by Fronetics | Mar 9, 2015 | Blog, Supply Chain

The Internet of Things (IoT) “represents the convergence of the physical and digital worlds. Physical objects are equipped with technology that enables the object to send and receive information via fixed-wire or wireless communications links to the Internet, and to then transmit information in one form or another.”

In 2003 there were an estimated 500 million IoT-connected devices. By 2010 there were 12.5 billion connected devices. Morgan Stanley estimates that there will be 75 billion IoT devices by 2020. Cisco makes a more conservative estimate 50 billion. Whether it is Morgan Stanley or Cisco who proves correct, what is clear is that the number of internet connected devices is growing exponentially.

Consumer convenience is often the focus of the IoT. However, the capabilities of the IoT reach far beyond consumer convenience. The IoT is game-changing for the logistics and supply chain industries. The IoT delivers the visibility and data necessary for supply chain optimization.

One Network Enterprises, a supply chain technology provider, offers this supply chain example:

“[The IoT] refers to data communication among a large range of assets or devices—from your fridge to your oven or, more pertinently, from your inventory to its container, from the container to the carrier, from the pallet to the warehouse. The more your assets can ‘speak’ to one another and share data, the more they can work together to help you improve your processes.”

The IoT has already moved into industrial environments including warehouses and manufacturing plants.

Examples of where the IoT is already having an impact on supply chains include:

- Transparency and visibility

- Proactive replenishment

- Predictive maintenance

- Reduction in asset loss

- Manufacturing flow management

- Product development and commercialization.

- Risk management.

- Operational efficiency

- Improved fleet management

The transparency and end-to-end visibility afforded by the IoT creates new opportunities that supply chain professionals can leverage in order to optimize supply chains and generate value. It is important to look at the potential of the IoT now and not later. The amount of data alone that is generated by the IoT creates a paradigm shift. Companies that embrace the Internet of Things and identify where and how it can play a role for their business will move forward and leave those who do not behind.

The Internet of Things has the potential to change everything.

To learn more about how the Internet of Things has and will continue to impact the supply chain see the full article How the Internet of Things will change your world on Supply Chain Quarterly. The article includes a focus on Internet of things and the warehouse.

![A different kind of green for the logistics and supply chain industries: St. Patrick’s Day [Infographic]](https://fronetics.com/wp-content/uploads/2024/10/St.-Patricks-Day-Infographic-800x675.jpg)

by Fronetics | Mar 5, 2015 | Blog, Supply Chain

St. Patrick’s Day by the numbers.

Between 1820 and 1930, nearly 4.5 million Irish immigrants made America their home. They brought with them their love for their home country and thus began a centuries-long annual celebration of all things Irish in America.

Today more than 122 million Americans celebrate Saint Patrick’s Day, making the holiday lucky for logistics and supply chain companies. From the delivery of 13 million pints of Guinness beer to pubs across the country to the packaging and transporting of holiday-themed parade and party supplies, it’s clear that green can lead to gold for these companies.

Check out our St. Patrick’s Day infographic and see why they call it the ‘luck o’ the Irish’.

![A different kind of green for the logistics and supply chain industries: St. Patrick’s Day [Infographic]](https://fronetics.com/wp-content/uploads/2024/10/St.-Patricks-Day-Infographic-800x675.jpg)

by Fronetics | Mar 5, 2015 | Blog, Supply Chain

St. Patrick’s Day by the numbers.

Between 1820 and 1930, nearly 4.5 million Irish immigrants made America their home. They brought with them their love for their home country and thus began a centuries-long annual celebration of all things Irish in America.

Today more than 122 million Americans celebrate Saint Patrick’s Day, making the holiday lucky for logistics and supply chain companies. From the delivery of 13 million pints of Guinness beer to pubs across the country to the packaging and transporting of holiday-themed parade and party supplies, it’s clear that green can lead to gold for these companies.

Check out our St. Patrick’s Day infographic and see why they call it the ‘luck o’ the Irish’.

by Fronetics | Feb 24, 2015 | Blog, Supply Chain, Warehousing & Materials Handling

As more warehouses and distribution centers turn to intelligent, high-tech solutions, it is important to take advantage of technology to optimize the efficiency and ultimately increase the revenue of your business.

Smart technology now stretches into virtually every aspect of our lives, so it should come as no surprise that distribution centers worldwide are finding unique ways to leverage these smart technologies to increase efficiencies, reduce operating costs, and improve safety. A closer look at today’s available technology shows just how intelligent the tools for the materials handling, logistics, and supply chain industry have become and the transformative impact they can have on operations. Innovations such as voice tasking, warehouse robotics technology, microprocessors, and the talking lift truck are fundamentally changing the way business is being done. Those who stay on top of these innovations gain an invaluable lead on the competition.

One such company realizing significant benefit from employing new technologies is Genco Supply Chain Solutions. Looking to improve routing and slot optimization while simplifying the receiving and retrieving processes at their 200,000-square-foot facility, Genco started using the Total Trax Sky-Trax Solution. TotalTrax Smart Truck Solutions turns traditional material handling vehicles into smart trucks. Image processing technology transmits images to a centralized monitoring system, giving supervisors real-time access to the warehouse. Genco’s results after implementation: a 12% increase in facility throughput, 99.9% inventory accuracy, a 20% increase equipment utilization, and a reduction of more than 50% in training time.

“With gained visibility to inventory and vehicle movement, we are now able to analyze each operator’s performance, including the amount of idle time and time spent with no load,” Cary Cameron, Genco’s vice president of strategic technologies, said in a press release. “The data and reporting Sky-Trax provides allows us to analyze the root cause [using Lean Six Sigma] and measure processes we’ve never been able to see before.”

Value is delivered in increased accountability and visibility as supervisors can make critical dispatching decisions in real-time and review historical data for improving operations. In numbers, the use of smart trucks for automatic inventory tracking routinely translates into 30% higher productivity. Drivers can focus on what they do best: driving. Customers can also count on substantial labor savings and improved OSHA safety compliance as a result of the uninterrupted monitoring of the warehouse.

As more warehouses and distribution centers turn to intelligent, high-tech solutions, it is important to take advantage of technology to optimize the efficiency and ultimately increase the revenue of your business. Keeping up with this kind of innovation can help any organization achieve better business results. Even more importantly, you should make sure your organization uses its smart system for a breadth of capabilities and applications to ensure getting the most out of it.

Is your business using smart technologies? If so, which ones have had the biggest impact?

by Fronetics | Feb 24, 2015 | Blog, Supply Chain, Warehousing & Materials Handling

As more warehouses and distribution centers turn to intelligent, high-tech solutions, it is important to take advantage of technology to optimize the efficiency and ultimately increase the revenue of your business.

Smart technology now stretches into virtually every aspect of our lives, so it should come as no surprise that distribution centers worldwide are finding unique ways to leverage these smart technologies to increase efficiencies, reduce operating costs, and improve safety. A closer look at today’s available technology shows just how intelligent the tools for the materials handling, logistics, and supply chain industry have become and the transformative impact they can have on operations. Innovations such as voice tasking, warehouse robotics technology, microprocessors, and the talking lift truck are fundamentally changing the way business is being done. Those who stay on top of these innovations gain an invaluable lead on the competition.

One such company realizing significant benefit from employing new technologies is Genco Supply Chain Solutions. Looking to improve routing and slot optimization while simplifying the receiving and retrieving processes at their 200,000-square-foot facility, Genco started using the Total Trax Sky-Trax Solution. TotalTrax Smart Truck Solutions turns traditional material handling vehicles into smart trucks. Image processing technology transmits images to a centralized monitoring system, giving supervisors real-time access to the warehouse. Genco’s results after implementation: a 12% increase in facility throughput, 99.9% inventory accuracy, a 20% increase equipment utilization, and a reduction of more than 50% in training time.

“With gained visibility to inventory and vehicle movement, we are now able to analyze each operator’s performance, including the amount of idle time and time spent with no load,” Cary Cameron, Genco’s vice president of strategic technologies, said in a press release. “The data and reporting Sky-Trax provides allows us to analyze the root cause [using Lean Six Sigma] and measure processes we’ve never been able to see before.”

Value is delivered in increased accountability and visibility as supervisors can make critical dispatching decisions in real-time and review historical data for improving operations. In numbers, the use of smart trucks for automatic inventory tracking routinely translates into 30% higher productivity. Drivers can focus on what they do best: driving. Customers can also count on substantial labor savings and improved OSHA safety compliance as a result of the uninterrupted monitoring of the warehouse.

As more warehouses and distribution centers turn to intelligent, high-tech solutions, it is important to take advantage of technology to optimize the efficiency and ultimately increase the revenue of your business. Keeping up with this kind of innovation can help any organization achieve better business results. Even more importantly, you should make sure your organization uses its smart system for a breadth of capabilities and applications to ensure getting the most out of it.

Is your business using smart technologies? If so, which ones have had the biggest impact?

by Fronetics | Feb 19, 2015 | Blog, Strategy, Supply Chain, Warehousing & Materials Handling

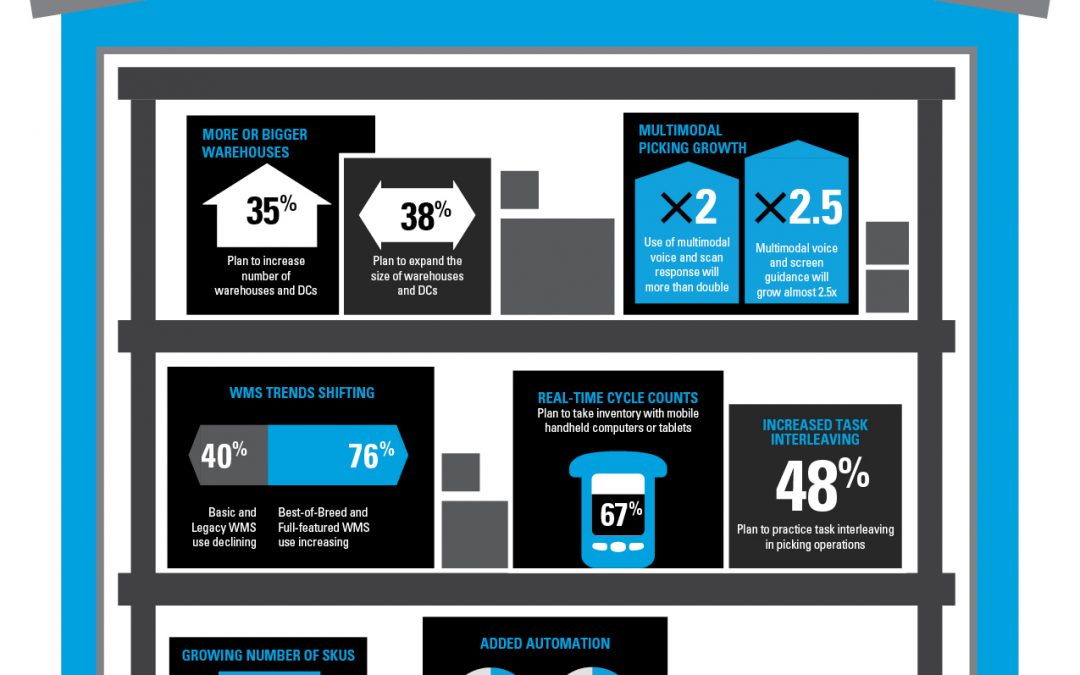

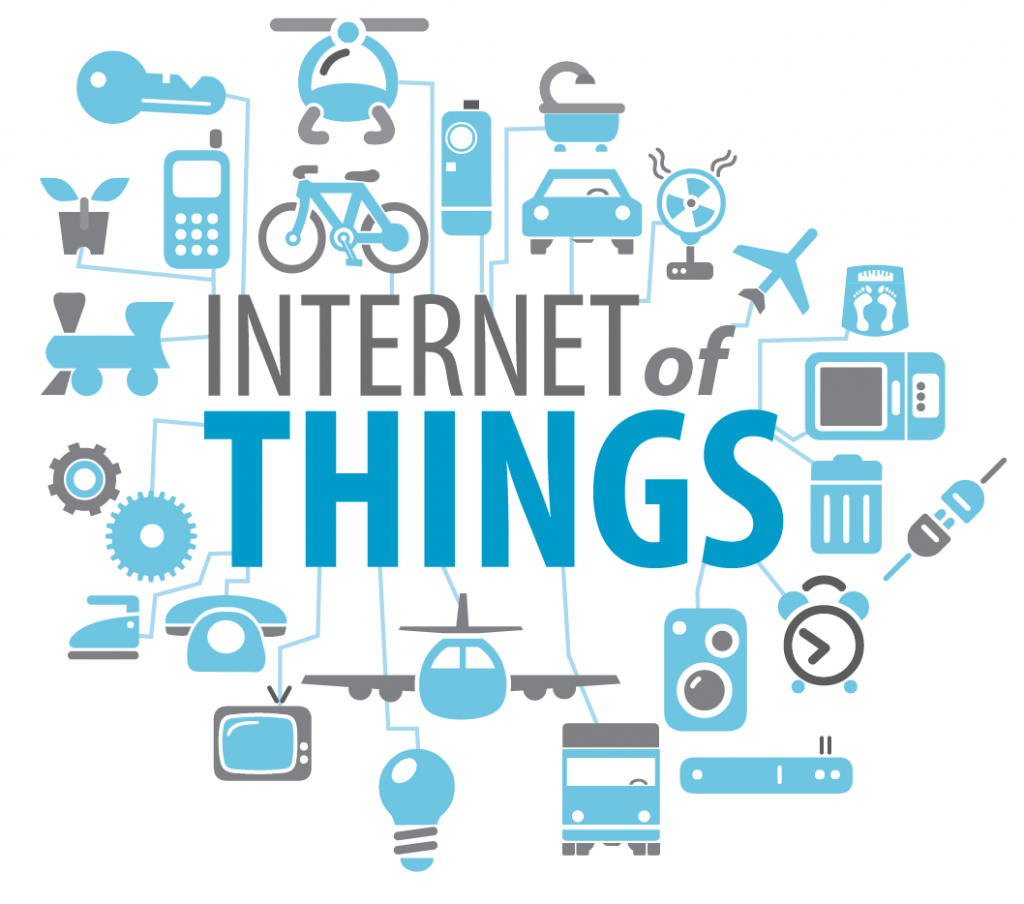

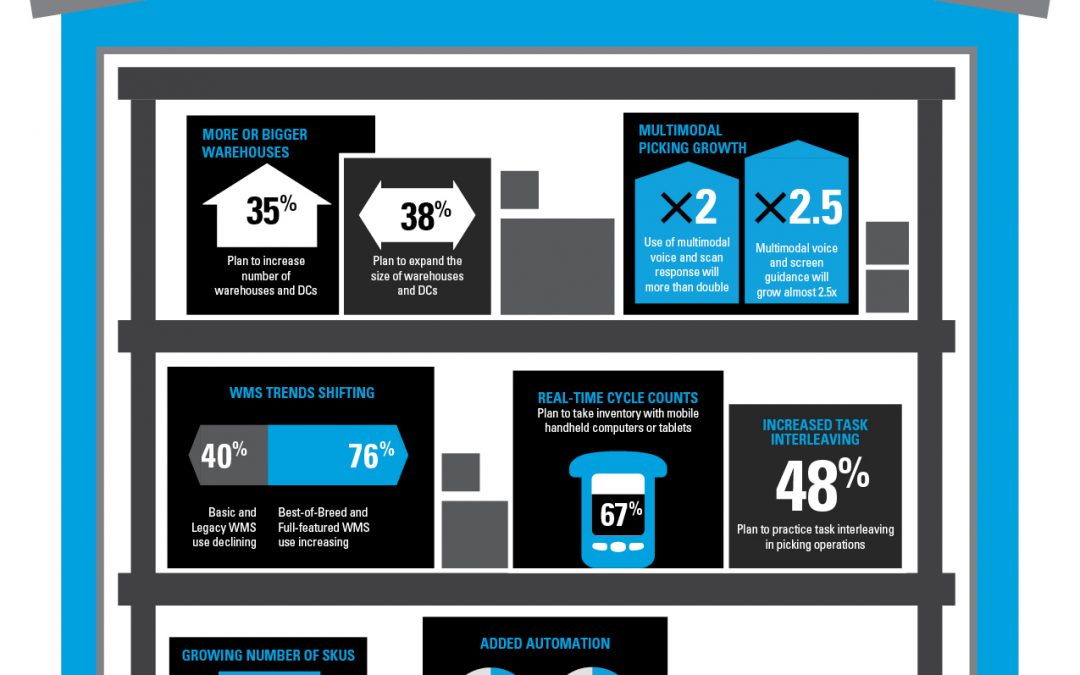

Source: Motorola

Growing in concert with consumer demand, distribution centers are getting bigger. In fact, a 2013 Motorola Warehouse Vision Survey reported that a full thirty-eight percent of respondents would be increasing the size of their warehouses and distribution centers over the next five years. And while there are certainly potential benefits, there are also plenty of potential problems. With good planning, though, organizations can successfully navigate around the pitfalls of distribution center growth.

Here’s how to achieve success when growing the size of your distribution center.

Streamline operations and processes

Increasing the square footage of your distribution center requires extensive strategy pre-planning. This means taking stock of your entire logistics and distribution process and strategically thinking about how these processes can be made more efficient. Areas where many companies can increase efficiencies include: decreasing reliance on paper, cross-docking, incorporating multi-modal wireless solutions, and revamping the pick strategy.

Optimize communication across departments

Communication is essential when growing your distribution center. Communicating across departments will enable your company to be able to effectively plan for both current capacity requirements as well as capacity requirements that are forecasted in the near-, mid-, and long-term. Building a larger distribution center only to outgrow it five years later is a costly mistake. Furthermore, communication across departments will allow for the right-sizing of both equipment and labor.

Be flexible

Allowing for flexibility is a key factor of successful growth. A large distribution center that can process a limited number of SKUs is, well, limited. A distribution center that is designed to be able to process a wide variety of goods and SKUs can reduce operating costs and enable your company to be more nimble. When designing your distribution center, keep flexibility at the forefront.

Invest and utilize technology

A larger distribution center requires more automation and more technology than a smaller distribution center. Similarly, a larger distribution benefits from mobile solutions. As more specific and sophisticated technology emerges, implementing smart technologies can aid in your efforts to achieve optimization of communications and streamline your operations more efficiently.

When the square footage of your distribution center grows, it is important to remember that you are dealing with a different beast. It’s one that requires extra careful thought. Taking the time to consider potential problems and preparing a solid plan of implementation before you begin will increase your odds of successful growth.

![A different kind of green for the logistics and supply chain industries: St. Patrick’s Day [Infographic]](https://fronetics.com/wp-content/uploads/2024/10/St.-Patricks-Day-Infographic-800x675.jpg)