by Elizabeth Hines | Aug 10, 2015 | Blog, Content Marketing, Marketing, Strategy

Being in the strategic advisory space, I get a lot of exposure to various business strategies, strategic plans, and sales plans, both internally to organizations and from outsiders looking to raise money or gain influence.

When it comes to strategic planning, too often there is “creative accounting.” That is, the artful creation of financials that match and make numerical sense, but have very little credibility in the real world because the important business details are left out.

Businesses spend far too much time creating spreadsheets and devote too little time paying attention to information that really matters. As a result, any plan that cannot be substantiated outside of a spreadsheet is doomed to be discounted…and so are the presenters.

Don’t get me wrong, you need to have a financial base and rock solid financial modeling in your planning efforts. It is, however, equally important to spend time on building credibility in those numbers by focusing on what interested parties need to know outside of the spreadsheets in order to make an informed decision.

I encourage clients to focus on these 4 items in order to build credibility in their financial plans and create a winning business model:

1) What is the opportunity? What the business will sell, who is buying, why are they buying, how much are they buying now, and how much and how fast will their buying increase (or decrease) and why?

2) Who are the people involved? The internal team, the external team, any outside resources or partners providing key services or important resources, contingencies for the partnerships and the switching costs involved if needed.

3) The financial context. How will interest rates, buying trends, competition, demand, and for that matter, supply shape the financials of the plan.

4) The up-side and the down-side risk. What can go right or wrong, to what extent (up or down) and how will the team or company adjust to the increased revenue opportunity as well as the opposite…the decrease in the need for the product or service. Do these risks and rewards make sense in real world scenarios?

Gone are the days where financial engineers can develop models without operational integrity. Business models that make sense financially and operationally are now in vogue…thank goodness.

Fronetics Strategic Advisors is a leading management consulting firm. Our firm works with companies to identify and execute strategies for growth and value creation.

Whether it is a wholesale food distributor seeking guidance on how to define and execute corporate strategy; a telematics firm needing high quality content on a consistent basis; a real estate firm looking for a marketing partner; or a supply chain firm in need of interim management, our clients rely on Fronetics to help them navigate through critical junctures, meet their toughest challenges, and take advantage of opportunities. We deliver high-impact results.

We advise and work with companies on their most critical issues and opportunities: strategy, marketing, organization, talent acquisition, performance management, and M&A support.

We have deep expertise and a proven track record in a broad range of industries including: supply chain, real estate, software, and logistics.

by Elizabeth Hines | Jul 16, 2015 | Blog, Strategy

Remember the days when a rear-view mirror was all we needed to make business decisions? Now, predictive analytics appears poised to turn hindsight into a relic of the past.

Two Gartner analysts echo that sentiment, stating, “Few technology areas will have greater potential to improve the financial performance and position of a commercial global enterprise than predictive analytics.”

Executives are eager to jump on the bandwagon too. Although only 13% of 250 executives surveyed by Accenture said they use big data primarily for predictive purposes, as many as 88% indicated big data analytics is a top priority for their company. With an increasing number of companies learning to master the precursors to developing predictive models — namely, connecting, monitoring, and analyzing — we can safely assume the art of gleaning business intelligence from foresight will continue to grow.

Amid the promises of predictive analytics, however, we also find a number of pitfalls. Some experts caution there are situations when predictive analytics techniques can prove inadequate, if not useless.

Let’s consider three examples:

- Predictive analytics works well in a stable environment in which the future of the business is likely to resemble its past and present. But Harvard Business School professor Clayton Christensen points out that in the event of a major disruption the past will do a poor job of foreshadowing future events. As an example, he cites the advent of PCs and commodity servers, arguing computer vendors who specialized in minicomputers in the 1980s couldn’t possibly have predicted their sales impact, since they were innovations and there was no data to analyze.

- Bias in favor of a positive result is another danger when interpreting data; One of the most common errors in predictive analytics projects. Speaking at the 2014 Predictive Analytics World conference in Boston, John Elder, president of consulting firm Elder Research, Inc., made a good point when he noted that people “‘often look for data to justify our decisions, when it should be the other way around.”

- Mining big data will further do little good if the insights are not directly tied to an operational process. I’ve a feeling more companies than we realize are wasting precious time and manpower on big data projects that are not adequately understood, producing trivia rather than actionable business intelligence.

With the above challenges in mind, talent acquisition and thorough A/B tests will be key components of any predictive analytics project. What else do you think organizations need to do to use foresight effectively?

You may also be interested in:

Fronetics Strategic Advisors is a leading management consulting firm. Our firm works with companies to identify and execute strategies for growth and value creation.

Whether it is a wholesale food distributor seeking guidance on how to define and execute corporate strategy; a telematics firm needing high quality content on a consistent basis; a real estate firm looking for a marketing partner; or a supply chain firm in need of interim management, our clients rely on Fronetics to help them navigate through critical junctures, meet their toughest challenges, and take advantage of opportunities. We deliver high-impact results.

We advise and work with companies on their most critical issues and opportunities: strategy, marketing, organization, talent acquisition, performance management, and M&A support.

We have deep expertise and a proven track record in a broad range of industries including: supply chain, real estate, software, and logistics.

by Elizabeth Hines | Jul 15, 2015 | Blog, Leadership, Strategy, Supply Chain

The sharing of tangible and intangible assets will increasingly become a fundamental feature of successful businesses.

The sharing of tangible and intangible assets will increasingly become a fundamental feature of successful businesses.

Few developments of late are as intriguing as the rise and disruptive impact of the collaborative economy. In a very short time, services that we may have thought of as permanent fixtures of our business and personal lives have been rendered obsolete by the sudden sharing of tangible and intangible assets in the peer-to-peer, business to consumer (B2C), and business to business (B2B) spheres.

B&B and hostels, car rental, and DVD rental are giving way to peer-to-peer accommodations, car sharing, and music and video streaming. The Marriott Hotel chain used the online platform LiquidSpace to convert empty conference rooms into rentable work spaces for guests as well as outside visitors. Walgreens teamed up with TaskRabbit, an online marketplace for outsourcing errands, to deliver products during flu season. The list is endless.

Rachel Botsman, an innovation strategist who has spent the past four years studying 500 collaborative economy startups worldwide, concludes in Harvard Business Review:

The real power of the collaborative economy is that it can serve as a zoom lens, offering a transformative perspective on the social, environmental, and economic value that can be created from any of a number of assets in ways and on a scale that did not exist before. In that transformation lie threats—and great opportunities.

While consumer sharing may have received the most media attention, Robert Vaughan, an economist at PwC Strategy & Inc., argues the open sharing of resources among businesses may present an even larger opportunity. Although, on the surface, it seems like an unlikely marriage – businesses do compete, after all – a growing number of successful collaborations prove Vaughan is right.

He writes:

In just a few years of activity, it has become clear that the unfettered exchange of otherwise unused major assets, including physical space and industrial equipment, allows a sharing company to operate more efficiently than its non-sharing rivals. Companies that go further still, wholeheartedly embracing the sharing of less tangible assets, may benefit from a different sort of change, one involving their culture, that builds new types of connections with, and sensitivity to, the world outside.

One example of an interesting collaboration involves General Electric and Quirky, an online inventor community. GE and other market giants such as IBM and Samsung file thousands of patents every year, most of which never move beyond the drawing board. The collaboration gives Quirky open access to GE’s patents, allowing for products that normally would not have been put to productive use – such as a smartphone controlled window air conditioner – to be brought to market.

Sometimes a direct collaboration may not even be necessary. A company may choose to place an undeveloped product on an online technology exchange, thereby opening itself to the possibility of building a connection to another company with complimentary expertise.

In many respects, enterprise sharing is still in its infancy and is likely to evolve just like Airbnb, whose concept seemed “fringe” when it launched in 2008 (it was initially marketed as a service for people to stay the night on their air beds in strangers’ homes). Now the company has amassed more than 650,000 rooms in 192 countries and threatens to disrupt not only the hotel industry but the entire hospitality sector.

Fronetics Strategic Advisors is a leading management consulting firm. Our firm works with companies to identify and execute strategies for growth and value creation.

Whether it is a wholesale food distributor seeking guidance on how to define and execute corporate strategy; a telematics firm needing high quality content on a consistent basis; a real estate firm looking for a marketing partner; or a supply chain firm in need of interim management, our clients rely on Fronetics to help them navigate through critical junctures, meet their toughest challenges, and take advantage of opportunities. We deliver high-impact results.

We advise and work with companies on their most critical issues and opportunities: strategy, marketing, organization, talent acquisition, performance management, and M&A support.

We have deep expertise and a proven track record in a broad range of industries including: supply chain, real estate, software, and logistics.

by Fronetics | Jul 1, 2015 | Blog, Leadership, Strategy

How to increase prices and retain customers

How to increase prices and retain customers

Companies raise prices all the time. There are various reasons, explanations, and results. Sometimes companies disclose the changes, but sometimes customers and clients never even catch wind of a change. Let’s have a look at the causes, the perception, and the actions to take.

Why?

Usually there’s an impetus for a company to raise prices. Perhaps there’s a business model already in place to raise future prices, but often a price increase is tied to another event. Here are some typical reasons:

Spike in raw material prices used in manufacturing products

Is there dearth of raw materials used to make the products your company is producing? Perhaps there’s a lack of access to the materials due to stalled transportation from inclement weather, natural disaster, drought, etc. Perhaps resources are dwindling or other roadblocks in the supply chain are driving up prices.

Services or products have become incredibly popular (value-based pricing)

Perhaps you realize that your services or products weren’t appropriately priced early on, and you’re realizing your product’s value in the market. You may also need to reduce demand for some time by increasing prices.

Unexpected change in business or a new tact

Perhaps you’ve lost business recently or your business strategy has changed and you need to cover costs by increasing prices. These changes can come with the opening of a new branch or factory, or the launch of new services or products.

Inflation and market trends

It would be nice to keep prices where they started 5, 10, or 20 years ago, but most businesses aren’t sustainable that way. As all prices of other goods and services rise, so too must yours.

Perception

As detailed in an article about the power or perception, behavioral economist Richard Thaler ran an experiment in which some study members were asked how much money they would give a friend to go buy beer at a “run-down grocery store”. Some study members were asked to get the alcohol at a “fancy hotel”. According to the article, “the fancy resort’s median price was 71% higher than the run-down store’s price.”

This might suggest that considering the perception of your product or services could be key to your next price adjustment. Considering what your current branding is, who your competitors are, and where you want to see your company could help shift your own perception of your company, and that of others. Aligning the two could be critical to successfully stewarding a price shift.

How?

It’s important thoroughly think through a price adjustment. Considering your own worth is important, but understanding that some clients and customers won’t be convinced can be a hard pill to swallow. To make the change more palatable, or even attractive, you should consider these options:

Consider the tactic (good-value pricing, value-added pricing)

Are you planning on going to offer any promotions or price discounts in the future? Are you going to attach value-added features and services to support the higher prices? Are you considering doing bundles packages? It’s important to answer theses questions so that you can communicate to clients and customers.

Consider timing

Have you recently increased prices? Does it feel too soon to do it again? You could risk loyalty from consumers and clients if price increases come back to back. However some believe that small increases frequently are better than large increases infrequently.

Are you implementing new, improved services or bundling new packages? An announcement tied to value increase or product change can be more comfortable for consumers and clients.

Make a solid announcement

Most people feel it is best to announce an increase, especially to current customers and channel partners, rather than try to hide the increase. People don’t want to feel fooled or ignored. They want transparency.

Understand that wording is critical

Being direct and confident in expressing the increase is the best tact. Remember that if you value your product and services, your customers and clients are more likely to as well.

Although you’re briefly sharing the reason for the increase, don’t feel the need to disclose sensitive financial information.

Lastly, provide clear timing on the changes and be sure that changes don’t violate any pre-existing agreements.

Although some customers and clients may bristle at an increase of prices, if you’ve been playing fairly and providing solid products and services, many loyal customers will come along for the ride. If you value yourself, and others value you, you can survive a price increase. You may even thrive from one.

Fronetics Strategic Advisors is a leading management consulting firm. Our firm works with companies to identify and execute strategies for growth and value creation.

Whether it is a wholesale food distributor seeking guidance on how to define and execute corporate strategy; a telematics firm needing high quality content on a consistent basis; a real estate firm looking for a marketing partner; or a supply chain firm in need of interim management, our clients rely on Fronetics to help them navigate through critical junctures, meet their toughest challenges, and take advantage of opportunities. We deliver high-impact results.

We advise and work with companies on their most critical issues and opportunities: strategy, marketing, organization, talent acquisition, performance management, and M&A support.

We have deep expertise and a proven track record in a broad range of industries including: supply chain, real estate, software, and logistics.

by Jennifer Hart Yim | May 13, 2015 | Blog, Leadership, Strategy, Supply Chain

This article is part of a series of articles written by MBA students and graduates from the University of New Hampshire Peter T. Paul College of Business and Economics.

Corey Ducharme is Green Belt Certified in Six Sigma. He has a BA in Business and is currently in the MBA program at the University of New Hampshire. He has consulted at major corporations including Johnson & Johnson, Universal Studios, Sony Pictures, Oklahoma Oil & Gas, and Suncor as a management consultant at D&A Management. He can be reached via e-mail.

We all use Six Sigma problem solving whether we know it or not

How do humans tend to solve problems? Consciously or unconsciously humans use a four-step method that is defined as:

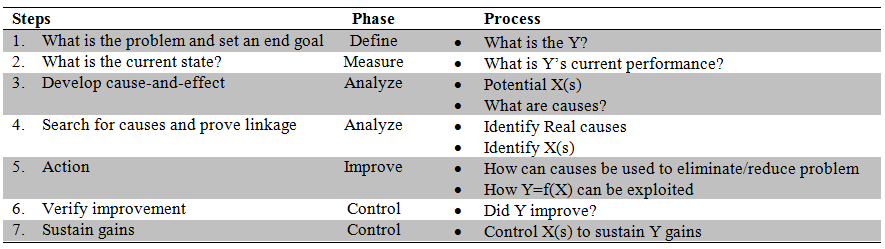

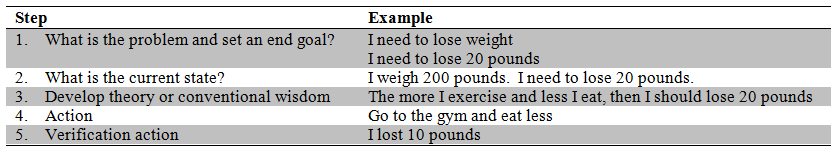

Table 1: Traditional Problem Solving Process

In the above example, the root cause is identified – exercise and eating less equals losing weight – and verified. The conventional wisdom is proven true and there is little need to consider a more robust or analytical method. Most humans solve their day-to-day issues in this manner whether consciously or unconsciously. My root-cause analysis in this case (I exercise and eat less) is verified by the fact that I lost ten pounds and sustainable until my goal is achieved. (Losing 20 pounds).

Six Sigma Problem Solving

What if the root-cause lies outside of conventional wisdom or is difficult to determine?

These needle-in-a-haystack problems – due to limited business resources – cause businesses to lose revenue and lead to process failures, poor quality, and poor customer service. These types of problems are at the heart of Six Sigma Problem Solving and are a way to find the needle-in-the-haystack.

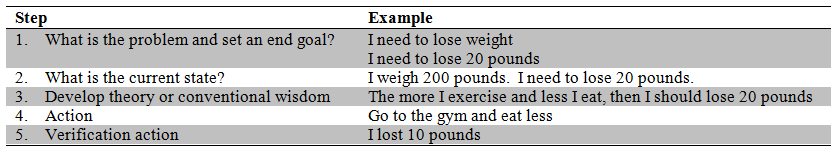

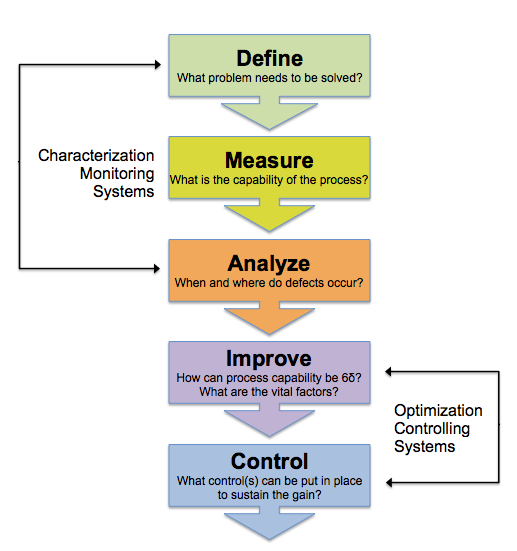

The Six Sigma methodology is based on the DMAIC process and using our weight loss example we begin to see the similarities between the two methods.

- Define Phase: What is the problem and set the end goal.

- Measure Phase: What is the current state?

- Analyze Phase: 1. Develop cause-and-effect analysis of problem. What are the real causes and prove cause and effect links.

- Improve Phase: Action

- Control Phase: 1. Verify improvement and 2. Sustainability

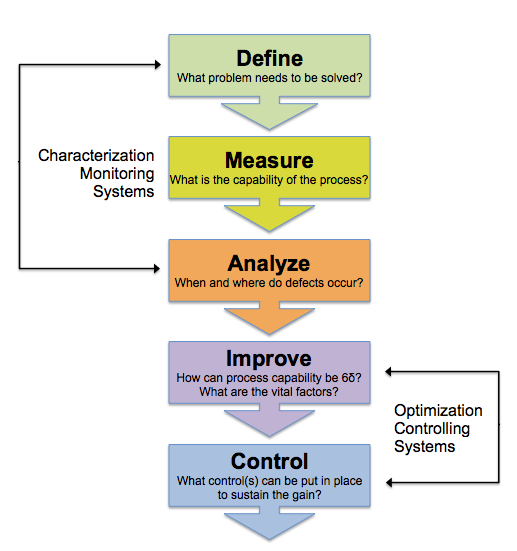

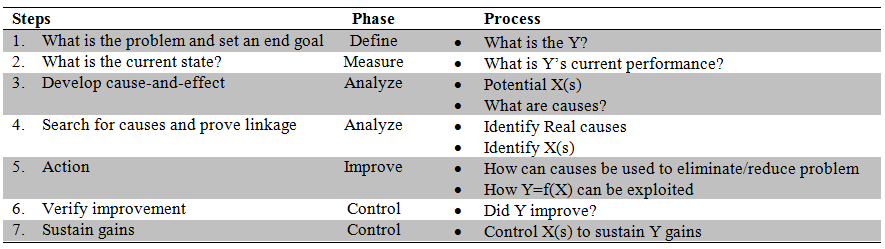

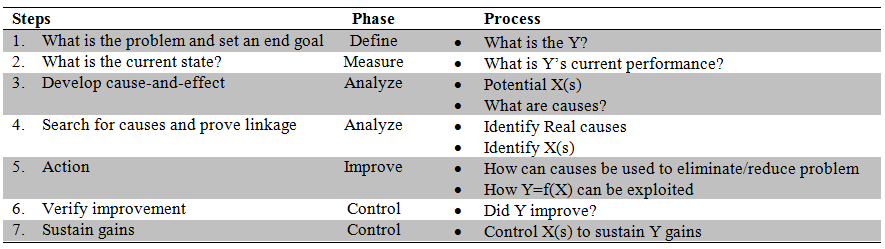

What differs between the phases of conventional and Six Sigma problem solving begins in the Analyze Phase. Six Sigma methodology demands the proof of cause be determined before a clear course of action is taken. The proof of cause must be data-driven as root-cause analysis is at the core of Six Sigma problem solving. It is also the reason that the Analyze phase is divided into the development of cause-effects and proof of cause-effect links.

The second difference is in the fifth phase. In the Traditional problem-solving methodology, verification comes in the form of losing weight. I can prove it by weighing myself. In Six Sigma problem solving, a two-step process is needed. Verification is essential (Did I improve?) and if so, a plan to sustain our gains is created. This is not necessary in a Traditional methodology because our cause-effect is proven (exercise/eat less = weight loss); however, in the Six Sigma methodology our cause-effect must be tested and verified.

The Linguistics of Six Sigma: Y=f(X)

To speak in the language of Six Sigma, we need to change ‘problem’ with ‘Y’ and ‘cause’ with ‘X’. The Y is the output and the X(s) are any inputs that are involved in producing the output. In other words, the Y = 100% customer satisfaction and X(s) are the variables that affect the level of customer satisfaction. For more, click the following link: Y=f(X).

Using Six Sigma linguistics and the DMAIC process, we can combine the Traditional problem solving steps in Table 1 and we see that our four-step process has become a more robust seven-step process. We can now use DMAIC to ask ourselves the most essential question:

If our root-cause analysis is discovered and proven true, then can the problem be solved or reduced by controlling or removing the cause(s)?

Table 2: DMAIC Problem Solving

Real World Example: Boeing

Boeing’s Six Sigma team in Everett, WA discovered that root cause analysis is often like finding a needle-in-a-haystack, especially for the maker of the world’s largest commercial twin-engine airplane with millions of components. (To read the entire story, click the following link: Problem-solving approach helps team pinpoint solution). Boeing discovered that recirculating air fans were being rejected during production, costing Boeing money in waste, removal, testing, and cost of replacing the component.

Boeing assembled a cross-functional ‘detective squad’ that included employees from Engineering, Quality, Manufacturing, Supply Management, Procurement, and their supplier Hamilton Sundstrand who began the problem-solving techniques of the DMAIC process by examining data from the fans and beginning root-cause analysis.

This analysis determined that Foreign Object Debris (FOD) damaged the fans and the test tools. Job done, right? Not according to Kent Kuiper, Six Sigma expert at Boeing, the team had to dig deeper. “For example,” he said, “when we found that FOD was a problem and determined the source for it, removing the FOD and replacing the fan wasn’t going to get us where we needed to go. We had to figure out a way to keep the FOD from happening again.”

Further inspection led the team to discover failures in ductwork caps and plastic sheeting – two items ironically intended to prevent FOD damage and two electrical issues. One failure of improperly modified test equipment and the second issue related to crimping procedures in manufacturing process that improved connections in the fans. The results? Although the FOD in the fans was the main X, the results were clear. “After 18 fan failures in two years, we went four and a half months without a rejection,” said Max Limb, a supplier field service representative. “We haven’t completely eliminated the rejections, but we’re close.”

“Our team has become well-versed in the concept of Six Sigma,” said Valerie Feiberti, Supply Management and Procurement Director of the Lean Promotion Team. “We feel very strongly that it provides a way to correct production-related problems and proactively design-in quality.”

Summary

The DMAIC methodology is essentially a series of common sense questions to determine root-cause analysis, identification of X(s), elimination of problems, and maintaining of gains. The DMAIC process asks the following questions:

- Define: What is the Y that is performing poorly?

- Measure: What is Y’s current performance?

- Analyze: What are the X(s)? Are they real?

- Improve: How can X(s) be controlled/eliminated?

- Control: How can X(s) be controlled to sustain gains in Y?

Six Sigma problem solving is the data-driven representation of the conscious or unconscious thinking we use to solve problems in our lives and can be used to solve may needle-in-a-haystack problems that vex businesses.