by Jennifer Hart Yim | Aug 28, 2020 | Blog, Logistics, Talent

Digital supply chain management requires a whole new set of skills. From an omnichannel mindset to enterprise IT use, here’s what defines success of logistics leaders.

Editor’s note: This is the final guest post in a three-part series by Kate Began of Polycase.

It took some time for the tech revolution to hit the logistics industry, but now that it’s here, everything is changing rapidly. Suddenly, it’s all about omnichannel commerce, digital transparency, and advanced analytics (among many other trends). And as the world of logistics changes, the leaders of the logistics industry will have to develop new skills with which to navigate it.

What skills will the logistics leaders of tomorrow (and today) need to effectively manage the new realities of the supply chain? These seven areas will define the success of a business’s digital supply chain operations and separate the organizations that can fuel their success with technology from the ones who must struggle to adapt to it.

To manage the digital supply chain, here are 7 skills logistics leaders need

1. Ability to adapt

Twenty-first-century logistics will require its leaders and managers to constantly learn how to use new tools and react to changing market conditions. The new logistics professional has to keep a steady hand at the tiller during times of big change and use solid data analysis to find the right path forward, even when market conditions aren’t perfectly clear.

Flexibility will be incredibly important in implementing the most cutting-edge logistics technologies such as logistics blockchain, automation, and IoT. But it’s also critical to the daily operations of logistics when it comes to filling in transportation gaps and devising on-the-spot solutions to problems. The logistician who can harness the new digital tools for these ends will be formidable indeed.

2. Proactive curiosity

Adaptation is easier when a business pursues the right new tech, rather than waiting for it to come to them. Good logistics management will also increasingly require a commitment to proactively keeping up with technological and industry trends.

The 21st-century logistician has to be well-versed in everything from industry white papers to what’s trending among logistics professionals on LinkedIn. They need to be able to spot key trends and prepare for them so that businesses can stay ahead of the curve and not get blindsided by major changes.

3. Strategic thinking

Thinking two steps ahead can be tough when the business environment is changing so rapidly, but that’s what the new millennium logistics professional has to do. They have to take the long view and keep a business’s core principles at heart when creating plans for the future.

The need for strategic thinking also means tempering enthusiasm for new tech with good judgment and analytical rigor. Unwise investment in unproven or poorly-implemented technologies can be just as disastrous for a supply chain as lagging behind in tech, so as always, there’s no substitute for clear-eyed analysis and solid planning.

4. Enterprise IT use and procurement

Enterprise IT is an increasingly critical skill set for logistics professionals. Almost all logistics companies now use enterprise IT software, such as ERP suites, to manage their supply chains, and digital logistics professionals must often make decisions about procurement and implementation of these sophisticated software products.

Knowing how to get all of these disparate technologies to work together can be an even more difficult and necessary skill. Cross-platform performance can require knowledge of APIs and other tools that have been foreign to the logistics industry until now. Much of today’s logistics software is also cloud-based, so it’s also useful to know the basic principles of SaaS architecture and cloud workflows.

5. Project management

Today’s logistics professional often has to assume leadership roles on major projects. In order to be an effective leader, they must be skilled at tasks such as:

● Identifying the strengths and weaknesses of team members and delegating tasks to them effectively

● Working with upper management to structure project calendars and deadlines

● Estimating costs and planning for the budgeting and deployment of resources

● Identifying key technological tools for driving project success

● Creating transparency at all levels of the project by deploying appropriate digital tools such as IoT sensors and shipment tracking

Twenty-first century logistics concentrates more operational and computing power in every employee’s hand than ever before—but that power only produces results when employees are managed properly by a competent project manager.

6. People skills

Speaking of managing people, logistics professionals must also remember that not everything in the digital supply chain is run by circuits in a plastic enclosure. On the contrary, old-fashioned people skills are as necessary in the logistics industry as they’ve ever been—perhaps even more so.

Supply chains now have more stakeholders than ever, and effective management requires communicating effectively with a wide variety of personalities and roles. A good supply chain manager will be able to use 21st-century communication tools to connect people and make sure everyone’s on the same page, but they must also be fluent in the “soft skills” of empathy and interpersonal contact.

Empathy also requires a zero-tolerance mindset for regressive elements like sexism and racism in the digital workplace. Logistics may not be HR, but much of the everyday work of combating prejudice is done at the ground level by managers. For a business to attract and retain the best talent, they must pursue an egalitarian vision that makes work a great place to be for everyone.

7. An omnichannel mindset

Business, both B2C and B2B, now flows through a multitude of channels. That means that for the 21st-century logistics professional, an omnichannel mindset is a must-have. Whoever your customers are, they’re now on mobile phones, tablets and even voice command services like Alexa. A business’s platform and its logistics operations must reflect this new reality.

The rise of omnichannel commerce means that logistics operations must find a way to interlock with every channel that’s important to a business. That means keeping in mind how channels such as brick-and-mortar stores, traditional online sales and mobile shopping are all distinct but interrelated and managing them with an eye toward keeping every part of the complex interplay running smoothly.

There’s no running away from the oncoming wave of disruptive technology in the digital supply chain, so the only option is to ride it. Logistics professionals who are flexible, curious and empathetic will have the best capability for managing these new realities and turning them into a profitable and efficient future.

Kate Began serves as the Sales and Marketing Manager for Polycase. She oversees the customer service representatives, assists with product development, and leads the marketing efforts from the Avon, Ohio headquarters.

Read more:

When short on time, updating old blog posts for SEO makes a lot of sense

5 ways Covid-19 has already changed American manufacturing

Stop hibernating: You’re missing out on company blog benefits

by Fronetics | Dec 14, 2017 | Blog, Logistics, Supply Chain

Here are our most-viewed blog posts from 2017 about the supply chain and logistics industries, including posts about some of the largest supply chain companies in the world, Starbucks and Amazon.

Throughout the year, we write innovative posts to help readers stay in the know with the latest news and happenings to the supply chain & logistics industries. These posts provide insightful and relevant information from thought leaders, current trends, and tips to stay ahead of your competitors. Here’s a look at our most popular posts from this year.

Here are our top 10 supply chain and logistics posts of 2017.

1. Supply Chain Putting the ‘Star’ in Starbucks

Starbucks’ closely managed supply chain may be the key to the premium coffee giant’s success. The international coffee giant has widely studied and acclaimed supply chain management practices, which, according to some, make Starbucks’ coffee and customer experience superior to those of its competitors. Read more.

2. 8 Must-Follow Logistics & Supply Chain Blogs for 2017

Supply chain professionals should be following these eight blogs to keep up with the latest industry news and happenings in the coming year. They cover a range of topics, from technology to strategy, and feature thought leadership by some of the brightest minds in the field. Read more.

3. Top 5 Trends to Know to Compete with Amazon’s Supply Chain

Supply chains must accept that they cannot equal the power of Amazon’s supply chain without embracing new trends. While supply chain entities struggle to stay competitive with the e-commerce giant, more organizations will look for ways to eliminate inefficiencies and boost operations. Fortunately, these five trends may alleviate some of the strains of competition by giving supply chain partners an advantage in the global market. Read more.

4. 5 Podcasts for the Supply Chain and Logistics Professionals

These podcasts bring the latest news and thought leadership in the supply chain and logistics industries right to your earbuds. Podcast’s popularity has skyrocketed since the smartphone became as necessary as car keys, giving you to-the-minute facts and information, right in the palm of your hand. If you’re looking to increase your podcast listening, here are five that highlight topics of interest to supply chain and logistics professionals. Read more.

5. What’s the Difference between Supply Chain Management and Logistics (Infographic)

Argentus’ infographic sheds light on the differences between these often-confused functions. Both Logistics and the wider Supply Chain are vital to how companies run today, but the two are still so often confused. We put together an infographic outlining some of the key differences and points of overlap between them. Read more.

6. 5 Books Every Supply Chain Professional Should Read

Add these books to your reading list to stay on top of industry trends and jump start your professional development. Read more.

7. What are the Supply Chain Impacts of Amazon’s Whole Foods Acquisition?

Amazon’s foray into the grocery space has larger implications for its overall strategy, and the possible benefits for the eCommerce goliath are diverse. Big news out of the grocery retail world as Amazon has announced its acquisition of major organic foods retailer Whole Foods Market – for an eye-popping $13.7 billion sale price that doesn’t look so massive given Amazon’s $136 billion sales volume in 2016. Read more.

8. Packaging Trends to Watch in 2017

Will sustainability trends from the consumer packaging industry have an impact on electronics manufacturing this year? Packaging trends suggest a wide range of startups, researchers, and big companies are committed to finding solutions that match the buzzwords du jour — sustainable, bio-degradable, natural, and eco-friendly. Read more.

9. The Top 3 Logistics and Supply Chain Blogs for 2017 – Readers’ Choice!

Our readers voted Morai Logistics, Women in Trucking, and the Oracle Supply Chain Management Blog as the top 3 logistics and supply chain blogs of 2017. Every year we ask our readers to vote for the best industry blogs. The results are always interesting — there’s really a lot of great supply chain and logistics content out there, plus it’s great to see where our readers are finding value. Read more.

10. The State of Supply Chains: The Supply Chain Has Gone Digital (Infographic)

2016 was the year of the digital supply chain — here’s a look at how things changed. The digital transformation has already reached most supply chain organizations. Per GT Nexus, 75% of executives surveyed recognized the digital supply chain as an important factor for the next five years. Read more.

Related posts:

by Jennifer Hart Yim | Sep 14, 2017 | Blog, Logistics, Strategy, Supply Chain

![The State of Supply Chains: The Supply Chain Has Gone Digital [Infographic]](https://fronetics.com/wp-content/uploads/2024/10/virtual-reality.jpg)

by Jennifer Hart Yim | Jan 23, 2017 | Big Data, Blog, Data/Analytics, Logistics, Strategy, Supply Chain

2016 was the year of the digital supply chain — here’s a look at how things changed.

This guest post comes to us from Adam Robinson, director of marketing for Cerasis, a top freight logistics company and truckload freight broker.

2016 marched onward with a drive to improve the use of digital technology throughout the supply chain. In our first supply chain trends post, we surmised the previous year’s trends would continue. However, this prediction proved to only touch on how important the digital supply chain would become.

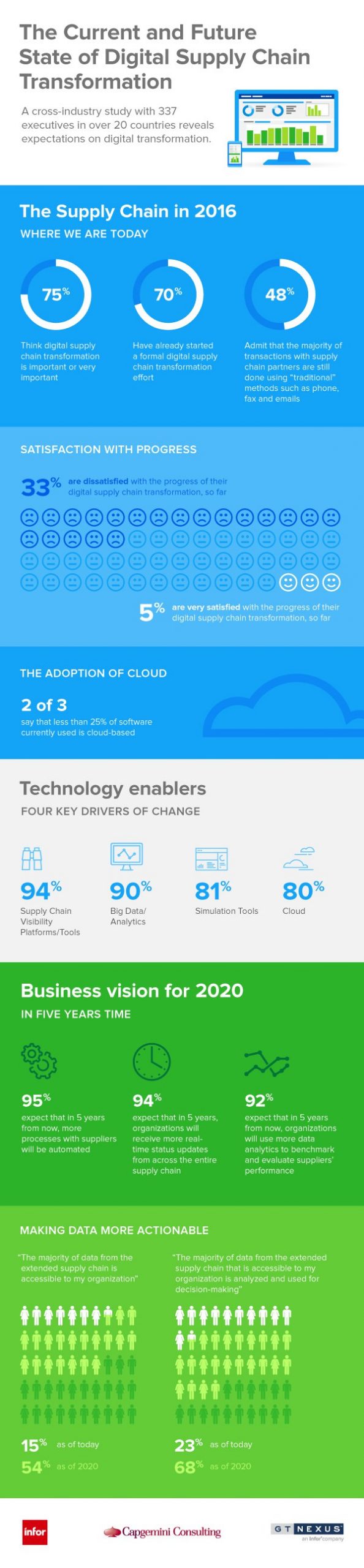

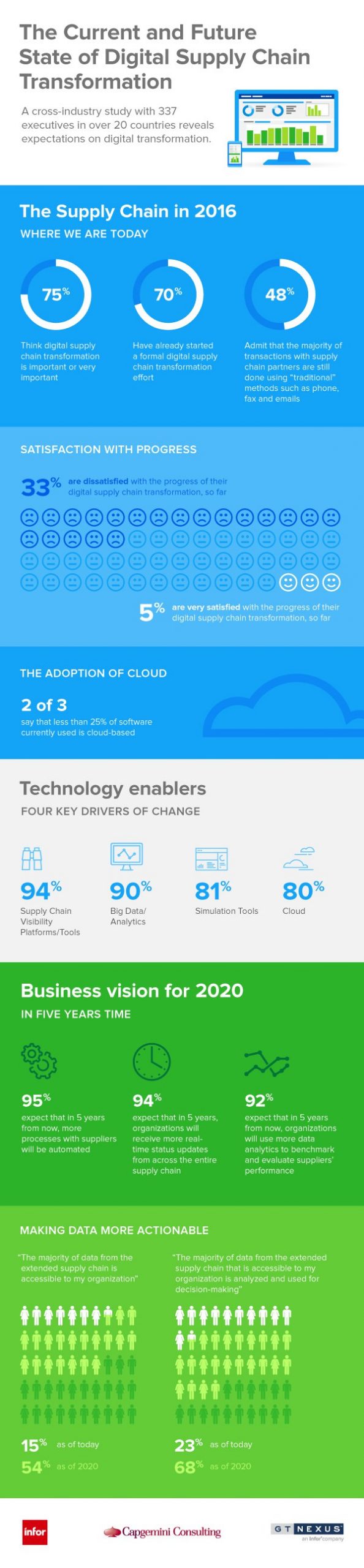

Within four months, the digital transformation had already reached most supply chain organizations. Per GT Nexus, 75% of executives surveyed recognized the digital supply chain as an important factor for the next five years. Meanwhile, 70% have also started processes to implement digital supply chain technologies throughout their companies.

Unfortunately, many supply chain entities continue to hope for a better tomorrow. In other words, the digital supply chain transformation has only been rated as very satisfying for 5% of respondents. In addition, just less than half (48%) of respondents report continued use of traditional technologies exclusively, which include the following:

- Fax machines

- Manual order entry and review

- Land-line phones, not voice over internet protocol (VoIP), which reduces overall costs and downtime

- Email, although beneficial, is susceptible to internet connectivity issues, security breaches and other problems

- Chaotic picking protocols

This infographic, created by GT Nexus, also shows other ways the digital supply chain evolved in 2016.

(Made with Canva)

Essentially, the digital supply chain is essential to gaining and maintaining competitive advantage. Digital technologies, reports Richard Howells of Forbes, including Big Data, analytics, the Internet of Things, social media, and point-of-sale reporting, enable business to know more about consumer needs and wants than ever before. Consequently, they can more accurately respond to changes in product demand across large distances and within infinitesimally small time frames.

Supply chain execs retained fundamentals throughout change.

Innovation is the driving force behind change and improvement in the modern world. Supply chains must evolve to meet an increasing number of omnichannel sales, and technologies must be integrated within existing systems to reach maximum efficiency and productive value.

As explained by Grant Marshbank of VSC Solutions, “The rate of change is not going to slow down. Technology will only delivery […] if it’s implemented with strategy and operations that adhere to best practices.”

Marshbank’s words highlighted the need to focus on fundamental concepts while responding to changes and improvements in the supply chain. For example, an optimized supply chain is good, but it opens more opportunities for errors. Simply putting all an organization’s proverbial eggs into one basket may be risky if appropriate auditing and review measures are not undertaken to ensure continued compliance and accuracy in all orders.

Change is a necessity for businesses, including the supply chain, to grow and expand. Yet many destructive forces can severely undermine a company’s progress. Bad weather, poor hiring practices or inefficient maintenance of consumers’ financial data can decimate a company. However, the response to hindrances in 2016 continued to showcase the importance of fundamental concepts, asserts Ryder, which include the following:

- Continually seeking the fastest, most cost-effective means of transporting products to consumers, including enhanced delivery optins.

- Expansion of global footprint while adhering to local, state, federal and international requirements

- Keeping companies accountable and focused on giving back to their domestic partners through reshoring or nearshoring

- Working with more outside agencies, also highlighted by Samantha Carr of Business 2 Community, including crowd-sourced logistics, warehouse optimization and outsourcing, and greater use of cloud-computing

Augmented reality found its place among consumers.

Augmented reality sounded amazing and far-fetched early in 2016, but the year has shown it to be one of the most successful product in existence. There tends to be more acceptance of technologies in the workplace once consumers can identify how they work.

For example, new hires are likely to pick up tablet-based systems more easily since they have been using them recreationally for some time. Essentially, the virtual-reality (VR), which is the precursor to augmented reality, hype of the 2016 Christmas shopping season is making more people excited about this new way to “see the world.”

While the VR hype may seem like it only emerged for Christmas, think about one of the hottest games of 2016, Pokémon Go! This app was built on augmented reality, combining the digital and physical worlds into one interactive environment. This technology, reports JOC.com, will be a key to practically eliminate extensive training courses and repair time requirements throughout the supply chain.

Ultimately, it translates into greater use of augmented reality in supply chains, which is growing by 100% annually, reports Barcoding Incorporated.

What’s next?

Clearly, technology dominated the conversation for 2016, but there are also changes in how supply chains operate that require a more in-depth discussion as well. In the next post of this series, we discuss the impact of artificial intelligence, agile processes and procurement expansion on the supply chain of 2016.

Related posts:

by Fronetics | Jul 6, 2015 | Big Data, Blog, Data/Analytics, Internet of Things, Logistics, Marketing, Strategy, Supply Chain

The battle for competitiveness in the cloud.

In this age of radical transformation for supply chains, top companies are tying together prevailing concepts, like big data and the Internet of Things (IoT), with cloud-based computing. Supply chains are being reimagined as digital networks that track not only physical goods, but also people, data, and money. As such, global technology giants continue to invest heavily in cloud computing.

The Chinese e-commerce company Alibaba Group Holding, Ltd. recently announced that it is launching its first international venture – a cloud computing hub in Silicon Valley, proving the fierce competition for market share is stiffening both globally and on the home turf. Notably, all five top-ranked companies listed by the 2013 Strategy & Global Information, Communications and Technology 50 study bet their future on cloud technologies. The companies (IBM, Microsoft, SAP, Oracle, and Cisco Systems) could not, until recently, be perceived as direct competitors, and now they all wield cloud-based portfolios as their competitive weapon of choice.

Analysts note:

The industry leaders are seeking dominant positions, wanting to become the kings of the cloud. As a group, they are putting distance between themselves and the second tier of followers.

For further proof data analytics is driving competition for cloud customers, we can look to a new report by Market & Research that shows data analytics and cloud computing are expected to record a combined growth of 26% annually over the next five years. The implication is that demand is hardly going to lessen as an increasing number of organizations need cloud solutions to manage and store the huge amounts of data that they use to transform manufacturing processes, fine-tune supply chains, forecast customer behavior, and optimize inventories – to name a fraction of potential applications.

And cloud-based computing is even moving the needle of interest in industries that seem inherently averse to making data and information more easily accessible. For example, concerns about data encryption, auditing controls, and transparency have stymied the adoption of cloud-based computing in the financial industry. According to a report by the Cloud Security Alliance, only 28% of American financial institutions have a cloud-based strategy in place, but as a sponsor of the report, Dr. Chenxi Wang, vice president of Cloud Security and Strategy at CipherCloud points out:

Cloud has made solid inroads in this industry with many firms looking to harnessing the power of cloud. There’s plenty of room for growth, particularly for providers who can fill the void for the auditing and data protection controls that are at the top of respondents’ cloud wish list.

Meanwhile, the public cloud services market alone could grow into a $100 billion industry by 2017, according to researcher IDC. Is your business prepared to leverage cloud computing for its supply chain activities? It’s coming, ready or not.

Fronetics Strategic Advisors is a leading management consulting firm. Our firm works with companies to identify and execute strategies for growth and value creation.

Whether it is a wholesale food distributor seeking guidance on how to define and execute corporate strategy; a telematics firm needing high quality content on a consistent basis; a real estate firm looking for a marketing partner; or a supply chain firm in need of interim management, our clients rely on Fronetics to help them navigate through critical junctures, meet their toughest challenges, and take advantage of opportunities. We deliver high-impact results.

We advise and work with companies on their most critical issues and opportunities: strategy, marketing, organization, talent acquisition, performance management, and M&A support.

We have deep expertise and a proven track record in a broad range of industries including: supply chain, real estate, software, and logistics.

![The State of Supply Chains: The Supply Chain Has Gone Digital [Infographic]](https://fronetics.com/wp-content/uploads/2024/10/virtual-reality.jpg)