by Elizabeth Hines | Oct 29, 2013 | Blog, Leadership, Logistics, Strategy

There are a host of issues and risks you need to consider and mitigate when implementing an international reverse logistics process. Here are six things to consider when taking your reverse logistics process international:

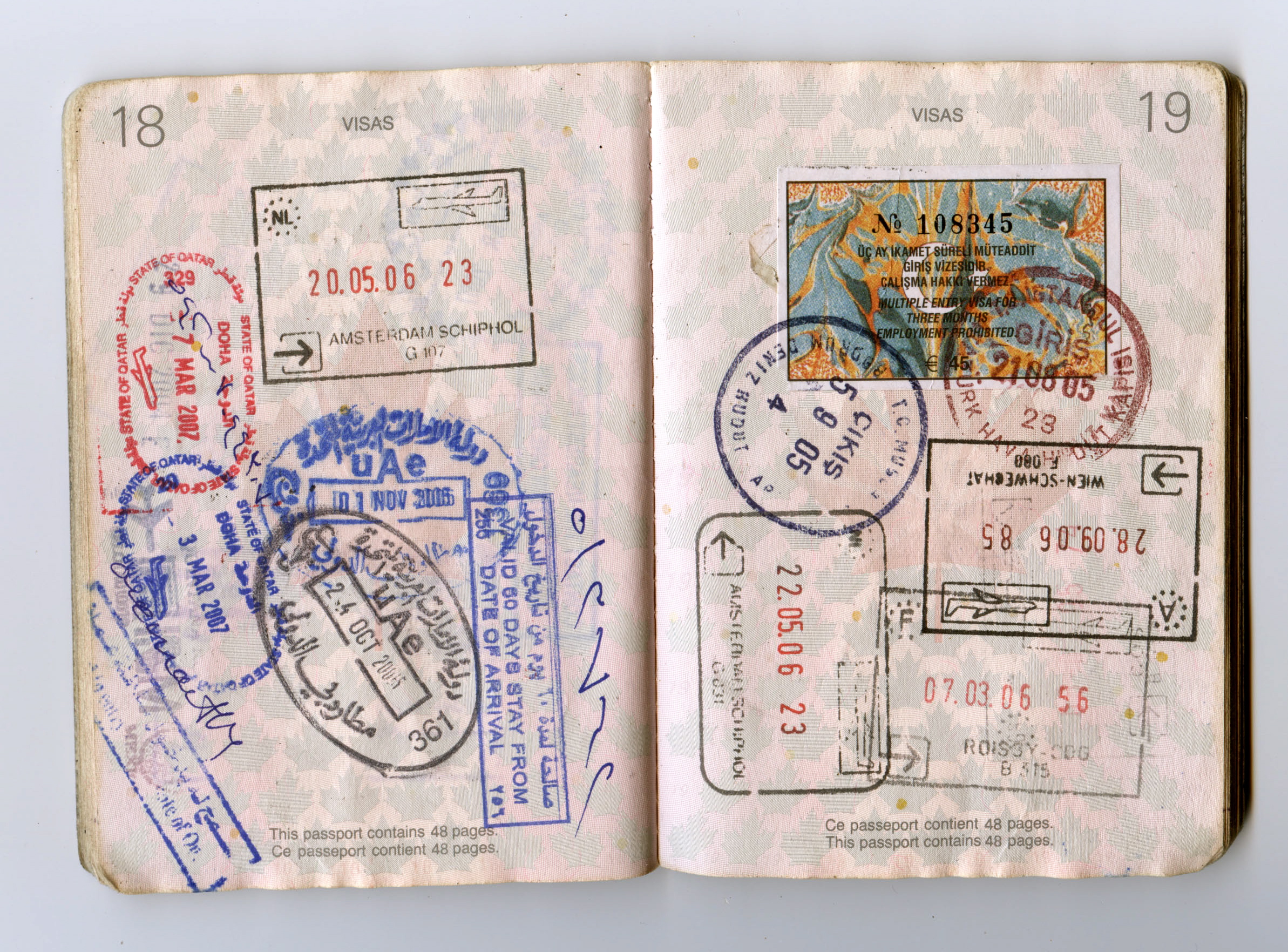

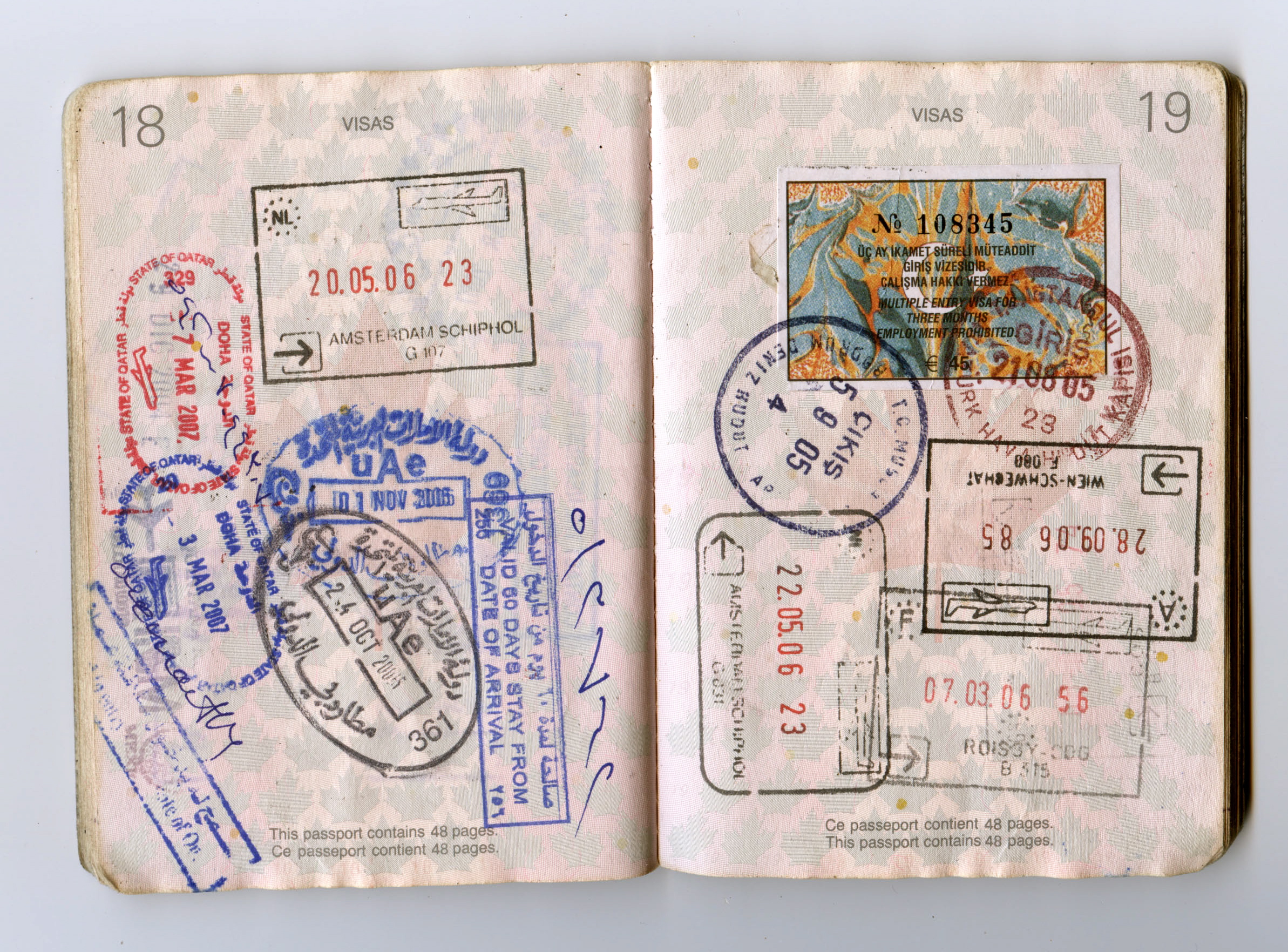

1. Laws, rules, and regulations

One of the first issues that you need to understand are the laws within the involved country (or countries) as well as any rules and regulations, such as taxes and tariffs, that focus specifically on border crossing of defective or non-working electronics. Not taking the time to understand the legal system could result in fines and/or costly delays.

2. Costs

Costs are another issue. Labor, transport, and disposal costs, for example, vary vastly from country to country. Accounting for even minor cost fluctuations is essential, and not only for budgeting and cost containment. Shifting cost can upend even the tightest client relationships.

3. Product classifications

Product classifications can vary from country to country. Research how the client country classifies product types. When it comes to defective or nonworking electronics, one country’s commodity can be another country’s contraband. Furthermore, misunderstandings can be expensive. For example, understanding product classifications such as tested-defected or non-tested-defective can mean the difference in being able to resell or recycle in one country to another.

4. Service levels

You must also consider service levels. What are the labor norms? Are they drastically different than those in the United States? How will the labor norms impact the service level agreements you have in place? More than likely you will find that what works well here in the United States will need to be amended elsewhere.

5. Culture

Another important thing to consider is culture. One cannot begin working in another country without taking the time to learn about and understand the culture. Although it may be tempting, don’t try and change the culture. Real success comes when you work with/within the culture.

6. How things work

Finally, take the time to fully understand what it means to work in the specific country. For example, does the country shut down around the Christmas holiday? What impact will that have on meeting deadlines? How far will you need to plan ahead?

by Elizabeth Hines | Feb 22, 2012 | Blog, Strategy

Over time, we discovered that throwing electronics away is extremely damaging to the environment. With the increasing innovation of new and trendy electronic devices continually entering the marketplace, there is high turnover and greater demand than ever before. Manufacturers and retailers are seeking partnerships with third party logistics (3PL) providers that can decrease e-waste through reverse logistics for used and outdated devices. With consumers more concerned about their carbon footprint, manufacturers and retailers as well as their supply chain partners have a commitment to reducing negative impact on the environment.

Fortunately, profitable businesses that have capitalized on this emerging green and are known as “urban miners.” In general, there are now two primary methods for disposing of our personal e-waste supply.

- Trade in the device for the latest model. This is common with smartphones, since they’re small and easy to carry. The process is convenient for the providers and device manufacturers as well. It’s the proverbial “win-win.”

- “Take-back” events. Typically orchestrated and sponsored by your local municipality, school, or civic organization, these are a local recycle e-waste process. It’s best for devices that are not readily exchangeable in their current form. You’ve probably seen flyers or advertisements encouraging you to bring your dead electronics to a local school parking lot or municipal depot where they will be loaded on a truck, never to be seen again, all in the name of charity and ecology.

There’s Gold in ‘Urban Mining’

While the local organization that hosts the event gets a portion of the fees paid to dispose of the electronics, it’s the e-waste disposal companies that do especially well.

Known as “Urban Miners” in the disposal world, these e-waste disposal companies aggregate millions of pounds of commodities that are bought and sold in a secondary market every day and shipped all over the world. E-waste disposal companies are mining items like plastics, precious and non-precious metals, and rare earth minerals from our basements and closets. It’s one of the most profitable and reliable forms or reverse supply chain.

There is no better testament to the old adage, “One man’s trash is another man’s gold.” I’m not saying this is an easy process. You need to be able to aggregate tons of e-waste material (literally) in order to make money. You need to have the “right” e-waste material, meaning recyclable and not so much disposable, and you need to have your fixed costs low enough to be able to afford the high-touch breakdown process. That’s one reason you see these take-back events popping up more often. These aggregators need tonnage in order to make the model work.

Sometimes they win. Sometimes they lose. But they are providing a service by relieving us of our e-waste in a compliant manner; and they’re supporting the charity or organization with some sort of share of the day’s take, and keeping the green theme going… thus, a win-win-win.

Today’s modern-day gold rush is happening right in our neighborhoods and cities. Instead of a pick and shovel, urban miners’ tools are a truck, a forklift, and a well-placed flyer.