by Jennifer Hart Yim | May 18, 2015 | Blog, Logistics, Strategy, Supply Chain

This article is part of a series of articles written by MBA students and graduates from the University of New Hampshire Peter T. Paul College of Business and Economics.

Michael Hickey is a former fifth grade teacher turned business professional. His experience includes content marketing in the IT industry and operations management for United Parcel Service. He will complete his MBA from the University of New Hampshire in 2015. He enjoys long walks along the conveyor belt and Ben and Jerry’s ice cream. He lives with his wife, Betsy, in Dover, New Hampshire and they are expecting their first child in June.

4 questions to ask when determining if a 3PL is right for your company

Third-party logistics, or 3PL, is an industry on the rise thanks to the constant innovations in complementary industries like telecommunications, data analytics, and cloud technologies. To avoid confusion, let’s call 3PL what it is: outsourcing. But it’s not the kind of outsourcing that typically comes to mind when you hear the term. Rather, it’s a specific type of outsourcing related to the operations side of a company in areas like order fulfillment, inventory and warehouse management, or transportation of finished goods. As many companies, and perhaps your competitors, begin to employ some form of 3PL, you may be tempted to follow suit. But before you hand over the keys, consider whether or not 3PL is a good fit for your company by answering these four questions:

Third-party logistics, or 3PL, is an industry on the rise thanks to the constant innovations in complementary industries like telecommunications, data analytics, and cloud technologies. To avoid confusion, let’s call 3PL what it is: outsourcing. But it’s not the kind of outsourcing that typically comes to mind when you hear the term. Rather, it’s a specific type of outsourcing related to the operations side of a company in areas like order fulfillment, inventory and warehouse management, or transportation of finished goods. As many companies, and perhaps your competitors, begin to employ some form of 3PL, you may be tempted to follow suit. But before you hand over the keys, consider whether or not 3PL is a good fit for your company by answering these four questions:

Question 1: What are your company’s core values?

Why do you exist as a company? What service or product do you provide that you believe is better than all others like it? And what are the core values that your company adheres to in good times and bad, for better or for worse? Core values make you who you are. They are the DNA of the company. Stonyfield Farm, for example, produces a variety of yogurts from their New Hampshire-based facility. One of their core values is that they use only organic ingredients, sourced from family-owned organic farms in their products. No ifs, ands, or buts. That’s a core value. It won’t change, during either boom or recession. And everything they do as a company must align with that. Your company’s strategic alignment stems from identification of its core values, and each decision you make as a company should work seamlessly with your strategic alignment.

Action step: Identify your core values. If 3PL conflicts with any core values, you should avoid forcing its implementation, even if there are cost savings to be gained.

Question 2: What are your company’s core competencies?

What are the things that your company does well? The Yankee Candle Company’s core competencies lie within their research and development and the chemists they employ. Their specialized skills and olfactory expertise drive the creation of precisely scented candles that make you say, “I know I smell a pumpkin pie, but I can’t find it anywhere!” Their competencies help them stand apart from the competition. You would be remiss to give over your core competency to someone else. If your expertise lies in local delivery and timely service, why outsource it to the guys with the brown trucks?

Action step: Identify your core competencies. If 3PL takes the place of any part of your core competencies, you could be weakening the overall value proposition of your company.

Question 3: Will using a 3PL provider allow you to enhance your core competencies to meet your company’s goals?

The purpose of debating whether or not to employ 3PL providers should not focus so much on reduced costs, which can be one of the foremost benefits, but rather whether or not it can enhance your core competencies and stimulate growth for your company. Is your goal to reach broader markets, but you lack the expertise to make it happen? Perhaps an e-commerce fulfillment provider could help you reach those markets. Do you have an outstanding product, but can only sell it to those within a small radius of your operations? Maybe this would be the appropriate time to call on the guys with the brown trucks.

Action step: Draw parallels between the service you wish to outsource and the goal it will meet.

Question 4: What is the cost to your company?

It’s the question that always needs to be considered. But don’t take this question at face value: we’re not just talking about how choosing a 3PL will affect the bottom line. Of course there will be monetary costs associated with hiring another company, and there is even a tipping point when using a 3PL may be cost ineffective. So after a careful cost/benefit analysis, consider the other costs associated with handing over part of your value chain to a third party:

Time costs: Does outsourcing add lead times or delivery times to orders? Decide whether possible time costs take away from your value proposition, or enable your company to meet larger goals.

Control costs: Are you willing to hand over direct control of part of your value chain to someone else? Keep in mind that it’s possible no one cares about your business quite as much as you do. Can you trust someone else to make the same kind of decisions you would make in respect to your company and its customers?

Reputation costs: What happens if a 3PL provider does not perform as anticipated? Will it put a blemish on your company’s image? If a farm outsources its delivery to a local trucking company, and the refrigeration in the trucks falters and causes food to spoil, will the customer assume that the trucking was bad, or do they just assume that the quality of the produce from the farm is questionable? It takes a long time to build up a reputation, and only a short time to dismantle it. Don’t risk it on a provider you can’t trust.

Action step: Vet your possible 3PL options to see whose values closely align with yours. It may prove to be a critical step in choosing the right provider as opposed to the cheapest one.

Third party logistics provides an avenue for companies to scale to capabilities they may never have had the ability to reach. Expanded consumer markets, faster delivery times, and more efficient inventory management are some of the benefits to be had. But before you get drawn towards the soft glow of higher revenues and wider margins through outsourcing, be careful to make sure that your choice to engage 3PL providers aligns with your company’s strategic plans. And if you do choose to outsource, take your time to find the right provider who can add the most value to your business, not just the least amount of digits on the balance sheet.

by Jennifer Hart Yim | May 18, 2015 | Blog, Logistics, Strategy, Supply Chain

This article is part of a series of articles written by MBA students and graduates from the University of New Hampshire Peter T. Paul College of Business and Economics.

Michael Hickey is a former fifth grade teacher turned business professional. His experience includes content marketing in the IT industry and operations management for United Parcel Service. He will complete his MBA from the University of New Hampshire in 2015. He enjoys long walks along the conveyor belt and Ben and Jerry’s ice cream. He lives with his wife, Betsy, in Dover, New Hampshire and they are expecting their first child in June.

4 questions to ask when determining if a 3PL is right for your company

Third-party logistics, or 3PL, is an industry on the rise thanks to the constant innovations in complementary industries like telecommunications, data analytics, and cloud technologies. To avoid confusion, let’s call 3PL what it is: outsourcing. But it’s not the kind of outsourcing that typically comes to mind when you hear the term. Rather, it’s a specific type of outsourcing related to the operations side of a company in areas like order fulfillment, inventory and warehouse management, or transportation of finished goods. As many companies, and perhaps your competitors, begin to employ some form of 3PL, you may be tempted to follow suit. But before you hand over the keys, consider whether or not 3PL is a good fit for your company by answering these four questions:

Third-party logistics, or 3PL, is an industry on the rise thanks to the constant innovations in complementary industries like telecommunications, data analytics, and cloud technologies. To avoid confusion, let’s call 3PL what it is: outsourcing. But it’s not the kind of outsourcing that typically comes to mind when you hear the term. Rather, it’s a specific type of outsourcing related to the operations side of a company in areas like order fulfillment, inventory and warehouse management, or transportation of finished goods. As many companies, and perhaps your competitors, begin to employ some form of 3PL, you may be tempted to follow suit. But before you hand over the keys, consider whether or not 3PL is a good fit for your company by answering these four questions:

Question 1: What are your company’s core values?

Why do you exist as a company? What service or product do you provide that you believe is better than all others like it? And what are the core values that your company adheres to in good times and bad, for better or for worse? Core values make you who you are. They are the DNA of the company. Stonyfield Farm, for example, produces a variety of yogurts from their New Hampshire-based facility. One of their core values is that they use only organic ingredients, sourced from family-owned organic farms in their products. No ifs, ands, or buts. That’s a core value. It won’t change, during either boom or recession. And everything they do as a company must align with that. Your company’s strategic alignment stems from identification of its core values, and each decision you make as a company should work seamlessly with your strategic alignment.

Action step: Identify your core values. If 3PL conflicts with any core values, you should avoid forcing its implementation, even if there are cost savings to be gained.

Question 2: What are your company’s core competencies?

What are the things that your company does well? The Yankee Candle Company’s core competencies lie within their research and development and the chemists they employ. Their specialized skills and olfactory expertise drive the creation of precisely scented candles that make you say, “I know I smell a pumpkin pie, but I can’t find it anywhere!” Their competencies help them stand apart from the competition. You would be remiss to give over your core competency to someone else. If your expertise lies in local delivery and timely service, why outsource it to the guys with the brown trucks?

Action step: Identify your core competencies. If 3PL takes the place of any part of your core competencies, you could be weakening the overall value proposition of your company.

Question 3: Will using a 3PL provider allow you to enhance your core competencies to meet your company’s goals?

The purpose of debating whether or not to employ 3PL providers should not focus so much on reduced costs, which can be one of the foremost benefits, but rather whether or not it can enhance your core competencies and stimulate growth for your company. Is your goal to reach broader markets, but you lack the expertise to make it happen? Perhaps an e-commerce fulfillment provider could help you reach those markets. Do you have an outstanding product, but can only sell it to those within a small radius of your operations? Maybe this would be the appropriate time to call on the guys with the brown trucks.

Action step: Draw parallels between the service you wish to outsource and the goal it will meet.

Question 4: What is the cost to your company?

It’s the question that always needs to be considered. But don’t take this question at face value: we’re not just talking about how choosing a 3PL will affect the bottom line. Of course there will be monetary costs associated with hiring another company, and there is even a tipping point when using a 3PL may be cost ineffective. So after a careful cost/benefit analysis, consider the other costs associated with handing over part of your value chain to a third party:

Time costs: Does outsourcing add lead times or delivery times to orders? Decide whether possible time costs take away from your value proposition, or enable your company to meet larger goals.

Control costs: Are you willing to hand over direct control of part of your value chain to someone else? Keep in mind that it’s possible no one cares about your business quite as much as you do. Can you trust someone else to make the same kind of decisions you would make in respect to your company and its customers?

Reputation costs: What happens if a 3PL provider does not perform as anticipated? Will it put a blemish on your company’s image? If a farm outsources its delivery to a local trucking company, and the refrigeration in the trucks falters and causes food to spoil, will the customer assume that the trucking was bad, or do they just assume that the quality of the produce from the farm is questionable? It takes a long time to build up a reputation, and only a short time to dismantle it. Don’t risk it on a provider you can’t trust.

Action step: Vet your possible 3PL options to see whose values closely align with yours. It may prove to be a critical step in choosing the right provider as opposed to the cheapest one.

Third party logistics provides an avenue for companies to scale to capabilities they may never have had the ability to reach. Expanded consumer markets, faster delivery times, and more efficient inventory management are some of the benefits to be had. But before you get drawn towards the soft glow of higher revenues and wider margins through outsourcing, be careful to make sure that your choice to engage 3PL providers aligns with your company’s strategic plans. And if you do choose to outsource, take your time to find the right provider who can add the most value to your business, not just the least amount of digits on the balance sheet.

by Elizabeth Hines | Apr 1, 2015 | Big Data, Blog, Data/Analytics, Logistics, Supply Chain

A distribution center struggling with a high number of forklift truck impacts found a way to leverage big data to address a nagging, costly warehouse issue. The company had installed a telematics solution on its forklift trucks, but could not determine the cause of the impacts. The time and location of impacts were known, as well as the identity of the drivers involved, but the company still needed to pull in more data sources for an effective assessment.

Forget for a moment the potential of adopting big data analytics throughout the entire supply chain and consider instead how big data can untangle and integrate seemingly unrelated masses of data to solve small problems in a warehouse or distribution center. That’s exactly what this company did.

By analyzing the link between environmental factors inside the distribution center and the forklift impact records, the culprit was swiftly identified: fast-moving thunderstorms that caused the humidity level to rise so quickly that the dehumidifiers could not keep up, increasing the risk of drivers losing control on the slippery concrete floor. That knowledge helped the company prevent sliding accidents by using a function of the telematics solution to reduce the maximum speed of the trucks when the humidity hit a certain level.

Indeed, distribution centers and warehouses present ideal environments — microcosms — for big data applications. Modern facilities are loaded with sensors and detectors to track every pallet and every piece of material handling equipment in real-time. Managers see the benefits in increased productivity, improved inventory flow, optimized equipment usage, and more. However, for that Eureka moment, organizations should also apply big data analytics across these multiple sources of data to uncover patterns that will drive even more, and perhaps surprising, operational improvements.

Rather than looking at data in isolation, a holistic approach holds significantly more power. Managers typically keep careful track of the performance of lift trucks, batteries, and chargers. But it is not until those entities are reviewed as a single system and matched with data coming off the lift trucks that a new level of revelations can be had.

Look for big data analytics to further raise the IQ of our “smart” warehouses and DCs. Inbound Logistics sums it up this way: “Accessing the right information to make smart decisions in the warehouse is one main reason why the demand for big data has grown so much — and so rapidly — in the distribution sector.”

Do you think distribution center and warehouse managers do enough to leverage big data?

by Elizabeth Hines | Apr 1, 2015 | Big Data, Blog, Data/Analytics, Logistics, Supply Chain

A distribution center struggling with a high number of forklift truck impacts found a way to leverage big data to address a nagging, costly warehouse issue. The company had installed a telematics solution on its forklift trucks, but could not determine the cause of the impacts. The time and location of impacts were known, as well as the identity of the drivers involved, but the company still needed to pull in more data sources for an effective assessment.

Forget for a moment the potential of adopting big data analytics throughout the entire supply chain and consider instead how big data can untangle and integrate seemingly unrelated masses of data to solve small problems in a warehouse or distribution center. That’s exactly what this company did.

By analyzing the link between environmental factors inside the distribution center and the forklift impact records, the culprit was swiftly identified: fast-moving thunderstorms that caused the humidity level to rise so quickly that the dehumidifiers could not keep up, increasing the risk of drivers losing control on the slippery concrete floor. That knowledge helped the company prevent sliding accidents by using a function of the telematics solution to reduce the maximum speed of the trucks when the humidity hit a certain level.

Indeed, distribution centers and warehouses present ideal environments — microcosms — for big data applications. Modern facilities are loaded with sensors and detectors to track every pallet and every piece of material handling equipment in real-time. Managers see the benefits in increased productivity, improved inventory flow, optimized equipment usage, and more. However, for that Eureka moment, organizations should also apply big data analytics across these multiple sources of data to uncover patterns that will drive even more, and perhaps surprising, operational improvements.

Rather than looking at data in isolation, a holistic approach holds significantly more power. Managers typically keep careful track of the performance of lift trucks, batteries, and chargers. But it is not until those entities are reviewed as a single system and matched with data coming off the lift trucks that a new level of revelations can be had.

Look for big data analytics to further raise the IQ of our “smart” warehouses and DCs. Inbound Logistics sums it up this way: “Accessing the right information to make smart decisions in the warehouse is one main reason why the demand for big data has grown so much — and so rapidly — in the distribution sector.”

Do you think distribution center and warehouse managers do enough to leverage big data?

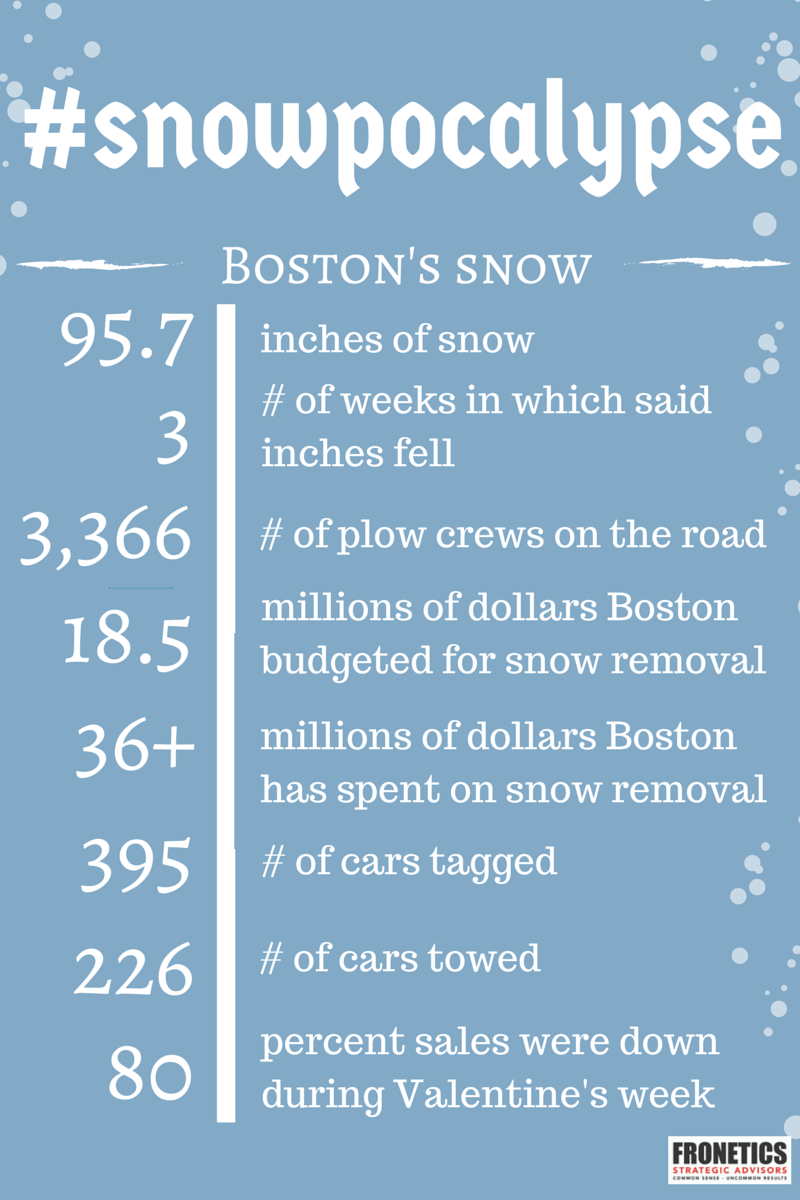

![Boston’s snow logistics [Infographic]](https://fronetics.com/wp-content/uploads/2024/10/Boston-snow-logistics-800x675.png)

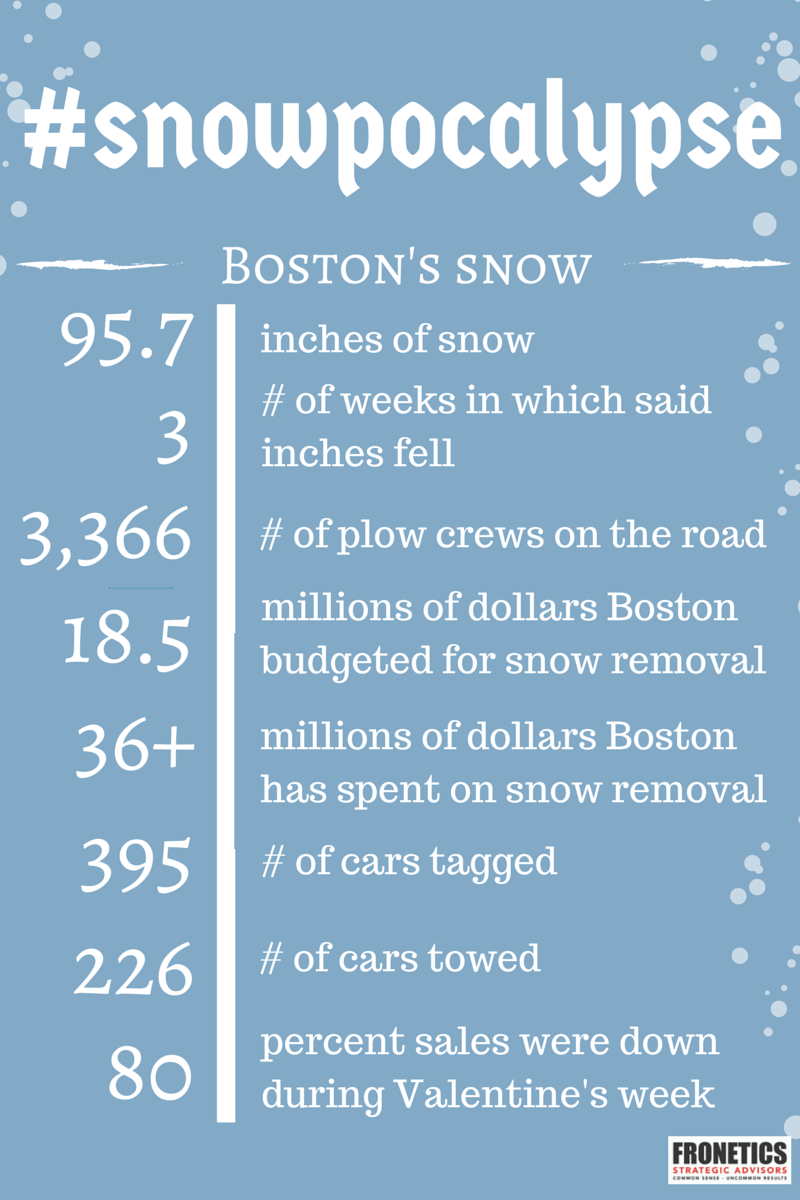

by Fronetics | Feb 17, 2015 | Blog, Current Events, Logistics, Strategy

The logistics of Boston’s snow #snowpocalypse

For the past three weeks we have been pretty much like this: shovel, snow blow, tackle commutes, juggle school cancellations, repeat.

Charlotte Wilder expressed the sentiments of many when she penned A Breakup Letter to Snow From the City of Boston. 95.7 inches of snow within 3 weeks is a lot of snow. The sheer amount of snow has forced the city’s public transportation to cancel operations. Schools have been cancelled, several for two weeks or more. Cars have been buried. Businesses have been forced to close. Businesses that have remained opened have realized dismal sales. Boston has opened snow farms and has purchased melting trucks. National Guard troops have been called in to help remove snow. #snowpocalypse 2015.

The snow has complicated the logistics of life. As we, individuals and businesses, complain about the economic, physical, and mental challenges associated with the snow it is important to put things into perspective. NPR’s Barbara Howard’s Blizzard of Perspective does just that.

Third-party logistics, or 3PL, is an industry on the rise thanks to the constant innovations in complementary industries like telecommunications, data analytics, and cloud technologies. To avoid confusion, let’s call 3PL what it is: outsourcing. But it’s not the kind of outsourcing that typically comes to mind when you hear the term. Rather, it’s a specific type of outsourcing related to the operations side of a company in areas like order fulfillment, inventory and warehouse management, or transportation of finished goods. As many companies, and perhaps your competitors, begin to employ some form of 3PL, you may be tempted to follow suit. But before you hand over the keys, consider whether or not 3PL is a good fit for your company by answering these four questions:

Third-party logistics, or 3PL, is an industry on the rise thanks to the constant innovations in complementary industries like telecommunications, data analytics, and cloud technologies. To avoid confusion, let’s call 3PL what it is: outsourcing. But it’s not the kind of outsourcing that typically comes to mind when you hear the term. Rather, it’s a specific type of outsourcing related to the operations side of a company in areas like order fulfillment, inventory and warehouse management, or transportation of finished goods. As many companies, and perhaps your competitors, begin to employ some form of 3PL, you may be tempted to follow suit. But before you hand over the keys, consider whether or not 3PL is a good fit for your company by answering these four questions:

![Boston’s snow logistics [Infographic]](https://fronetics.com/wp-content/uploads/2024/10/Boston-snow-logistics-800x675.png)