Robotics and Automation for Manufacturing: Hurdles or Assets?

Implementing robotics and automation for manufacturing can be costly and a challenge for public perception – but, ultimately, these technologies are crucial assets for the industry.

Highlights:

- Hurdles companies face concerning automation include public perception, potential safety hazards, and cost.

- However, robots actually make factories safer and protect human workers from having to perform dangerous tasks.

- Advantages of automation include decreased long-term costs, reduced error rate, improved productivity, and enhanced data collection.

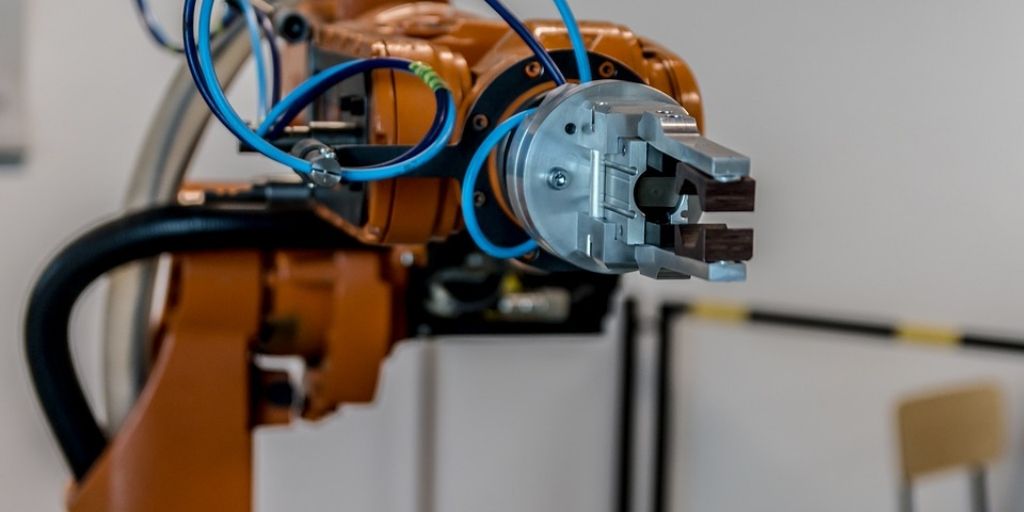

As machine learning, or Artificial Intelligence (AI), gains sophistication and technologies continue to improve, supply chain companies are increasingly needing to evaluate the benefits and pitfalls of robotics and automation for manufacturing.

While current evidence suggests that experts are correct in predicting that automation will prove a significant competitive advantage, manufacturing companies are often faced with equally significant hurdles when it comes to implementing these technologies.

So, on balance, are robotics and automation for manufacturing assets, or do they present insurmountable hurdles? Let’s look at the case for each.

3 challenges of robotics and automation for manufacturing

1) Perception

When companies begin considering or implementing robotics and automation for manufacturing, they do so in the context of a public steeped in the kind of sci-fi lore that breeds hysteria on this issue. While public fears of Cylons and the like taking manufacturing jobs may seem like frivolous concerns, the battle that companies face when it comes to public perception is quite significant and should not be overlooked.

In addition to the more hysterical fears of robot uprising, manufacturing companies are faced with the need to combat negative public perception and employee fears when it comes to replacing traditional manual labor with capitalized assets. In short, the fear that “robots are taking our jobs” should not be underestimated as a challenge faced by companies considering manufacturing automation.

2) Dangers

In addition to cultural perceptions of robots as potentially threatening, there are real safety concerns when it comes to robotics and automation for manufacturing. A notorious accident in a Volkswagen factory in Germany, in which a worker was killed by a malfunctioning robot, has been widely reported in the media and serves as a cautionary tale about the dangers posed by automation.

Manufacturers seeking to implement automation are faced with the task of ensuring that factories remain safe for humans and robots to work collaboratively. This requires investment in safety features, as well as training and oversight.

3) Implementation costs

Perhaps the biggest hurdle to companies’ acquisition of robotics and automation for manufacturing is the cost. While these technologies are becoming more affordable, the high initial capital outlay presents a serious barrier, particularly for smaller and midsized manufacturers.

In addition to the costs of equipment, there are expenses associated with maintenance, compliance, software, and human worker training. Companies may be aware of the long-term benefits of automation but unable mount the initial costs or stomach ongoing expenses.

Robotics and automation for manufacturing: the case for overcoming the hurdles

Now it’s time to look at how these technologies are assets and whether it’s worth facing the challenges associated with implementing them.

Robots aren’t here to replace humans.

When it comes to combatting the public perception that robots will render humans obsolete, there’s one simple truth that sums it up best: robots will not replace humans. In fact, automation works best alongside human workers and maximizes the strengths of each, leading to enhanced employee value. Automation frees up human workers to work in their core competencies, focusing on strategic work, oversight, and administration.

Automation helps make factories safer.

While the dramatic examples of robots causing injury and death are harrowing, and deserve attention, it’s important not to sweep under the rug the fact that automation actually makes factories much safer for human workers. By performing tasks that put humans at risk, robots can remove workers from traditionally hazardous situations or exposure to harmful materials.

As these technologies develop, they are becoming increasingly safe and include provisions that facilitate working collaboratively with humans. Robotics can increase access to difficult or dangerous locations. Improvements in sensors, dexterity, artificial intelligence, and trainability are helping to ensure that robotics and automation for manufacturing are safe.

Automation as a value driver

While costs associated with implementation and maintenance may be significant, arguably, with the competitive advantages presented by robotics and automation for manufacturing, companies can’t afford not to automate.

Robots improve the speed and accuracy of routine operations, reducing costly error rates and increasing productivity. They decrease long-term costs, provide labor utilization and stability (particularly when labor is in short supply), and optimize picking, sorting, and storing times. The vastly improved data collection provided by automated manufacturing means reducing the frequency of costly inventory checks while increasing accuracy.

The bottom line: the hurdles presented by robotics and automation for manufacturing are well worth navigating.

Related posts: