by Fronetics | Apr 1, 2015 | Blog, Internet of Things, Supply Chain

During his TED talk on the Internet of Things (IoT) technologist, Dr. John Barrett, described how every thing: appliances, furniture, vehicles, equipment, soil, food, animals and humans can become connected, identified, monitored, managed, and controlled. By 2032 he predicts that each person could come in contact with 3,000 to 5,000 connected things each day. IBM sees the Internet of Things as the planet’s new central nervous system.

The Internet of Things is already here and developing—monitoring our footsteps, heartbeats, lighting, home temperature and environment— and it will continue to grow at a rapid rate: “The growth in IoT will far exceed that of other connected devices. By 2020, the number of smartphones, tablets, and PCs in use will reach about 7.3 billion units,” said Peter Middleton, research director at Gartner. “In contrast, the IoT will have expanded at a much faster rate, resulting in a population of about 26 billion units at that time.”

The IoT and the Supply Chain

This will have a huge impact on the supply chain as we currently know it. In his talk, Dr. Barrett describes how a food processing company waiting for a delivery of shellfish will be able to not only “know where the food delivery is, but its entire storage and shipping history since the moment it came on board” the boat. Already, some vendors are able to remotely monitor their vending machines and access data about temperature, supply, and theft. In the future vending machines will be able to recognize a customer, recall their past preferences, and “even refuse to vend a certain product based on a shopper’s age, medical record, dietary requirements or purchase history.”

How else will we see IoT inform end-to-end transactions within the supply chain? Transparency in the supply chain is already growing with the swell of ERP and SCM, and with its growth it brings collaboration, clarity, and trust. With the increased use of Radio Frequency Identification (RFID) computer chips can talk to each other, and gather and deliver more detailed information than ever. Visibility in the chain will continue to expand and improve operations. The IoT will impact the supply chain in many ways including the following:

- Stock management

- Preventative maintenance

- User insight

- Manufacturing flow management

- Product stability

- Operational efficiency

- Improved fleet management

An Example of Success

Many companies are already employing the IoT, and as a result they are seeing improvements while working out the kinks of this new technology. UPS has increased single carrier deliveries with the use of sensors. According to David Barnes, the company’s chief information officer, more than 200 measurements can be tracked on a delivery truck from “how fast the vehicle is traveling, how aggressively it’s accelerating or decelerating, the RPMs and the fuel consumption. We can hook into the engine bus environment. We also put in a GPS unit. There are sensors on the engine and on components like starter motors and seat belts.” The analysis of this data is a main focus for UPS and has resulted in improved safety management, fuel efficiency, environmental impact, and customer satisfaction. One carrier reported that his deliveries increased from 90 a day to 120 a day. UPS drivers have seen an increase in salary as the company’s revenue multiplies.

The $1 billion UPS invests in technology per year is producing results, but what are the downfalls of telematics and other advancements? The union representing UPS workers has already set forth some demands: drivers cannot be monitored without being informed and cannot be disciplined “based solely on data.” One driver noted that it “does feel like big brother.”

Issues of security, privacy, accuracy, capacity, and the growth of software substitution in the workplace are all matters that need to be examined as IoT explodes. As IoT matures, it is wise for companies, especially those in manufacturing and logistics, to pay close attention. As reported by Gartner, by 2020, “Economic value-add (which represents the aggregate benefits that businesses derive through the sale and usage of IoT technology) is forecast to be $1.9 trillion across sectors.” With the increased possibility, reach, and data of the IoT will come complex decisions and opportunities for businesses.

Fronetics’ Kate Lee has written extensively about the Internet of Things and the supply chain. Her article, How the Internet of Things will change your world, was published in the Quarter 1, 2015 edition of Supply Chain Quarterly.

by Fronetics | Mar 9, 2015 | Blog, Supply Chain

The Internet of Things (IoT) “represents the convergence of the physical and digital worlds. Physical objects are equipped with technology that enables the object to send and receive information via fixed-wire or wireless communications links to the Internet, and to then transmit information in one form or another.”

In 2003 there were an estimated 500 million IoT-connected devices. By 2010 there were 12.5 billion connected devices. Morgan Stanley estimates that there will be 75 billion IoT devices by 2020. Cisco makes a more conservative estimate 50 billion. Whether it is Morgan Stanley or Cisco who proves correct, what is clear is that the number of internet connected devices is growing exponentially.

Consumer convenience is often the focus of the IoT. However, the capabilities of the IoT reach far beyond consumer convenience. The IoT is game-changing for the logistics and supply chain industries. The IoT delivers the visibility and data necessary for supply chain optimization.

One Network Enterprises, a supply chain technology provider, offers this supply chain example:

“[The IoT] refers to data communication among a large range of assets or devices—from your fridge to your oven or, more pertinently, from your inventory to its container, from the container to the carrier, from the pallet to the warehouse. The more your assets can ‘speak’ to one another and share data, the more they can work together to help you improve your processes.”

The IoT has already moved into industrial environments including warehouses and manufacturing plants.

Examples of where the IoT is already having an impact on supply chains include:

- Transparency and visibility

- Proactive replenishment

- Predictive maintenance

- Reduction in asset loss

- Manufacturing flow management

- Product development and commercialization.

- Risk management.

- Operational efficiency

- Improved fleet management

The transparency and end-to-end visibility afforded by the IoT creates new opportunities that supply chain professionals can leverage in order to optimize supply chains and generate value. It is important to look at the potential of the IoT now and not later. The amount of data alone that is generated by the IoT creates a paradigm shift. Companies that embrace the Internet of Things and identify where and how it can play a role for their business will move forward and leave those who do not behind.

The Internet of Things has the potential to change everything.

To learn more about how the Internet of Things has and will continue to impact the supply chain see the full article How the Internet of Things will change your world on Supply Chain Quarterly. The article includes a focus on Internet of things and the warehouse.

by Fronetics | Mar 9, 2015 | Blog, Supply Chain

The Internet of Things (IoT) “represents the convergence of the physical and digital worlds. Physical objects are equipped with technology that enables the object to send and receive information via fixed-wire or wireless communications links to the Internet, and to then transmit information in one form or another.”

In 2003 there were an estimated 500 million IoT-connected devices. By 2010 there were 12.5 billion connected devices. Morgan Stanley estimates that there will be 75 billion IoT devices by 2020. Cisco makes a more conservative estimate 50 billion. Whether it is Morgan Stanley or Cisco who proves correct, what is clear is that the number of internet connected devices is growing exponentially.

Consumer convenience is often the focus of the IoT. However, the capabilities of the IoT reach far beyond consumer convenience. The IoT is game-changing for the logistics and supply chain industries. The IoT delivers the visibility and data necessary for supply chain optimization.

One Network Enterprises, a supply chain technology provider, offers this supply chain example:

“[The IoT] refers to data communication among a large range of assets or devices—from your fridge to your oven or, more pertinently, from your inventory to its container, from the container to the carrier, from the pallet to the warehouse. The more your assets can ‘speak’ to one another and share data, the more they can work together to help you improve your processes.”

The IoT has already moved into industrial environments including warehouses and manufacturing plants.

Examples of where the IoT is already having an impact on supply chains include:

- Transparency and visibility

- Proactive replenishment

- Predictive maintenance

- Reduction in asset loss

- Manufacturing flow management

- Product development and commercialization.

- Risk management.

- Operational efficiency

- Improved fleet management

The transparency and end-to-end visibility afforded by the IoT creates new opportunities that supply chain professionals can leverage in order to optimize supply chains and generate value. It is important to look at the potential of the IoT now and not later. The amount of data alone that is generated by the IoT creates a paradigm shift. Companies that embrace the Internet of Things and identify where and how it can play a role for their business will move forward and leave those who do not behind.

The Internet of Things has the potential to change everything.

To learn more about how the Internet of Things has and will continue to impact the supply chain see the full article How the Internet of Things will change your world on Supply Chain Quarterly. The article includes a focus on Internet of things and the warehouse.

by Fronetics | Dec 17, 2014 | Big Data, Blog, Data/Analytics, Internet of Things

The Internet of Things (IoT) is ubiquitous. Because of this it can seem abstruse. Puneet Mehta does a great job of putting the concept in layman’s terms: “[A] plethora of “dumb” objects becom[ing] connected, sending signals to each other and alerts to our phones, and creating mounds of “little data” on all of us that will make marketers salivate.”

The mounds of data created by the advent of the IoT does not just make marketers salivate. Gartner predicts that the IoT will add $1.9 trillion in value to the economy by 2020. Looking ahead, Cisco estimates that the IoT will create over $14 trillion in value over the next 10 years.

In 2003 there were 500 million connected devices. Cisco estimates that this number will increase to 50 billion by 2020. Morgan Stanley believes this number will be higher – it estimates there will be 75 billion IoT devices by 2020.

“Dumb” objects are becoming connected; the physical and digital worlds are converging. Mounds of data are being collected.

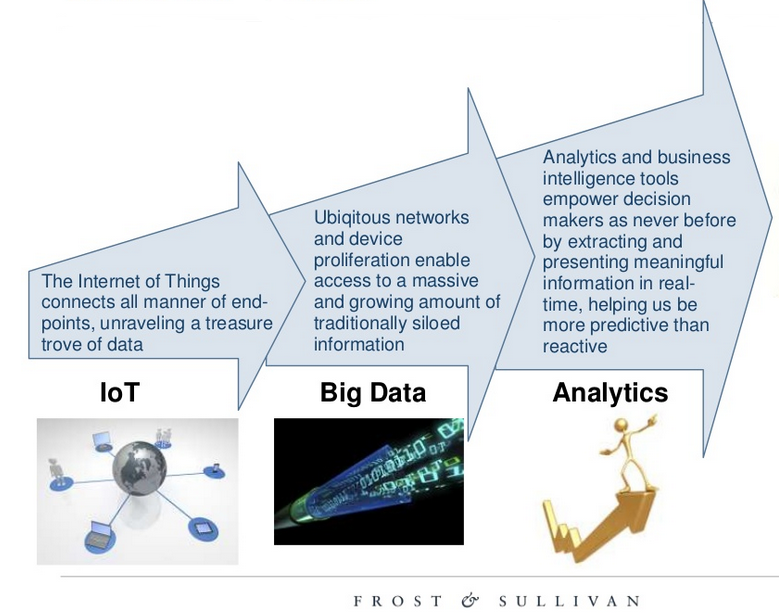

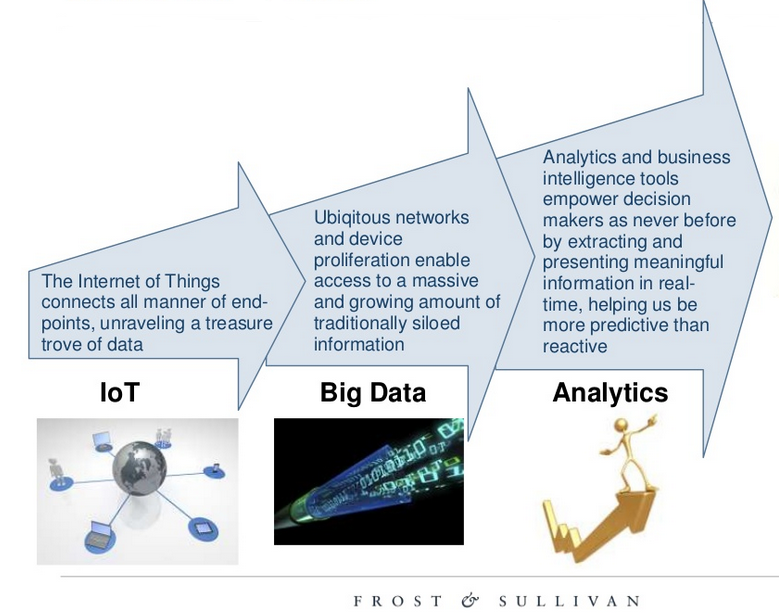

IoT and Big Data

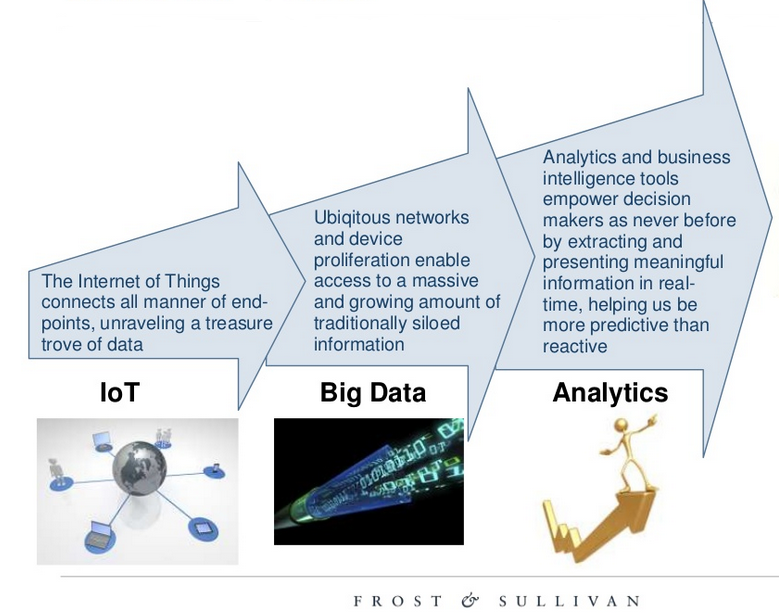

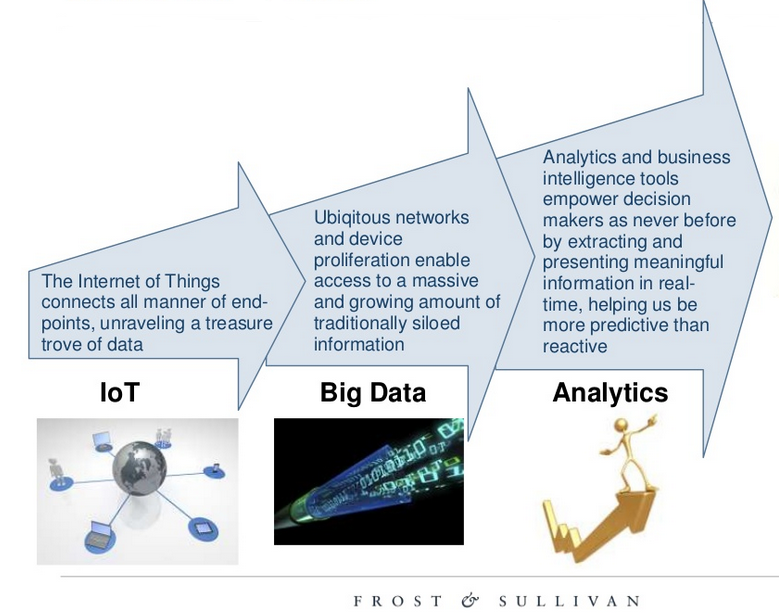

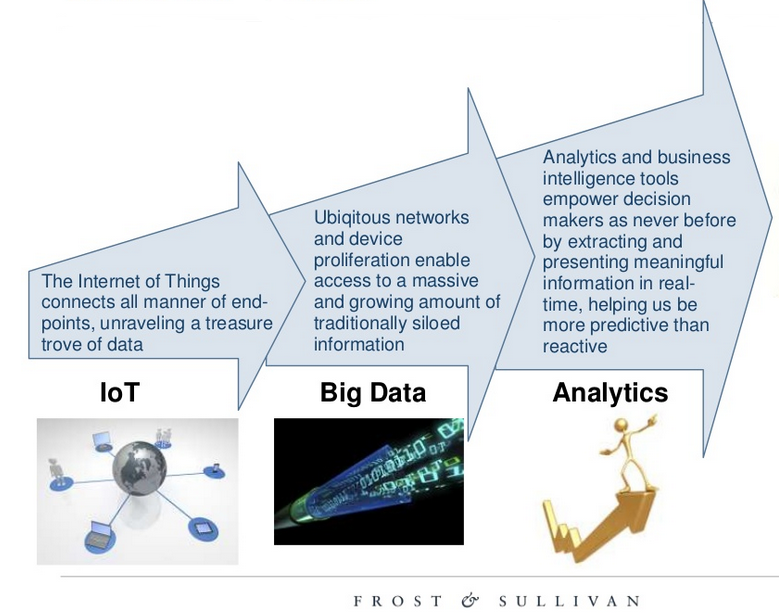

Mukul Krishna, from Frost & Sullivan, presented a simple incremental view of the relationship between the IoT and big data. In short, IoT devices can be thought of as data sources. These data sources generate an incredible amount of data – much of which was previously not accessible. The information and insights from big data allow for better decision-making.

The amount of big data created each day in 2012 was 2.5 exabytes (2.5×1018). In 2014 the amount of data were created each day was 2.3 zettabytes (2.3×1021),

An IDC forecast shows that the Big Data technology and services market will grow at a 27% compound annual growth rate (CAGR) to $32.4 billion through 2017 – or at about six times the growth rate of the overall information and communication technology market.

The need for a plan

McKinsey & Company offer sage advice: put a plan in place.

The payoff from joining the big-data and advanced-analytics management revolution is no longer in doubt. The tally of successful case studies continues to build, reinforcing broader research suggesting that when companies inject data and analytics deep into their operations, they can deliver productivity and profit gains that are 5 to 6 percent higher than those of the competition. The promised land of new data-driven businesses, greater transparency into how operations actually work, better predictions, and faster testing is alluring indeed.

But that doesn’t make it any easier to get from here to there.

So how does one get from here to there?

The answer, simply put, is to develop a plan. Literally. It may sound obvious, but in our experience, the missing step for most companies is spending the time required to create a simple plan for how data, analytics, frontline tools, and people come together to create business value. The power of a plan is that it provides a common language allowing senior executives, technology professionals, data scientists, and managers to discuss where the greatest returns will come from and, more important, to select the two or three places to get started.

What impact has the IoT and big data had on your company? Does your company have a plan in place?

by Fronetics | Dec 17, 2014 | Big Data, Blog, Data/Analytics, Internet of Things

The Internet of Things (IoT) is ubiquitous. Because of this it can seem abstruse. Puneet Mehta does a great job of putting the concept in layman’s terms: “[A] plethora of “dumb” objects becom[ing] connected, sending signals to each other and alerts to our phones, and creating mounds of “little data” on all of us that will make marketers salivate.”

The mounds of data created by the advent of the IoT does not just make marketers salivate. Gartner predicts that the IoT will add $1.9 trillion in value to the economy by 2020. Looking ahead, Cisco estimates that the IoT will create over $14 trillion in value over the next 10 years.

In 2003 there were 500 million connected devices. Cisco estimates that this number will increase to 50 billion by 2020. Morgan Stanley believes this number will be higher – it estimates there will be 75 billion IoT devices by 2020.

“Dumb” objects are becoming connected; the physical and digital worlds are converging. Mounds of data are being collected.

IoT and Big Data

Mukul Krishna, from Frost & Sullivan, presented a simple incremental view of the relationship between the IoT and big data. In short, IoT devices can be thought of as data sources. These data sources generate an incredible amount of data – much of which was previously not accessible. The information and insights from big data allow for better decision-making.

The amount of big data created each day in 2012 was 2.5 exabytes (2.5×1018). In 2014 the amount of data were created each day was 2.3 zettabytes (2.3×1021),

An IDC forecast shows that the Big Data technology and services market will grow at a 27% compound annual growth rate (CAGR) to $32.4 billion through 2017 – or at about six times the growth rate of the overall information and communication technology market.

The need for a plan

McKinsey & Company offer sage advice: put a plan in place.

The payoff from joining the big-data and advanced-analytics management revolution is no longer in doubt. The tally of successful case studies continues to build, reinforcing broader research suggesting that when companies inject data and analytics deep into their operations, they can deliver productivity and profit gains that are 5 to 6 percent higher than those of the competition. The promised land of new data-driven businesses, greater transparency into how operations actually work, better predictions, and faster testing is alluring indeed.

But that doesn’t make it any easier to get from here to there.

So how does one get from here to there?

The answer, simply put, is to develop a plan. Literally. It may sound obvious, but in our experience, the missing step for most companies is spending the time required to create a simple plan for how data, analytics, frontline tools, and people come together to create business value. The power of a plan is that it provides a common language allowing senior executives, technology professionals, data scientists, and managers to discuss where the greatest returns will come from and, more important, to select the two or three places to get started.

What impact has the IoT and big data had on your company? Does your company have a plan in place?