by Jennifer Hart Yim | May 11, 2017 | Blog, Current Events, Logistics, Manufacturing & Distribution, Supply Chain, Transportation & Trucking, Warehousing & Materials Handling

This post comes to us from Adam Robinson of Cerasis, a top freight logistics company and truckload freight broker.

Imagine a world where automation comes together with technology to deliver products without human intervention. An order is placed by a consumer. 3-D printers pick up the details and print the finished product. It’s then picked by robots from the shelves, packaged and placed into a self-driving truck. The trucks leave the facility, and drones are automatically dispatched from the truck to deliver products while moving. The truck never stops until arriving for reloading.

This example generates a huge amount of data that can leverage in the supply chain. But, the same data can have a drastic impact on transportation planners and agencies around the globe. While this example may still be a few years off, it is important that you understand how the top emerging trends in automation will shape supply chains and transportation processes in the coming years.

The Standard Definition & Components of Automation

Today: There is a standard definition of automation in the supply chain. Anything that can be handled via today’s computer systems can be automated. This includes billing, generation of bills of lading, compliance reports, and even movements throughout a factory or warehouse floor.

Historically, automation has been applied to virtual processes, like order auditing or customer service reports. However, the trends in automation are changing to reflect actions that function more like artificial intelligence, not just a search and locate program on the computer.

Additive Manufacturing

What is it?

Additive manufacturing includes all actions in the supply chain that can enhance existing factory production, if not replace it entirely. Additive manufacturing may be handled manually, but automating this process is as simple as turning on the power and connecting to the Internet of Things (IoT).

For example, additive manufacturing might involve the use of 3-D printers to create replacement parts at the store for consumers.

Today’s status: Unfortunately, the capacity of 3-D printers remains in infancy, capable of only producing simplified parts out of liquid polymers.

Virtual Reality Comes to the Forefront.

Meanwhile, Google Glass and other virtual reality tech are changing how customers complete their orders. In addition, the same technology can be overlaid with augmented reality to give repair technicians and individuals greater resource access when making repairs, checking order contents and fulfilling orders.

For example, augmented reality glasses will soon detect package dimensions and classify the package according to dimensional pricing models.

Today’s Status: Today, this technology is limited to automated identification and data capture (AIDC) applications. Advancements in virtual reality over the past year indicate its future might be much closer than “meets the eye.”

Additive manufacturing will gradually move products from warehouses and distribution centers to be closer to end-users. As a result, the amount of last-mile traffic may increase.

Robotics Enhance Inbound and Outbound Logistics for Shippers.

Another trend in automation involves robotics. By definition, robotics are the icons of automation. They perform functions at the request of a system or person, but more of today’s robotic systems are performing duties upon request from an order fulfillment system.

The order process automatically notifies robots in warehouses and triggers the flow of processes as seen in the opening example.

Robotics Improve Inbound and Outbound Logistics.

Robotics are not isolated to warehouse pulling for outbound logistics. They can be used to manage inbound and outbound processes and strategy. Through trends in automation and robotics, supply chain companies will have the tools and resources necessary to ramp up throughput and decrease product cycle from order to delivery. Therefore, more trucks and drivers will be needed, but the looming driver shortage and capacity crunch will trigger another automation trend.

Autonomous Vehicles/ Trucks

Automation begets automation. With advances in technology and the IoT, most major companies, including Uber, Facebook, Google, and Amazon, have launched autonomous vehicle and truck pilot programs.

These driverless vehicle programs will give supply chains access to a new inexhaustible resource for moving products, overcoming the challenges inherent in the driver shortage and capacity crunch.

The driver shortage and capacity crunch are likely to come to a head in 2017, as consumers demand more product, at lower costs and faster than ever before.

Some setbacks have occurred, like the first self-driving car wreck earlier this year. With each setback and challenge, companies have pushed back to overcome the obstacles.

In response to increased interest in driverless vehicles and trucks, the National Transportation Safety Board (NTSB) has issued recommendations and created an advisory panel to review ongoing driverless vehicle advancements and maintain public safety.

Transporters and supply chains will respond to this direction by leveraging the trends in automation and power of data to ensure compliance with increased government oversight, through the agencies you represent.

Companies have already tested cross-country driverless trucks, albeit with a person ready in the cab to take over in the event of a system failure. However, the wide-scale deployment of this level of driverless trucks is far from implementation.

In the interim, more automated vehicle systems will work in tandem with drivers to enhance safety and maintain vehicle control. Similar systems are already deployed in crash and pedestrian detection systems, automated braking and tracking control in today’s vehicles. It is not difficult to apply today’s technology and automated features to the fleets and drivers of 2017.

Trends in Automation: Whats the Potential?

The potential applications of this type of technology can include real-time traffic condition monitoring and warnings, redirecting traffic before pile-ups and accidents occur, similar to Google Maps’ capacity to show traffic congestion in real-time.

Data through such systems can automatically feed back into transportation planners’ systems to automatically change signal phase and timing and enable immediate rerouting or adjustment of traffic flow on a broader scale.

Related posts:

by Fronetics | Apr 27, 2017 | Blog, Content Marketing, Marketing, Social Media, Supply Chain

In April’s social media news, changes are coming down the pike for Google, LinkedIn, Facebook, and Instagram.

April has been an interesting month for social media news. Google, LinkedIn, Facebook, and Instagram all announced changes to their core products that will affect businesses using these platforms for social engagement and/or advertising.

Make sure you’re following our blog and/or social media pages to get our monthly updates on changes that may affect your social marketing program.

Google may be rolling out ad blocker for Chrome

Although its business model largely depends on advertising, Google is considering putting a stop to ads that are ruining users’ experiences. A potential ad-blocking feature on its Chrome browser would identify unacceptable ads based on standards set by the Coalition for Better Ads in March. Google could roll out this new feature in the next few weeks or choose not to move ahead with it at all — either way, the company is declining to comment.

LinkedIn introduces trending storylines

Storylines are now bringing user interests and the most important stories in their industries to the daily newsfeed. The algorithm includes several perspectives, such as “relevant influencers and news publishers to people in your network.” Each storyline also has a unique hashtag associated with it, so users can join in on the conversation and expand their networks based on common interests.

Facebook is moving closer to virtual reality

At the F8 developer conference, Facebook announced the release of Facebook 360 Capture SDK, a toolkit that makes it easier to capture and share virtual reality video. The ‘Book’s engineers are calling this new process “cube mapping,” which is more efficient and has better image quality than standard 360 video. “We look forward to seeing VR 360 selfies, experiences, e-sports, and more—all in 360,” said Facebook product developers in a mid-April blog post.

Instagram launches offline browsing

Instagram currently downloads images on the fly, querying parent company Facebook’s servers for new content when the app is launched. The updated app, however, will tap a cache instead. It will store any browsed images and will automatically update when internet becomes available. Users will also be able to write comments, like and save photos, and unfollow and follow anytime, as Instagram will queue offline actions to execute when next online.

Facebook Stories expands globally

Facebook Stories are short, user-generated picture and video collections that disappear within 24 hours. Users can add different filters and overlays to content using the in-app camera. A simultaneous messenger update, called Direct, allows users to send photos and videos that disappear after a short time to friends. This popular Snapchat-like format has proven very successful on Instagram, which now boasts more than 150 million Stories users across the globe.

Related posts:

![The State of Supply Chains: The Supply Chain Has Gone Digital [Infographic]](https://fronetics.com/wp-content/uploads/2024/10/virtual-reality.jpg)

by Jennifer Hart Yim | Jan 23, 2017 | Big Data, Blog, Data/Analytics, Logistics, Strategy, Supply Chain

2016 was the year of the digital supply chain — here’s a look at how things changed.

This guest post comes to us from Adam Robinson, director of marketing for Cerasis, a top freight logistics company and truckload freight broker.

2016 marched onward with a drive to improve the use of digital technology throughout the supply chain. In our first supply chain trends post, we surmised the previous year’s trends would continue. However, this prediction proved to only touch on how important the digital supply chain would become.

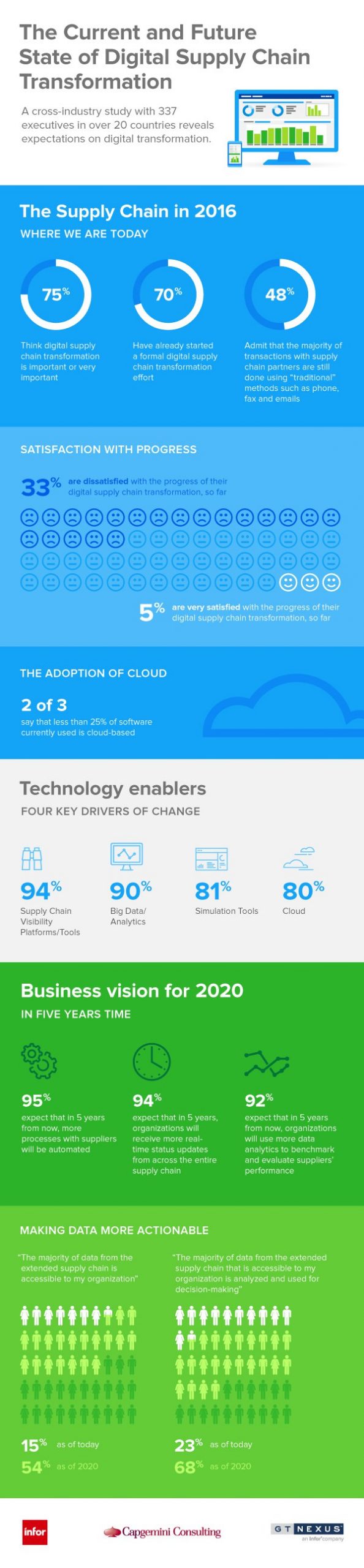

Within four months, the digital transformation had already reached most supply chain organizations. Per GT Nexus, 75% of executives surveyed recognized the digital supply chain as an important factor for the next five years. Meanwhile, 70% have also started processes to implement digital supply chain technologies throughout their companies.

Unfortunately, many supply chain entities continue to hope for a better tomorrow. In other words, the digital supply chain transformation has only been rated as very satisfying for 5% of respondents. In addition, just less than half (48%) of respondents report continued use of traditional technologies exclusively, which include the following:

- Fax machines

- Manual order entry and review

- Land-line phones, not voice over internet protocol (VoIP), which reduces overall costs and downtime

- Email, although beneficial, is susceptible to internet connectivity issues, security breaches and other problems

- Chaotic picking protocols

This infographic, created by GT Nexus, also shows other ways the digital supply chain evolved in 2016.

(Made with Canva)

Essentially, the digital supply chain is essential to gaining and maintaining competitive advantage. Digital technologies, reports Richard Howells of Forbes, including Big Data, analytics, the Internet of Things, social media, and point-of-sale reporting, enable business to know more about consumer needs and wants than ever before. Consequently, they can more accurately respond to changes in product demand across large distances and within infinitesimally small time frames.

Supply chain execs retained fundamentals throughout change.

Innovation is the driving force behind change and improvement in the modern world. Supply chains must evolve to meet an increasing number of omnichannel sales, and technologies must be integrated within existing systems to reach maximum efficiency and productive value.

As explained by Grant Marshbank of VSC Solutions, “The rate of change is not going to slow down. Technology will only delivery […] if it’s implemented with strategy and operations that adhere to best practices.”

Marshbank’s words highlighted the need to focus on fundamental concepts while responding to changes and improvements in the supply chain. For example, an optimized supply chain is good, but it opens more opportunities for errors. Simply putting all an organization’s proverbial eggs into one basket may be risky if appropriate auditing and review measures are not undertaken to ensure continued compliance and accuracy in all orders.

Change is a necessity for businesses, including the supply chain, to grow and expand. Yet many destructive forces can severely undermine a company’s progress. Bad weather, poor hiring practices or inefficient maintenance of consumers’ financial data can decimate a company. However, the response to hindrances in 2016 continued to showcase the importance of fundamental concepts, asserts Ryder, which include the following:

- Continually seeking the fastest, most cost-effective means of transporting products to consumers, including enhanced delivery optins.

- Expansion of global footprint while adhering to local, state, federal and international requirements

- Keeping companies accountable and focused on giving back to their domestic partners through reshoring or nearshoring

- Working with more outside agencies, also highlighted by Samantha Carr of Business 2 Community, including crowd-sourced logistics, warehouse optimization and outsourcing, and greater use of cloud-computing

Augmented reality found its place among consumers.

Augmented reality sounded amazing and far-fetched early in 2016, but the year has shown it to be one of the most successful product in existence. There tends to be more acceptance of technologies in the workplace once consumers can identify how they work.

For example, new hires are likely to pick up tablet-based systems more easily since they have been using them recreationally for some time. Essentially, the virtual-reality (VR), which is the precursor to augmented reality, hype of the 2016 Christmas shopping season is making more people excited about this new way to “see the world.”

While the VR hype may seem like it only emerged for Christmas, think about one of the hottest games of 2016, Pokémon Go! This app was built on augmented reality, combining the digital and physical worlds into one interactive environment. This technology, reports JOC.com, will be a key to practically eliminate extensive training courses and repair time requirements throughout the supply chain.

Ultimately, it translates into greater use of augmented reality in supply chains, which is growing by 100% annually, reports Barcoding Incorporated.

What’s next?

Clearly, technology dominated the conversation for 2016, but there are also changes in how supply chains operate that require a more in-depth discussion as well. In the next post of this series, we discuss the impact of artificial intelligence, agile processes and procurement expansion on the supply chain of 2016.

Related posts:

![The State of Supply Chains: The Supply Chain Has Gone Digital [Infographic]](https://fronetics.com/wp-content/uploads/2024/10/virtual-reality.jpg)