by Fronetics | Jan 3, 2019 | Blog, Content Marketing, Logistics, Marketing, Social Media, Supply Chain

Live video streaming helps businesses promote transparency, good communication, and relatability.

Live video is one the biggest trends in social media marketing right now. According to the 2018 Social Media Marketing Industry Report, 77 percent of marketers plan to increase their use of video this year and 68 percent want to start using live video.

[bctt tweet=”77 percent of marketers plan to increase their use of video this year and 68 percent want to start using live video.” username=”Fronetics”]

It’s really no surprise video has gained such traction. Platforms like YouTube made the transition from watching TV in your home to watching videos on your phone seamless. And live streaming fits in with today’s emphasis on corporate transparency and putting a real, human face to business social media accounts. It allows brands to drop their corporate façade and connect to users in a more human way.

Before you ask, let me say it again: Yes, video can work for the supply chain.

Starbucks and live streaming

You don’t have to take our word for it. Look at the success of Starbucks. Back in 2016 the coffee giant tried their first live feed at an event in Queens, New York, to promote National Voter Registration Day. The live video showcased Starbuck’s involvement in the community and their dedication to social events. It was a huge success. The streaming content allowed viewers who wouldn’t otherwise be able to make the event learn about the cause and its importance.

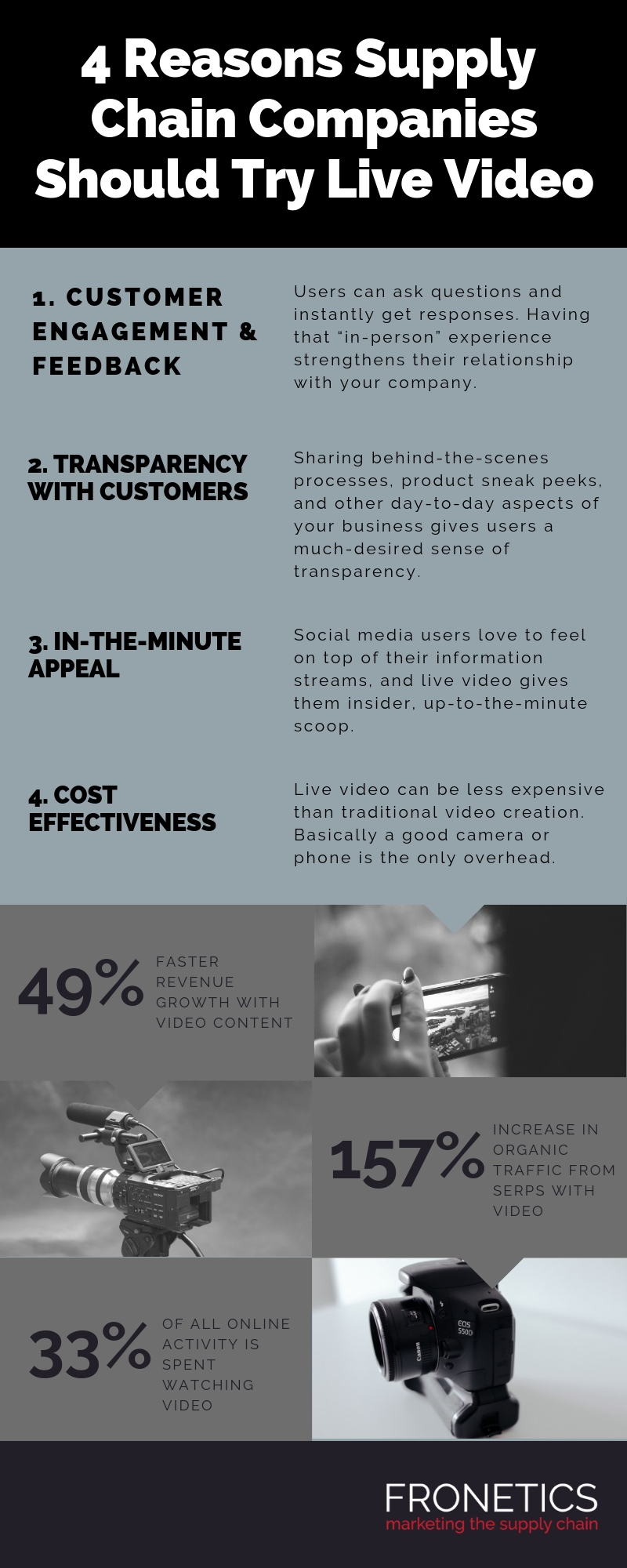

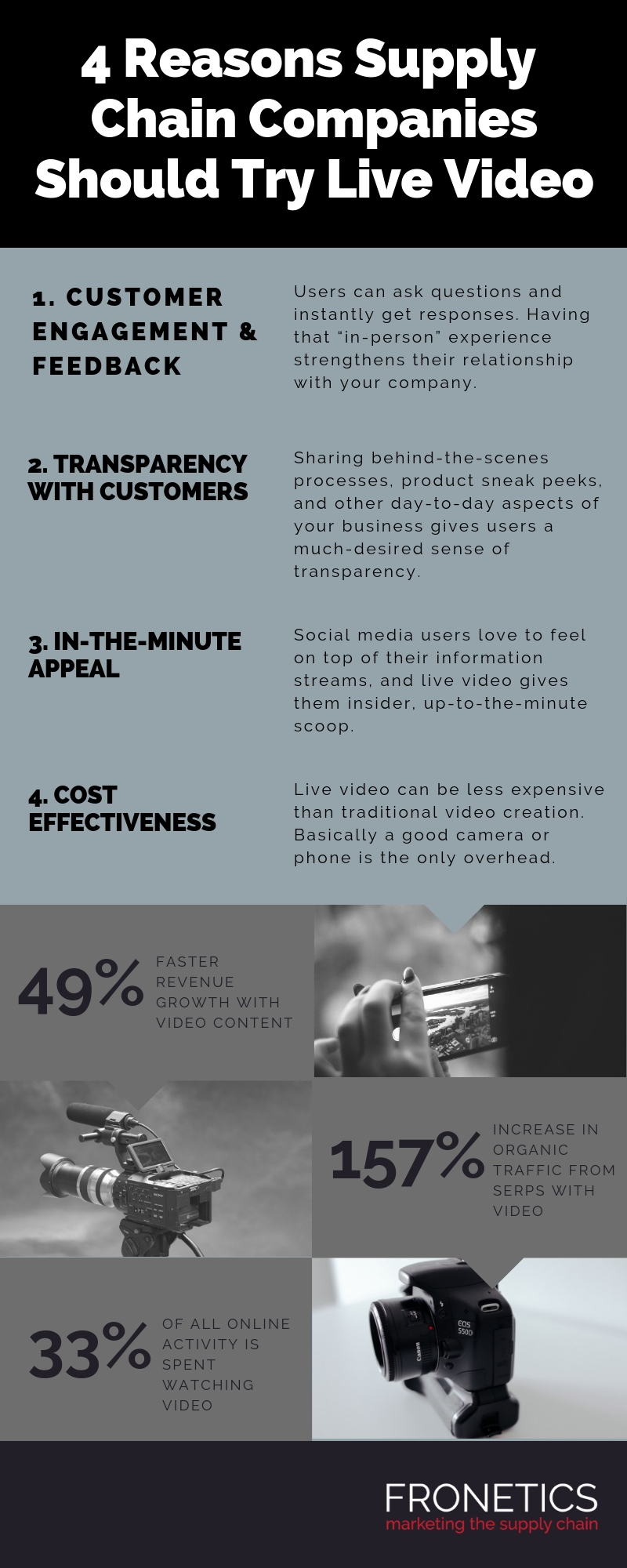

Still not convinced? Check out this infographic with 4 reasons why the supply chain needs to try live video.

Infographic: 4 reasons the supply chain needs live video

(Made with Canva)

Live streaming platforms

Want to dive into live video, but don’t know where to start? Here’s a few of the most popular platforms.

- Facebook Live: Facebook Live lets you broadcast in real time for up to 90 minutes per session. Users who have recently engaged (or who frequently engage) with your page will receive a notification that you are streaming live, and they can go to your page to view the video. Viewers can comment and react during the course of your broadcast, allowing you to read their remarks and respond immediately.

- Periscope: Twitter-owned and run, Periscope is a standalone platform but integrates seamlessly with Twitter. It has more than 10 million users, more than two million of whom log in daily. The service lets users live stream from their mobile devices and push out those streams on Twitter.

- YouTube Live: YouTube Live enables YouTube to utilize its expansive creator and advertising network to generate even more video to be hosted and monetized. YouTube makes it incredibly easy to aim, shoot and post live video.

Related posts:

by Fronetics | Dec 14, 2017 | Blog, Logistics, Supply Chain

Here are our most-viewed blog posts from 2017 about the supply chain and logistics industries, including posts about some of the largest supply chain companies in the world, Starbucks and Amazon.

Throughout the year, we write innovative posts to help readers stay in the know with the latest news and happenings to the supply chain & logistics industries. These posts provide insightful and relevant information from thought leaders, current trends, and tips to stay ahead of your competitors. Here’s a look at our most popular posts from this year.

Here are our top 10 supply chain and logistics posts of 2017.

1. Supply Chain Putting the ‘Star’ in Starbucks

Starbucks’ closely managed supply chain may be the key to the premium coffee giant’s success. The international coffee giant has widely studied and acclaimed supply chain management practices, which, according to some, make Starbucks’ coffee and customer experience superior to those of its competitors. Read more.

2. 8 Must-Follow Logistics & Supply Chain Blogs for 2017

Supply chain professionals should be following these eight blogs to keep up with the latest industry news and happenings in the coming year. They cover a range of topics, from technology to strategy, and feature thought leadership by some of the brightest minds in the field. Read more.

3. Top 5 Trends to Know to Compete with Amazon’s Supply Chain

Supply chains must accept that they cannot equal the power of Amazon’s supply chain without embracing new trends. While supply chain entities struggle to stay competitive with the e-commerce giant, more organizations will look for ways to eliminate inefficiencies and boost operations. Fortunately, these five trends may alleviate some of the strains of competition by giving supply chain partners an advantage in the global market. Read more.

4. 5 Podcasts for the Supply Chain and Logistics Professionals

These podcasts bring the latest news and thought leadership in the supply chain and logistics industries right to your earbuds. Podcast’s popularity has skyrocketed since the smartphone became as necessary as car keys, giving you to-the-minute facts and information, right in the palm of your hand. If you’re looking to increase your podcast listening, here are five that highlight topics of interest to supply chain and logistics professionals. Read more.

5. What’s the Difference between Supply Chain Management and Logistics (Infographic)

Argentus’ infographic sheds light on the differences between these often-confused functions. Both Logistics and the wider Supply Chain are vital to how companies run today, but the two are still so often confused. We put together an infographic outlining some of the key differences and points of overlap between them. Read more.

6. 5 Books Every Supply Chain Professional Should Read

Add these books to your reading list to stay on top of industry trends and jump start your professional development. Read more.

7. What are the Supply Chain Impacts of Amazon’s Whole Foods Acquisition?

Amazon’s foray into the grocery space has larger implications for its overall strategy, and the possible benefits for the eCommerce goliath are diverse. Big news out of the grocery retail world as Amazon has announced its acquisition of major organic foods retailer Whole Foods Market – for an eye-popping $13.7 billion sale price that doesn’t look so massive given Amazon’s $136 billion sales volume in 2016. Read more.

8. Packaging Trends to Watch in 2017

Will sustainability trends from the consumer packaging industry have an impact on electronics manufacturing this year? Packaging trends suggest a wide range of startups, researchers, and big companies are committed to finding solutions that match the buzzwords du jour — sustainable, bio-degradable, natural, and eco-friendly. Read more.

9. The Top 3 Logistics and Supply Chain Blogs for 2017 – Readers’ Choice!

Our readers voted Morai Logistics, Women in Trucking, and the Oracle Supply Chain Management Blog as the top 3 logistics and supply chain blogs of 2017. Every year we ask our readers to vote for the best industry blogs. The results are always interesting — there’s really a lot of great supply chain and logistics content out there, plus it’s great to see where our readers are finding value. Read more.

10. The State of Supply Chains: The Supply Chain Has Gone Digital (Infographic)

2016 was the year of the digital supply chain — here’s a look at how things changed. The digital transformation has already reached most supply chain organizations. Per GT Nexus, 75% of executives surveyed recognized the digital supply chain as an important factor for the next five years. Read more.

Related posts:

by Jennifer Hart Yim | May 10, 2017 | Blog, Current Events, Logistics, Strategy, Supply Chain

Updated January 16, 2025

Starbucks’ closely managed supply chain may be the key to the premium coffee giant’s success.

Highlights:

- Starbucks attributes much of its success to its vertically integrated supply chain, managing every step from coffee bean sourcing to final cup, allowing for consistent quality control and ethical sourcing practices across its global operations.

- Unlike its competitor Dunkin’ Donuts, which outsources most operations, Starbucks directly manages relationships with 300,000 coffee growers worldwide through its Coffee and Farmer Equity (C.A.F.E.) standards, ensuring both quality standards and ethical practices.

- This supply chain strategy has contributed to Starbucks’ significant market dominance, with the company generating $32.2 billion in revenue in 2023 and operating nearly 37,000 stores globally, far outpacing Dunkin’ Donuts’ presence and revenue.

The Secret is the Supply Chain, According to Starbucks

The international coffee giant has widely studied and acclaimed supply chain management practices, which, according to some, make Starbucks’ coffee and customer experience superior to those of its competitors.

So, what exactly is Starbucks doing differently than other international coffee retailers? Is its coffee truly better?

The Standards

Starbucks uses a vertically integrated supply chain, which means that the company is involved in every step of its supply chain process, all the way from the coffee bean to the cup of coffee sold to consumers. The use of a vertically integrated system means that Starbucks works directly with its nearly 300,000 worldwide coffee growers. The company believes that interacting directly with farmers ensures that all of its coffee beans will achieve the same quality and flavor standards.

Starbucks also works directly with growers because the company is committed to only selling ethically sourced, Fair Trade coffee. The company even has its own Coffee and Farmer Equity (C.A.F.E) standards and Coffee Sourcing Guidelines (CSG), which require that all suppliers must meet certain ethical, sustainability, and quality standards. Starbucks uses a stringent vetting process to ensure its growers meet and adhere to these guidelines.

Not only do the C.A.F.E. practices and CSG benefit Starbucks, they also provide advantages for suppliers. The guidelines protect workers’ rights and ensure that all growers have safe and humane working conditions. Suppliers also must adhere to minimum-wage requirements and commit to not using child or forced labor.

Lastly, as a part of its C.A.F.E. guidelines, Starbucks commits to providing its suppliers with special training and education programs. Starbucks’ direct interaction with growers, along with their sourcing and social responsibility standards, make suppliers feel like they are integral parts of Starbucks’ corporation. The close relationship and frequent communication between Starbucks and its suppliers, therefore, make the company’s supply chain less susceptible to major disruptions, such as overplanting or worker shortages.

The Process

After the growers pick and package the coffee beans, truckers drive the unroasted beans to ocean liners that ship the beans to six storage sites in the U.S. and Europe. The beans are roasted in these storage facilities and then packaged for shipment to Starbucks’ eight central, and forty-eight regional, distribution centers. By only using a handful of storage facilities, Starbucks can closely manage the sites’ operations and guarantee that all beans are roasted and packaged in the exact same way.

The company’s close control over the roasting process also ensures that Starbucks’ coffee tastes the same in all of its retail locations. Starbucks’ active participation in the supply chain also ensures that the distribution centers receive the products they need so they can fulfill orders and make their roughly 70,000 weekly deliveries on time.

The size and scale of Starbucks’ operations should make its supply chain inherently complex. In 2008, however, Peter Gibbons, the Executive Vice President of Global Supply Chain Operations, overhauled the company’s expensive, ever-growing supply chain into a streamlined, cost-effective process that relies on simple operational structures and metrics.

First, he grouped all supply chain jobs into four categories: plan, source, make, and deliver. Next, he developed a highly centralized logistics system that allows the company to better manage and coordinate its global network. Lastly, he implemented a binary, 0 or 1 “scorecard system” to assess all supply chain activities on four metrics: safety in operations; service measured by on-time delivery and order-fill rates; total supply chain costs; and enterprise savings.

Along with the simple tools and processes that Gibbons created, Starbucks also relies heavily on digital technology to manage its supply chain. The company uses an automated information system that allows it to monitor demand, inventory, capacity, and scheduling in real time. Therefore, Starbucks can quickly adjust its plans and operations as needed. Starbucks’ simple structure and management tools, as well as its use of digital technology, allow the company to achieve a high level of efficiency and agility, both of which are key to organizational success.

The Market

Starbucks’ biggest competitor in the international coffee market is Dunkin’ Donuts. In contrast to Starbucks, which owns its entire supply chain, Dunkin’ Donuts outsources its production processes. Dunkin’ Donuts relies on a third-party intermediary, National DCP, to handle the company’s supply chain operations.

Dunkin’ Donuts also franchises its manufacturing locations, as well as nearly all of its retail spaces. Conversely, Starbucks franchises less than 50% of its retail locations, and, as of March 2016, was no longer accepting applications for new U.S. franchises. Starbucks also uses few to no intermediaries to carry out its supply chain operations.

Unlike Starbucks — which is committed to using 100% sustainably grown, Fair Trade-certified coffee beans — Dunkin’ Donuts promises to produce its coffee as “sustainably as possible.” The company works with Fair Trade USA and the Rainforest Alliance to implement sustainable sourcing practices, as well as training programs for farmers. However, Dunkin’ Donuts only offers two permanent menu items that are Fair Trade-certified: 30% Rainforest Alliance Certified™ Dark Roast Blend and 100% Fair Trade Certified™ espresso.

While Starbucks’ critics may try to argue that the company’s supply chain model and social responsibility efforts are not true differentiators, the statistics tell a different story.

Starbucks was founded roughly twenty years after Dunkin’ Donuts, but the company is already much larger than its rival. In 2023, Starbucks generated $32.2 billion dollars in revenue, while Dunkin’ earned only $1.4 billion. Starbucks also has a larger global presence, with nearly 37,000 retail stores in 80 markets worldwide, compared to Dunkin’s 13,500 locations in 40 countries.

Starbucks also primarily markets to higher-income customers looking for a premium coffee experience, while Dunkin’ Donuts has traditionally retailed to more blue-collar consumers who want coffee on the go. Therefore, Starbucks’ clientele is willing to pay more for coffee that they perceive to be made from higher-quality, socially responsible sources. It used to be that Starbucks’ customers would also pay more for coffee in order to enjoy the amenities offered in the company’s coffeehouses, but even with a consumer shift towards drive-thru and mobile pick-up preferences, Starbucks’ customers seem willing to pay more for convenience. Because Starbucks’ patrons generally have higher disposable incomes than those of Dunkin’ Donuts’ customers, they are less likely to adjust their consumption patterns during economic downturns. Thus, Starbucks is less susceptible than Dunkin’ Donuts to major fluctuations in revenues that could result from negative macroeconomic swings.

The Future

While Dunkin’ Donuts loyalists, particularly those in New England, may never accept the merits of Starbucks coffee, majority opinion argues that Starbucks offers higher-quality beverages and better customer experiences. Statistics show that Starbucks is outperforming its rival, which is evidence of the success of a simple and efficient global supply chain. In fact, Starbucks, which is already larger than Dunkin’ Donuts both domestically and abroad, plans to open more new retail spaces than its competitor over the next five years.

Therefore, one question remains for coffee drinkers and market analysts: Does America actually run on Dunkin’? Or is Starbucks’ coffee really the fuel running our caffeine-crazed country (and world)?

We love writing about all things related to the supply chain, including Starbucks’ supply chain. Need quality content written for your supply chain business? We’re a content agency focused exclusively on working with companies like yours. Let’s chat.

This article is part of a series of articles written by MBA students and graduates from the University of New Hampshire Peter T. Paul College of Business and Economics.

Related posts:

by Fronetics | Oct 20, 2016 | Big Data, Blog, Data/Analytics, Logistics, Manufacturing & Distribution, Strategy, Supply Chain, Warehousing & Materials Handling

These industry leaders are leveraging insights from big data to solve business problems and drive profitable customer action.

Big data is more than just a buzzword: It’s helping companies make big-impact business decisions based on customer behaviors, purchasing patterns, and preferences.

Not all organizations have the resources to invest in big data. But for those that do, the payoff can big significant. The trick, of course, is knowing which numbers to analyze, what can be predicted, how to use big data for your particular business needs.

Let’s look at five big brands that are leveraging big data successfully to drive profitable customer action.

How 5 big brands use big data

1. Amazon

Amazon’s free same-day delivery service, Prime Now, allows Prime members to shop for over 25,000 products that can be delivered to their doorsteps within two hours. How can Amazon accurately predict the specific wants of millions of people across the country at a given time to prepare local inventory for immediate delivery? Aside from efficient warehousing and logistics, the company uses data on purchase history to optimally locate and stock its warehouses. This strategy also helps to reduce the time inventory stays in stock, diminishing working capital requirement.

2. Starbucks

Have you ever wondered how two neighborhood Starbucks locations can both stay in business? The company examines data on local traffic, demographics, and customers to determine the potential success of a new location before expanding. Starbucks can then choose to open a new store where it would be most successful, even if it’s just a few blocks from one of their other locations.

3. Walmart

In preparation for Hurricane Sandy, Walmart analyzed historical sales data before expected inclement weather and found an uptick in sales of flashlights, emergency equipment, and — to everyone’s surprise — strawberry Pop-Tarts in several locations. The company has since leveraged timely analysis of real-time data to drive business performance. As Walmart Senior Statistical Analyst Naveen Peddamail told Forbes: “If you can’t get insights until you’ve analysed your sales for a week or a month, then you’ve lost sales within that time. Our goal is always to get information to our business partners as fast as we can, so they can take action and cut down the turnaround time. It is proactive and reactive analytics.”

4. Rolls-Royce

Rolls-Royce has implemented big data processes in three key areas of their operations: design, manufacture, and after-sales support. Each design simulation for one of their jet engines, for example, generates tens of terabytes of data, which computer systems analyze to determine the viability of the design. The company’s manufacturing systems are increasingly moving toward a networked, Internet of Things (IoT) industrial environment. And after-sales support is completely changed by big-data analysis. Expert engineers continually examine real-time analysis from sensors fitted to all Rolls-Royce engines and propulsion systems to diagnose faults and mitigate issues.

5. Capital One

Big data helps Capital One determine the optimal times to send particular customers certain offers. The team analyzes demographic data and spending habits of their customers to optimize their offerings, which has increased conversion rates on their offers and generated more leads from their marketing budget.

How does your business use big data?

Related posts: