapper”!!

When introduced in 1986, “The Clapper” light switch was considered a significant breakthrough in home automation. Today, with advances in communication, sensors, and internet-connected devices, you can change the temperature of your home, your lights, appliances, and security system all from your smartphone — from anywhere in the world. This is just one simple example in the growing “Internet of Things” technology. The potential is enormous, not just in home automation but in industrial applications like manufacturing and distribution.

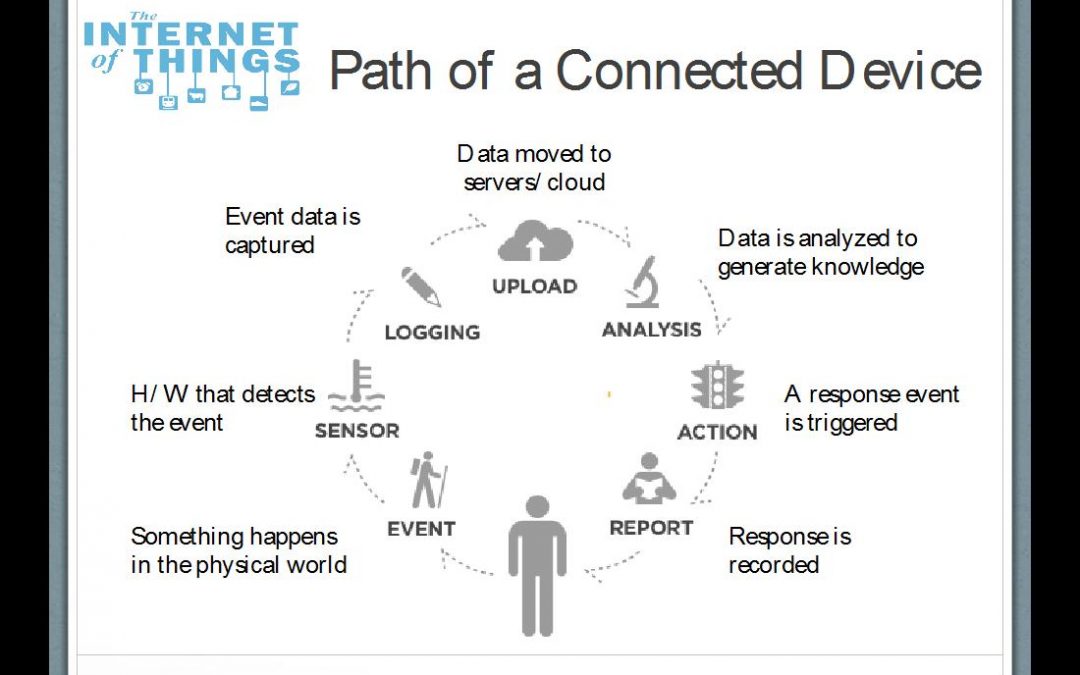

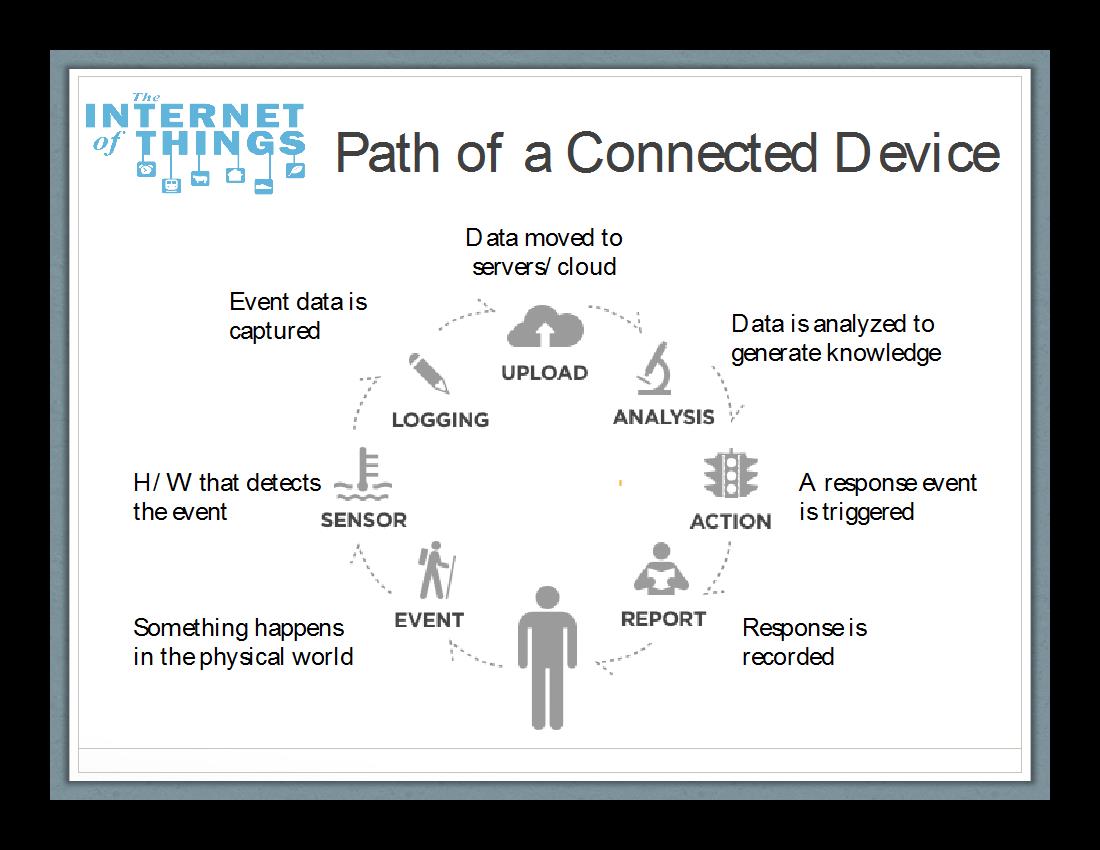

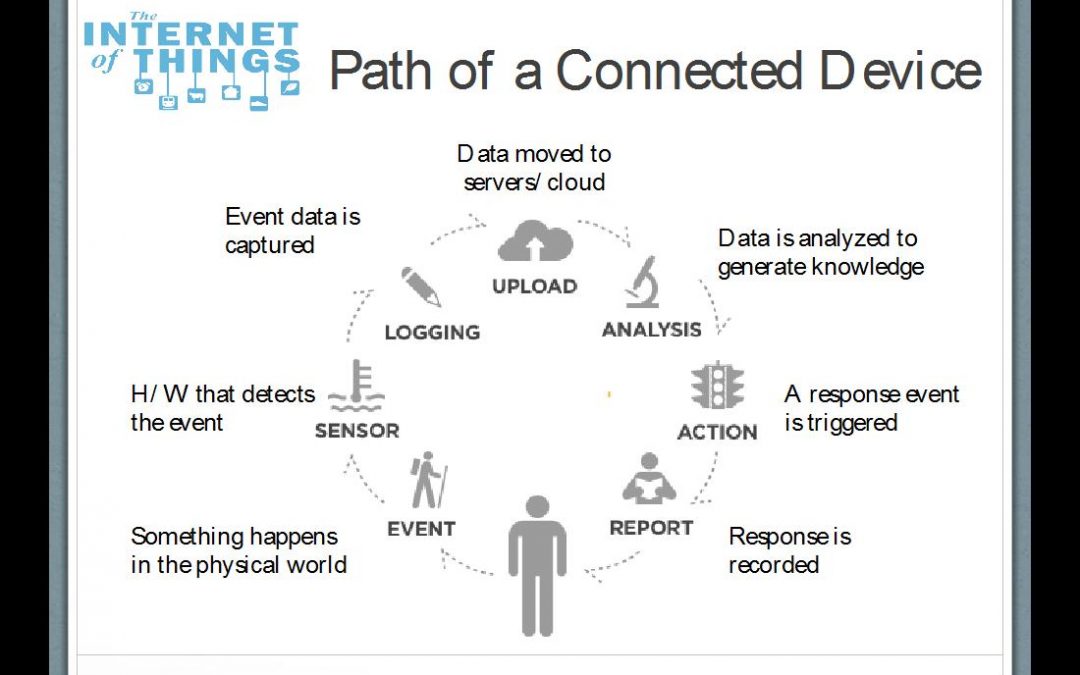

The Internet of Things (IoT) is broadly defined as the merging of the physical and digital worlds. It’s a scenario in which people and/or objects can be uniquely identified with the ability to share information over a network without any actual conscious intervention. The data is automatically transferred, analyzed, and used to trigger an event. Figure 1 below demonstrates how one of these devices functions and interacts with the Internet and other devices.

Figure 1.

The IoT and Supply Chain Management

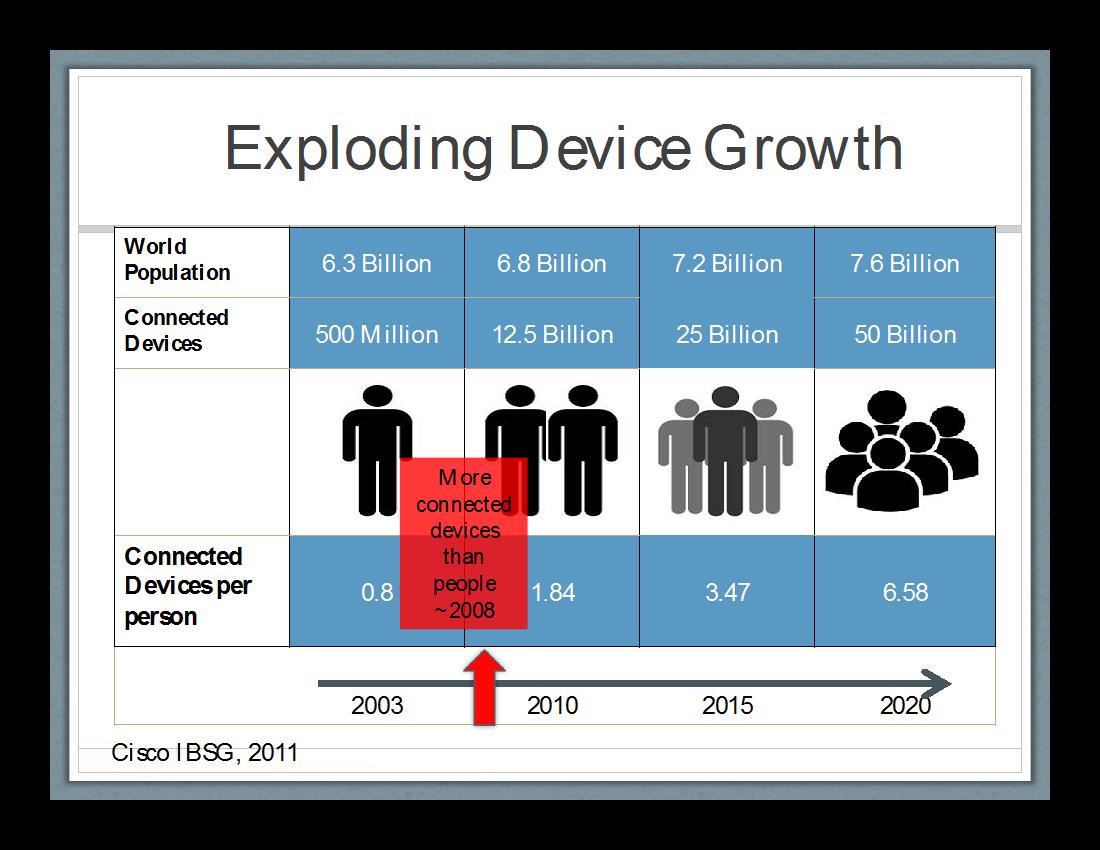

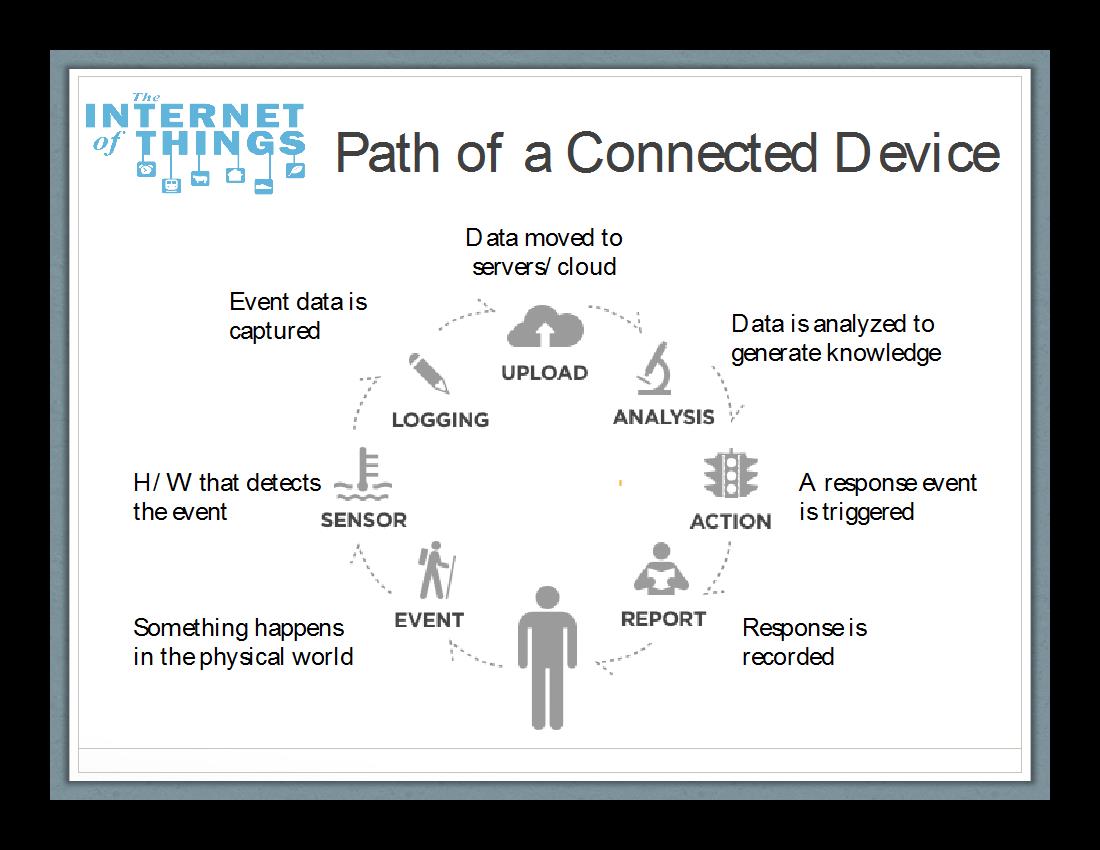

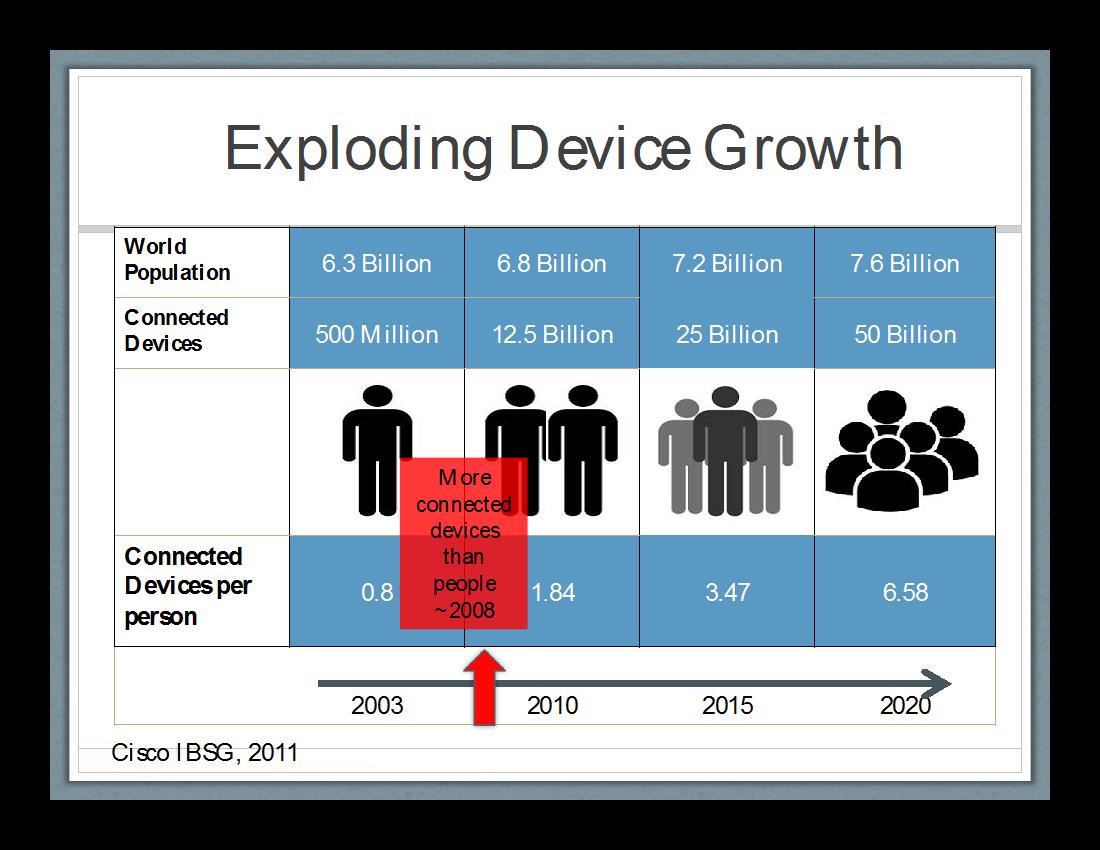

While many of us may be familiar with recent advancements in home automation, like the Nest thermostat, the real impacts of IoT will be in Supply Chain Management. Recent reports by Cisco, IDC and Gartner all claim that a significant increase in the number of devices making up the Internet of Things will have a profound impact on how future supply chains will operate. The 2011 Cisco report predicts there will be 50 billion connected devices globally by 2020, or about 6.5 devices for each person, up from only approximately 2.5 today (see figure 2). More active devices means more available data — to the point where they will be ubiquitous and transparent in our every day lives.

Figure 2.

Impacts to supply chain will be broad and far-reaching, utilizing Big Data to gather and analyze information across the entire process.

Some IoT devices have been in place for some time, such as commercial telematics now used in trucking fleets to improve logistics efficiency. Other commercial type applications — like fabrics that use sensors within clothing and industrial fabrics to monitor human health or manufacturing processes — are just being developed now.

Mark Morely of GSX, a leading provider of monitoring and management solutions, recently discussed three key impacts he believed IoT would have on the Supply Chain industry: Pervasive Visibility, Proactive Replenishment, and Predictive Maintenance. This is a great way to explain the immediate benefits, so I will summarize Mark’s description and expand with some real-world examples.

Three key impacts the IoT will have on the supply chain industry

1) Pervasive Visibility

Mark describes this as the ability to track and monitor a shipment in real time using a combination of sensors (RFID), connected devices, and communication channels (3G/4G, GPS, internet). It provides the ability to have real-time transit status, including location, temperature, and diagnostics — far more information than legacy infomatics provided.

One great example I found is from a company called Purefresh, who are at the cutting edge of Supply Chain IoT technology. They offer not only real-time shipment condition tracking, but also the ability to model and develop transit routes to optimize freshness in perishable cargo — taking into account environmental elements, such as ozone, atmospheres, and temperature. They indicate that an estimated “30% to 50% (or 1.2-2 billion tons) of all food produced on the planet is lost before reaching a human stomach.” IoT advancements will not only better optimize transit flow but also better serve humanity.

2) Proactive Replenishment

It’s the capability to automatically recognize the need to order and restock a product on a “machine-to-machine” basis, reducing the need for human interaction. The most common example is that vending machines will know when it’s out of or low on a Snickers bars and immediately trigger an alert to reorder them, instead of waiting for a service person to check on the vending machine and reorder products manually. The result is less human intervention, quicker replenishment, better sales forecasting and ultimately increased revenues. Oh, and many more happy office workers who really need a mid-afternoon sugar rush!

Opportunities for this technology go far beyond the candy vending machine though. Industries with time critical inventories like hospitals and pharmacies can better maintain supplies by supplementing human inventory control with real time use tracking. A much less critical but more broadly used application comes from Coke’s Freestyle fountain soda machine. It’s about the same size as the existing vending machines but it can dispense 126 kinds of flavors, offering an almost infinite amount of combinations. It uses Radio Frequency ID (RFID) cartridges that store the concentrated syrups in the machine. The RFID chips detect how much of each syrup it has and what combinations are being used. When it detects that it needs supplies, it transmits the information to both Coca-Cola and the storeowner including what has been sold, a record of when sales occurred, troubleshooting information, and service data. As a result, soda sales and customer satisfaction increases, all with less effort by the storeowner.

3) Predictive Maintenance

This application is closer to the true machine-to-machine communications the IoT was intended for. From large-scale manufacturing to diagnostics on the family minivan, predictive maintenance utilizes sensors and connected devices to monitor and react to issues. This self-diagnosis capability can detect a potential issue before there’s a failure, order a replacement part, and even schedule maintenance to avoid costly downtime.

Not only does predictive maintenance help keep factories running longer and the family minivan from unexpectedly breaking down, it can improve efficiency throughout the whole supply chain. If equipment manufacturers constantly receive service data from factory equipment, they can better trend problems and focus on those issues for future products. Parts depots can better forecast inventories and determine consistent safety stock levels. IoT, in this example, is a true B2B (business to business) — automating the communication between businesses on every link of the chain.

In relation to home automation, predictive maintenance will become integrated into our everyday lives. Appliances will become smarter, more efficient, and easier to monitor. Internet-connected sensors will be embedded into everything from refrigerators to washers/dryers and HVAC systems. So much so that companies like GE are investing heavily into these technologies, in both commercial and industrial applications. These connected appliances will perform self-diagnosis, determine the most cost-efficient time to operate, and even automatically order maintenance parts like furnace filters when needed. Imagine getting an alert on your smartphone that your forced hot air furnace needs a new air filter, and it has already been ordered through your Amazon account. It just saved you effort in remembering to check the filter and ordering it — leading to a cleaner, longer-lasting, and more efficient furnace.

So, why isn’t IoT here yet?

It’s close but there are still hurdles to overcome. In recent years, advances in sensor technologies, 4G communications, and cloud computing has made achieving Internet of Things capabilities even more possible. But for companies in the Supply Chain to leverage these opportunities, they will need to expand investment into cloud-based platforms that can support scalable devices and data-analysis services.

Critical to IoT’s success will be the necessary “middleware” software communication protocols to link all these devices. Companies like ProSyst and open-source SW projects like OPENIoT are pioneering these capabilities. But even with this progress, agreements on industry standards will be key to long-term platform success.

Having a common IoT protocol will be necessary to link the physical and digital worlds on a consistent and economical basis. Understanding the need for standards and common architectures, Intel has led the way by recently creating the not-for-profit Industrial Internet Consortium (IIC) with other vested companies like AT&T, Cisco, GE, and IBM. The connected Supply “Chain” will become exponentially longer once these common standards are in place.

The Internet of Things trend is quickly approaching and will impact the way we live and work through increased productivity and efficiency. Supply Chain Management will continue utilizing these advanced technologies to improve factory workflow, increase material tracking, and optimize distribution to maximize revenues.

In 1986, I recall how innovative I thought the Clapper was — I couldn’t have imagined how connected we would become only 28 years later. And the next 28 will be sure to amaze.

Steve Mondazzi is a Principal Master Planner in the Defense Contracting industry. After 20 years’ experience in project management and schedule development, he decided to further his education by recently earning a Masters in Technology Management at the University of New Hampshire. He’s a certified PMI Project Management Professional, an entrepreneur, and an avid lover of all things technology. He currently resides in Massachusetts with his wife, two teenagers, and an excessive collection of headphones. Steve can be contacted via his Twitter account @schedulepro or through LinkedIn.

Related posts:

by Jennifer Hart Yim | Jun 19, 2014 | Blog, Logistics, Manufacturing & Distribution, Strategy, Supply Chain

Entrants to the market need to understand the barriers to entry and problems with management and transparency within the pet food industry supply chain.

This article is part of a series of articles written by MBA students and graduates from the University of New Hampshire Peter T. Paul College of Business and Economics.

The pet food industry is a market that boasts $21.57 billion dollars in sales in the United States (2013). With 95.6 million cats and 83.3 million dogs owned in the United States, it is no wonder that there is such a large market for the food that the self-proclaimed “pet parents” feed them. However, it isn’t all good news for aspiring entrants, as they must first understand the supply chain that dictates this growing industry.

To manufacture, or not to manufacture

When a pet food company chooses to produce a product, they essentially have three options: 1) manufacture it themselves, or choose a co-packer who will either 2) use a private label or 3) manufacture the food to the specifications of the brand.

A contract packer (co-packer), otherwise known as a contract manufacturer, is a company that manufactures and packages foods for their clients. The manufacturer works under a contract with the hiring company to manufacture the pet food as though the hiring company was doing it themselves.

Co-packers can manufacture several different brands and for several companies at once. An example of a co-packer would be C.J. Foods, Inc. with manufacturing plants in Bern, Kansas, and The Pawnee City, Nebraska. According to C.J. Foods Inc., the company produces over 300 varieties of animal foods, including dog, cat, reptile, and exotic bird.

Companies typically outsource to another entity for production due to cost savings, rather than building their own plant. Additionally, they can focus on their own core competence, whether it is marketing, sales, etc. The manufacture’s core competency is production, and they have the experience and knowledge to produce the pet foods already. However, there can be many challenges associated with the management of pet food supply chains and co-packers in particular.

The challenges with co-packers

As the pet food market grows and becomes more complex, the sourcing of ingredients becomes more complicated.

Foreign suppliers source products from numerous small farms, and identities become lost and commingled. Unfortunately, brands are relying on these suppliers to meet food-safety criteria.

Additionally, these brands typically rely on audits of suppliers by private third-party companies that carry no guarantee. An example of this would be Kellogg and Peanut Corporation of America (PCA). Kellogg had PCA audited by AIB international, and PCA passed with a superior rating. However after the recall (explained in detail below), the FDA found leaks and rodent infestations within the plant.

Pet food industry product recalls

There have been two major recalls within the pet food industry in recent years.

One, the largest in history, was the ChemNutra recall in 2007. Two Chinese export firms sold wheat gluten bags tainted with melamine to Las Vegas-based ChemNutra, “the Chinese ingredient specialist importer.” ChemNutra then sold the tainted wheat gluten to pet food makers under false certificates of analysis. As a result, 5,300 pet foods were recalled, and thousands of cats and dogs were injured/killed. Owners of both the Chinese companies and ChemNutra pleaded guilty to various misdemeanors involving the mis-branding of food and conspiracy to commit wire fraud.

The second recall involves a 2009 salmonella outbreak in the Peanut Corporation of America’s plant in Blakely, Georgia. PCA knowingly shipped salmonella-tainted products across the country to many manufacturers, including those in the pet food industry. Along with the shipments, they sent certificates of analysis that indicated the product contained no salmonella, but they had yet to receive the test results (which were positive). This resulted in 3,200 pet food products being recalled, 8 deaths, and 500 illnesses. A 76-count indictment charged four former officials at PCA with numerous infractions relating to salmonella-tainted peanuts and peanut products.

These two examples are the horrific results from a lack of control over the supply chain within the manufacturing of pet foods. The consequences of these recalls, first and foremost, can cause the injury and death of both pets and people. Beyond that, there is implicit lost brand trust, consumer demand decrease, headaches for retailers/wholesalers, and severe cost increases for the company.

Solution: Improving supply chain management

Given the information above, it is essential that companies proactively work to avoid recalls through better management of the supply chain.

Co-packers become problematic when an ingredient or plant is infected because that trickles down to the many different brands and companies for whom they manufacture. That is not to say that pet food companies should never use a co-packer, especially because the cost-saving benefits can be so great. Pet food companies, however, should do their research prior to choosing a co-packer.

If you are using a private label, know where the co-packer is sourcing its ingredients. If you are not using a private label, you need to ensure you know the suppliers with whom the co-packer is working. The same rule applies if your pet food company has its own manufacturing plant, as well.

Secondly, pet food manufacturers can supplement third-party audits of co-packers’ plants with their own inspection and testing of ingredients and plant surfaces.

As a consumer purchasing these foods off the shelf, attempt to do your research, too. Although you may not be able to see exactly where products are coming from due to confidentiality of competitive sourcing, you can choose brands that have a commitment to transparency and educating the consumer on where their ingredients are sourced from. An example of this would be Natura Pet Products, which launched its “See Beyond The Bag” campaign. This part of their interactive website allows consumers to click on any product and view where in the world any specific ingredient in the product is being sourced from. Additionally, consumers can educate themselves on how Natura ensures a quality manufacturing process.

In conclusion, pet food manufacturing can be a difficult industry if a company is not well versed in the associated challenges. If a tight reign is held over the supply chain and quality manufacturing follows, the pet food industry is a growing market with a bright outlook for companies vying to do business within it.

Mikayla Cadoret recently completed her MBA at the University of New Hampshire – Paul College of Business and Economics. She is an experienced sales representative and is interested in pursuing a career in marketing or supply chain management. She can be reached at [email protected].

If technology continues to advance, humans may be obsolete in the supply chain as a result of both automation and RFID utilization. Both technologies have been introduced into the supply chain over the past decade, resulting in a major shift in performance and costs. While automation is a process which can navigate product throughout facilities, RFID can improve efficiency dramatically as well as being the major driver for the elimination of human involvement in the supply chain.

If technology continues to advance, humans may be obsolete in the supply chain as a result of both automation and RFID utilization. Both technologies have been introduced into the supply chain over the past decade, resulting in a major shift in performance and costs. While automation is a process which can navigate product throughout facilities, RFID can improve efficiency dramatically as well as being the major driver for the elimination of human involvement in the supply chain.