by Fronetics | Apr 5, 2018 | Blog, Content Marketing, Marketing, Social Media, Supply Chain

Adidas and FIFA have found great success in using social media in supply chain management.

Sometimes, a success story can be a powerful motivator. FIFA and Adidas have been extremely successful in using social media in supply chain management. Here’s how it works for these organizations and why your business should consider it.

FIFA and Adidas

These two brands are a match made in heaven. In fact, their relationship spans the 48 years since 1970, when Adidas began supplying the official match ball for all FIFA World Cup matches. And clearly it’s been working for both brands, as they have recently extended their partnership until 2030.

With a global supply chain consisting of more than 1,000 independent factories around the world, Adidas is harnessing the power of social media as it relates to the supply chain.

How they used social media in supply chain management

In 2014, the brand launched the #allin campaign on Twitter, letting users follow the progress of the official 2014 World Cup soccer ball (nicknamed the Brazuca). The ball even had its own Twitter handle. Videos showed the Brazuca outfitted with cameras and sent on a journey around the world.

As you can imagine, this creative marketing was social media gold. Adidas was able to leverage its partnership with the FIFA World Cup and engage its audience in a meaningful and lasting way.

According to Waterloo blogger Jaime Salinas, “Adidas is using social media to improve their organization’s supply chain management globally by creating transparency, increased visibility, communications and quality control that leads to reduced operational and labor costs.”

For example, the Adidas SMS Worker Hotline allows direct communication with factory workers, bridging the gap that can exist between management and workers. The system allows the workers to have anonymity, ensures transparency in tracking complaints. It also allows correction efforts to happen in real time.

The takeaway

So what can your business learn from this duo’s successes with social media in supply chain management?

“Social media can improve [an] organization’s supplying chain management,” writes Salinas. “It can create more visibility, improve communication, increase control, and reduce operational and labor costs.” This creates a more efficient and steady supply chain, which in turn increases customer satisfaction.

Salinas concludes, “The ripple effect of using social media to improve supply chain management can expand outwardly across virtually internal and external organizations, which is great for business.”

Related posts:

by Fronetics | Dec 18, 2017 | Blog, Leadership

Our most-viewed leadership posts from this year cover positive and negative leadership characteristics and provide examples of exceptional industry leaders.

One of my favorite experiences from 2017 was interviewing Ellen Voie, the CEO of Women In Trucking. A true inspiration, Voie exhibits tangible passion for promoting more gender diversity into the transportation space, but her practical, strategic approach is the hallmark of her success. She is an exceptional leader, and I feel privileged to have gotten this opportunity.

Our top leadership posts from 2017 examine what makes a good leader, as well as what makes a bad leader. They also look at some executive thought leadership about industry trends, and talk about graduate programs from which future leadership may be matriculating.

Top 10 leadership posts

1) 80% of Executives Say Procurement Isn’t Strategic Enough

Tis guest post from Argentus Supply Chain Recruiting looks at insights from the Procurement 2020 Survey. The survey of 200 C-Suite executives from a variety of industries and functions presents a rather dispiriting picture of the Procurement function today — or at least how it’s perceived. The majority of executives don’t think procurement is crucial to business leadership, and that it isn’t a key input when making high-level strategic decisions. Read full post

2) Women In Trucking’s Ellen Voie Paves the Way for Women Drivers & Managers

Ellen Voie is successfully breaking down barriers and changing the perception of the trucking industry. As founder and president of Women In Trucking (WIT), Voie and her team work to promote the organization’s mission “to encourage the employment of women in the trucking industry, promote their accomplishments, and minimize obstacles faced by women working in the industry.” I spoke with Voie about her experiences in the transportation industry, as well as her hopes for WIT and the future of women truckers. Read full post

3) Top Supply Chain Management MBA Programs 2018

We write frequently about the importance of recruiting and strengthening the relationship between academia and the supply chain industry as means to solve the growing supply chain talent gap. If your company is looking to hire, consider strengthening your rapport with schools that offer supply chain programs or specialties. The U.S. News & World Report annual rankings give companies in the supply chain and logistics industries an idea of where some of the brightest graduates, who will be seeking employment in the upcoming months, will be coming from. Read full post

4) 5 Ways to Push Employees to Be Their Best without Stressing Them Out

Management works to create a balance between pushing employees and pushing them past their limits. Leaders should create a safe and supportive environment where employees feel respected and, in turn, cooperative and productive. With this is mind, it’s important to incorporate tangible ways of reducing stress for your employees. This post offers some ideas. Read full post

5) How to Be a Bad Leader: 6 Common Characteristics of Poor Leadership

What’s the number one reason talented employees quit? Gallop polls show that 50% of employees cite their managers as the reason for leaving. A bad leader can cost your company. And poor leadership at the highest levels of a company can be detrimental to a business. This post outlines 6 common characteristics of poor leadership that should be red flags to all companies. Read full post

6) Should You Get an MBA in Supply Chain or a Designation?

Again, our friends at Argentus Supply Cain Recruiting ask an important question: What value do you see in getting a Master’s Degree in Business/Supply Chain vs. some of the designations out there? The recruiting experts speak to what companies are looking for in hiring, and how graduating from these programs builds your personal brand. Read full post

7) Should You Freeze Hiring During Uncertain Economic Times?

Despite an 8-year bull market, many businesses are still licking the wounds caused by the 2007 financial crisis. Add a volatile political climate and predictions of impending economic turbulence, and you can’t blame those growing wary of rapid growth or expansion opportunities. But, as the supply chain is already suffering from a talent gap, can companies afford to slow or freeze hiring — or, even, to downsize? Research suggests that organizations that balance caution with a forward-looking talent-acquisition strategy may fair best through difficult economic times. Read full post

8) Why Supply Chain and Logistics Executives Should Be Active on Social Media (as Themselves)

With their relative celebrity, supply chain and logistics executives are uniquely positioned to attract a following of customers, prospects, potential talent, industry peers, and admirers. They can use social media to connect with these people, share their ideas and industry news, and become the human face of their brands. It amplifies the company’s social media efforts in a way brands can’t do themselves. Read full post

9) Women Leaders Who Make the Supply Chain Flow

We have had the opportunity to interview 6 supply chain leaders about their professional experiences, as well as their thoughts on gender diversity in the industry and beyond. Interviewees include: Kendrea Durr-Smith, Director of Global Trade Compliance, Arrow Electronics; Barbara Jorgensen, Co-Founder and Managing Editor, Electronics Purchasing Strategies; Hailey McKeefrey, Editor-in-Chief, EBN; Cathy Morris, Senior Vice President and Chief Strategy Officer, Arrow Electronics; Mickey North Rizza, VP of Strategic Services, BravoSolution; and Kelli Saunders, President, Morai Logistics. Read full post

10) There Are Lessons in Success, Not Just Failure

Companies have a responsibility to ask the tough questions when things go awry. We have all been in these meetings: we diagnose failures, and we dissect the process, tools and staff involved to get to the root of the problem. Unfortunately, most companies only step back and really dive into what happened when something bad happens. But what if companies took the same approach when something went right? Read full post

Related posts:

SaveSave

by Fronetics | Dec 4, 2017 | Blog, Leadership, Strategy

Making the shift from doing to leading can be challenging for any supervisor, but great leaders need to master the skill of delegating.

Delegating is a true skill set. Some leaders find it very difficult to let go of the control over daily tasks. They spend their time focusing on mundane details, instead of passing the work to their qualified team members.

To be an efficient leader, you must develop the skill of moving tasks off you plate. Delegating is a great way of encouraging your team members and creating new opportunities for their professional growth and development.

“True organizational productivity requires engaged, informed personnel willing and eager to work toward the organization’s mission and vision. And it all starts with a simple concept that’s amazingly hard for some people to implement: letting go of control,” writes Laura Stack for Vistage.com.

And though letting go of control can be very difficult, the increasing pressure of having all the responsibilities fall on you can have major impacts on the quality of your work. If delegating doesn’t come naturally to you, practice! In a recent article in the Harvard Business Review, Director in PwC’s Leadership Coaching Center of Excellence Jesse Sostrin suggests three practical tips for easing into the art of delegating.

3 tips to master the skill of delegating

Choose the right people

If you want to save time and focus on leading your staff, you need to have a strong team behind you. A large part of feeling comfortable delegating is having trust in the people that support your efforts. Knowing you have smart, capable team members allows leaders to be confident in the work that’s taking place. To get the most out of delegating, set up a reporting structure and make it known that you’re available for help. Then step back and give your team the space to do their jobs.

Inspire their commitments

Fully committed team members understand how their work is contributing to the big picture. “Once you’ve defined the work, clarified the scope of their contribution, and ensured that it aligns with their capacity, carefully communicate any and all additional expectations for complete understanding. This is crucial when you have a precise outcome or methodology in mind,” writes Sostrin. Make your expectations challenging, yet achievable. And always keep your door open. Open lines of communication are key in ensuring your team understands your expectations and is committed to the work.

Stay engaged, but not involved

Being too involved can lead to micromanaging. Being too hands-off can lead to missed opportunities to offer support and help. Finding the balance between the two is crucial in being an efficient delegator. You need to find the spot where you can offer support but give your team the space they need to feel confident in their own abilities. Not sure where that sweet spot is? Ask! Some employees will appreciate a little more guidance, where others will want to figure it out on their own. As you practice delegating, you’ll get to know your team better and learn the best ways to support them. And never shy away from sharing praising when a task is done correctly.

Delegating is a must for saving time and money in any office. However, delegating is much more than just assigning tasks. When done correctly, it creates opportunity and empowerment for your staff, as well as yourself. It will take a bit of practice, but it’s never too late to start mastering new skills.

Related posts:

![What’s the Difference Between Supply Chain Management and Logistics [Infographic]](https://fronetics.com/wp-content/uploads/2024/10/Supply-Chain-Managementvs.Logistics.jpg)

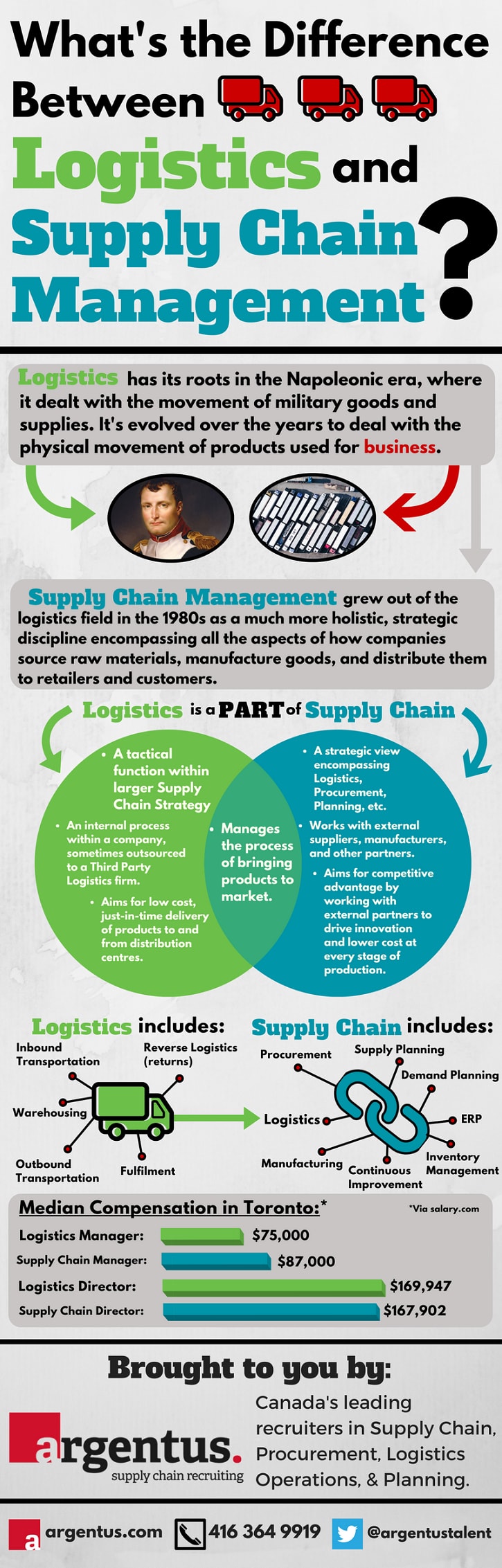

by Jennifer Hart Yim | Jun 29, 2017 | Blog, Logistics, Supply Chain

Argentus’ infographic sheds light on the differences between these often-confused functions.

This guest post comes to us from Argentus Supply Chain Recruiting, a boutique recruitment firm specializing in Supply Chain Management and Procurement.

Both Logistics and the wider Supply Chain are vital to how companies run today, but the two are still so often confused. We put together an infographic outlining some of the key differences and points of overlap between them. While it may be an obvious distinction to many pros across the field, there’s still a lot of ambiguity – sometimes within companies, as well – about what constitutes Logistics, and what constitutes Supply Chain Management. As a recruitment firm with over a decade of experience specialized in this area, we figure we’d weigh in!

In short, Logistics is a part of Supply Chain Management that deals with the physical movement of goods for just in time delivery. Supply Chain, as a field, grew out of Logistics in the 80s to encompass a wider strategic consideration of everything that’s involved in bringing a product to market.

Check out the infographic below, where we dive into the topic in more detail! We’ve stepped up our game, if we do say so ourselves.

Logistics vs. Supply Chain Management

We hope you found the infographic informative! Weigh in down in the comments if there’s anything we missed, or more you have to add about the differences between these functions.

Related posts:

by Jennifer Hart Yim | May 10, 2017 | Blog, Current Events, Logistics, Strategy, Supply Chain

Updated January 16, 2025

Starbucks’ closely managed supply chain may be the key to the premium coffee giant’s success.

Highlights:

- Starbucks attributes much of its success to its vertically integrated supply chain, managing every step from coffee bean sourcing to final cup, allowing for consistent quality control and ethical sourcing practices across its global operations.

- Unlike its competitor Dunkin’ Donuts, which outsources most operations, Starbucks directly manages relationships with 300,000 coffee growers worldwide through its Coffee and Farmer Equity (C.A.F.E.) standards, ensuring both quality standards and ethical practices.

- This supply chain strategy has contributed to Starbucks’ significant market dominance, with the company generating $32.2 billion in revenue in 2023 and operating nearly 37,000 stores globally, far outpacing Dunkin’ Donuts’ presence and revenue.

The Secret is the Supply Chain, According to Starbucks

The international coffee giant has widely studied and acclaimed supply chain management practices, which, according to some, make Starbucks’ coffee and customer experience superior to those of its competitors.

So, what exactly is Starbucks doing differently than other international coffee retailers? Is its coffee truly better?

The Standards

Starbucks uses a vertically integrated supply chain, which means that the company is involved in every step of its supply chain process, all the way from the coffee bean to the cup of coffee sold to consumers. The use of a vertically integrated system means that Starbucks works directly with its nearly 300,000 worldwide coffee growers. The company believes that interacting directly with farmers ensures that all of its coffee beans will achieve the same quality and flavor standards.

Starbucks also works directly with growers because the company is committed to only selling ethically sourced, Fair Trade coffee. The company even has its own Coffee and Farmer Equity (C.A.F.E) standards and Coffee Sourcing Guidelines (CSG), which require that all suppliers must meet certain ethical, sustainability, and quality standards. Starbucks uses a stringent vetting process to ensure its growers meet and adhere to these guidelines.

Not only do the C.A.F.E. practices and CSG benefit Starbucks, they also provide advantages for suppliers. The guidelines protect workers’ rights and ensure that all growers have safe and humane working conditions. Suppliers also must adhere to minimum-wage requirements and commit to not using child or forced labor.

Lastly, as a part of its C.A.F.E. guidelines, Starbucks commits to providing its suppliers with special training and education programs. Starbucks’ direct interaction with growers, along with their sourcing and social responsibility standards, make suppliers feel like they are integral parts of Starbucks’ corporation. The close relationship and frequent communication between Starbucks and its suppliers, therefore, make the company’s supply chain less susceptible to major disruptions, such as overplanting or worker shortages.

The Process

After the growers pick and package the coffee beans, truckers drive the unroasted beans to ocean liners that ship the beans to six storage sites in the U.S. and Europe. The beans are roasted in these storage facilities and then packaged for shipment to Starbucks’ eight central, and forty-eight regional, distribution centers. By only using a handful of storage facilities, Starbucks can closely manage the sites’ operations and guarantee that all beans are roasted and packaged in the exact same way.

The company’s close control over the roasting process also ensures that Starbucks’ coffee tastes the same in all of its retail locations. Starbucks’ active participation in the supply chain also ensures that the distribution centers receive the products they need so they can fulfill orders and make their roughly 70,000 weekly deliveries on time.

The size and scale of Starbucks’ operations should make its supply chain inherently complex. In 2008, however, Peter Gibbons, the Executive Vice President of Global Supply Chain Operations, overhauled the company’s expensive, ever-growing supply chain into a streamlined, cost-effective process that relies on simple operational structures and metrics.

First, he grouped all supply chain jobs into four categories: plan, source, make, and deliver. Next, he developed a highly centralized logistics system that allows the company to better manage and coordinate its global network. Lastly, he implemented a binary, 0 or 1 “scorecard system” to assess all supply chain activities on four metrics: safety in operations; service measured by on-time delivery and order-fill rates; total supply chain costs; and enterprise savings.

Along with the simple tools and processes that Gibbons created, Starbucks also relies heavily on digital technology to manage its supply chain. The company uses an automated information system that allows it to monitor demand, inventory, capacity, and scheduling in real time. Therefore, Starbucks can quickly adjust its plans and operations as needed. Starbucks’ simple structure and management tools, as well as its use of digital technology, allow the company to achieve a high level of efficiency and agility, both of which are key to organizational success.

The Market

Starbucks’ biggest competitor in the international coffee market is Dunkin’ Donuts. In contrast to Starbucks, which owns its entire supply chain, Dunkin’ Donuts outsources its production processes. Dunkin’ Donuts relies on a third-party intermediary, National DCP, to handle the company’s supply chain operations.

Dunkin’ Donuts also franchises its manufacturing locations, as well as nearly all of its retail spaces. Conversely, Starbucks franchises less than 50% of its retail locations, and, as of March 2016, was no longer accepting applications for new U.S. franchises. Starbucks also uses few to no intermediaries to carry out its supply chain operations.

Unlike Starbucks — which is committed to using 100% sustainably grown, Fair Trade-certified coffee beans — Dunkin’ Donuts promises to produce its coffee as “sustainably as possible.” The company works with Fair Trade USA and the Rainforest Alliance to implement sustainable sourcing practices, as well as training programs for farmers. However, Dunkin’ Donuts only offers two permanent menu items that are Fair Trade-certified: 30% Rainforest Alliance Certified™ Dark Roast Blend and 100% Fair Trade Certified™ espresso.

While Starbucks’ critics may try to argue that the company’s supply chain model and social responsibility efforts are not true differentiators, the statistics tell a different story.

Starbucks was founded roughly twenty years after Dunkin’ Donuts, but the company is already much larger than its rival. In 2023, Starbucks generated $32.2 billion dollars in revenue, while Dunkin’ earned only $1.4 billion. Starbucks also has a larger global presence, with nearly 37,000 retail stores in 80 markets worldwide, compared to Dunkin’s 13,500 locations in 40 countries.

Starbucks also primarily markets to higher-income customers looking for a premium coffee experience, while Dunkin’ Donuts has traditionally retailed to more blue-collar consumers who want coffee on the go. Therefore, Starbucks’ clientele is willing to pay more for coffee that they perceive to be made from higher-quality, socially responsible sources. It used to be that Starbucks’ customers would also pay more for coffee in order to enjoy the amenities offered in the company’s coffeehouses, but even with a consumer shift towards drive-thru and mobile pick-up preferences, Starbucks’ customers seem willing to pay more for convenience. Because Starbucks’ patrons generally have higher disposable incomes than those of Dunkin’ Donuts’ customers, they are less likely to adjust their consumption patterns during economic downturns. Thus, Starbucks is less susceptible than Dunkin’ Donuts to major fluctuations in revenues that could result from negative macroeconomic swings.

The Future

While Dunkin’ Donuts loyalists, particularly those in New England, may never accept the merits of Starbucks coffee, majority opinion argues that Starbucks offers higher-quality beverages and better customer experiences. Statistics show that Starbucks is outperforming its rival, which is evidence of the success of a simple and efficient global supply chain. In fact, Starbucks, which is already larger than Dunkin’ Donuts both domestically and abroad, plans to open more new retail spaces than its competitor over the next five years.

Therefore, one question remains for coffee drinkers and market analysts: Does America actually run on Dunkin’? Or is Starbucks’ coffee really the fuel running our caffeine-crazed country (and world)?

We love writing about all things related to the supply chain, including Starbucks’ supply chain. Need quality content written for your supply chain business? We’re a content agency focused exclusively on working with companies like yours. Let’s chat.

This article is part of a series of articles written by MBA students and graduates from the University of New Hampshire Peter T. Paul College of Business and Economics.

Related posts:

![What’s the Difference Between Supply Chain Management and Logistics [Infographic]](https://fronetics.com/wp-content/uploads/2024/10/Supply-Chain-Managementvs.Logistics.jpg)