by Fronetics | Oct 28, 2015 | Blog, Consumer Electronics, Data Security, Data/Analytics, Logistics, Strategy, Supply Chain

When it comes to IT Asset Disposal here are 5 must-ask questions for third-party providers.

When the industry thinks of data breaches it raises the specter of a savvy hacker lurking very far, and yet very close, intermingling with a larger organization of internet criminals, breaking into our technology and gathering most private information: credit card and bank account details, social security numbers, and personal health and income data. The recent breaches at Anthem insurance and the retail giant Target make users worry about the trail they leave when they swipe a card or populate a form with personal information. This is how individuals think identities might be exposed. Individuals often don’t think about what happens when a company retires old servers, computers, printers, copiers, and scanners. What happens to confidential data? This is something businesses must think about.

ITAD

Receipt, processing, destruction and disposal of hardware and software are a necessary and growing business. The Blumberg Advisory Group’s 2014 ITAD Trends Report shows that data security is the number one reason why companies implement an IT asset disposition (ITAD) strategy. News reports highlight examples of sensitive data being found on retired assets, frompersonal photos and information to matters of national security. The costs associated with data breaches and with the improper disposal of IT assets are great. They include financial implications such as penalties, the loss of customer loyalty, and the tarnishing of one’s reputation. To mitigate risk, asset recovery management is critical to companies operating in today’s global supply chain.

According to Transparency Market Research (TMR) as reported inElectronics Purchasing Strategies, ITAD represents an estimated $9.8 billion handling 48 million tons of discontinued or excess technology gear. According to TMR, by 2019 the predicted market will grow to $41 billion made on 141 million tons of used equipment. Concerns about data security have resulted in companies becoming more aware of the need for ITAD and the need to budget for it. In 2014, 87 percent of companies reported having an ITAD budget; 38 percent more than in 2012.

Outsourcing this complex work can be a necessity for many companies who don’t understand the intricacies, regulations, labor and cost of asset disposition. Electronically stored data is subject to stringent HIPAA/HITECH, FACTA, SOX, GLB, and FERPA regulations, complicating responsible disposal. Secure and thorough “wiping” of data is critical, and the environmental impact of retired assets is also a vital concern.

More and more companies, 65 percent of companies larger than 10,000 workers and up to one third of all businesses, are turning to 3rd-party service providers to manage end-of-life assets. The factors seen as most important in selecting a 3rd-party service provider include: adoption of industry-recognized compliance standards (97 percent); a well-documented and enforced chain of custody (95 percent); and high-quality, thorough client reporting (95 percent).

Reduce, Reuse, Recycle

ITAD is expensive and it can be risky. It is, therefore, important to find a 3rd-party service provider who can ensure as much safety and security as possible. Many ITAD companies have a split business model working with upstream partners to collect and process retired material, then turning to downstream partners who are looking to purchase used technology gear. Given this model, your server could be someone else’s server one day. Ensuring proper receipt and processing is critical.

Must-Ask Questions

These are must-ask questions businesses should ask 3rd-party providers before hiring them. Be certain these questions are answered thoroughly and confidently.

1. What is your specialization?

2. Is there uniformity in the process?

3. Who would manage our relationship?

4. How flexible are your operations?

5. What if something goes wrong?

Companies operating in today’s global supply chain need to take the necessary steps to mitigate risk when it comes to asset recovery management.

You may also like:

The importance of Asset Recovery Management in the Global Supply Chain

Content marketing ROI for reverse logistics companies

This article was originally published on Electronics Purchasing Strategies.

by Fronetics | Oct 15, 2015 | Blog, Consumer Electronics, Logistics, Marketing, Social Media, Strategy, Supply Chain

Consumers are using social media to help them make purchase decisions. An infographic by Invesp provides key details including that:

- 4 in 10 social media users have purchased an item online or in-store after sharing it or marking it as a favorite on Twitter, Facebook or Pinterest.

- 50% of those purchases take place within a week; 80% take place within 3 weeks.

- 71% of consumers are more likely to make a purchase based on social media referrals.

- Twitter is the most influential for tech purchases, and the least influential for gardening and decor.

- The top 2 ways Twitter helps solidify purchase decisions are: purchase location identification and product discovery.

A Consumer Electronics Association (CEA) study found similar results. CEA found that 24 percent of consumers who use social media say that they always or almost always refer to social media websites before they make a consumer electronics purchase. For high engagement users (13.5 or more hours per week) this increases to 65 percent.

Here’s how companies can use this information to reduce returns.

Inform

Use social media to give consumers the basic facts about your company and your product.

Educate

Use social media to educate consumers about your product. Specifically, social media can be used to educate the consumer about how the product can be used, the benefits that can be realized by the use of the product, and the ROI of the product.

Engage

Use social media to engage with consumers.

If a consumer is considering the product, use social media to answer questions the consumer has, or to address concerns. Similarly, if the customer has already purchased your product, you can use social media to answer questions the consumer has, or to address concerns.

Through the use of social media you can enable consumers to make more informed purchase decisions. Additionally, you can use social media to answer questions and better educate consumers on how to use your product thereby reduce no fault found returns.

This was originally published on Electronics Purchasing Strategies.

by Fronetics | Aug 26, 2015 | Blog, Consumer Electronics, Strategy, Supply Chain

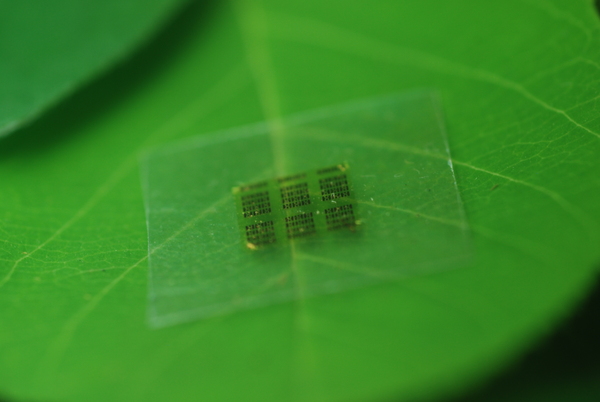

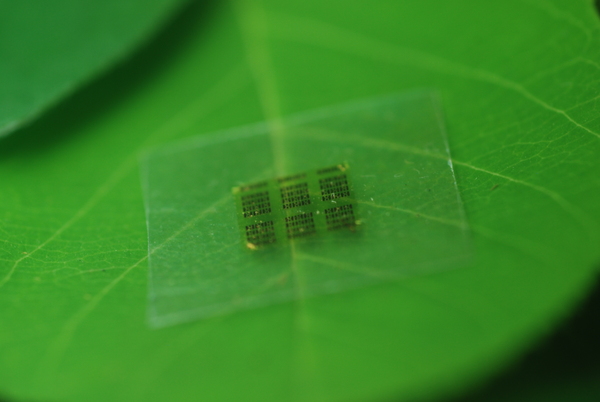

Source: University of Wisconsin -Madison

In 2014 the global consumer electronic market was valued at $1,224.8 billion. Future Market Insights projects that the market will reach $2,976.1 billion by 2020, reflecting a CAGR of 15.4% during the forecast period, 2015 – 2020. As the industry grows, driven by our desire for new technology, so does the amount of electronic waste (e-waste).

Right now 70% to 80% of our old gadgetry goes straight into landfills. According to research firm MarketsandMarkets, the global volume of e-waste generated is expected to reach 93.5 million tons in 2016, up from 41.5 million tons in 2011 at a compound annual growth rate of 17.6%. This waste contains hazardous materials which are harmful to human health and to the environment and are both non-renewable and non-biodegradable.

Semiconductor chips are one of the contributors to the hazardous materials found in e-waste. Researchers at the University of Wisconsin recently announced that they have created a new computer chip – one that is biodegradable and one which reduces the amount of semiconducting material used in manufacturing by a factor of up to 5,000. In spite of these changes, the new chip performs at the same level as traditional chips.

The new computer chip retains the active components of traditional chips, but in the base layer the new chip replaces silicon with cellulose nanofibril (CNF), a flexible, biodegradable material made from wood. This change means that the computer chip can decompose in nature.

In a press release Zhenqiang “Jack” Ma, research lead and UW-Madison electrical and computer engineering professor, says this about the new chips: “Now the chips are so safe you can put them in the forest and fungus will degrade it. They become as safe as fertilizer.”

While these new chips are game-changing with respect to human health and the environment, they are also poised to transform the consumer electronics industry. The transformative nature of the chips, and the one that will likely be the tipping point to adoption, is their transparency and flexibility.

Ma’s new chips are ready for commercialization.

by Jennifer Hart Yim | Jun 18, 2015 | Blog, Logistics, Manufacturing & Distribution, Strategy, Supply Chain

This article is part of a series of articles written by MBA students and graduates from the University of New Hampshire Peter T. Paul College of Business and Economics.

Ben Minerd received his B.S. in Computer Engineering from the University of New Hampshire in 2011 and will be completing his MBA from UNH in May 2015. When not working as a systems engineer, Ben enjoys skiing, hiking, and flying drones.

Some of you technologically curious readers may be familiar with Moore’s Law which predicted that the number of transistors in a dense integrated circuit would double every two years. What all that nerd speak (as a nerd I can use that phrase) boils down to is that the processing capability of electronic chips is increasing at a crazy rate. Like, scary fast.

On the flip side, electronics are really cheap these days. Yes, the $10,000 Apple Watch might be a tad pricey, but I’m talking about the industry as a whole. You can buy a computer that fits in your pocket for $200 that is many hundreds, maybe thousands, of times more powerful than my first computer and I’m one of those whiny millennial youngsters.

How can consumer electronics companies afford to sell their scary fast devices this cheaply? One reason is that the devices are being made by other devices (cue ominous music), as automation and electronics manufacturing are natural complements of each other. But another big factor in the cheap tech equation is the ever-increasing separation of technology development from technology manufacturing.

Contract Manufacturing

Big name companies like Apple, Google, Microsoft, and Amazon are doing less and less of their own widget building these days in favor of contract manufacturing (or CM). Contract manufacturing is essentially the outsourcing of your products’ fabrication and assembly to some other company (who is hopefully better at it than you are).

In theory, using a contract manufacturer should lower your costs and give you access to capabilities that you wouldn’t have access to otherwise. This is especially true of small businesses looking to produce physical goods (versus intangibles like software), where the up-front cost of building your own factory is immense and maybe even a non-starter. Or maybe you’re a big tech company who isn’t good at making hardware (ahem, Google) and you want to stick to your core competencies.

Whatever your reason, contract manufacturing is the unicorn that will slash your costs with its rainbow laser beam eyes. Well, maybe not entirely.

Hidden Costs

To loosely paraphrase Pee-wee Herman, every decision we make in business has a big ‘but’. For the economist reader, you can equate this with TANSTAAFL—There Ain’t No Such Thing As A Free Lunch. One action almost always leads to some other potentially unexpected outcome. Certain people have even gone so far as to say this is always the case (some guy named Isaac Newton).

One of the biggest contributors to hidden costs within contract manufacturing is the loss of control over your production processes. While this might be obvious or even desired, there may be some complications as a result of this new relationship that you hadn’t thought of previously.

Communication is always an important topic, but even more so when it comes to contract manufacturing. Not only may your production team physically reside on the other side of the globe, but things like language, culture, and time zone differences can make it difficult to keep good lines of communication open.

Quickly ramping up or ramping down production to meet changing demand can become a lot more challenging, too. This is partly due to the nature of the shared resources that you are buying access to when you team up with a CM.

A classic example of a culmination of these issues came from Cicso in the early 2000’s, back when out-sourcing was in its infancy. Cisco had been riding the surging wave of growth in the telecommunications industry which starting leading to supplier shortages. Shortly thereafter, the bottom fell out of telecom and Cisco forgot to turn off the contract manufacturing tap. Before long, Cisco’s raw-parts inventory rose by more than 300% from Q3 to Q4 2000, leading to a $2.2 billion write-off of inventory. Wall Street responded as you might expect, causing Cisco’s stock to fall by 50%.

The Human Cost

Perhaps the greatest hidden cost is one that may never make it to your company’s balance sheet: exploitation of workers in the developing countries where many contract manufacturers do business. It’s no secret that the biggest driver behind outsourcing is low labor costs. While it’s not always apples-to-apples to compare a production worker’s wage in China to one in the U.S., by any measurement the difference is more than a factor of 10 (although that number is dropping).

This dirty little secret of the consumer electronics industry came to light in 2012 when it was discovered that Foxconn, the largest electronics CM with over $100 billion in revenue and manufacturer of the Apple iPad, was mistreating some of their workers. Conditions grew so bad that in some cases workers decided to jump to their death rather than survive in that environment.

Bottom Line

Contract manufacturing might very well still be the right choice for you, just keep in mind that you may have more “unknown unknowns” than you had, well, known about. The more you can discuss with your CM candidate up front, the better your relationship will likely be. Also, some of these “gotcha’s” can be planned for in the agreement between you and your CM, so don’t skimp on the up-front work. And remember, there is no unicorn with rainbow laser beam eyes. That I know of.