by Fronetics | Jun 8, 2015 | Blog, Manufacturing & Distribution, Strategy, Supply Chain

For many years robots seemed like the brainchild of science fiction writers and directors, meeting the needs of humans as we saw in the Jetsons, or challenging them as we saw in Battlestar Galatica. Occasionally we hear stories on the news of robots being built in basement labs at prestigious universities such as MIT or Stanford. Recently there was a report on NPR about how one of UCal Berkeley’s robots couldn’t easily figure out how to fold laundry, so, one could ask: what are we worried about? If robots can’t fold laundry in under ten minutes, could they take over manufacturing?

There has been a downward trend in manufacturing jobs since 1980 in the U.S. with similar spirals in Japan, Germany, and China. Is there a correlation between the decrease in manufacturing employment and the rise of the robot? According to the Wall Street Journal, in 2014 most industrial robots were operating in the same countries/regions: Japan (306,700 robots), North America (237,400), China (182,300), South Korea (175,600), and Germany (175,200).

In the same WSJ article, a new generation of robots is profiled. These robots are “smarter, more mobile, more collaborative, and more adaptable.” They are also less bulky and less dangerous for humans to work next to. One might say that the newest generation of robots is acquiring many of the positive qualities of human workers, and that that, combined with many skills humans don’t and can’t possess, makes them the ultimate worker. If robots supersede the work humans can physically do, in a faster, safer, more efficient way, then what will come of the human worker?

Many believe that robots will allow for manufacturers to return to the U.S. from their low-paying, cost-saving plants overseas. They also believe that robots won’t take away from jobs, but rather create them. According to the International Federation of Robotics (IFR), robots actually create millions of jobs. The IFR’s reports oppose the idea that manufacturing jobs are waning. In 2011 article Positive Impact of Industrial Robots on Employment, the author, Metra Martech, stated, “The German and Japanese (automotive) manufacturers who have invested heavily in automation and robots have maintained a lead in the quality market. Germany has increased the number of people employed in the automotive sector.”

The IFR also states that there are many other benefits to robots in manufacturing:

- robots carry out work in areas that would be unsafe for humans.

- robots carry out work that would not be economically viable in a high wage economy.

- robots carry out work that would be impossible for humans.

“The Second Economy”, one in which computers have business interactions only with other computers, is upon us. According the to economist, Brian Arthur, who coined the term, things might not look so bright for the future of the American worker. He states, “If the Second Economy does achieve that rate of growth, it will be replacing the work of approximately 100 million workers. To put that number in perspective, the current total employed civilian labor force today is 146 million. A sizeable fraction of those replaced jobs will be made up by new ones in the Second Economy. But not all of them. Left behind may be as many as 40 million citizens of no economic value in the U.S alone. The dislocations will be profound.”

Others, some who are at the forefront of technology, are also very concerned about the rise of robots. Apple co-founder, Steve Wozniak, is one of the worried. He was recently quoted saying, “Computers are going to take over from humans, no question… Like people including Stephen Hawking and Elon Musk have predicted, I agree that the future is scary and very bad for people. If we build these devices to take care of everything for us, eventually they’ll think faster than us and they’ll get rid of the slow humans to run companies more efficiently.T”

The stuff of sci-fi is becoming a reality. As we humans make the robots that will replace us, only time will tell if that will benefit our race or harm it.

by Fronetics | Nov 26, 2014 | Blog, Manufacturing & Distribution, Supply Chain

MIT’s Julie Shah was named one of MIT Technology Review’s 35 Innovators Under 35 in 2014. In an interview with Will Knight, Shah discusses the possibility of collaboration between human robots:

“In factories there are usually physical barriers between people and robots. Originally, this was for safety—industrial robots were unwieldy and unyielding. Although robots are increasingly designed to safely share human work spaces, even in these settings, people do one set of jobs and robots do another.

Imagine if robots could be truly collaborative partners, able to anticipate and adapt to the needs of their human teammates. Such robots could greatly extend productivity. That possibility is really exciting to me.”

Shah is working companies including BMW, Boeing, and Embraer to develop robots that can interact intelligently with human co-workers.

According to Shah:

“If you can develop a robot that’s capable of integrating into the human part of the factory-if it just has a little bit of decision-making ability, a little bit of flexibility- that opens up a new type of manufacturing process more generally.”

Research conducted by Shah has found that teams made up of humans and robots collaborating efficiently can be more productive than teams made of either humans or robots alone. Shah’s experiments have shown that the collaborative process reduced human idle time by 85%. Additionally, Shah found that workers seem to be comfortable with the idea of robotic coworkers.

Are you ready for a robot to join your team? What are your thoughts on teams made up of humans and robots?

by Fronetics | Nov 26, 2014 | Blog, Manufacturing & Distribution, Supply Chain

MIT’s Julie Shah was named one of MIT Technology Review’s 35 Innovators Under 35 in 2014. In an interview with Will Knight, Shah discusses the possibility of collaboration between human robots:

“In factories there are usually physical barriers between people and robots. Originally, this was for safety—industrial robots were unwieldy and unyielding. Although robots are increasingly designed to safely share human work spaces, even in these settings, people do one set of jobs and robots do another.

Imagine if robots could be truly collaborative partners, able to anticipate and adapt to the needs of their human teammates. Such robots could greatly extend productivity. That possibility is really exciting to me.”

Shah is working companies including BMW, Boeing, and Embraer to develop robots that can interact intelligently with human co-workers.

According to Shah:

“If you can develop a robot that’s capable of integrating into the human part of the factory-if it just has a little bit of decision-making ability, a little bit of flexibility- that opens up a new type of manufacturing process more generally.”

Research conducted by Shah has found that teams made up of humans and robots collaborating efficiently can be more productive than teams made of either humans or robots alone. Shah’s experiments have shown that the collaborative process reduced human idle time by 85%. Additionally, Shah found that workers seem to be comfortable with the idea of robotic coworkers.

Are you ready for a robot to join your team? What are your thoughts on teams made up of humans and robots?

by Fronetics | Sep 24, 2014 | Blog, Marketing, Social Media, Supply Chain, Talent

“Practice makes perfect.” This is what we have been told by our parents, our teachers, Malcolm Gladwell, and researchers. And, as pointed out by Fast Company, “There’s even a Macklemore song about it, so that makes it real.”

Here’s the problem – it’s not real. A 2014 study found that practice doesn’t make perfect. Instead, reaching a mastery level of whatever it is that you are trying to reach is dictated by your personality, intelligence, and a number of other factors.

Where does that leave us? For business it reaffirms the adage: “Do what you do best, and outsource the rest.”

During a Small Business Week panel discussion Gene Marke, Inc. columnist and owner of the Marks Group, discussed the importance of strategic partnerships and outsourcing:

“One of the smartest things I’ve been seeing companies do is that they do what they do best and outsource the rest. Companies are now thinking more about partners they can work with to provide the type of technologies, services, and solutions they cannot do or don’t have time to do.”

Dan Leberman, the vice president and general manager of PayPal’s North American online small and medium business unit, expressed similar sentiments:

“It’s all about knowing your company’s core competencies. As a small business, you need to decide what you’ll build and what you’ll give to a partner.”

The supply chain and logistics industries have been slower to adopt social media and inbound marketing than other industries. Reasons for this include: a lack of understanding of the benefits, lack of experience, and both time and budget constraints. In short, inbound marketing and associated activities including content creation and social media management are great examples of what companies within the supply chain and logistics industry should consider outsourcing.

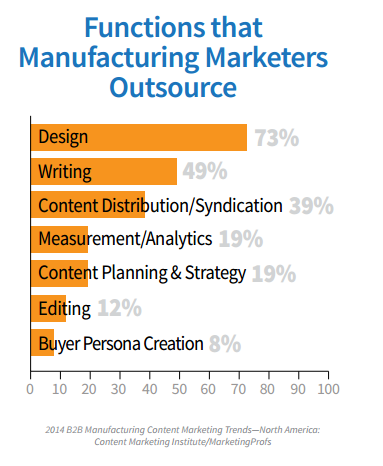

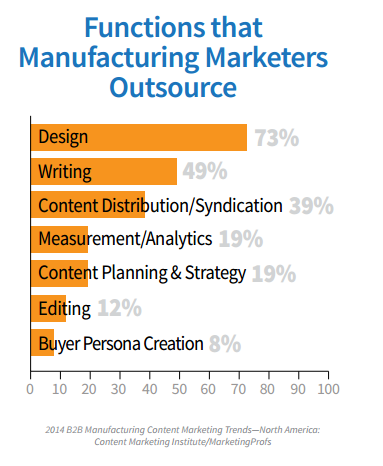

A 2014 study found that 86 percent of manufacturing marketers have adopted content marketing and that the majority (55 percent) of companies look to outsource partners for help.

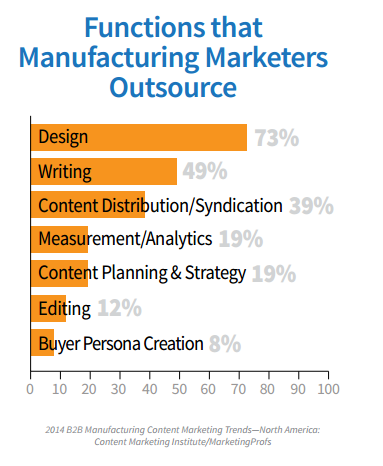

As shown below, manufacturing marketers outsource a variety of content functions including writing, distribution, design, and editing.

Now that we know practice doesn’t make perfect – play to your company’s strengths and considering outsourcing the rest.

by Fronetics | Aug 12, 2014 | Blog, Content Marketing, Marketing, Social Media, Supply Chain

Connectivity, mobility and accessibility are game changers for business. Companies that recognize this and adapt accordingly will succeed, companies that don’t will not.

Unnovation

Olaf Swantee, CEO of EE, calls this refusal to innovate “unnovation” and defines it as the following:

If unnovation ever made it into the Oxford English Dictionary, I believe the description would be something along the lines of “unnovation (noun) … the refusal to identify, create, embrace or adopt new ideas, leading to the unnecessary and un-timely end to a business, which is ultimately overtaken by external progress.

What are companies who have fallen prey to unnovation? Yell (Google), Borders (Amazon), and Blockbuster Video (Netflix) are just three examples.

Companies within the supply chain, and the supply chain industry in general, are at risk of falling prey to unnovation despite being in a prime position to innovate.

Unnovation and the supply chain

KPMG’s 2013 Global Manufacturing Outlook reported that the US manufacturing sector “seems primed for an era of ‘hyper-innovation,’ in which companies develop not only new products, but also entirely new ways to build them.” Unfortunately, companies within the manufacturing sector are not primed for innovation. KPMG found that 44 percent of survey respondents reported that they still use “old” technologies such as email, fax, and “snail” mail to manage their supply chains.

Similarly, the supply chain industry has been slow to participate in social media and to invest in creating a strong online presence. The primary reason: a lack of understanding of the business case or value.

Participating in social media and investing in creating a strong online presence are fundamentally different from the traditional strategies which companies within the supply chain industry have employed to attract new customers, foster relationships with current customers, communicate with partners, and grow their bottom line. Because of the stark contrast between “old” and “new,” companies do not recognize how these strategies can positively impact their bottom line and therefore decide to steer clear – they feel engaging is too risky. The reality is that not participating is risky; not participating is unnovation.

These companies embrace change

Keychain Logistics

Companies that choose to unnovate will be eclipsed by companies who embrace the world of mobility, connectivity and accessibility. Keychain Logistics is one company that has decided to embrace change.

Bryan Beshore, Keychain’s founder, recognized the changes taking place and decided not just to embrace them, but to also capitalize on them. Keychain leveraged the ideas of mobility, connectivity and accessibility and created a new way for the freight transportation industry to conduct business. Keychain is a marketplace that connects drivers directly with shippers – and is available via mobile app.

Keychain has also become an active participant on social media. This participation has enabled the company to shape their offering with a solid understanding of what people want from a transportation provider. Furthermore, Beshore notes that social media has helped grow their business: “From phone calls to interviews, crowdfunded campaign partnerships, and beyond, social media has certainly helped us grow our business.”

Cerasis

Another company that has been successful – Cerasis. For 15 years the freight logistics company used traditional sales and marketing strategies. This strategy worked; however, the company recognized that if it were going to remain competitive and grow it needed to adapt. The company launched a digital, social media, and content marketing strategy. The strategy lead to an increase in website traffic of close to 670 percent, an increase in search visits by close to 2,190 percent and, most importantly, the company acquired 35 new customers – a significant number for the industry.

Swantee believes that if companies choose unnovation, “Ultimately, it could lead to disastrous consequences for their businesses, their staff and their future.” I agree. If a company wants to remain relevant and competitive, and if a company wants to grow – it needs to recognize that connectivity, mobility and accessibility are game changers for business.