by Fronetics | Nov 21, 2017 | Blog, Current Events, Marketing

These 10 podcasts for marketers discuss the latest news and trends in the marketing world relevant to the supply chain and logistics industries.

Podcasts have surged in popularity over the past few years. At least 112 million Americans have listened to podcasts, a figure up 11% from last year, with 67 million listening at least monthly. So why are they so popular?

Podcasts are a series of digital audio files that listeners can subscribe to. With the flexibility to listen at their convenience, followers are drawn to the ease and mobility of podcasts. And the available topics are endless.

For supply chain and logistics marketers, podcasts provide the latest digital marketing news, as well as innovative trends that are new to your industry. Here are 10 podcasts that deliver the most up-to-date news in marketing for supply chain and logistics companies.

10 supply chain and logistics marketing podcasts

Millions of dollars are being left on the table right now by supply chain companies because of poor marketing! Supply Chain Gold delivers actionable marketing strategies and information to logistics and 3PL companies, distribution centers, and fulfillment centers to help bring in more sales and increase profit margins. The Supply Chain Gold podcast warehouses internet marketing secrets that your company can leverage to lower customer acquisition costs, grow revenue, increase net profits, drive brand recognition, and dominate your industry.

- #AskGaryVee

Gary Vaynerchuk — author, speaker, and owner of multi-million dollar marketing company VaynerMedia — uses his podcast to answer questions about marketing, social media, and general entrepreneurial topics that his followers ask on social media. If you’re looking for a high-intensity host whose responses are no-fluff, honest, and a tad explicit from time to time, Gary might be just the straight-talking expert you need.

The Marketing Book podcast helps business owners and marketers keep up with the smartest thinking in the quickly changing field of modern marketing. Each episode interviews authors and marketers to give you actionable marketing insights, tips, tactics and resources to help grow your business.

Social Media Examiner’s weekly podcast is hosted by Michael Stelzner and other members of SME’s team. Each podcast focuses on new social media features and strategies, providing listeners with actionable tips they can use to improve their social media results.

Copyblogger FM is a weekly, short-form broadcast hosted by Sonia Simone. Each week she and a team of rotating experts discuss the week’s news and updates in the field of content marketing, email marketing, copywriting, conversion optimization, and more.

John J. Wall and Christopher S. Penn host a 20-minute, weekly show recorded in a local coffee shop. The podcast is designed to be casual and conversational. They share tips on social marketing, SEO, search marketing, copywriting, affiliate marketing, and more. They also take listener questions.

Industry experts Eric Siu and Neil Patel offer users unconventional marketing wisdom that will make you want to kick some of your traditional strategies to the curb. Their goal is to bring valuable, actionable marketing tips in just 10 minutes.

Buffer’s blog is highly successful, so no wonder its podcast is equally informative. The content will appeal to anyone who practices social media marketing, whether you’re brand new to marketing or you’re a social media practitioner. They regularly have industry leaders on the show, including Mari Smith and Neil Patel.

Know Your Audience is a weekly podcast that interviews journalists, bloggers, data scientists, and analytics/audience development professionals. The goal is to start a meaningful conversation about what it takes to create engaging content and learn from the people who are shaping the future of media.

Listen and learn from interviews with social business leaders representing top brands and agencies. Host Bernie Borges leads an educational format as guests share their experiences and insights on social business topics including marketing, selling, customer service, employee advocacy, recruiting and commerce to fuel your social business journey.

Related posts:

by Jennifer Hart Yim | Nov 15, 2017 | Blog, Supply Chain, Warehousing & Materials Handling

Tracking these logistics metrics can help you identify and tackle issues in your warehouse before they become a problem.

This guest post comes to us from Demetra Mallios at Catch-Up Logistics, a full-service provider of ambient and temperature-controlled food-grade distribution and warehousing services.

The supply chain plays an integral part in maintaining a well-functioning organization. A well-structured and organized warehouse will help you achieve your distribution goals and adequately analyze metrics.

You can think of it like when you are trying to decide what to make for dinner, but cannot remember what food you have in your fridge. If your items are organized and you are aware of what is in your fridge (the warehouse), then you can properly make your dinner decision (packing and preparing for delivery distribution).

While you may be aware of some metrics to track, you might still be missing others. But, that’s where we come in with our list of the top 10 logistics metrics to measure supply chain efficiency in your warehouse.

10 logistics metrics to measure supply chain efficiency in your warehouse

1. On-Time Shipping

A distribution center’s primary objective is clear in its name: It must accurately and efficiently distribute goods that are coming in and out of the warehouse. In other words, the correct product must be placed on the correct transportation method at the appropriate time. In order to complete this task, you must monitor late shipping departures to the warehouse and early completion of freight loading time.

Although it may seem that finishing shipment loads ahead of schedule is a good idea, in reality it could affect the departure and duties of other shipments. So, your business can be sure to monitor these shipment details via a 3PL system. You should also take into account the varying loading and transportation times needed to shift freights before out-bounding product. (Because delaying shipping can be just as bad as receiving the birthday present you ordered for your mom days later, timing matters.)

2. Warehouse Capacity

While there are measures out there to monitor inventory, it is essential that you complete manual observation as well. A distribution center needs to be aware of its ability to increase or decrease its loading times, create more storage space, and accurately track inventory. Currently, many distribution centers incorporate RFID measures to check inventory. However, you should not underestimate the need for manual observation in order to successfully analyze the listed criteria.

3. Accurate Order Fulfillment

Another highly important metric is, of course, the accuracy of the order picking processes. When your employee goes to retrieve a pallet of a specific product, you want to be able to measure how quickly and accurately that task is completed. However, realistically, human error will sometimes occur, which makes the tracking of the picking and moving process vital. A distribution center does not want to be in a situation in which it is unaware of lost, damaged, or misplaced product.

4. Properly Storing Incoming Product

This metric relates to the previous one about order fulfillment, in that it requires a similar tracking process. Accurate inbound storage is essential for accurate outbound deliveries. Without a well-organized inventory in the receiving end, the outbound end will have trouble accurately and efficiently fulfilling orders.

Additionally, the incoming product needs to be recorded correctly, so that inventory capacity can consistently be updated. Furthermore, incoming product and procedures can vary depending on the type of warehouse and storage facility you are operating. For instance, Catch-Up Logistics focuses on food storage. Therefore, it is essential that the product is placed in the correct freezer, cooler, or ambient temperature zone. If this is not done properly, not only will we ruin the product, but we will also lose credibility in our ability to provide high-quality warehousing services.

5. Peaks in Warehouse Capacity

Changes in product demand can, of course, influence the amount of inventory you are willing to hold in your warehouse distribution center. For instance, the holiday season will result in a peak in inventory, as companies need to store more seasonal product. With Catch-Up Logistics, Thanksgiving is a prime example, as our turkey inventory grows and distribution needs to be timely.

6. Total and Individual Cycle Times

In order to be sure that your warehouse is running efficiently, you should be tracking the cycle times. The total cycle time refers to the time needed to properly place the product in inventory from its time of arrival and then ship it from the distribution center. Individually, you can record the dock-to-load time, picking, packing, and preparing the freight for shipping times. This will enable you to see whether or not a certain process is underperforming and can be improved.

7. Damaged Products

You are bound to deal with damaged product at some point while either receiving inventory or moving it. Thus, it is important to record whether or not the product was already damaged upon arrival or if it was due to mishandling in the distribution center. Knowing this data and taking proper action to reduce such mishaps will help improve the efficiency of your warehouse.

8. Employee Turnover Rate

Because working in a distribution center can be exhausting, it is common for employees to search for other job opportunities. However, being able to minimize the turnover with incentives and an improved working environment can benefit the business. It is best to try and maintain employment, instead of consistently searching for new workers and spending the time and resources to train them, only to have them leave in a few months.

9. Accurate Tracking of Trailers

If your warehouse distribution center makes use of trailers for shipping product, it is essential that you are aware of their location at all times. (For instance, Catch-Up Logistics utilizes trailers for shipping.) A great method for tracking this information is through the use of a GPS tracking system.

10. Recording Temperatures

If you have a food storage warehouse facility, it is essential to install a temperature-monitoring system. At Catch-Up Logistics, we monitor the daily temperatures of all the freezers, coolers, and ambient temperature storage spaces to ensure the optimal temperature for proper food storage and health reasons. Additionally, such a system will notify you of any irregular changes in temperature so that you can immediately solve an arising problem before the food product becomes unusable.

There are many aspects to maintaining a well-functioning warehouse distribution system, as demonstrated from the list of metrics above. Although these tracking suggestions may at first appear excessive and time-consuming, they will help you improve the efficiency of your warehouse.

Being aware of potential issues will allow you to tackle the problem before it has a chance to further develop. So, what are you waiting for? If you have not already begun using these metrics, you should consider implementing them as soon as possible!

Related posts:

by Fronetics | Jan 12, 2016 | Blog, Leadership, Marketing, Strategy, Supply Chain, Talent

Recruiting and retaining top talent is one of the largest issues the supply chain faces today. It has, in many ways, become an industry of gaps: skills, talent, and gender, to name a few. How can companies secure their future by acquiring, developing, and keeping employees with the potential to undertake future leadership roles?

Fronetics Strategic Advisors works with clients to understand and execute on talent acquisition, performance management, learning and development, and succession management. We also work with clients to design and develop roles and responsibilities, on leadership development, mentoring and counseling, and on performance management and compensation strategies.

Here are our most-read talent articles of 2015:

While the number of full-time women in the workforce is up 15% since 1979, the number of women in the manufacturing sector is the lowest it has been since 1971.The gender gap extends more broadly to the supply chain, as well, with 70% and 80% of positions held by men. This article examines the talent crisis within the industry as an opportunity to help close the gender gap, and offers suggestions for building that bridge. Read the full article.

This interview with Rodney Apple, founder of the SCM Talent Group and supply chain recruiter for the majority of his 19-year career within the staffing industry, examines the challenges facing the industry and opportunities to address the talent crisis moving forward. Read the full article.

The outlook seems dire: by 2025, 60 million baby boomers will exit the workforce, leaving a gigantic gap when 40 million millennials take their place. What’s more, as few as 20% of the workforce will possess the broad range of skills required of 60% of all new supply chain jobs. The good news is that this looming crisis represents an ideal opportunity for recent college grads and mid-level supply chain management. Companies hoping to appeal to top candidates in the future should be proactive about meeting their professional needs through initiatives like competitive salaries and cross-functional training — or else, they might miss out. Read the full article.

Zappos offers new hires a $4,000 bonus to quit after an initial training program — and it actually has helped them retain top talent. Offering an early out to employees can be an effective method to detect personnel issues up front and ultimately can save your company from a major financial loss in the future. Read the full article.

When it comes to your career, connections matter. This article lists five reasons why building a strong network is crucial to your professional success. Read the full article.

Millennials — or, those born after 1981 — potentially could breathe new life into the graying supply chain industry. This article examines who millennials are and how companies might attract and retain talent within this oft-misunderstood generation. Read the full article.

Promising employees expect more from their employers when they outperform their peers — and not just in terms of compensation (though that is very important). When those expectations are met with disappointment, the company is at risk for losing top talent. This article discusses strategies for mitigating the loss of talented employees. Read the full article.

According to one study, only 12.5% of companies in the supply chain industry engage in formal succession planning, or the process of identifying top internal performers with the potential to fill key leadership positions. With the dearth of talent facing the supply chain, employers would be wise to invest in succession planning (and their most promising employees) — particularly through these three aspects of the process. Read the full article.

Focusing on education and training, employee retention and growth, and rethinking the talent pool itself does not address the bigger issue in the supply chain skills gap: the industry just isn’t perceived as sexy. What can companies do to overhaul their image and attract new and qualified talent? Read the full article.

Replacing employees is extremely costly — anywhere from 50 to 400% of their annual salaries, it is estimated — yet more than 2 million people voluntarily leave their jobs each month. Companies who are not tending to their human resource assets may be taking a major financial hit. Here are five employee retention strategies to help create a culture where employees are satisfied and interested in working for you long term. Read the full article.

by Jennifer Hart Yim | Aug 7, 2014 | Blog, Marketing, Social Media, Supply Chain, Transportation & Trucking

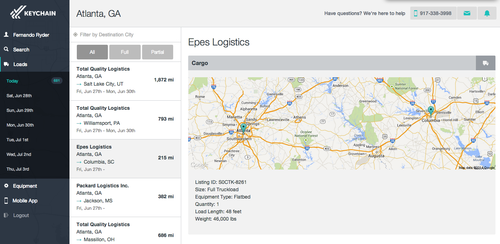

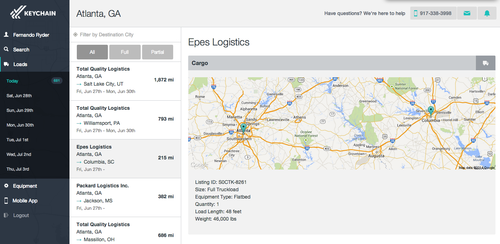

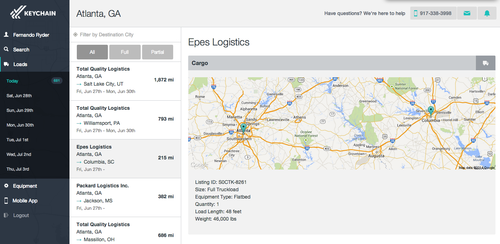

This guest post is written by Keychain Logistics. Keychain Logistics is a leading transportation provider enabling businesses to directly engage carriers, track shipments, and monitor its logistics needs online.

It’s 2012. Platforms like Uber, Airbnb, and Homejoy are growing rapidly. New customers are signing up via search, paid referrals, and social media. Marketing teams at each are delicately balancing the supply and demand of their output with a spread of calculations that, if not projected carefully, may lead to service outages and upset customers.

Now what’s going on here, and what does this have to do with logistics?

The companies above, alongside many others eating the world today with software, are all marketplaces.

Speaking in online terms, a marketplace is where buyers and sellers of a particular product or service can collaborate in a streamlined process to achieve what they want from the other side.

In exchange for facilitating relationships, thus saving time and resources for the entities wanting to connect, marketplaces may charge subscription fees, transaction commissions, or depend simply on high traffic volume to sell other assets like media space or proprietary content.

But facilitating relationships is only a necessary component, and not a sufficient one, to the success of a marketplace. This is because some buyers and sellers feel that the benefit of a marketplace has been fully realized upon their connection, and thus don’t stick around for the platform to send a bill.

What marketplaces must do to maintain engaged users, then, is create experiences inside the application that remove the incentive to circumvent it. And this is a tough challenge to solve.

One great example of this is Odesk.com, a marketplace connecting freelancers with employers who have projects to outsource. In exchange for this service, Odesk charges a 10% fee to employers per transaction. While this may sound steep, Odesk meets this ask with a suite of free management tools such as random monitor screenshots that let employers track the productivity of an outsourced team member without worrying about being overbilled on hours.

For freelancers, Odesk requires employers to place valid credit cards on file pre-hire, protecting them from employers who might otherwise attempt to avoid a payment. Tools like this make the Odesk platform (and its fees) worth every penny, thus creating a winning marketplace that helps both sides get what they deserve.

That said, let’s get back to logistics and how Keychain Logistics fits into this marketplace, value-adding, supply and demand spectrum.

The transportation industry is one of the largest, oldest conglomerates on the planet, with millions of drivers and thousands of shippers and brokerages in the US alone. The industry is also a fragmented one, with the biggest brokerage only commanding ~3% market share.

If anything is clear about business, it is that markets become more efficient through consolidation. From Coca-Cola buying a new beverage brand to a toy manufacturer owning its own factories, market consolidation is a common practice and, if done right, typically results in positive benefits for end-customers such as lower prices, higher quality, and so forth.

But for a myriad of reasons we won’t go into today, this kind of consolidation has yet to happen in the transportation industry.

Introducing Keychain.

Keychain is a marketplace connecting drivers directly with shippers, and the benefits are three-fold:

1. Shippers (effectively, employers) can bypass expensive commissions by man-powered brokerages,

2. drivers can book loads while on the go, and

3. Keychain verifies user insurance policies and other legal compliance measures, prior to allowing entry to the platform.

To achieve the win-win harmony of a successful marketplace, not only does Keychain facilitate the relationships but it also addresses the circumvention component with tools for drivers and shippers such as mobile apps, online dashboards, easy payment gateways, and in-app communications between parties.

Keychain is the technological consolidation of a market that just won’t give up its antiquated methods. Together, we can bring much needed efficiency to the efficiency business: logistics.

by Elizabeth Hines | Jul 31, 2014 | Blog, Data/Analytics, Strategy, Supply Chain

Want to have a better-run business? Define clear metrics and use them as a launch pad to move your organization forward.

Metrics enable you to operate more effectively and efficiently because they provide you with valuable information on how you can drive improvement and how you can apply resources (people, time, money) to the activities and programs that will get you to where you need to go.

Critical metrics for effective business are ones that focus on the strategic goals of your organization. Here are five metrics every business can benefit from using:

Financial metrics

Make sure you have, at the very least, a quarterly plan in place. A yearly plan is ideal, but a quarterly plan is a good starting point. Track against your plan. Looking at financials in aggregate is not a helpful exercise. Rather, look at your financials on a granular level.

Business metrics

Determine what makes your customers happy and what enables your organization. Track these. Soon, you will know what you should do more of and what should be cut back.

Customer metrics

Determine the who, what, when, and why of your customers. Knowing what matters to them will help you understand how to serve them better.

Vendor metrics

Determine the who, what, when, and why of your vendors. Relationship management and partnering can only be built on a strong foundation.

Quality metrics

When it comes to quality it is important to look at anything and everything. That is, the quality of your products, the quality of your relationships with your clients, the quality of work your employees produce… Start tracking all of this.

Track the data

Develop tracking methods for each of these five metrics. Archive the data. Learn by studying the results on a regular basis. You’ll start understanding how to drive the direction of your organization. You’ll develop a focus for your organization and your performance. You’ll be able to make better decisions and drive performance.

Although most (if not all) of the material will be used internally, you should make sure that it is “external facing ready.” What you are creating is a database that you can query when you need it. In the end, you’ll have, at your fingertips, a decision database to run a better business.