by Elizabeth Hines | Oct 10, 2017 | Blog, Consumer Electronics, Current Events, Manufacturing & Distribution, Strategy, Supply Chain

Of legal obligation, financial incentives, and convenience, what best drives consumers to practice proper e-waste recycling?

The United States is a nation of consumers, and there are few things we enjoy more than our electronic gadgets. Unfortunately, for every new device — or upgrade — introduced to the market, there’s an older model that becomes obsolete.

The world produced 41.8 million metric tons of e-waste in 2014, according to a study published by the United Nations University. So how can we combat this growing problem?

The recycling option… and sometimes law

Recycling products that we’re no longer using is always good practice. It can help protect the environment from hazards that are in our electronics and batteries. And many times, the device can be refurbished and donated to a person in need.

Sometimes just asking people to recycle isn’t enough, though. Some governments have made it illegal not to recycle. For example, the EU has gone so far as to institute the Battery Directive. Understanding that batteries commonly contain elements such as mercury, cadmium, and lead, the EU has set an objective of improving environmental performances of batteries, and setting a standard for their waste management as well.

In the United States, cities like New York City have made it illegal to simply throw out electronic devices. Instead, residents need to bring their devices to a recycling center, many of them conveniently located at other electronic retail outlets.

Incentives

If less hazardous waste in landfills, a cleaner environment, and compliance with laws and regulations aren’t enough, how about saving money as an incentive to recycle e-waste?

Many manufacturers and retailers offer discounts on purchases with the return of old devices. Best Buy, for example, has experimented with trade-in and recycling programs that offer gift cards or cash for customers who bring in old devices. As programs like this can leave the retailer struggling to break even, they often aren’t financially attractive enough to be the sole incentive drawing consumers to recycle e-waste.

But one incentive that is very effective is also, probably, the most obvious — convenience. One survey found that 43% of respondents would be more likely to recycle e-waste were cell phone and battery recycling part of curb-side pickup.

The convenience of curb-side pickup for paper, plastic, and aluminum helped to make recycling ubiquitous in neighborhoods across the country. It’s the same thought process that leads researchers to believe that the convenience of a curb-side pickup will encourage more individuals to recycle their electronic devices and batteries.

This post originally appeared on EBN Online.

Related posts:

by Elizabeth Hines | Feb 21, 2017 | Blog, Consumer Electronics, Manufacturing & Distribution, Strategy, Supply Chain

Will sustainability trends from the consumer packaging industry have an impact on electronics manufacturing this year?

As we wrap up the first big consumer holiday of 2017, it’s interesting to think about how innovation in packaging never stops. While many of the newest ideas are hitting consumer applications first, perhaps they will point to new directions for electronics manufacturing as well.

Packaging trends suggest a wide range of startups, researchers, and big companies are committed to finding solutions that match the buzzwords du jour — sustainable, bio-degradable, natural, and eco-friendly.

Here are some sustainability trends in packaging that I think will gain momentum in 2017.

2017 packaging trends to watch

1) Multiple uses

Great packaging protects not only your product, but also your brand. But what if the packaging is part of the product itself?

That is the case with innovations such as the expandable bowl by Swedish design studio Tomorrow Machine. Using 100% bio-based and biodegradable materials, the company created a cellulose wrapper that hugs freeze-dried food and morphs into a bowl when hot water is poured into the spout. The bowl ― a sustainable packaging award winner ― is now in good company, and I expect more will follow.

2) Unconventional materials

Egg shells, fermented sugars, barley, and wheat ribbons — those were the materials used to create, in turn:

- Bio-compostable films: Nano-particles from waste eggshells helped researchers at Tuskegee University in Alabama make a plastic film that is completely sustainable and 700% more flexible than other bio-plastic blends. Film made of the new material could be used in retail packaging, grocery bags and food containers.

- A prototype PHBottle: The European PHBottle project aims to initially create a bottle, cap, and sleeve, although use in other applications (non-food packaging and non-packaging uses) will be tested. The bio-plastic material used to make the bottle comes from the transformation of organic matter found in juice processing by-products.

- Edible six-pack rings for beer: Imagine washing down the six-pack ring with your favorite beer. Although that moment is not quite here yet, the future is looking up for a piece of plastic that is notorious for ensnaring wildlife. The first bio-degradable edible six-pack ring for beer is the result of a partnership between Saltwater Brewery; We Believers, an advertising agency; and Entelequia, Inc., a small startup in Mexico. Made from barley and wheat ribbons spent grain from the brewing process, the rings are safe for wildlife to eat and sturdy enough to support the cans.

3) Reusable packaging

The throw-away culture is not for everyone. In fact, Mintel’s Global Packaging Trends 2017 shows 63% of U.S. consumers actively seek out packages they can re-use. More than half of consumers also say they would prefer to buy foods with minimal or even no packaging. With such great demand for waste reduction, innovation is bound to pick up even more momentum.

What do you think 2017 will bring in terms of sustainable packaging for the electronics industry? Let us know about promising innovations you’ve seen.

This post originally appeared on EBN Online.

Related posts:

by Fronetics | Jul 21, 2015 | Blog, Leadership, Strategy, Supply Chain

A “revolution” is what Pope Francis recently called it – the necessity for humans to change attitudes, beliefs, and behaviors in order create a sustainable ecosystem and society. In his encyclical, entitled Praise be to you – On Care For Our Common Home, he called upon all people and organizations to push against the increasing drive for power at the expense of the earth and other human beings, stating, “We are not faced with two separate crises, one environmental and the other social, but rather one complex crisis which is both social and environmental.”

Pope Francis is one large voice in a sea of voices— secular and non-secular— who have been pleading for change for decades. Recent record-breaking temperatures, storms, and droughts cannot be ignored. What is the role of each person in these battles? What is the role of governments, NGOs, companies?

The supply chain impacts: water, environment, raw materials, energy, animals, humans – essentially the entire planet and those who exist on it.

Cathy Morris, senior vice president and chief strategy officer for Arrow Electronics, Inc., calls attention to the fact that “everything hinges on an effective supply chain.” Specifically: “Products can be made, money can be invested, ideas can be brought to fruition, but without the supply chain everything stops.” The scope of influence of this trillion dollar industry has a significant impact on our planet and our environment.

In an interview with the Harvard Business Review, Peter Senge states that the perception of sustainability must shift, “They might not say this, but most companies act as if sustainability is about being less bad. There’s certainly a need to reduce your carbon footprint. But people don’t get excited about incremental changes like that. They need a more ambitious vision.”

The supply chain holds within it the power to impact many things, from stocking your grocery and clothing stores, to making the cars you use to get to those stores, or the pieces of the computer you use to purchase those things online. The supply chain is also the packing and the raw materials to make the packing. It’s the boat, the truck, the train, and the plane to move the materials. From the products to the moving of products, there are few areas of daily living that does not involve the supply chain.

The supply chain also holds within it the power to impact the sustainability of the ecosystem. In the past several decades we have seen increasing evidence that human behavior is altering the state of the earth. According to PWC, “While climate change and increasing temperatures now seem inevitable, there are high levels of uncertainty about the manifestations and magnitude of their impact. What is certain, though, is that climate change will have a multiplier effect on supply chain risk.”

In the 1980s we saw that we, as individuals, were contributing to the hole in ozone layer by emitting man-made gases. Although the ozone appears to be slowly recovering, a larger issue looms: greenhouse gases. The three main gases that traps and heat the earth, Carbon Dioxide (72% of total), Methane (18% of total), and Nitrous Oxide (9% of total), come from our need for energy (power stations 21.3% and Fossil fuel retrieval 11.3%), products (industrial processes (16.8%), transportation (14%), and food (agricultural byproducts) 12.5%) rounding out the top emitters by sector.

In our contemporary pursuit for an easier life, people consume more products, energy, and water. We desire heat when it’s cold, air-conditioning when it’s hot. We want to travel in cars and planes. We want more, better, faster, cheaper. According to the NASA website, “In its Fourth Assessment Report, the Intergovernmental Panel on Climate Change, a group of 1,300 independent scientific experts from countries all over the world under the auspices of the United Nations, concluded there’s a more than 90 percent probability that human activities over the past 250 years have warmed our planet.” The same report showed that “climate change is a material risk to supply chains across industries, and according to the CDP, more than 50 percent of an average corporation’s carbon emissions typically come from the supply chain.”

According to BSR’s report, Business Action for Climate-Resistant Supply Chains, there are five areas of supply chain climate risks that require consideration by all companies:

- The physical risk to suppliers’ assets and operations

- The risk of reduced availability or increased costs of inputs

- The risk of changing regulations in sourcing or distribution markets

- The risk of climate-related disruptions in communities that impact supplier workforce availability and productivity

- Stakeholder, or reputational, risk

We know the facts, we know much of the damage, so now what? Humans contribute, the supply chain contributes. At this point people want to move beyond the blame game and work to improve and, in some cases, reverse the damage. There’s an expectation that individuals will help in this effort, driving more efficient cars, finding renewable sources of energy, and focusing on recycling, but companies are also being asked to do their part, particularly the vast world of the supply chain. According to the UN Global Compact website, “A company’s entire supply chain can make a significant impact in promoting human rights, fair labour practices, environmental progress and anti-corruption policies. However, UN Global Compact participants rank supply chain practices as the biggest challenge to improving their sustainability performance.”

Fronetics Strategic Advisors is a leading management consulting firm. Our firm works with companies to identify and execute strategies for growth and value creation.

Whether it is a wholesale food distributor seeking guidance on how to define and execute corporate strategy; a telematics firm needing high quality content on a consistent basis; a real estate firm looking for a marketing partner; or a supply chain firm in need of interim management, our clients rely on Fronetics to help them navigate through critical junctures, meet their toughest challenges, and take advantage of opportunities. We deliver high-impact results.

We advise and work with companies on their most critical issues and opportunities: strategy, marketing, organization, talent acquisition, performance management, and M&A support.

We have deep expertise and a proven track record in a broad range of industries including: supply chain, real estate, software, and logistics.

by Fronetics | Jul 20, 2015 | Blog, Logistics, Marketing, Social Media, Strategy, Supply Chain

Sourcemap: doing well by doing good.

Leonardo Bonanni’s company, Sourcemap, is doing well by doing good, and he’s helping companies to do the same. In working on his doctoral thesis at MIT, Leonardo Bonanni created a service that is good for the world on many levels – it saves companies money and it works towards sustainability through transparency. Bonanni is bringing the people what they want. Consider these numbers from recent surveys:

- more than 88% of consumers think companies should try to achieve their business goals while improving society and the environment

- 83% of employees would seriously consider leaving their job if their employer used child labor in sweatshop factories

- 65% would seriously consider leaving their job if their company harmed the environment

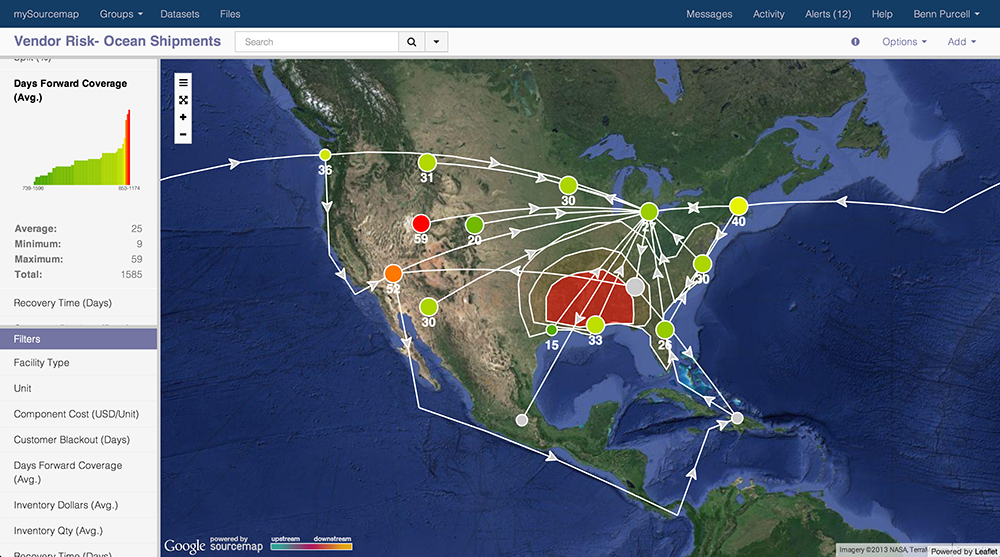

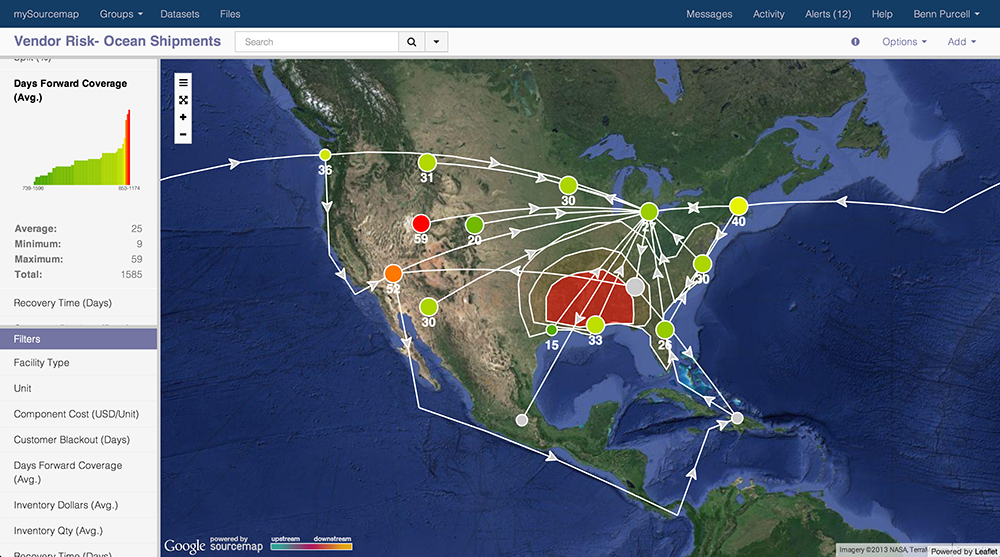

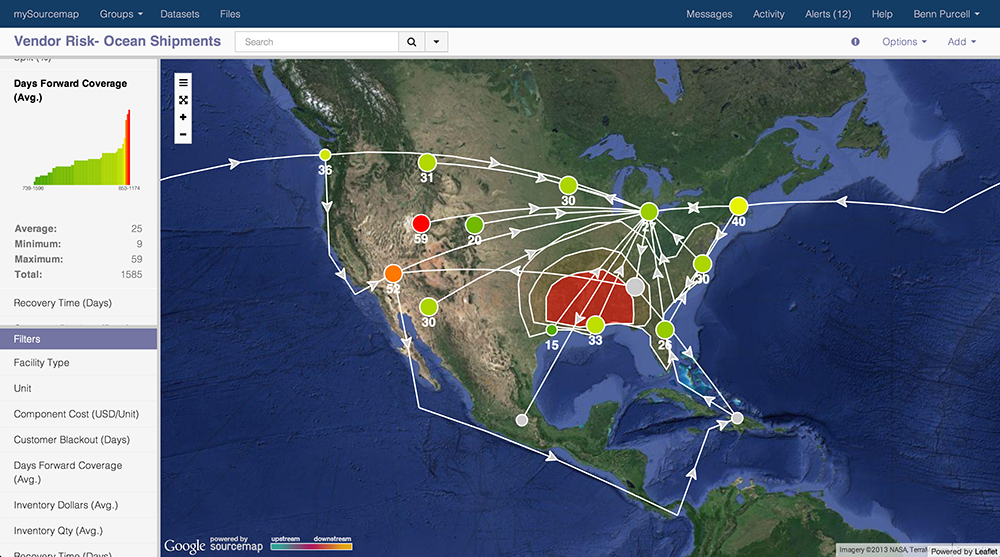

Bonanni’s innovative company, Sourcemap, helps clients visually map the supply chain route, from raw materials to end-users, providing unique and important visibility. Companies like Stoneyfield, Mars Chocolate, Fairphone, and Office Depot can see risks and disruptions in the supply chain in real time, act responsibly, promote sustainability, and please consumers who are increasingly curious and conscientious about materials sourcing.

The likes of the Wall Street Journal, Forbes, and The Guardian have taken interest in Dr. Bonanni and Sourcemap. Here he shares some insights with Fronetics on the growth of the company and how he won’t rest until mapping the supply chain is status quo.

What’s the most exciting thing going on at Sourcemap right now?

2015 is the year of supply chain mapping. When we started helping companies trace their products to the source, it was 2007 and the question was ‘why would we want to do that?’ Today it’s ‘how fast can we start?’ Whether it’s risk, sustainability, or simply finding more efficient ways to source products, companies need a big picture of the end-to-end supply chain. What’s exciting is how fast and far we help our clients get there – sometimes in as little as one day.

Tell me about how the maps are built. Are the maps on the free source platform built the same way as the maps on the enterprise platform?

Sourcemap started as a service for consumers to find out where products come from (free.sourcemap.com is still the only website where anyone can make a supply chain map, no training required). Users log in and map a supply chain – from raw material to end customer – as easily as drawing dots and lines on a Google map. Soon after the free website launched manufacturers approached us to see if we could help them figure out where their products come from. We had a lot of experience from serving millions of visitors through our free website, so we knew how to make a robust and intuitive interface for supply chain mapping. We adapted the technology to enterprise needs by adding company specific KPI’s, network analytics, and real-time reporting. The difference is that our enterprise users don’t draw the supply chains one link at a time. Their maps are automatically generated in near-real time from transportation, purchasing, and product lifecycle management databases.

Is it hard to convince businesses that there is an economic or competitive advantage to a utilizing a platform like Sourcemap?

It’s true that Sourcemap was originally built for sustainability, and it can be hard for companies to dedicate resources to long-term issues when short-term priorities come up every day. But our first success wasn’t helping companies be more sustainable in the long term. It was helping them tackle short-term crises, by developing a supply chain repository for emergency response and business continuity planning. Our clients were spending days and weeks to determine how a natural or human-made disaster was impacting any of thousands of suppliers worldwide. We brought that time down to minutes. Then supply chain managers started to see the benefit of knowing not just who they buy from, but who their suppliers buy from – and making decisions to consolidate or diversify supply, move inventories around, and decide when to in-source / out-source processes. These decisions represent huge savings in overall supply chain cost.

This is fantastic tool for companies who are proud of their supply chains, but what about those companies who aren’t, or who aren’t even fully aware of the steps and impact of their chain?

Over the years we’ve worked with companies big and small, with widely differing visibility into their supply chains. What we’ve seen is that the biggest benefit – the low-hanging fruits – are there for first-time supply chain mappers. These are companies that have expanded through acquisitions, are entering new markets or introducing new products – basically any organization that needs to account for a whole new way of doing business. Then, supply chain mapping is the easiest way to keep tabs on everyone in the supply chain and make sure that decisions are taken with an eye on the big picture.

In the years you’ve been doing this work have you seen a shift in consumer demand around the sourcing of materials and making of products? Is there increasing social pressure for companies to “do good”?

We’ve seen two drivers for supply chain sustainability and transparency: companies who want to attract the best talent, and brands looking to differentiate their product by providing information on its price, its composition, or its source.

Given that you teach at Columbia, I’m wondering if you see a difference in the passion, awareness, and attitude around sustainability with younger generations? Have you seen growth in the enrollment numbers in your classes?

I like to teach one or two evening classes a year (this Fall at NYU) to see how supply chain thinking is evolving as it becomes more mainstream. My class hasn’t changed much since it started in 2007, but the students have. Sustainability used to be a futuristic concern, and no one outside logistics departments ever talked about supply chains. Today there is a real desire among students to be social entrepreneurs, and part of that means thinking about products and services holistically – making sure that the social and environmental impacts are drivers of innovation, not just a nice-to-have. Enrollment has grown, and so has the number of departments where supply chains play a role: from engineering, architecture and design to business, public policy and international affairs.

Has social media played a role in the growth of the business and/or the operations of the business?

Sourcemap wouldn’t be here without social media. The fact that our supply chain maps can be embedded in other websites attracted over a million visitors in the first year. We saw brands embedding maps of their supply chains on their own websites, and we got a tremendous amount of traffic from being embedded and linked from the Huffington Post, Wired and Fast Company.

What are your ultimate goals for Sourcemap?

Supply chain mapping – knowing where products originate – gets easier the more companies do it. It requires information sharing, which means tighter collaboration between buyers and sellers. We’ve seen it become a requirement of purchasing departments: if you want to sell your products, disclose the raw material origins. That makes it easier to trust – and verify – the quality, the compliance, the sustainability of the product. Personally, I won’t rest until supply chain mapping becomes part of doing business as usual.

Dr. Leonardo Bonanni is Founder and CEO of Sourcemap, the supply chain mapping company. The New York-based startup offers enterprise software for companies to trace products, evaluate social, environmental and financial risks, and monitor improvements over time. One day soon you’ll be able to scan a product on a store shelf and be connected to the people who made it through the Sourcemap social network.

Leo is a supply chain transparency advocate named among the 100 Most Influential People in Business Ethics (2011) and America’s Most Promising Social Entrepreneurs (2012). He teaches sustainability at Columbia and at MIT, where he received his doctorate from the MIT Media Lab. He has a background as an architect, an inventor and a performer.

Fronetics Strategic Advisors is a leading management consulting firm. Our firm works with companies to identify and execute strategies for growth and value creation.

Whether it is a wholesale food distributor seeking guidance on how to define and execute corporate strategy; a telematics firm needing high quality content on a consistent basis; a real estate firm looking for a marketing partner; or a supply chain firm in need of interim management, our clients rely on Fronetics to help them navigate through critical junctures, meet their toughest challenges, and take advantage of opportunities. We deliver high-impact results.

We advise and work with companies on their most critical issues and opportunities: strategy, marketing, organization, talent acquisition, performance management, and M&A support.

We have deep expertise and a proven track record in a broad range of industries including: supply chain, real estate, software, and logistics.

by Jennifer Hart Yim | Jun 22, 2015 | Blog, Manufacturing & Distribution, Strategy, Supply Chain

This article is part of a series of articles written by MBA students and graduates from the University of New Hampshire Peter T. Paul College of Business and Economics.

Melanie Payeur graduated from the University of New Hampshire in 2007 with a degree in Mechanical Engineering. She has since worked in various roles supporting manufacturing and packaging operations in the food and beverage industry.

Do you know where your byproducts go?

Do you know where your byproducts go?

Manufacturing often produces some sort of physical byproduct. Examples range from plastic strapping on a pallet of corrugate boxes to carbon dioxide collected off a tank of fermenting beer. Byproducts are the unspoken of and often neglected “cousin” of manufacturing.

Byproducts of manufacturing can be compared to the stage crew at a Broadway show or on a Hollywood movie set. They serve an important purpose. Without the lights, cameras, and curtains, there is no show. Similarly, without plastic strapping, a pallet of corrugate would fall over during transport because it wasn’t properly secured.

The stars of the show are the finished goods on store shelves. Just like people don’t stick around to see the name of the on-set hair-stylist when the credits roll at a movie, consumers often don’t think about the byproducts associated with the packaged food they eat or other goods they purchase. It’s possible that they don’t even know these things exist.

However, consumers are becoming more conscious of supply chain issues. Many have an awareness what Fair Trade is in association with sourcing of products such as coffee and cocoa beans. They discuss agricultural sourcing and the ethical (or not) treatment of animals raised to be part of the food chain. Even the effects of emissions and chemical waste on the environment are among topics of which many consumers have some awareness.

Plastic old, Plastic new

What about the plastic strapping on that pallet of corrugate though? Where does it go? Who even knows it exists other than the operator that cuts it off the pallet in the factory? Could it become a plastic bottle someday? Or a swing set? Maybe it will become plastic strapping again?

While countless other types of byproducts exist, plastic is a particularly interesting example. Fluctuations in the price of petroleum are directly correlated to the price of brand new, non- recycled plastic pellets. It is completely possible, and often realistic, that it is less expensive to create brand new plastic strapping than it is to recycle old strapping.

Trailer Bags and Trash Bowls

Creative and novel uses of byproducts are happening today. One example is a Swiss company called Freitag who produces trendy messenger bags, wallets, and purses from old side panel tarps (popular on tractor trailers in Europe). At the end of their useful life on the road, these tarps are purchased by Freitag and sewn into functional accessories.

Another example specifically related to plastic are Garbage Bowls made famous by Food Network host, Rachael Ray. These bowls are made from recycled pieces of broken plates. There’s a byproduct in there somewhere!

While these are great examples of repurposing byproducts into something new, the truth is that Freitag was originally looking for a material that would create a durable and functional product. Lucky for them, reusing something that might have otherwise been thrown away is a great marketing story. They charge an average of $200 for a standard messenger bag. Is it realistic that the reverse situation can create profits? Can we find another use for production process byproducts which would create a trendy or otherwise highly desirable product?

Can we do better than throwing our byproducts away?

If it’s not a company’s core competency, it probably shouldn’t get into the business of designing handbags. However, as supply chain professionals, we should understand all of the byproducts of our manufacturing process; especially those related to materials that we source as inputs, like plastic strapping.

It is as important to look at the waste stream from our process as it is to examine how we source raw materials. Are we recycling our byproducts? Is there someone who is looking for our ‘trash’ as an input to their process? Do we have the opportunity to have a profitable side business as a coincidental supplier to someone else? At the very least, can we do better than throwing our byproducts away?

An example of success can be seen in the food manufacturing industry. Some companies donate or sell their byproducts to the Bakery Feeds Program. This organization creates animal feed out of food byproducts such as misshapen cupcakes and other edible process waste. It might be cost neutral to dispose of waste in this way, but that is better than otherwise paying for disposal.

I challenge you to examine the waste streams associated with your process. Identify where at least one of your byproducts could go. From here to there and there to here, your byproducts could end up anywhere.