by Fronetics | Feb 4, 2014 | Blog, Logistics, Marketing, Social Media, Strategy

This article also appeared on DC Velocity.

Research conducted by Adrian Gonzalez, founder and president of Adelante SCM, found that 30 percent of respondents (supply chain professionals) reported that their companies block access to social media sites. One of the reasons for the lack of participation in social media by these companies is likely due to a lack of understanding of what social media is and the role it can play in business. As noted by Gonzalez: “many supply chain executives and companies are stuck on the starting line because they can’t get past the word ‘social’ and the perception it creates.”

In a 2013 article in MIT Sloan Management Review, Gerald C. Kane, Associate Professor at the Carroll School of Management at Boston College, wrote: “When asked to define social media, most people probably rely on something similar to Supreme Court Justice Potter Stewart’s definition of obscenity: ‘I know it when I see it.’” Unfortunately this approach to defining social media tends to perpetuate stereotypes and does not accurately reflect what social media is and how it can be utilized by business. What, then, is social media? Social media is defined by the Oxford English Dictionary as: “websites and applications that enable users to create and share content or to participate in social networking.” These websites and applications are inclusive of Twitter, Facebook, LinkedIn, and Google+. Social media is part of a larger framework called social technologies. The McKinsey Global Institute defines social technologies as: “IT products and services that enable the formation and operation of online communities, where participants have distributed access to content and distributed rights to create, add, and/or modify content.” Social technologies are inclusive of Yammer, Jive, Moxie, and Supply Chain Operating Networks such as Descartes, GT Nexus, Elemica, E2open, LeanLogistics, and One Network. Also included in social technologies are network-based business intelligence and analytics.

Clara Shih, CEO and Founder of Hearsay Social, and Lisa Shalett, Managing Director and Head of Brand Marketing and Digital Strategy at Goldman Sachs, call attention to the fact that when you get right down to it, social media encompasses “a set of new and innovative ways for businesses and customers to do what they have always done: build relationships, exchange information, read and write reviews, and leverage trusted networks of friends and experts.” Furthermore, engaging in social media and utilizing social technologies provides business with the tools to manage status, social networks, and established relationships—all drivers of firm performance. Social media and social networking also enable companies to be able to better manage risk, create demand, define their reputation, innovate, enhance business intelligence, and improve productivity.

To learn more about social media and the role it can play in business, see our white paper: Social Media and the Logistics and Supply Chain Industries: Why Not Participating is a Risk You Can’t Afford to Take.

by Elizabeth Hines | Jan 21, 2014 | Blog, Logistics, Strategy, Supply Chain

This post was originally published on EBN.

Summer is over, fall has arrived, and winter is right around the corner. As the days grow shorter and colder, don’t let inertia take over. Instead, put your packaging on a diet.

Here are three reasons why a packaging slim down will improve the health of your company’s supply chain and the world:

1. You can save money. By reducing the amount of packing you use for a product and/or by using right-size packaging, you can reduce transportation costs and materials costs.

For example, the packaging used for Apple’s iPhone 5 is 28 percent smaller than the packaging that was used for the original iPhone. The reduction in the size of the packaging translates into being able to fit 60 percent more iPhones on each shipping pallet. Apple points out that this saves the company one 747 flight for every 416,667 units they ship.

Poland Spring provides another example. Poland Spring has reduced the amount of resin that goes into the making of their bottles by a significant amount — from 14.6 grams of resin per bottle in 2005 to 9.2 grams of resin per bottle in 2012. Not only is the bottle 40 percent lighter (read: reduced transportation cost), the company also saves a sizeable amount of money each year in materials. In a recent Slate.com article Kim Jeffery, CEO of Nestle Waters North America (Poland Spring’s parent company), is quoted as saying:

You can’t be a public company and ask shareholders to bear the burden of higher costs just so you can be green. It has to be consistent with creating shareholder value. There needs to be a return on these investments. So, for example, when you use 200 million fewer pounds of resin a year, at 90 cents a pound, that’s a huge savings.

By my calculations, that’s a savings of $180 million annually.

2. It is better for the environment. Putting your packaging on a diet can reduce the amount of waste, CO2 emissions, deforestation, water use, water contamination, and hazardous material use.

In a September 2013 Packaging Digest article, Ron Sasine, senior director of packaging for private brands for Walmart, wrote that as a result of the company’s efforts to reduce packaging it was “able to reduce the overall greenhouse gas impact of our packaging by an average of 9.8 percent in our Walmart U.S. stores, 9.1 percent in our Sam’s Clubs in the U.S. and 16 percent in our Walmart Canada stores.”

3. It makes your customers happy. A 2012 survey conducted by Packaging World and DuPont Packaging & Industrial Polymers found that the primary focus of the packaging world over the next 10 years will shift from cost to sustainability. Specifically, the report found that 45 percent of those surveyed believe that perceived “greenness” will be important to consumers.

Additionally, a 2012 study released by Perception Research Services reported that in 2011 significantly more shoppers were more likely to choose environmentally friendly packaging than in 2010 (36 percent versus 28 percent), and that half of shoppers surveyed were willing to pay for environmentally friendly packaging.

Tell us your thoughts on packaging trends in the electronics industry. What’s important to you and your customers?

by Elizabeth Hines | Jan 21, 2014 | Blog, Logistics, Strategy, Supply Chain

This post was originally published on EBN.

Summer is over, fall has arrived, and winter is right around the corner. As the days grow shorter and colder, don’t let inertia take over. Instead, put your packaging on a diet.

Here are three reasons why a packaging slim down will improve the health of your company’s supply chain and the world:

1. You can save money. By reducing the amount of packing you use for a product and/or by using right-size packaging, you can reduce transportation costs and materials costs.

For example, the packaging used for Apple’s iPhone 5 is 28 percent smaller than the packaging that was used for the original iPhone. The reduction in the size of the packaging translates into being able to fit 60 percent more iPhones on each shipping pallet. Apple points out that this saves the company one 747 flight for every 416,667 units they ship.

Poland Spring provides another example. Poland Spring has reduced the amount of resin that goes into the making of their bottles by a significant amount — from 14.6 grams of resin per bottle in 2005 to 9.2 grams of resin per bottle in 2012. Not only is the bottle 40 percent lighter (read: reduced transportation cost), the company also saves a sizeable amount of money each year in materials. In a recent Slate.com article Kim Jeffery, CEO of Nestle Waters North America (Poland Spring’s parent company), is quoted as saying:

You can’t be a public company and ask shareholders to bear the burden of higher costs just so you can be green. It has to be consistent with creating shareholder value. There needs to be a return on these investments. So, for example, when you use 200 million fewer pounds of resin a year, at 90 cents a pound, that’s a huge savings.

By my calculations, that’s a savings of $180 million annually.

2. It is better for the environment. Putting your packaging on a diet can reduce the amount of waste, CO2 emissions, deforestation, water use, water contamination, and hazardous material use.

In a September 2013 Packaging Digest article, Ron Sasine, senior director of packaging for private brands for Walmart, wrote that as a result of the company’s efforts to reduce packaging it was “able to reduce the overall greenhouse gas impact of our packaging by an average of 9.8 percent in our Walmart U.S. stores, 9.1 percent in our Sam’s Clubs in the U.S. and 16 percent in our Walmart Canada stores.”

3. It makes your customers happy. A 2012 survey conducted by Packaging World and DuPont Packaging & Industrial Polymers found that the primary focus of the packaging world over the next 10 years will shift from cost to sustainability. Specifically, the report found that 45 percent of those surveyed believe that perceived “greenness” will be important to consumers.

Additionally, a 2012 study released by Perception Research Services reported that in 2011 significantly more shoppers were more likely to choose environmentally friendly packaging than in 2010 (36 percent versus 28 percent), and that half of shoppers surveyed were willing to pay for environmentally friendly packaging.

Tell us your thoughts on packaging trends in the electronics industry. What’s important to you and your customers?

by Fronetics | Jan 7, 2014 | Blog, Leadership, Strategy, Talent

how to hire a leader

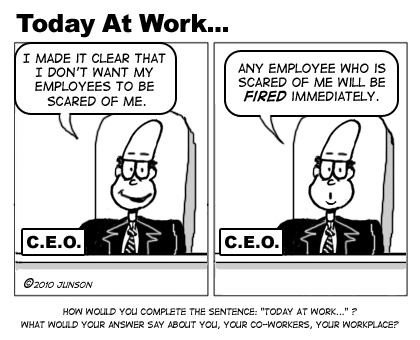

Businesses don’t fail, leaders do – a lot. Studies have shown that the rate of failure of executives coming into new companies ranges from 30 to 40 percent after 18 months. The costs and implications of a poor leadership hire are enormous. Given the odds, how can you hire a leader – a true leader? Here are five tips:

Ask the right question

Just one interview question can give you enormous insight into the abilities and qualifications of the candidate. The question: “Tell me about the last person you fired.” According to Marc Barros, co-founder and former CEO of Contour, this question and the discussion that will follow will give you the “strongest indicator of the candidate’s leadership ability.” Specifically, the candidate’s response will shed light on their communication style and skills, their willingness and ability to admit mistakes, and the candidate’s level of empathy and emotion.

Conduct your own due diligence

When it comes to finding the next leader for your company, don’t leave due diligence in the hands of someone else. Take the time to learn about the candidate, talk to people who have worked with the candidate in the past, and gather as much information on the person as you can.

Go beyond the typical interview

Going beyond the typical interview is revealing in that enables you to see the candidate outside of the canned interview environment (an environment which many have mastered). Some ideas: have the candidate give a presentation, facilitate a meeting, or write up their thoughts on how to tackle a specific problem.

Opinions matter

Have the candidate meet with employees of various positions and levels within the company. After each person meets with the candidate get their feedback – and listen. It is amazing how often a candidate will let their guard down when they perceive they are meeting with someone that “doesn’t matter.” The truth is that these meetings do matter as they can provide you with some of the best insight into the candidate and their leadership style.

Hire from inside

When you hire from inside your company, you will get a leader who knows how to succeed in the company’s culture.

by Fronetics | Jan 7, 2014 | Blog, Leadership, Strategy, Talent

how to hire a leader

Businesses don’t fail, leaders do – a lot. Studies have shown that the rate of failure of executives coming into new companies ranges from 30 to 40 percent after 18 months. The costs and implications of a poor leadership hire are enormous. Given the odds, how can you hire a leader – a true leader? Here are five tips:

Ask the right question

Just one interview question can give you enormous insight into the abilities and qualifications of the candidate. The question: “Tell me about the last person you fired.” According to Marc Barros, co-founder and former CEO of Contour, this question and the discussion that will follow will give you the “strongest indicator of the candidate’s leadership ability.” Specifically, the candidate’s response will shed light on their communication style and skills, their willingness and ability to admit mistakes, and the candidate’s level of empathy and emotion.

Conduct your own due diligence

When it comes to finding the next leader for your company, don’t leave due diligence in the hands of someone else. Take the time to learn about the candidate, talk to people who have worked with the candidate in the past, and gather as much information on the person as you can.

Go beyond the typical interview

Going beyond the typical interview is revealing in that enables you to see the candidate outside of the canned interview environment (an environment which many have mastered). Some ideas: have the candidate give a presentation, facilitate a meeting, or write up their thoughts on how to tackle a specific problem.

Opinions matter

Have the candidate meet with employees of various positions and levels within the company. After each person meets with the candidate get their feedback – and listen. It is amazing how often a candidate will let their guard down when they perceive they are meeting with someone that “doesn’t matter.” The truth is that these meetings do matter as they can provide you with some of the best insight into the candidate and their leadership style.

Hire from inside

When you hire from inside your company, you will get a leader who knows how to succeed in the company’s culture.