![The supply chain gender gap [Infographic]](https://fronetics.com/wp-content/uploads/2024/10/supply-chain-gender-gap.jpg)

by Fronetics | May 26, 2015 | Blog, Strategy, Supply Chain, Talent

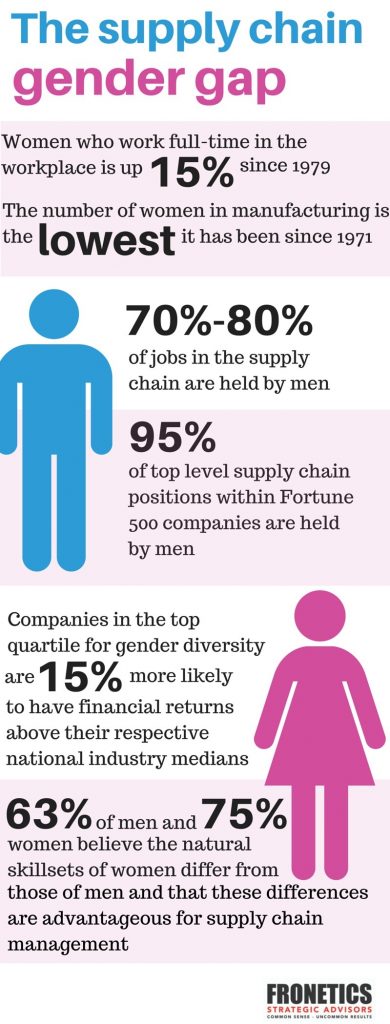

The number of women who work full-time in the workforce is up 15% since 1979. In the manufacturing sector, the story is very different. The number of men working in the manufacturing sector has increased, while the number of women working in the sector has declined. The number of women in the sector now stands at the lowest it has been since 1971.

Looking more broadly at the supply chain industry, it is clear that there is a significant gender gap. Between 70% and 80% of positions within the supply chain industry are held by men and 95% of top level supply chain positions within Fortune 500 companies are held by men. By comparison, men hold 85% of all executive officer positions within Fortune 500 companies.

The dearth of women working, at all levels, in the supply chain is not because women do not have the skillset and ability to succeed within the industry. Women are as capable as men when it comes to working within the supply chain industry. Indeed, it has been put forth that women are better suited for roles in supply chain management than men. Research conducted by SCM World found that the majority of men (63%) and women (75%) believe that the natural skillsets of women differ from those of men and that these differences are advantageous for supply chain management. Similarly, new research by McKinsey & Company found that companies in the top quartile for gender diversity are 15%more likely to have financial returns above their respective national industry medians.

The talent gap; an opportunity

According to Supply Chain Insights 60% of companies within the supply chain industry have job openings and 51% of companies are seeing an increase in turnover of supply chain leaders. Looking ahead, there are an estimated 1.4 million new supply chain workers needed by 2018 and the Bureau of Labor and Statistics predicts that the number of logistics jobs is expected to grow by 22 percent by 2022 – nearly double the rate of other professions. The supply chain talent gap arguably presents an opportunity to increase the number of women in positions throughout the supply chain and close the gender gap. The big question is how.

Addressing the gender gap

Here are 4 ways the supply chain industry can address the gender gap:

1. Increase visibility and tackle the image problem

93% of most companies’ supply chain is invisible. This statistic could also be used to reflect the number of people who know what the supply chain industry is; few people outside of the industry know what the supply chain is and what career opportunities there are. This needs to change.

To attract new talent the industry needs to make people aware of the supply chain – what it is, the integral role it plays in business, and the various opportunities there are within the industry.

2. Rethink talent acquisition and promotion

Within the supply chain industry the typical path up the corporate ladder has started out on the shop floor. If the industry is going to attract women and new talent companies need to look not only beyond their four walls, but also outside of the industry itself. When it comes to talent acquisition smart companies focus on the qualities of the individual and what they can bring to the table.

3. Move from talk to action

Battalia Winston’s Susan Medina and Peter Gomez point out that: companies without a proactive diversity-building strategy will fall victim to common-pitfalls and will fall flat.

“It’s important to acknowledge that diversity building is a proven growth strategy, not a superficial endeavor. But paying lip service to diversity and inclusion without a proactive strategy will lead to failure. Organizations need to prioritize, collaborate, and think long term.”

4. Take control

Women tend only to apply for jobs that they feel they are a 100% match; men do so even when they meet no more than 60% of the requirements. Similarly, men tend to be promoted more often than women simply because they speak up and ask for a promotion.

Women need to take responsibility for themselves and for their own careers. Women need to apply for jobs with confidence, even when they don’t have 100% of the requirements. They also need to speak up and ask for a promotion.

Kevin O’Marah, Chief Content Officer at SCM World, sums up the issue of the supply chain gender gap nicely: “Women in supply chain are too few, and their path to the top is at least partially blocked. Yet we all seem to think they bring something to the party that will make it better. The time to break this problem down is now.”

![The supply chain gender gap [Infographic]](https://fronetics.com/wp-content/uploads/2024/10/supply-chain-gender-gap.jpg)

by Fronetics | May 26, 2015 | Blog, Strategy, Supply Chain, Talent

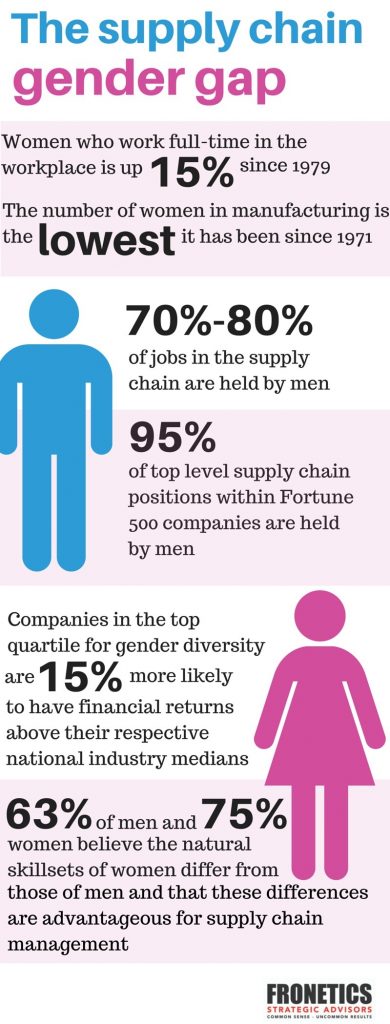

The number of women who work full-time in the workforce is up 15% since 1979. In the manufacturing sector, the story is very different. The number of men working in the manufacturing sector has increased, while the number of women working in the sector has declined. The number of women in the sector now stands at the lowest it has been since 1971.

Looking more broadly at the supply chain industry, it is clear that there is a significant gender gap. Between 70% and 80% of positions within the supply chain industry are held by men and 95% of top level supply chain positions within Fortune 500 companies are held by men. By comparison, men hold 85% of all executive officer positions within Fortune 500 companies.

The dearth of women working, at all levels, in the supply chain is not because women do not have the skillset and ability to succeed within the industry. Women are as capable as men when it comes to working within the supply chain industry. Indeed, it has been put forth that women are better suited for roles in supply chain management than men. Research conducted by SCM World found that the majority of men (63%) and women (75%) believe that the natural skillsets of women differ from those of men and that these differences are advantageous for supply chain management. Similarly, new research by McKinsey & Company found that companies in the top quartile for gender diversity are 15%more likely to have financial returns above their respective national industry medians.

The talent gap; an opportunity

According to Supply Chain Insights 60% of companies within the supply chain industry have job openings and 51% of companies are seeing an increase in turnover of supply chain leaders. Looking ahead, there are an estimated 1.4 million new supply chain workers needed by 2018 and the Bureau of Labor and Statistics predicts that the number of logistics jobs is expected to grow by 22 percent by 2022 – nearly double the rate of other professions. The supply chain talent gap arguably presents an opportunity to increase the number of women in positions throughout the supply chain and close the gender gap. The big question is how.

Addressing the gender gap

Here are 4 ways the supply chain industry can address the gender gap:

1. Increase visibility and tackle the image problem

93% of most companies’ supply chain is invisible. This statistic could also be used to reflect the number of people who know what the supply chain industry is; few people outside of the industry know what the supply chain is and what career opportunities there are. This needs to change.

To attract new talent the industry needs to make people aware of the supply chain – what it is, the integral role it plays in business, and the various opportunities there are within the industry.

2. Rethink talent acquisition and promotion

Within the supply chain industry the typical path up the corporate ladder has started out on the shop floor. If the industry is going to attract women and new talent companies need to look not only beyond their four walls, but also outside of the industry itself. When it comes to talent acquisition smart companies focus on the qualities of the individual and what they can bring to the table.

3. Move from talk to action

Battalia Winston’s Susan Medina and Peter Gomez point out that: companies without a proactive diversity-building strategy will fall victim to common-pitfalls and will fall flat.

“It’s important to acknowledge that diversity building is a proven growth strategy, not a superficial endeavor. But paying lip service to diversity and inclusion without a proactive strategy will lead to failure. Organizations need to prioritize, collaborate, and think long term.”

4. Take control

Women tend only to apply for jobs that they feel they are a 100% match; men do so even when they meet no more than 60% of the requirements. Similarly, men tend to be promoted more often than women simply because they speak up and ask for a promotion.

Women need to take responsibility for themselves and for their own careers. Women need to apply for jobs with confidence, even when they don’t have 100% of the requirements. They also need to speak up and ask for a promotion.

Kevin O’Marah, Chief Content Officer at SCM World, sums up the issue of the supply chain gender gap nicely: “Women in supply chain are too few, and their path to the top is at least partially blocked. Yet we all seem to think they bring something to the party that will make it better. The time to break this problem down is now.”

by Jennifer Hart Yim | May 21, 2015 | Blog, Strategy, Supply Chain

This article is part of a series of articles written by MBA students and graduates from the University of New Hampshire Peter T. Paul College of Business and Economics.

Lindsey Marley completed dual undergraduate degrees in Business and History at Southern New Hampshire University. She is in her final semester of the MBA program at the University of New Hampshire. In her free time she enjoys traveling, reading, and spending time with her husband and their two dogs.

On November 24, 2012 there was a deadly fire at a garment manufacturing company which killed 112 people in Dhaka, Bangladesh. Another manufacturing facility in Dhaka collapsed on April 24, 2013 killing 142 people. The ready-made garment manufacturing industry in Bangladesh has grown to $19 billion dollars and is reported to be one of the most unsafe industries in the world. The consequences of corporations being lax in the sourcing of their products can have horrific consequences for people, the environment, and the company. Consumers in developed countries are demanding companies be more responsible in their sourcing as a result of the wealth of information found on the Internet about the production of goods and services.

Responsible Sourcing

The concept of responsible sourcing is in itself still being developed; however, responsible sourcing generally consists of two parts – people and the environment. There are several organizations which have provided guidelines to assist companies in developing their own code of conduct including:

One such industry-specific coalition, which was created in response to numerous tragedies such as those described above, is the Alliance for Bangladesh Worker Safety which was founded in 2013 by a group of North American apparel companies and retailers.

Alliance: A Global Response

The Alliance created a binding five-year agreement to improve worker safety among the largest importing companies of Bangladesh garments. Some of the most well-known participants include Limited, Carter’s Inc, Fruit of the Loom, Gap Inc, Kohl’s Department Stores, LL Bean, Macy’s, Target Corporation, and Wal-Mart Stores, Inc. The Alliance is accomplishing its mission through the use of a collective fund which was $42 million at the time of its creation.

The International Labour Organization has assisted the Alliance in the creation of an operational guide. The Alliance focuses on opening lines of communication between employees and management to ensure worker safety. Interviews with employees regarding existing safety practices and training are conducted and then safety discussions are coordinated between those employees and members of management. The Alliance also requires assessments be completed of garment manufacturing plants by independent engineers to certify worker safety and the structural soundness of facilities. After the initial evaluation and recommendations, the independent auditors return to confirm the changes previously discussed have been made as well as to assess the manufacturer’s ongoing compliance.

Had the Alliance been in place prior to the fire in 2012 the auditors would have found the illegally stored mounds of fabric and yarn, which accelerated the spread of flames, and required the materials to be stored in a more appropriate and safe manner. Another aspect of the fatal fire which could have been prevented was the allegation of factory managers directing employees to ignore the fire alarm. This wasted precious time for workers to exit the building safely. Ultimately, this lead many employees, trapped by the flames and smoke, to jump from upper floors to the rooftops of surrounding buildings or to their deaths. The tripartisan relationship that is created between the Alliance, employees, and management representatives is critical to ensure a clear, consistent message regarding basic employee safety. This communication helps to empower workers and could have encouraged them to challenge management’s direction to disregard the alarm when the fire broke out.

With regard to the building collapse of 2013, it was determined the four upper floors had been constructed illegally without permits. The three pronged scope of the Alliance (worker safety, fire safety, and structural soundness) again could have prevented this tragedy. In this situation, management at the garment manufacturing facility were aware of structural concerns before the collapse, but as in the case of the fire, ignored the risk and kept the factory open. Engineers working for the Alliance drill into factory walls to determine the structural integrity of the concrete and rebar used during construction to determine structural soundness.

Your Span of Control

These examples highlight the importance of maintaining a large span of control throughout your supply chain to ensure responsible sourcing. It is no small task to exercise this breadth of control for any company; however, companies can utilize the resources provided by the organizations listed above to develop their own requirements for responsible sourcing and supplier relationships. Companies can derive the maximum consumer exposure by enforcing responsible sourcing across their entire supply chain. It is also important to engrain this behavior into the culture particularly among employees who have the most interactions with the ultimate consumer.

Communicating to Your Customers

Consumer communication is the final piece of the responsible sourcing puzzle which brings together the voluntarily socially responsible company with their expecting consumer base. Responsible sourcing without informing consumers is a waste of good public relations. Many companies bury the information about their responsible sourcing efforts on the corporate website where consumers have to hunt for the information. Some coalitions and third party companies provide the insignia to compliant participants as a means of notifying consumers of their membership, but that is not always an option. If possible, a company’s commitment to responsible sourcing should be quickly and clearly communicated on its product packaging, in its digital footprint, and in the way it conducts and manages its supply chain.

The fast food giant Chipotle consistently communicates its commitment to responsibly sourced ingredients in its signage, website, commercials, and in its direct to consumer communications at the individual locations. The pervasive nature of the company’s responsible sourcing efforts has been strongly rewarded by its ever-growing customer base. In a time where consumers are switching brands to support socially responsible companies, it is imperative to keep a company’s responsible sourcing objectives, actions, and accomplishments at the forefront of consumer’s minds.

by Jennifer Hart Yim | May 21, 2015 | Blog, Strategy, Supply Chain

This article is part of a series of articles written by MBA students and graduates from the University of New Hampshire Peter T. Paul College of Business and Economics.

Lindsey Marley completed dual undergraduate degrees in Business and History at Southern New Hampshire University. She is in her final semester of the MBA program at the University of New Hampshire. In her free time she enjoys traveling, reading, and spending time with her husband and their two dogs.

On November 24, 2012 there was a deadly fire at a garment manufacturing company which killed 112 people in Dhaka, Bangladesh. Another manufacturing facility in Dhaka collapsed on April 24, 2013 killing 142 people. The ready-made garment manufacturing industry in Bangladesh has grown to $19 billion dollars and is reported to be one of the most unsafe industries in the world. The consequences of corporations being lax in the sourcing of their products can have horrific consequences for people, the environment, and the company. Consumers in developed countries are demanding companies be more responsible in their sourcing as a result of the wealth of information found on the Internet about the production of goods and services.

Responsible Sourcing

The concept of responsible sourcing is in itself still being developed; however, responsible sourcing generally consists of two parts – people and the environment. There are several organizations which have provided guidelines to assist companies in developing their own code of conduct including:

One such industry-specific coalition, which was created in response to numerous tragedies such as those described above, is the Alliance for Bangladesh Worker Safety which was founded in 2013 by a group of North American apparel companies and retailers.

Alliance: A Global Response

The Alliance created a binding five-year agreement to improve worker safety among the largest importing companies of Bangladesh garments. Some of the most well-known participants include Limited, Carter’s Inc, Fruit of the Loom, Gap Inc, Kohl’s Department Stores, LL Bean, Macy’s, Target Corporation, and Wal-Mart Stores, Inc. The Alliance is accomplishing its mission through the use of a collective fund which was $42 million at the time of its creation.

The International Labour Organization has assisted the Alliance in the creation of an operational guide. The Alliance focuses on opening lines of communication between employees and management to ensure worker safety. Interviews with employees regarding existing safety practices and training are conducted and then safety discussions are coordinated between those employees and members of management. The Alliance also requires assessments be completed of garment manufacturing plants by independent engineers to certify worker safety and the structural soundness of facilities. After the initial evaluation and recommendations, the independent auditors return to confirm the changes previously discussed have been made as well as to assess the manufacturer’s ongoing compliance.

Had the Alliance been in place prior to the fire in 2012 the auditors would have found the illegally stored mounds of fabric and yarn, which accelerated the spread of flames, and required the materials to be stored in a more appropriate and safe manner. Another aspect of the fatal fire which could have been prevented was the allegation of factory managers directing employees to ignore the fire alarm. This wasted precious time for workers to exit the building safely. Ultimately, this lead many employees, trapped by the flames and smoke, to jump from upper floors to the rooftops of surrounding buildings or to their deaths. The tripartisan relationship that is created between the Alliance, employees, and management representatives is critical to ensure a clear, consistent message regarding basic employee safety. This communication helps to empower workers and could have encouraged them to challenge management’s direction to disregard the alarm when the fire broke out.

With regard to the building collapse of 2013, it was determined the four upper floors had been constructed illegally without permits. The three pronged scope of the Alliance (worker safety, fire safety, and structural soundness) again could have prevented this tragedy. In this situation, management at the garment manufacturing facility were aware of structural concerns before the collapse, but as in the case of the fire, ignored the risk and kept the factory open. Engineers working for the Alliance drill into factory walls to determine the structural integrity of the concrete and rebar used during construction to determine structural soundness.

Your Span of Control

These examples highlight the importance of maintaining a large span of control throughout your supply chain to ensure responsible sourcing. It is no small task to exercise this breadth of control for any company; however, companies can utilize the resources provided by the organizations listed above to develop their own requirements for responsible sourcing and supplier relationships. Companies can derive the maximum consumer exposure by enforcing responsible sourcing across their entire supply chain. It is also important to engrain this behavior into the culture particularly among employees who have the most interactions with the ultimate consumer.

Communicating to Your Customers

Consumer communication is the final piece of the responsible sourcing puzzle which brings together the voluntarily socially responsible company with their expecting consumer base. Responsible sourcing without informing consumers is a waste of good public relations. Many companies bury the information about their responsible sourcing efforts on the corporate website where consumers have to hunt for the information. Some coalitions and third party companies provide the insignia to compliant participants as a means of notifying consumers of their membership, but that is not always an option. If possible, a company’s commitment to responsible sourcing should be quickly and clearly communicated on its product packaging, in its digital footprint, and in the way it conducts and manages its supply chain.

The fast food giant Chipotle consistently communicates its commitment to responsibly sourced ingredients in its signage, website, commercials, and in its direct to consumer communications at the individual locations. The pervasive nature of the company’s responsible sourcing efforts has been strongly rewarded by its ever-growing customer base. In a time where consumers are switching brands to support socially responsible companies, it is imperative to keep a company’s responsible sourcing objectives, actions, and accomplishments at the forefront of consumer’s minds.

by Jennifer Hart Yim | May 20, 2015 | Blog, Manufacturing & Distribution, Strategy, Supply Chain, Warehousing & Materials Handling

This article is part of a series of articles written by MBA students and graduates from the University of New Hampshire Peter T. Paul College of Business and Economics.

David Chadwick is an MBA student at the University of New Hampshire with a background in retail store management and electrical engineering.

If technology continues to advance, humans may be obsolete in the supply chain as a result of both automation and RFID utilization. Both technologies have been introduced into the supply chain over the past decade, resulting in a major shift in performance and costs. While automation is a process which can navigate product throughout facilities, RFID can improve efficiency dramatically as well as being the major driver for the elimination of human involvement in the supply chain.

If technology continues to advance, humans may be obsolete in the supply chain as a result of both automation and RFID utilization. Both technologies have been introduced into the supply chain over the past decade, resulting in a major shift in performance and costs. While automation is a process which can navigate product throughout facilities, RFID can improve efficiency dramatically as well as being the major driver for the elimination of human involvement in the supply chain.

RFID (Radio Frequency Identification) is a form of extremely low-power data communication between a RFID scanner and an RFID tag. The tags are placed on any number of items, ranging from individual parts to shipping labels. The RFID tag itself consists of a microchip and antennae, usually without a battery to power it. The tags can be printed using special printers, which wirelessly load the identifying information to the tags. The information on the tags can be used for a wide variety of tasks. When an item goes through the RFID scanners, information is read from the tag, which could include any amount of information, such as:

- Order ID number

- Product bin location

- Order status

- Serial numbers for individual product components

- Location logs

The information is not limited to just holding ID and serial numbers. Since the information can be updated and transferred through any RFID receiver when in range, it can be joined with other software to update databases, send information online, and more. The amount of information that RFID can provide can be matched with order management systems to track shipment and stock locations automatically as the products move through warehouses and trucks. Powerful receivers can also track the exact location of products within a warehouse in real time, instead of relying on time and location logs to determine the location. This has been a major benefit to UPS, who’ve had RFID tracking chips in their warehouses for over ten years.

The largest problem facing supply chain management today is the potential for the occurrence of devastating errors. These errors could lead to trucks leaving product behind, not stocking to capacity, losing product, or delivering to the wrong locations. There are numerous reasons for such errors to occur, but the most common factor in their inception is human error. Much of the errors faced result from manual inspection and control over product flow in warehouses by humans. Many systems still operate using written data tables and checklists, which can be written incorrectly. Despite major advancements in technology over the past decade, the digital world is being sourced by analog supply chains. This is an aspect which RFID control can create beneficial change.

RFID can lead to completely autonomous warehouses and distribution centers. This can be seen in current warehouses with high levels of automation, where picking machines transport bins of product to a central sorting area to be boxed, before returning to their location. Zebra uses this technique to ensure product location accuracy as a means of reducing lost merchandise. Zebra places a great deal of importance on product visibility and transparency as well as accuracy in locations. Implementation of RFID into this system can ensure that both the correct product and the correct quantities of product are collected at both points, thereby eliminating errors seen in traditional analog supply networks. Coupled with the potential for self-driving trucks and the ever expanding internet of things in the cloud, product information can be tracked at all stages of shipment and storage, increasing accuracy, efficiency, and accountability. Where warehouses and receiving departments had to endure a certain amount of shrinkage of products in the past, a fully utilized RFID-enabled supply network can determine exactly where product is at all times, ensuring that theft is discovered immediately and enforced.

While the reduction of human interaction in the supply chain and warehouses in general can be eliminated with enough technology, it is uncertain to what degree this technology will be implemented in all aspects of supply chain management. While there are huge benefits to operating in such a system, the major negatives include high initial costs and restructuring costs associated with implementing this network into existing, analog networks. Humanity may not be completely removed from the supply chain in the future, but this technology, as well as more advanced techniques for automation, will increase the efficiency and reduce the costs required to operate these newer supply chains dramatically while significantly reducing errors and inefficiencies.

![The supply chain gender gap [Infographic]](https://fronetics.com/wp-content/uploads/2024/10/supply-chain-gender-gap.jpg)