by Fronetics | Mar 25, 2015 | Blog, Content Marketing, Logistics, Marketing, Supply Chain

B2B companies are creating more content than ever before. This is true too for companies within the logistics and supply chain industries.

Fronetics Strategic Advisors conducted a survey focused on the use of content within the logistics and supply chain industries. The survey found that companies within the logistics and supply chain industries are using content as a marketing tool and are realizing results. 79% of survey respondents reported that content is an effective marketing tool.

Survey respondents reported that their company uses content to:

- Strengthen overall brand awareness (96%)

- Generate leads (83%)

- Establish the company as an industry leader (74%).

To learn more about the role of content with the logistics and supply chain industries, download the report.

by Fronetics | Mar 24, 2015 | Blog, Strategy, Supply Chain

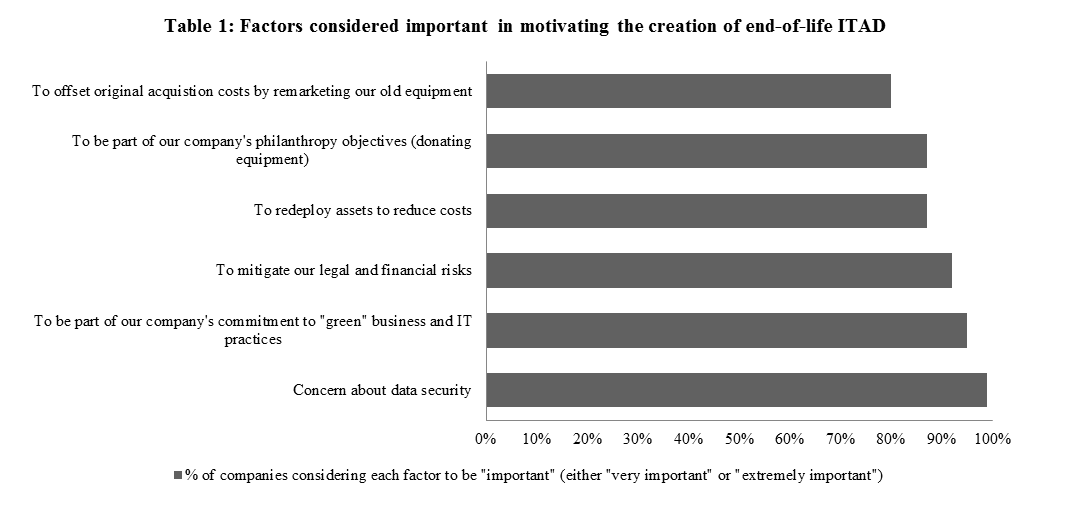

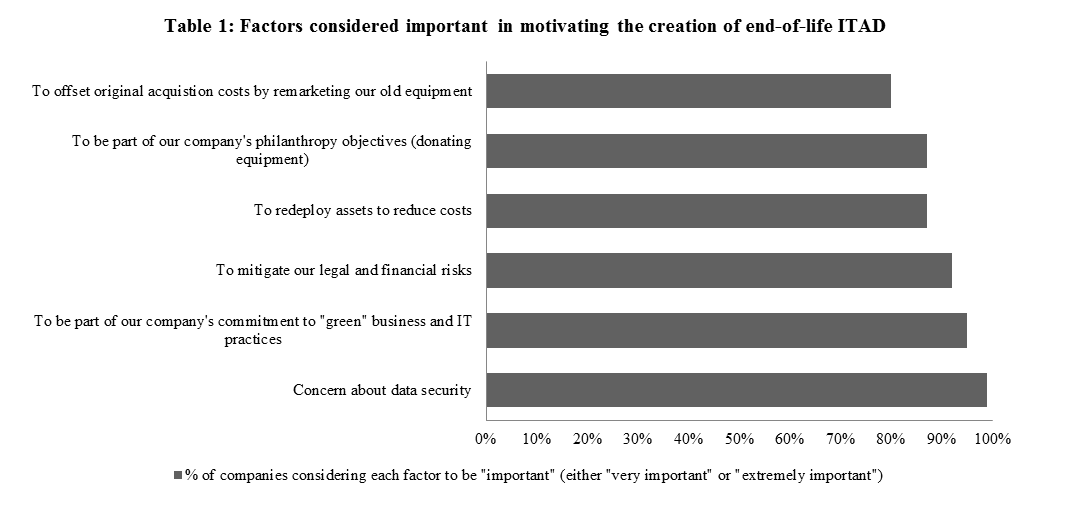

The Blumberg Advisory Group’s 2014 ITAD Trends Report shows that data security is the number one reason why companies implement an IT asset disposition (ITAD) strategy. That companies are concerned about data security is no surprise. Ongoing media reports have not only focused on data breaches, but have also highlighted examples of sensitive data being found on retired assets. The costs associated with data breaches and with the improper disposal of IT assets are great. They include financial implications such as penalties as well as the loss of customer loyalty and reputation. To mitigate risk, asset recovery management is critical to companies operating in today’s global supply chain.

Data security is viewed as an important piece of asset recovery management

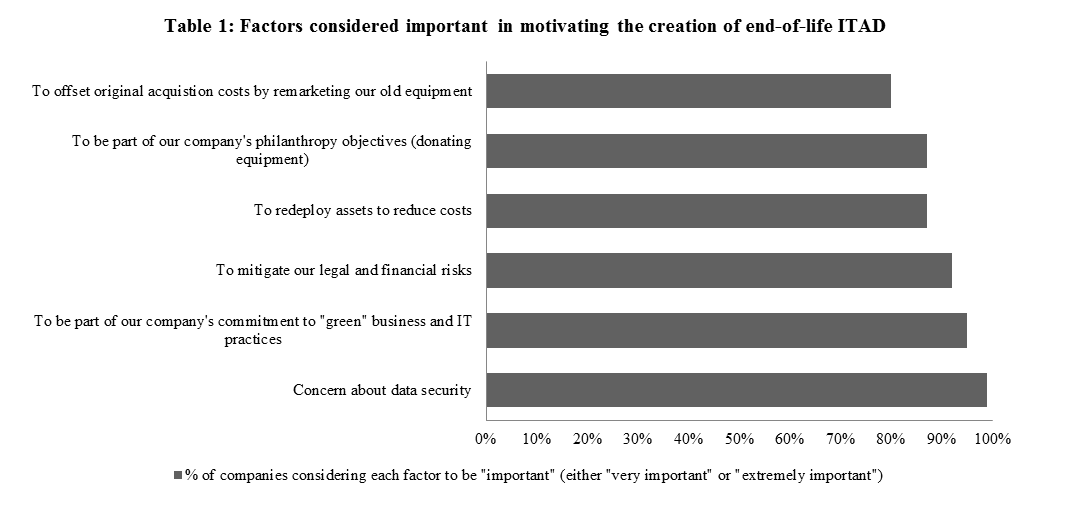

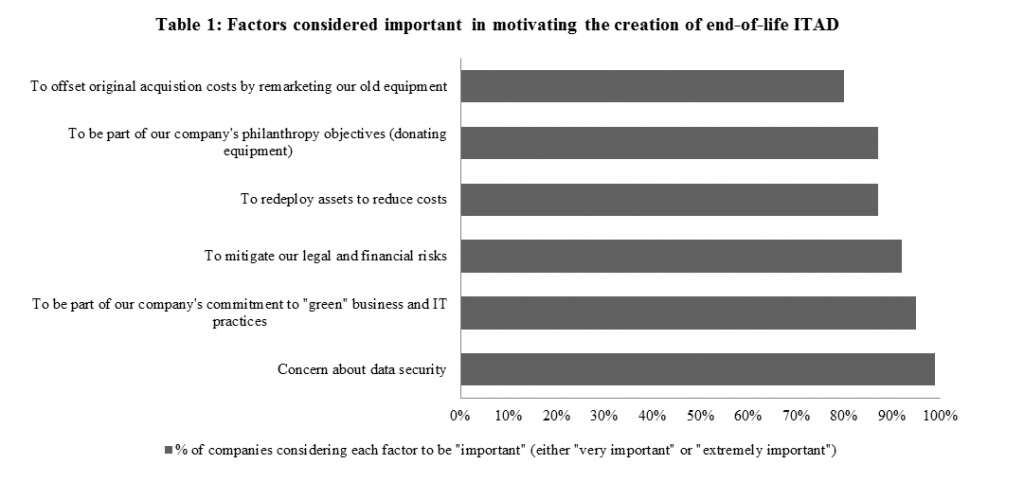

Ninety-nine percent of companies surveyed by the Blumberg Advisory Group reported that “concern about data security” is either “very important” or “extremely important” with respect to motivating the creation of their current end-of-life IT disposition strategy. Other important factors include: commitment to “Green” businesses and IT practices, mitigating legal and financial risks, and redeploying assets to reduce costs (Table 1).

Concerns about data security have resulted in companies becoming more aware of the need for ITAD and the need to budget for it. In 2014 87 percent of companies reported having an ITAD budget; 38 percent more than in 2012.

Companies turn to 3rd-party service providers

The majority (63 percent) of companies reported that they use a 3rd-party service provider to manage end-of-life assets. The factors seen as most important in selecting a 3rd-party service provider include: adoption of industry-recognized compliance standards (97 percent); a well-documented and enforced chain of custody (95 percent); and high-quality, thorough client reporting (95 percent).

What to look for in a 3rd-party service provider

ITAD is expensive and it can be risky. It is therefore important to find a 3rd-party service provider who can provide as much safety and security as possible. It is also important to find a provider that takes the time to understand your business and your needs – and develops and manages an asset recovery program that is right for you rather than one that is “out of the box.”

We have put together a list of five must-ask questions. These are questions you should ask providers with whom your company is considering engaging. Before engaging, make sure that you are given answers to these questions and that you feel confident with responses.

-

What is your specialization?

3rd-party service providers are becoming increasingly specialized, particularly when comes to corporate IT take-outs. This specialization is largely being driven by data security and data breach concerns. If your company has highly specialized assets it is essential to determine what specializations, if any, the provider has.

-

Is there uniformity in the process?

Does the provider operate on a single global platform, or will it be necessary to use different platforms for different regions of operation. Uniformity in the process generally increases the ease of operation and ease of use.

-

Who would manage our relationship?

Would the provider assign one global account manager, or will it be necessary to interface with several account managers? Again, this boils down to ease of operation and ease of use.

-

How flexible are your operations?

Disruptions such as recent closure of west coast ports, natural disasters such as Hurricane Sandy, and changing standards and regulations (on a local, regional, and global scale) all impact the supply chain. Given this, it is important that flexibility be a component of asset recovery management.

-

What if something goes wrong?

This question is the most important question to ask. If something goes wrong and if ITAD does not occur as it should, what happens? Does the provider carry indemnification? If so, how much does the provider carry? Will the provider work with you to mitigate risk?

Data security, data breaches, and the improper disposal of assets are issues which global supply chain companies face on a day to day basis. The economic and social implications of the mismanagement of asset recovery are great. It is therefore important that companies operating in today’s global supply chain take the necessary steps to mitigate risk when it comes to asset recovery management.

by Fronetics | Mar 24, 2015 | Blog, Strategy, Supply Chain

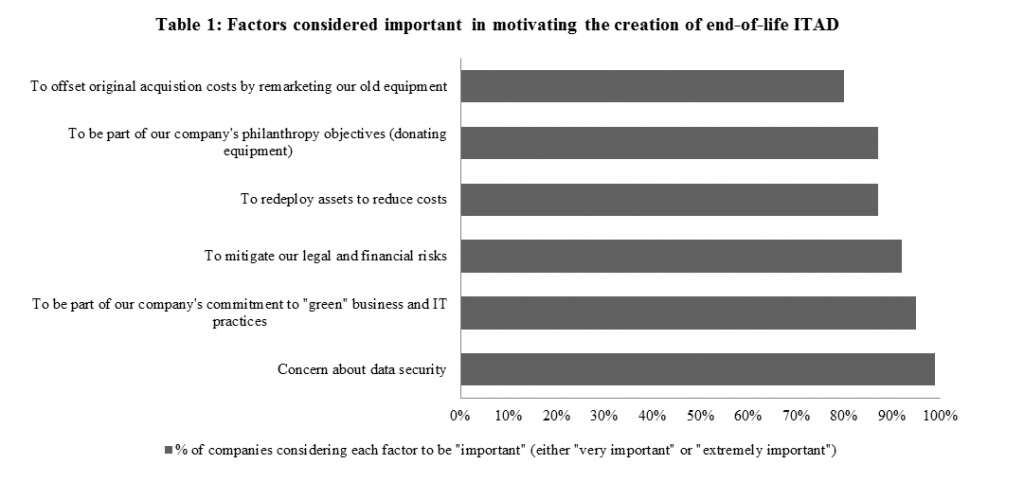

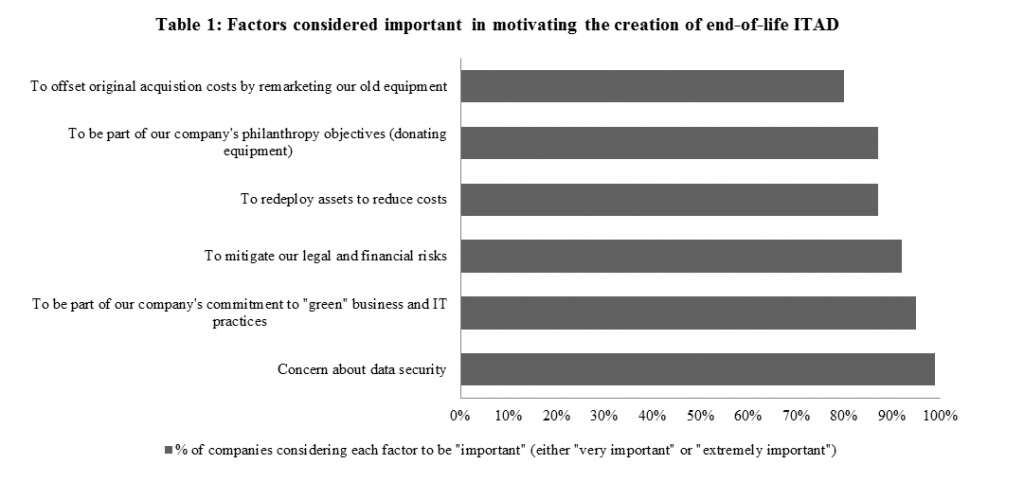

The Blumberg Advisory Group’s 2014 ITAD Trends Report shows that data security is the number one reason why companies implement an IT asset disposition (ITAD) strategy. That companies are concerned about data security is no surprise. Ongoing media reports have not only focused on data breaches, but have also highlighted examples of sensitive data being found on retired assets. The costs associated with data breaches and with the improper disposal of IT assets are great. They include financial implications such as penalties as well as the loss of customer loyalty and reputation. To mitigate risk, asset recovery management is critical to companies operating in today’s global supply chain.

Data security is viewed as an important piece of asset recovery management

Ninety-nine percent of companies surveyed by the Blumberg Advisory Group reported that “concern about data security” is either “very important” or “extremely important” with respect to motivating the creation of their current end-of-life IT disposition strategy. Other important factors include: commitment to “Green” businesses and IT practices, mitigating legal and financial risks, and redeploying assets to reduce costs (Table 1).

Concerns about data security have resulted in companies becoming more aware of the need for ITAD and the need to budget for it. In 2014 87 percent of companies reported having an ITAD budget; 38 percent more than in 2012.

Companies turn to 3rd-party service providers

The majority (63 percent) of companies reported that they use a 3rd-party service provider to manage end-of-life assets. The factors seen as most important in selecting a 3rd-party service provider include: adoption of industry-recognized compliance standards (97 percent); a well-documented and enforced chain of custody (95 percent); and high-quality, thorough client reporting (95 percent).

What to look for in a 3rd-party service provider

ITAD is expensive and it can be risky. It is therefore important to find a 3rd-party service provider who can provide as much safety and security as possible. It is also important to find a provider that takes the time to understand your business and your needs – and develops and manages an asset recovery program that is right for you rather than one that is “out of the box.”

We have put together a list of five must-ask questions. These are questions you should ask providers with whom your company is considering engaging. Before engaging, make sure that you are given answers to these questions and that you feel confident with responses.

-

What is your specialization?

3rd-party service providers are becoming increasingly specialized, particularly when comes to corporate IT take-outs. This specialization is largely being driven by data security and data breach concerns. If your company has highly specialized assets it is essential to determine what specializations, if any, the provider has.

-

Is there uniformity in the process?

Does the provider operate on a single global platform, or will it be necessary to use different platforms for different regions of operation. Uniformity in the process generally increases the ease of operation and ease of use.

-

Who would manage our relationship?

Would the provider assign one global account manager, or will it be necessary to interface with several account managers? Again, this boils down to ease of operation and ease of use.

-

How flexible are your operations?

Disruptions such as recent closure of west coast ports, natural disasters such as Hurricane Sandy, and changing standards and regulations (on a local, regional, and global scale) all impact the supply chain. Given this, it is important that flexibility be a component of asset recovery management.

-

What if something goes wrong?

This question is the most important question to ask. If something goes wrong and if ITAD does not occur as it should, what happens? Does the provider carry indemnification? If so, how much does the provider carry? Will the provider work with you to mitigate risk?

Data security, data breaches, and the improper disposal of assets are issues which global supply chain companies face on a day to day basis. The economic and social implications of the mismanagement of asset recovery are great. It is therefore important that companies operating in today’s global supply chain take the necessary steps to mitigate risk when it comes to asset recovery management.

by Fronetics | Mar 23, 2015 | Blog, Supply Chain, Talent

What you need to know about the supply chain talent gap.

The supply chain talent gap has been called a “perfect storm.” Few topics are shrouded in such doom and gloom. Every report cites doomsday statistics of the impending crisis when, by 2025, 60 million baby boomers will exit the workforce, leaving a gigantic gap when 40 million millennials take their place. To make matters worse, the retirement exodus is only one factor contributing to the sinking ship. Future supply chain professionals need to master not only the hard analytical skills but also the soft leadership skills fueled by the transition from an industrial economy to an economy grounded in service and information. In numbers, it means only 20% of the workforce will possess the skills required of 60% of all new supply chain jobs.

But listen up, all you forward-thinking millennials and midlevel supply chain managers with cross-functional expertise. There’s some good news: The market can’t get enough of you.

Yes, amid all the dire facts, there is opportunity. There has never been a better time to be, so to speak, on the other side of the table — a college graduate or a motivated professional looking for a career with upward mobility? What other field of work can offer as much promise to new recruits and current employees as the supply chain industry?

Just as all reports predict a brewing crisis, they also tout talent management as the primary remedy. For a self-motivated individual, fresh out of college or in the midst of a corporate climb, this focus on professional development presents a smorgasbord of options. Many companies have taken note and adopted a strategy of action for recruiting and retaining new talent. A growing number of university program offerings reflect a strengthening partnership between academia and the supply chain industry. Many supply chain companies are building partnerships with academic programs to offer internship opportunities; a move that’s creating strong early relationships with students and will likely have a positive effect on future recruitment efforts. A company that can offer its current staff competitive salaries in addition to cross-functional training is much better positioned to meet the challenges of the talent shortage and the evolving nature and demands of the supply chain.

Another way companies within the logistics and supply chain industries are attracting top talent is through their use of social media. Considering the global reach and vast talent pool of LinkedIn’s 300 million users, the business-focused social network is helping companies with open positions that might require a unique and specific skill set to connect with candidates across the globe.

What’s clear is that companies that follow a plan of inaction will be left behind. This new talent pool will swiftly turn down a company that remains stuck on strict functional divisions and favors the old siloed approach to doing business. Many supply chain managers have grown up in such divided organizations themselves, so they have been slow to take appropriate action to retain and train talent, according to a Supply Chain Insights survey, leaving those better prepared with a competitive advantage.

If a company does not appeal to the desires of top candidates, individuals will take their talent elsewhere. And there will always be another company to welcome them. As Rebooting Work author Maynard Webb points out in a 2013 interview with Elance, in order for companies to remain competitive they’ll need to adapt to the modern workforce. “Companies have traditionally thought of people as a disposable resource,” he says. “They have valued their buildings much more than employees… this doesn’t make sense in a world where the best people can choose to work wherever they want. Businesses have to realize that some jobs can be done from anywhere, anytime, and save the brick and mortar buildings for the few jobs that demand a physical presence.”

Touting the unlimited opportunities and unparalleled growth in the supply chain field should be part of turning the tide. Sure, there is a lot of talk about doom, but mainly for those companies that fail to attract and retain top talent.

by Fronetics | Mar 23, 2015 | Blog, Supply Chain, Talent

What you need to know about the supply chain talent gap.

The supply chain talent gap has been called a “perfect storm.” Few topics are shrouded in such doom and gloom. Every report cites doomsday statistics of the impending crisis when, by 2025, 60 million baby boomers will exit the workforce, leaving a gigantic gap when 40 million millennials take their place. To make matters worse, the retirement exodus is only one factor contributing to the sinking ship. Future supply chain professionals need to master not only the hard analytical skills but also the soft leadership skills fueled by the transition from an industrial economy to an economy grounded in service and information. In numbers, it means only 20% of the workforce will possess the skills required of 60% of all new supply chain jobs.

But listen up, all you forward-thinking millennials and midlevel supply chain managers with cross-functional expertise. There’s some good news: The market can’t get enough of you.

Yes, amid all the dire facts, there is opportunity. There has never been a better time to be, so to speak, on the other side of the table — a college graduate or a motivated professional looking for a career with upward mobility? What other field of work can offer as much promise to new recruits and current employees as the supply chain industry?

Just as all reports predict a brewing crisis, they also tout talent management as the primary remedy. For a self-motivated individual, fresh out of college or in the midst of a corporate climb, this focus on professional development presents a smorgasbord of options. Many companies have taken note and adopted a strategy of action for recruiting and retaining new talent. A growing number of university program offerings reflect a strengthening partnership between academia and the supply chain industry. Many supply chain companies are building partnerships with academic programs to offer internship opportunities; a move that’s creating strong early relationships with students and will likely have a positive effect on future recruitment efforts. A company that can offer its current staff competitive salaries in addition to cross-functional training is much better positioned to meet the challenges of the talent shortage and the evolving nature and demands of the supply chain.

Another way companies within the logistics and supply chain industries are attracting top talent is through their use of social media. Considering the global reach and vast talent pool of LinkedIn’s 300 million users, the business-focused social network is helping companies with open positions that might require a unique and specific skill set to connect with candidates across the globe.

What’s clear is that companies that follow a plan of inaction will be left behind. This new talent pool will swiftly turn down a company that remains stuck on strict functional divisions and favors the old siloed approach to doing business. Many supply chain managers have grown up in such divided organizations themselves, so they have been slow to take appropriate action to retain and train talent, according to a Supply Chain Insights survey, leaving those better prepared with a competitive advantage.

If a company does not appeal to the desires of top candidates, individuals will take their talent elsewhere. And there will always be another company to welcome them. As Rebooting Work author Maynard Webb points out in a 2013 interview with Elance, in order for companies to remain competitive they’ll need to adapt to the modern workforce. “Companies have traditionally thought of people as a disposable resource,” he says. “They have valued their buildings much more than employees… this doesn’t make sense in a world where the best people can choose to work wherever they want. Businesses have to realize that some jobs can be done from anywhere, anytime, and save the brick and mortar buildings for the few jobs that demand a physical presence.”

Touting the unlimited opportunities and unparalleled growth in the supply chain field should be part of turning the tide. Sure, there is a lot of talk about doom, but mainly for those companies that fail to attract and retain top talent.

by Fronetics | Mar 9, 2015 | Blog, Supply Chain

The Internet of Things (IoT) “represents the convergence of the physical and digital worlds. Physical objects are equipped with technology that enables the object to send and receive information via fixed-wire or wireless communications links to the Internet, and to then transmit information in one form or another.”

In 2003 there were an estimated 500 million IoT-connected devices. By 2010 there were 12.5 billion connected devices. Morgan Stanley estimates that there will be 75 billion IoT devices by 2020. Cisco makes a more conservative estimate 50 billion. Whether it is Morgan Stanley or Cisco who proves correct, what is clear is that the number of internet connected devices is growing exponentially.

Consumer convenience is often the focus of the IoT. However, the capabilities of the IoT reach far beyond consumer convenience. The IoT is game-changing for the logistics and supply chain industries. The IoT delivers the visibility and data necessary for supply chain optimization.

One Network Enterprises, a supply chain technology provider, offers this supply chain example:

“[The IoT] refers to data communication among a large range of assets or devices—from your fridge to your oven or, more pertinently, from your inventory to its container, from the container to the carrier, from the pallet to the warehouse. The more your assets can ‘speak’ to one another and share data, the more they can work together to help you improve your processes.”

The IoT has already moved into industrial environments including warehouses and manufacturing plants.

Examples of where the IoT is already having an impact on supply chains include:

- Transparency and visibility

- Proactive replenishment

- Predictive maintenance

- Reduction in asset loss

- Manufacturing flow management

- Product development and commercialization.

- Risk management.

- Operational efficiency

- Improved fleet management

The transparency and end-to-end visibility afforded by the IoT creates new opportunities that supply chain professionals can leverage in order to optimize supply chains and generate value. It is important to look at the potential of the IoT now and not later. The amount of data alone that is generated by the IoT creates a paradigm shift. Companies that embrace the Internet of Things and identify where and how it can play a role for their business will move forward and leave those who do not behind.

The Internet of Things has the potential to change everything.

To learn more about how the Internet of Things has and will continue to impact the supply chain see the full article How the Internet of Things will change your world on Supply Chain Quarterly. The article includes a focus on Internet of things and the warehouse.