by Jennifer Hart Yim | Jun 5, 2014 | Blog, Manufacturing & Distribution, Strategy, Supply Chain

This article is part of a series of articles written by MBA students and graduates from the University of New Hampshire Peter T. Paul College of Business and Economics.

By now we have all heard the story of GM’s faulty ignition switches that are being linked to thirteen deaths and thirty one front-end collisions. The ignition switches in car models: Chevy Cobalt; Chevy HHR; Pontiac G5; Pontiac Solstice; Saturn Ion; and Saturn Sky, lacked the torque specs required by GM engineers. Heavy key chains, bumpy roads, or an accidental knee hit were all reasons reported that could cause the ignition switch to rotate to the off or idle position. Once this happened, the driver would lose control and the air bags would fail to deploy if a front end collision occurred. A total of 2.6 million vehicles were recalled, of that 2.2 million were in the United States. For this type of recall, GM was not requiring vehicles to go back to the manufacturer or be disposed. Rather, a more robust key ignition was distributed to all authorized GM dealerships and customers were told to bring their cars to the local dealership and a new ignition switch would be put in for them.

Despite the massive recall and all the negative publicity that goes along with such an event, GM still posted positive numbers in their quarterly earnings. GM posted an operating income of $0.5 billion for 1Q14, which is included the $1.3 billion recall-related charge. Furthermore, GM controlled approximately 17% of the U.S. market share. After the ignition switch incidents started to gain traction, GM swore to reorganize their global engineering department, and they did. So, if GM’s sales profitability is surviving, their negative press contained, and their market share intact, what exactly went wrong?

Two-thirds of General Motors automotive costs in 2014 are from supplier sourced parts. However, this was not always the situation. Back in 1999, GM underwent an extensive effort to disassemble their vertical integration in hopes of reducing overall costs. At this time, Delphi Automotive was owned by GM, but separated during the same year. For decades, GM was Delphi’s only customer, and even when Delphi executives knew GM was going to make them a public company, they were only able to move 22% of their business to other customers. When GM officially made Delphi a public company, 82.3% of their shares went to GM shareholders. That means that only 17.7% of Delphi was sold to public investors. In order to survive as a company, Delphi had to start making cost reduction decisions. To do this, companies often lay off employees and make cheaper parts, Delphi was no different. Now during this same time period, GM executives were focused on focused on costs reductions and were driven by numbers, hence the selling off of Delphi. It should be noted that if a company sells off their single largest parts supplier, fully aware that the move may cause the supplier to go belly up, there will be some strained relationships. Delphi was now thrown into a position where they must compete with other parts suppliers for GM’s business. An important part of the deal GM made when selling off Delphi was to keep all current supplier contracts. In addition, GM gave Delphi the opportunity to match any competitor’s bid until 2002. The earliest model of a recalled GM car was 2003.

Strained supplier relationships are not ideal for business, but should not affect the quality of a product, such as an ignition switch. Let’s fast forward to 2008. Delphi had declared bankruptcy three years prior and GM was beginning to pull them out of their financial burden. A contract was found between GM and Delphi that was drafted in 2008. The document is a little difficult to follow, but there are a few interesting lines in Section 5.09 Product Liability Claims. It appears that, GM said they would share the blame with Delphi for any claims against them. However, GM would not be held responsible if one of Delphi’s parts, or a part made for Delphi by a third party, fails. The contract continues on to say that GM would pay any legal fees if a claim was made against Delphi, but Delphi must defend GM through a potential lawsuit. This contract was drafted and signed in 2008, during which Delphi was bankrupt, so it appears they had little negotiating power.

This raises concerns specifically about the ignition switch specs. It came out that GM officials knew the ignition switch they purchased from Delphi was not up to their standards. After some more research, an email transaction between Delphi officials in regards to the plunger, the vital part that holds the key slot in place with a spring, and the ignition switch. At the end of the document, the original engineer drawings are attached. From the technical drawings it can be seen that Delphi did in fact outsource the design specs, and possibly the manufacturing, for the plunger design. Another document, that was preceding the email transaction, appears to inform GM that the plunger part was changed and the responsibility of the supplier is “closed”. This could have been a legal move meant to save Delphi if any claims were made related to these parts.

After all of this evidence, where does the blame lie? It would appear that GM used their powers to force Delphi into a contract that held them responsible for any claims against their products. While Delphi did warn GM that the torque requirement for their ignition switch did not meet GM’s requirement, it is unclear whether or not a verbal warning will play into the legal battle. This case is currently ongoing, and it will be interesting to see how it plays out.

Connor Harrison holds a B.S.M.E and MBA from the University of New Hampshire.

by Fronetics | Jan 28, 2014 | Blog, Logistics, Marketing, Social Media, Strategy, Supply Chain

Social media and social media technologies have rapidly changed the way companies do business across every type of industry. Social media brings businesses closer to their customers, provides a platform for communication and building thought leadership, and when executed properly it can help drive business and provide a significant return on investment. Businesses that ignore social media forgo these opportunities and miss out on potential business development opportunities.

According to The McKinsey Global Institute, 90 percent of companies who were using social media or social technologies for their business reported benefiting from their efforts in 2012. And how could they not? Utilizing a social media technology can increase a company’s reach into their industry and provides optimal channels for communicating with their customers.

The supply chain and logistics industries are two industries that have not adopted social media and social technologies as quickly as others. Business owners in these have a difficult time seeing past the “social” aspect of these technologies and understanding what the implied benefits of using social technologies can mean for their business. Many find themselves asking “why?” instead of “how?” when considering implementing a social media strategy, and ultimately allocate resources elsewhere within their businesses.

The Fronetics white paper, Social Media and the Logistics and Supply Chain Industries: Why Not Participating is a Risk You Can’t Afford to Take, provides meaningful insights into why supply chain and logistics companies need to be using social media and the value of these technologies. Learn how to move past the barriers to adoption, how to leverage social technologies, and learn what a social presence can mean for your business.

To learn more about why your business needs social media, download Social Media and the Logistics and Supply Chain Industries: Why Not Participating is a Risk You Can’t Afford to Take today.

by Fronetics | Jan 28, 2014 | Blog, Logistics, Marketing, Social Media, Strategy, Supply Chain

Social media and social media technologies have rapidly changed the way companies do business across every type of industry. Social media brings businesses closer to their customers, provides a platform for communication and building thought leadership, and when executed properly it can help drive business and provide a significant return on investment. Businesses that ignore social media forgo these opportunities and miss out on potential business development opportunities.

According to The McKinsey Global Institute, 90 percent of companies who were using social media or social technologies for their business reported benefiting from their efforts in 2012. And how could they not? Utilizing a social media technology can increase a company’s reach into their industry and provides optimal channels for communicating with their customers.

The supply chain and logistics industries are two industries that have not adopted social media and social technologies as quickly as others. Business owners in these have a difficult time seeing past the “social” aspect of these technologies and understanding what the implied benefits of using social technologies can mean for their business. Many find themselves asking “why?” instead of “how?” when considering implementing a social media strategy, and ultimately allocate resources elsewhere within their businesses.

The Fronetics white paper, Social Media and the Logistics and Supply Chain Industries: Why Not Participating is a Risk You Can’t Afford to Take, provides meaningful insights into why supply chain and logistics companies need to be using social media and the value of these technologies. Learn how to move past the barriers to adoption, how to leverage social technologies, and learn what a social presence can mean for your business.

To learn more about why your business needs social media, download Social Media and the Logistics and Supply Chain Industries: Why Not Participating is a Risk You Can’t Afford to Take today.

by Fronetics | Dec 2, 2013 | Blog, Marketing, Social Media, Strategy

Not too long ago I did not use Twitter and I relished being able to say that I had never sent a Tweet. I believed Twitter was not applicable to me – I don’t follow celebrity gossip and whereabouts, I don’t like the idea of sharing my personal thoughts and experiences with 232 million strangers, and I have yet to take a “selfie” (much less share it with said 232 million strangers). In short, I didn’t use Twitter because I did not understand Twitter and I had no idea of its value. When I finally decided to remove my head from the sand and take stock of Twitter I was blown away not only by what Twitter really is, but also by my ignorance. Using Twitter for business is essential. If you and your business have not yet taken the plunge into the Twitter pool it is time to grab your trunks and jump.

A 2013 study conducted by the Center for Marketing Research at the University of Dartmouth found that 77 percent of Fortune 500 companies have an active corporate blog. The study also found that rank influences Twitter use – 43 percent of the Twitter accounts are held by companies in the top 200 on the list as compared with the bottom 200 which hold 43 percent of the Twitter accounts. Similarly, 67 percent of the Inc. 500 use Twitter. Looking at small businesses, in 2013 Constant Contact reported that 25 percent of small businesses use Twitter – up from only 7 percent last year.

Why is it important to know who is using Twitter? Because those who are using Twitter are more likely to gain customers than those who don’t. A survey conducted by Market Probe International found that 72 percent of those who follow a business on Twitter are more likely to make a purchase from that business and that 82 percent of followers are more likely to recommend a product or service to friends and family. The survey also found that 85 percent of respondents reported feeling a closer connection to a small business if they follow them on Twitter.

In addition to demand generation, the following are reasons why you and your business should use Twitter:

- Increase market intelligence

- Drive traffic to your website

- Monitor your business and your brand

- Connect with customers

- Manage risk

- Share information

Still skeptical?

SJF Material Handling Equipment is the single largest source for new, used and refurbished material handling equipment in the US. The company has built an extensive and successful social media network – one which uses Twitter – with the objective of increasing sales. The company has 55,797 followers on Twitter (and is gaining 200 to 400 followers each week). Stafford Sterner, President of SJF, says that Twitter enables the company to cover more ground and attract customers from unexpected and often unrelated circles.

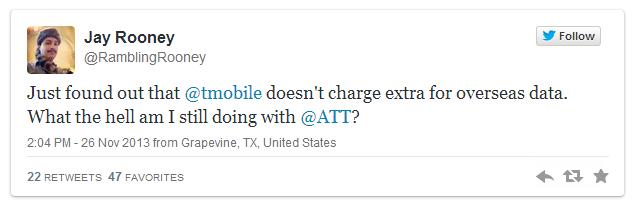

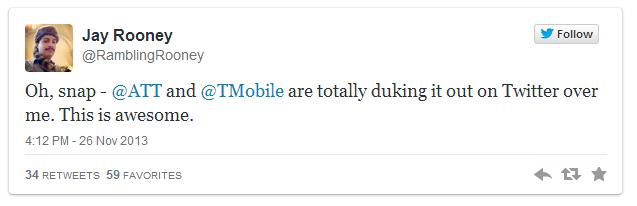

Another example is the battle for customers between AT&T and T-Mobile that played out on Twitter. The throw down began when Jay Rooney Tweeted that he was considering a switch from AT&T to T-Mobile.

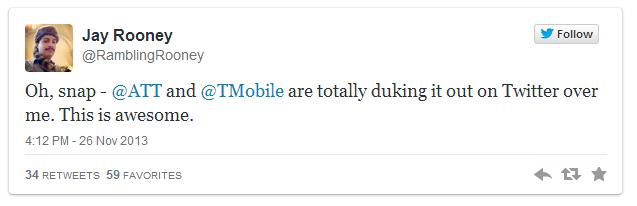

What occurred next was an all-out battle between AT&T and T-Mobile for Jay Rooney (and other customers) – both companies took to Twitter to try to convince Rooney that their company and service is the best. Rooney does a great job of summarizing the exchange:

The battle for Rooney intensifies and T-Mobile’s Chief Executive John Legere jumps in the fray:

Impressed, Jay Rooney decides to make the jump to T-Mobile. What’s more, the conversation caught the attention of many others. In the end, the exchange netted customers for T-Mobile.

(For more on the exchange, check out ZDNet’s article on battle between AT&T and T-Mobile.)

Ready to take the plunge? Social Media Examiner has a great how to article on how to use Twitter for business and for marketing.

by Elizabeth Hines | Nov 12, 2013 | Blog, Leadership, Strategy

Source: www.Chickenmaker.net

A 2013 study conducted by Deloitte found that 64 percent of the global executives surveyed reported they had a risk management program in place that is specific to the supply chain. That being said, 45 percent of the respondents said their programs were somewhat effective or not effective at all. Respondents — especially those in the technology, industrial products, and diversified manufacturing sectors — reported that supply chain disruptions have become more costly over the past three years. They also cited margin erosion and sudden demand change as two of the most costly problems. Moreover, the 2013 Global Supply Chain and Risk Management Survey conducted by the MIT Forum for Supply Innovation and PricewaterhouseCoopers found that in the last 12 months more than 60 percent of companies surveyed reported that their performance indicators had dropped by more than three percent due to supply chain disruptions. While there are many factors which are likely to contribute to the issues pointed to in these studies, I believe that one is that companies focus largely developing risk management strategies to mitigate and cope cataclysmic events and not the day-to-day bumps in the road. As such, companies tend to be ill-prepared to handle the day-to-day bumps.

Big events are outlier events

Because big events such as hurricanes, tornados, tsunamis, and terrorist attacks can have a long-lasting impact and often visual impact on the logistics and supply chain industries they tend to stay top of mind. That being said, these events are outlier events. “Outlier events have much more influence than they should,” Professor Ananth Raman of Harvard Business School told David Stauffer for an article for the school’s website. M. Eric Johnson, director of the Center for Digital Strategies at Dartmouth College’s Tuck School of Business, told Stauffer for the same article, “Managers will often consider the giant risk but ignore the smaller risks that create friction in the supply chain.” When companies ignore the smaller risks, they do so at their peril.

You can’t ignore the day-to-day

Creating risk management strategies that focus on the everyday events is critical. Dealing with these events in a reactive and piecemeal fashion is inefficient and ineffective and can significantly hurt your company. The following are some tips on what to consider when developing an effective risk management strategy which focuses on the everyday risks:

- Employ a strategy that is robust and closely monitored.

- Put a leader in charge.

- Clearly define your process and make it comprehensive. Establish a well-defined process to mitigate events such as cashflow contingencies, client credit risk and default, competitor interruptions, inventory risk, data backup and recovery, key client attrition, employee satisfaction and retention, social media use and abuse, and reputation recovery.

- Make sure the strategy is both nimble and flexible. Being intractable can exacerbate issues.

- Don’t forget about human resources. Don’t be afraid to move employees into new roles. Moving an employee into a new role permanently (or for a specified period to deal with an event) is a powerful and effective strategy.

- Be first. If there is a problem, be sure that the clients hear about the problem from you. When you contact clients, tell them what the issue is and what you are doing to address it. Be clear, concise, and honest.

- Educate. Take the time to make sure everyone is educated about the strategy. If just one person knows the strategy, it will not be effective.

A big event might happen, but everyday events will happen… every day. Don’t give your company Chicken Little syndrome by focusing only on big events.