by Fronetics | Nov 12, 2019 | Blog, Strategy, Supply Chain

Organizations implementing sustainable supply chain practices face increased expenses associated with upfront investments. But new strategies are emerging to change that.

Highlights:

- 93% of supply chain organizations have implemented environmental initiatives. Still, more plan to do so in the next five years.

- Unlike some sustainability initiatives that require large upfront investment, other strategies synergize with business interests.

- A holistic vision is key to initiating sustainable practices.

Sustainability is on-trend in the business world. But, how do you view sustainable initiatives — a debilitating upfront investment or an exciting opportunity to enhance your company’s bottom line? Many small businesses find themselves in the former camp. However, new strategies are emerging that may change that.

What does sustainable practice mean?

A recent study conducted by Llamasoft and the Economist Intelligence Unit surveyed 250 senior executives from manufacturing and retail companies worldwide. The report showed that 93% of supply chain organizations have implemented environmental initiatives. Still, more plan to do so in the next five years.

Regulatory standards and consumer priorities are making it increasingly urgent for companies of all sizes to rethink their operations in terms of sustainability. A 2018 Nielsen study found that 81% of global consumers are convinced that companies have a responsibility to employ policies that prevent further harm to the planet. The U.S. has seen increased regulation related to environmental protection, including emissions standards and the recovery/reuse of packaging material. In the U.K., companies employing more than 500 people are required to report on their sustainability practices, and, according to Nielsen, 71% of Europeans place a high value on maintaining ethical and sustainable lifestyles.

Whether this means costs or benefits for your organization depends a great deal on what exactly you understand sustainability to mean. While it’s easy to associate sustainability with hard-to-achieve environmental goals, industry experts are starting to think a little more capaciously about how companies can participate in a sustainable supply chain. If we think about sustainability as “meeting the needs of today without compromising the ability of future generations to meet their own,” then organizations can find more flexible strategies for achieving sustainability that suit their needs and abilities.

Organizations implementing green initiatives face increased expenses associated with upfront investments. New equipment, more expensive sourcing costs, and the personnel required to oversee these changes make the early stages of investing in sustainable practices a daunting prospect for many companies. And the obstacles don’t end there. According to Llamasoft’s study, significant challenges facing sustainability initiatives include the difficulty of monitoring complex supply chains and the need for organizational structures that can implement new policies. Interestingly, 38% of executives surveyed cite the costs associated with these challenges as a deterrent to implementing further initiatives.

Yet 33% reported that their companies had initiated sustainability drives because of the benefits to their bottom line. What accounts for the difference?

Sustainable practices: the bottom line

As the survey indicates, sustainability and profitability are not actually mutually exclusive options. Unlike some sustainability initiatives that require large upfront investment, other strategies synergize with business interests.

Efforts aimed at increasing the efficiency and agility of supply chain organizations can yield sustainability benefits as a rewarding side-effect. Consolidating shipments, efficient route design, and multi-echelon inventory optimization serve both profitability and sustainability goals. Intelligent product design that allows for efficiency of shipping and storage also contributes to carbon footprint reduction. Just think of Costco’s switch from round to square pistachio jars that enhanced supply and storage capacities and reduced the emissions of its truck fleet at the same time! Additionally, periodically overhauling operations with sustainability in mind has proven to be a good tactic for efficiency, as well, leading to more precise inventory levels and more accurate predictive management.

Upfront costs can often be quickly recouped not only through improved efficiency, but also through the brand identity enhancement associated with companies that effectively publicize their sustainability practices. Integrating green initiatives into marketing and branding strategies offers an intangible advantage beyond measurable profits or benefits to the planet.

Many businesses are looking to brand themselves as leaders in sustainability. Many large organizations successfully do this by engaging with suppliers to encourage sustainable practices throughout the supply chain. In the past, large organizations used environmental criteria as a tie-breaker in awarding contracts to smaller supply companies. But, sustainable practices are increasingly becoming a requirement in order for supply chain companies to bid in the first place. In fact, 88% of executives surveyed by Llamasoft indicated that their organizations keep track of supplier sustainability ratings, often developing their own evaluations, such as:

- Supplier scorecards that allow companies to rate the practices of other businesses in their supply chain, facilitating comparison among potential suppliers

- Public targets, which some companies require suppliers to meet in order to retain their contracts (Hewlett Packard, for instance, has launched a campaign requiring 80% of their suppliers to set certain emissions reduction targets by 2025.)

- Awards that allow companies to recognize suppliers that successfully initiate green policies

Sustainable practices for small companies

These benefits, however, are predominantly available to large global companies that have the capital, scale of operations, and leverage with trading partners to make sustainable practices practical. So, what can small businesses do to rate highly for sustainability — not to mention, gain the same branding advantages enjoyed by large organizations?

A holistic vision is key to initiating sustainable practices. Your company’s sustainability doesn’t ride solely on internal practices, such as the management of your fleet. It is just as important to consider how sustainable your suppliers are, for example.

From this perspective, selecting off-shore suppliers with lower per-unit costs can often incur longer-term disadvantages. Companies risk increasing their carbon footprint due to the greater shipping distance. Further, longer lead times necessitate holding more inventory, which equates to higher holding costs and storage facility energy emissions.

In short, the best way for any business — large or small — to practice sustainability is to optimize practices throughout the supply chain. Regulatory standards and consumer preferences are increasingly bending that way, and soon you’ll be in the minority if you’re not an active advocate for a sustainable supply chain.

This post originally appeared on EBN Online.

Related posts:

by Fronetics | Jul 20, 2015 | Blog, Logistics, Marketing, Social Media, Strategy, Supply Chain

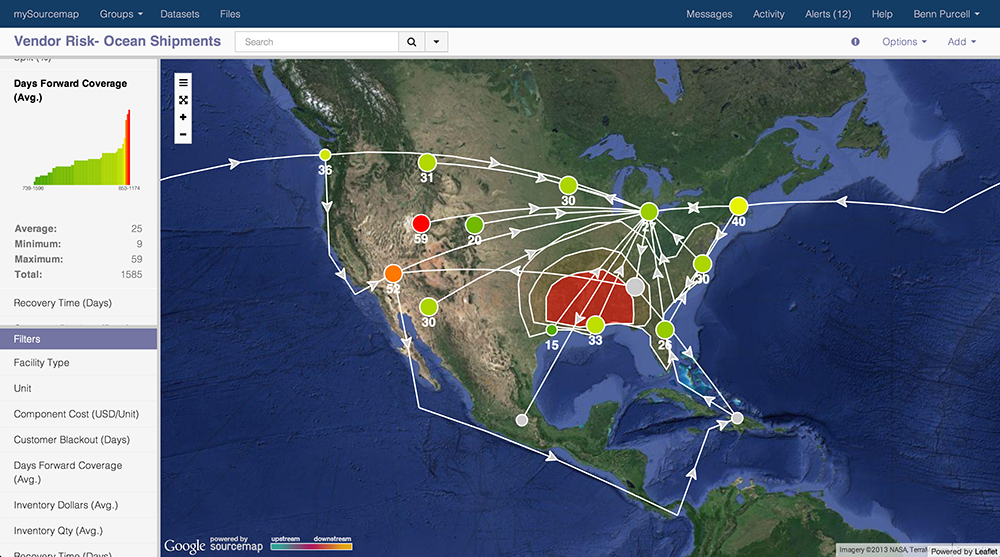

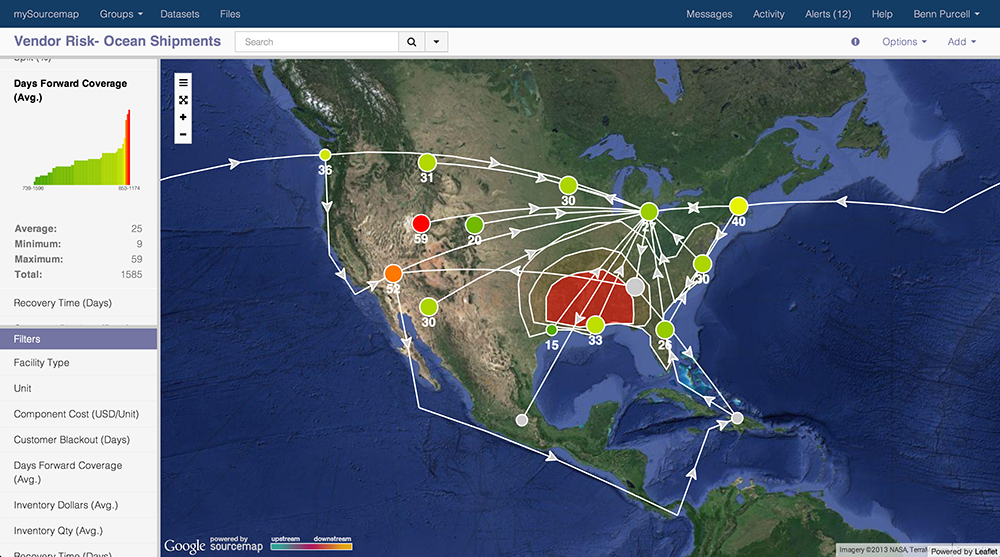

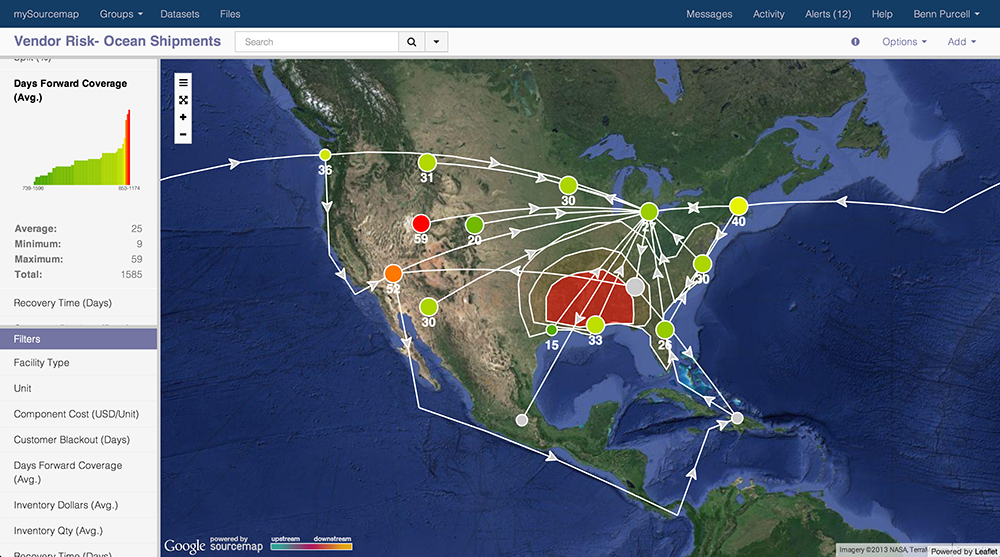

Sourcemap: doing well by doing good.

Leonardo Bonanni’s company, Sourcemap, is doing well by doing good, and he’s helping companies to do the same. In working on his doctoral thesis at MIT, Leonardo Bonanni created a service that is good for the world on many levels – it saves companies money and it works towards sustainability through transparency. Bonanni is bringing the people what they want. Consider these numbers from recent surveys:

- more than 88% of consumers think companies should try to achieve their business goals while improving society and the environment

- 83% of employees would seriously consider leaving their job if their employer used child labor in sweatshop factories

- 65% would seriously consider leaving their job if their company harmed the environment

Bonanni’s innovative company, Sourcemap, helps clients visually map the supply chain route, from raw materials to end-users, providing unique and important visibility. Companies like Stoneyfield, Mars Chocolate, Fairphone, and Office Depot can see risks and disruptions in the supply chain in real time, act responsibly, promote sustainability, and please consumers who are increasingly curious and conscientious about materials sourcing.

The likes of the Wall Street Journal, Forbes, and The Guardian have taken interest in Dr. Bonanni and Sourcemap. Here he shares some insights with Fronetics on the growth of the company and how he won’t rest until mapping the supply chain is status quo.

What’s the most exciting thing going on at Sourcemap right now?

2015 is the year of supply chain mapping. When we started helping companies trace their products to the source, it was 2007 and the question was ‘why would we want to do that?’ Today it’s ‘how fast can we start?’ Whether it’s risk, sustainability, or simply finding more efficient ways to source products, companies need a big picture of the end-to-end supply chain. What’s exciting is how fast and far we help our clients get there – sometimes in as little as one day.

Tell me about how the maps are built. Are the maps on the free source platform built the same way as the maps on the enterprise platform?

Sourcemap started as a service for consumers to find out where products come from (free.sourcemap.com is still the only website where anyone can make a supply chain map, no training required). Users log in and map a supply chain – from raw material to end customer – as easily as drawing dots and lines on a Google map. Soon after the free website launched manufacturers approached us to see if we could help them figure out where their products come from. We had a lot of experience from serving millions of visitors through our free website, so we knew how to make a robust and intuitive interface for supply chain mapping. We adapted the technology to enterprise needs by adding company specific KPI’s, network analytics, and real-time reporting. The difference is that our enterprise users don’t draw the supply chains one link at a time. Their maps are automatically generated in near-real time from transportation, purchasing, and product lifecycle management databases.

Is it hard to convince businesses that there is an economic or competitive advantage to a utilizing a platform like Sourcemap?

It’s true that Sourcemap was originally built for sustainability, and it can be hard for companies to dedicate resources to long-term issues when short-term priorities come up every day. But our first success wasn’t helping companies be more sustainable in the long term. It was helping them tackle short-term crises, by developing a supply chain repository for emergency response and business continuity planning. Our clients were spending days and weeks to determine how a natural or human-made disaster was impacting any of thousands of suppliers worldwide. We brought that time down to minutes. Then supply chain managers started to see the benefit of knowing not just who they buy from, but who their suppliers buy from – and making decisions to consolidate or diversify supply, move inventories around, and decide when to in-source / out-source processes. These decisions represent huge savings in overall supply chain cost.

This is fantastic tool for companies who are proud of their supply chains, but what about those companies who aren’t, or who aren’t even fully aware of the steps and impact of their chain?

Over the years we’ve worked with companies big and small, with widely differing visibility into their supply chains. What we’ve seen is that the biggest benefit – the low-hanging fruits – are there for first-time supply chain mappers. These are companies that have expanded through acquisitions, are entering new markets or introducing new products – basically any organization that needs to account for a whole new way of doing business. Then, supply chain mapping is the easiest way to keep tabs on everyone in the supply chain and make sure that decisions are taken with an eye on the big picture.

In the years you’ve been doing this work have you seen a shift in consumer demand around the sourcing of materials and making of products? Is there increasing social pressure for companies to “do good”?

We’ve seen two drivers for supply chain sustainability and transparency: companies who want to attract the best talent, and brands looking to differentiate their product by providing information on its price, its composition, or its source.

Given that you teach at Columbia, I’m wondering if you see a difference in the passion, awareness, and attitude around sustainability with younger generations? Have you seen growth in the enrollment numbers in your classes?

I like to teach one or two evening classes a year (this Fall at NYU) to see how supply chain thinking is evolving as it becomes more mainstream. My class hasn’t changed much since it started in 2007, but the students have. Sustainability used to be a futuristic concern, and no one outside logistics departments ever talked about supply chains. Today there is a real desire among students to be social entrepreneurs, and part of that means thinking about products and services holistically – making sure that the social and environmental impacts are drivers of innovation, not just a nice-to-have. Enrollment has grown, and so has the number of departments where supply chains play a role: from engineering, architecture and design to business, public policy and international affairs.

Has social media played a role in the growth of the business and/or the operations of the business?

Sourcemap wouldn’t be here without social media. The fact that our supply chain maps can be embedded in other websites attracted over a million visitors in the first year. We saw brands embedding maps of their supply chains on their own websites, and we got a tremendous amount of traffic from being embedded and linked from the Huffington Post, Wired and Fast Company.

What are your ultimate goals for Sourcemap?

Supply chain mapping – knowing where products originate – gets easier the more companies do it. It requires information sharing, which means tighter collaboration between buyers and sellers. We’ve seen it become a requirement of purchasing departments: if you want to sell your products, disclose the raw material origins. That makes it easier to trust – and verify – the quality, the compliance, the sustainability of the product. Personally, I won’t rest until supply chain mapping becomes part of doing business as usual.

Dr. Leonardo Bonanni is Founder and CEO of Sourcemap, the supply chain mapping company. The New York-based startup offers enterprise software for companies to trace products, evaluate social, environmental and financial risks, and monitor improvements over time. One day soon you’ll be able to scan a product on a store shelf and be connected to the people who made it through the Sourcemap social network.

Leo is a supply chain transparency advocate named among the 100 Most Influential People in Business Ethics (2011) and America’s Most Promising Social Entrepreneurs (2012). He teaches sustainability at Columbia and at MIT, where he received his doctorate from the MIT Media Lab. He has a background as an architect, an inventor and a performer.

Fronetics Strategic Advisors is a leading management consulting firm. Our firm works with companies to identify and execute strategies for growth and value creation.

Whether it is a wholesale food distributor seeking guidance on how to define and execute corporate strategy; a telematics firm needing high quality content on a consistent basis; a real estate firm looking for a marketing partner; or a supply chain firm in need of interim management, our clients rely on Fronetics to help them navigate through critical junctures, meet their toughest challenges, and take advantage of opportunities. We deliver high-impact results.

We advise and work with companies on their most critical issues and opportunities: strategy, marketing, organization, talent acquisition, performance management, and M&A support.

We have deep expertise and a proven track record in a broad range of industries including: supply chain, real estate, software, and logistics.

by Jennifer Hart Yim | May 21, 2015 | Blog, Strategy, Supply Chain

This article is part of a series of articles written by MBA students and graduates from the University of New Hampshire Peter T. Paul College of Business and Economics.

Lindsey Marley completed dual undergraduate degrees in Business and History at Southern New Hampshire University. She is in her final semester of the MBA program at the University of New Hampshire. In her free time she enjoys traveling, reading, and spending time with her husband and their two dogs.

On November 24, 2012 there was a deadly fire at a garment manufacturing company which killed 112 people in Dhaka, Bangladesh. Another manufacturing facility in Dhaka collapsed on April 24, 2013 killing 142 people. The ready-made garment manufacturing industry in Bangladesh has grown to $19 billion dollars and is reported to be one of the most unsafe industries in the world. The consequences of corporations being lax in the sourcing of their products can have horrific consequences for people, the environment, and the company. Consumers in developed countries are demanding companies be more responsible in their sourcing as a result of the wealth of information found on the Internet about the production of goods and services.

Responsible Sourcing

The concept of responsible sourcing is in itself still being developed; however, responsible sourcing generally consists of two parts – people and the environment. There are several organizations which have provided guidelines to assist companies in developing their own code of conduct including:

One such industry-specific coalition, which was created in response to numerous tragedies such as those described above, is the Alliance for Bangladesh Worker Safety which was founded in 2013 by a group of North American apparel companies and retailers.

Alliance: A Global Response

The Alliance created a binding five-year agreement to improve worker safety among the largest importing companies of Bangladesh garments. Some of the most well-known participants include Limited, Carter’s Inc, Fruit of the Loom, Gap Inc, Kohl’s Department Stores, LL Bean, Macy’s, Target Corporation, and Wal-Mart Stores, Inc. The Alliance is accomplishing its mission through the use of a collective fund which was $42 million at the time of its creation.

The International Labour Organization has assisted the Alliance in the creation of an operational guide. The Alliance focuses on opening lines of communication between employees and management to ensure worker safety. Interviews with employees regarding existing safety practices and training are conducted and then safety discussions are coordinated between those employees and members of management. The Alliance also requires assessments be completed of garment manufacturing plants by independent engineers to certify worker safety and the structural soundness of facilities. After the initial evaluation and recommendations, the independent auditors return to confirm the changes previously discussed have been made as well as to assess the manufacturer’s ongoing compliance.

Had the Alliance been in place prior to the fire in 2012 the auditors would have found the illegally stored mounds of fabric and yarn, which accelerated the spread of flames, and required the materials to be stored in a more appropriate and safe manner. Another aspect of the fatal fire which could have been prevented was the allegation of factory managers directing employees to ignore the fire alarm. This wasted precious time for workers to exit the building safely. Ultimately, this lead many employees, trapped by the flames and smoke, to jump from upper floors to the rooftops of surrounding buildings or to their deaths. The tripartisan relationship that is created between the Alliance, employees, and management representatives is critical to ensure a clear, consistent message regarding basic employee safety. This communication helps to empower workers and could have encouraged them to challenge management’s direction to disregard the alarm when the fire broke out.

With regard to the building collapse of 2013, it was determined the four upper floors had been constructed illegally without permits. The three pronged scope of the Alliance (worker safety, fire safety, and structural soundness) again could have prevented this tragedy. In this situation, management at the garment manufacturing facility were aware of structural concerns before the collapse, but as in the case of the fire, ignored the risk and kept the factory open. Engineers working for the Alliance drill into factory walls to determine the structural integrity of the concrete and rebar used during construction to determine structural soundness.

Your Span of Control

These examples highlight the importance of maintaining a large span of control throughout your supply chain to ensure responsible sourcing. It is no small task to exercise this breadth of control for any company; however, companies can utilize the resources provided by the organizations listed above to develop their own requirements for responsible sourcing and supplier relationships. Companies can derive the maximum consumer exposure by enforcing responsible sourcing across their entire supply chain. It is also important to engrain this behavior into the culture particularly among employees who have the most interactions with the ultimate consumer.

Communicating to Your Customers

Consumer communication is the final piece of the responsible sourcing puzzle which brings together the voluntarily socially responsible company with their expecting consumer base. Responsible sourcing without informing consumers is a waste of good public relations. Many companies bury the information about their responsible sourcing efforts on the corporate website where consumers have to hunt for the information. Some coalitions and third party companies provide the insignia to compliant participants as a means of notifying consumers of their membership, but that is not always an option. If possible, a company’s commitment to responsible sourcing should be quickly and clearly communicated on its product packaging, in its digital footprint, and in the way it conducts and manages its supply chain.

The fast food giant Chipotle consistently communicates its commitment to responsibly sourced ingredients in its signage, website, commercials, and in its direct to consumer communications at the individual locations. The pervasive nature of the company’s responsible sourcing efforts has been strongly rewarded by its ever-growing customer base. In a time where consumers are switching brands to support socially responsible companies, it is imperative to keep a company’s responsible sourcing objectives, actions, and accomplishments at the forefront of consumer’s minds.

by Jennifer Hart Yim | May 21, 2015 | Blog, Strategy, Supply Chain

This article is part of a series of articles written by MBA students and graduates from the University of New Hampshire Peter T. Paul College of Business and Economics.

Lindsey Marley completed dual undergraduate degrees in Business and History at Southern New Hampshire University. She is in her final semester of the MBA program at the University of New Hampshire. In her free time she enjoys traveling, reading, and spending time with her husband and their two dogs.

On November 24, 2012 there was a deadly fire at a garment manufacturing company which killed 112 people in Dhaka, Bangladesh. Another manufacturing facility in Dhaka collapsed on April 24, 2013 killing 142 people. The ready-made garment manufacturing industry in Bangladesh has grown to $19 billion dollars and is reported to be one of the most unsafe industries in the world. The consequences of corporations being lax in the sourcing of their products can have horrific consequences for people, the environment, and the company. Consumers in developed countries are demanding companies be more responsible in their sourcing as a result of the wealth of information found on the Internet about the production of goods and services.

Responsible Sourcing

The concept of responsible sourcing is in itself still being developed; however, responsible sourcing generally consists of two parts – people and the environment. There are several organizations which have provided guidelines to assist companies in developing their own code of conduct including:

One such industry-specific coalition, which was created in response to numerous tragedies such as those described above, is the Alliance for Bangladesh Worker Safety which was founded in 2013 by a group of North American apparel companies and retailers.

Alliance: A Global Response

The Alliance created a binding five-year agreement to improve worker safety among the largest importing companies of Bangladesh garments. Some of the most well-known participants include Limited, Carter’s Inc, Fruit of the Loom, Gap Inc, Kohl’s Department Stores, LL Bean, Macy’s, Target Corporation, and Wal-Mart Stores, Inc. The Alliance is accomplishing its mission through the use of a collective fund which was $42 million at the time of its creation.

The International Labour Organization has assisted the Alliance in the creation of an operational guide. The Alliance focuses on opening lines of communication between employees and management to ensure worker safety. Interviews with employees regarding existing safety practices and training are conducted and then safety discussions are coordinated between those employees and members of management. The Alliance also requires assessments be completed of garment manufacturing plants by independent engineers to certify worker safety and the structural soundness of facilities. After the initial evaluation and recommendations, the independent auditors return to confirm the changes previously discussed have been made as well as to assess the manufacturer’s ongoing compliance.

Had the Alliance been in place prior to the fire in 2012 the auditors would have found the illegally stored mounds of fabric and yarn, which accelerated the spread of flames, and required the materials to be stored in a more appropriate and safe manner. Another aspect of the fatal fire which could have been prevented was the allegation of factory managers directing employees to ignore the fire alarm. This wasted precious time for workers to exit the building safely. Ultimately, this lead many employees, trapped by the flames and smoke, to jump from upper floors to the rooftops of surrounding buildings or to their deaths. The tripartisan relationship that is created between the Alliance, employees, and management representatives is critical to ensure a clear, consistent message regarding basic employee safety. This communication helps to empower workers and could have encouraged them to challenge management’s direction to disregard the alarm when the fire broke out.

With regard to the building collapse of 2013, it was determined the four upper floors had been constructed illegally without permits. The three pronged scope of the Alliance (worker safety, fire safety, and structural soundness) again could have prevented this tragedy. In this situation, management at the garment manufacturing facility were aware of structural concerns before the collapse, but as in the case of the fire, ignored the risk and kept the factory open. Engineers working for the Alliance drill into factory walls to determine the structural integrity of the concrete and rebar used during construction to determine structural soundness.

Your Span of Control

These examples highlight the importance of maintaining a large span of control throughout your supply chain to ensure responsible sourcing. It is no small task to exercise this breadth of control for any company; however, companies can utilize the resources provided by the organizations listed above to develop their own requirements for responsible sourcing and supplier relationships. Companies can derive the maximum consumer exposure by enforcing responsible sourcing across their entire supply chain. It is also important to engrain this behavior into the culture particularly among employees who have the most interactions with the ultimate consumer.

Communicating to Your Customers

Consumer communication is the final piece of the responsible sourcing puzzle which brings together the voluntarily socially responsible company with their expecting consumer base. Responsible sourcing without informing consumers is a waste of good public relations. Many companies bury the information about their responsible sourcing efforts on the corporate website where consumers have to hunt for the information. Some coalitions and third party companies provide the insignia to compliant participants as a means of notifying consumers of their membership, but that is not always an option. If possible, a company’s commitment to responsible sourcing should be quickly and clearly communicated on its product packaging, in its digital footprint, and in the way it conducts and manages its supply chain.

The fast food giant Chipotle consistently communicates its commitment to responsibly sourced ingredients in its signage, website, commercials, and in its direct to consumer communications at the individual locations. The pervasive nature of the company’s responsible sourcing efforts has been strongly rewarded by its ever-growing customer base. In a time where consumers are switching brands to support socially responsible companies, it is imperative to keep a company’s responsible sourcing objectives, actions, and accomplishments at the forefront of consumer’s minds.