by Fronetics | Apr 9, 2015 | Blog, Leadership, Strategy, Supply Chain

Change management is the process of taking an individual or a group of people from a current state to a more desired state. Its recent prevalence, and often necessity, is heavily due to new technology and globalization. As humans we experience change constantly, on micro and macro levels. Today alone, around 350,000 babies will be born and 150,000 people will die. Gas prices might have dropped recently or your favorite flavor of potato chips might be discontinued. Stock prices rise and fall by the second. Nearly everything changes, yet the word change is often scary or stressful, especially when applied to the workplace.

Alan L. Milliken wrote in his article The Importance of Change Management in the Supply Chain that the key components of a successful business are process, technology, and people. He terms this the “Triad of Operational Excellence.” How is this “triad” involved in change management?

Process:

Sometimes process is the reason for implementing change. Are the processes in the supply chain preventing timely order fulfillment? Can the current process ensure proper, safe, and secure delivery? Are current processes compliant with regulations, nimble enough to weather unexpected change, efficient and modern enough to match innovative competitors? These are all good points to assess. When implementing change is it critical to understand a company’s current capabilities, what needs to be changed, and whether the current systems and finances can support change.

Technology:

Often change management can be spurred by a need for technological growth. If the end-to-end supply chain has antiquated practices, and one member of the chain is transitioning to modern technology, the rest of the players involved may feel the need to change despite being resistant to new technologies or feeling overwhelming by the cost and steps required to transition.

Some companies with decades or a century of business behind them, may be nervous about shifting to a social media driven, on-demand paradigm. There are many benefits to modernizing, and seeing the long-term view of how technology and media can assist business is critical. One company that has made changes to the way they present their business is the packaging supply company, Laddawn. Overhauling their website and providing customers with new purchasing capabilities has put them at the forefront amongst competitors. According to CEO, Ladd Lavallee, “It’s difficult for manufacturers to invest in service, or service technologies, because production can easily consume our time and money. But we need to make our customers’ lives easier if we want to keep winning their business in a shrinking world.”

People:

If leaders aren’t on board with a change management process their frustration or hesitation can seep into others’ mindsets. Studies have shown that emotional contagion occurs in society, and in business. People who cultivate a positive mind-set perform better in the face of challenge. When Bert’s Bee’s was rapidly growing on the global market, then-CEO, John Replogle, worked positive emotional contagion into his workplace, realizing, “Leaders, by virtue of their authority, exert a disproportionate impact on the mood of those they supervise.” He saw this change as an opportunity for people to grow as the company was growing.

In a sweeping meta-analysis of 225 academic studies, Sonja Lyubomirsky, Laura King, and Ed Diener found that happy employees have, on average, 31% higher productivity; their sales are 37% higher; their creativity is three times higher. According to executive coach and business consultant, Sara Regan, of Common Focus Consulting, thoughtful leadership during change is critical to success and employee satisfaction, “The biggest mistake I see leaders make is that they are too late in bringing others into the process. It usually creates more work in the end since it heightens anxiety and resistance then making the leader push harder instead of listen. The way in which leaders approach change impacts the end results but also the ongoing trust and engagement of the team.”

Certainly there are times when change is not necessary in a company, but when it is, aligning the process, technology, and people are key to reaching a new, more successful and desired state.

by Fronetics | Apr 1, 2015 | Blog, Internet of Things, Supply Chain

During his TED talk on the Internet of Things (IoT) technologist, Dr. John Barrett, described how every thing: appliances, furniture, vehicles, equipment, soil, food, animals and humans can become connected, identified, monitored, managed, and controlled. By 2032 he predicts that each person could come in contact with 3,000 to 5,000 connected things each day. IBM sees the Internet of Things as the planet’s new central nervous system.

The Internet of Things is already here and developing—monitoring our footsteps, heartbeats, lighting, home temperature and environment— and it will continue to grow at a rapid rate: “The growth in IoT will far exceed that of other connected devices. By 2020, the number of smartphones, tablets, and PCs in use will reach about 7.3 billion units,” said Peter Middleton, research director at Gartner. “In contrast, the IoT will have expanded at a much faster rate, resulting in a population of about 26 billion units at that time.”

The IoT and the Supply Chain

This will have a huge impact on the supply chain as we currently know it. In his talk, Dr. Barrett describes how a food processing company waiting for a delivery of shellfish will be able to not only “know where the food delivery is, but its entire storage and shipping history since the moment it came on board” the boat. Already, some vendors are able to remotely monitor their vending machines and access data about temperature, supply, and theft. In the future vending machines will be able to recognize a customer, recall their past preferences, and “even refuse to vend a certain product based on a shopper’s age, medical record, dietary requirements or purchase history.”

How else will we see IoT inform end-to-end transactions within the supply chain? Transparency in the supply chain is already growing with the swell of ERP and SCM, and with its growth it brings collaboration, clarity, and trust. With the increased use of Radio Frequency Identification (RFID) computer chips can talk to each other, and gather and deliver more detailed information than ever. Visibility in the chain will continue to expand and improve operations. The IoT will impact the supply chain in many ways including the following:

- Stock management

- Preventative maintenance

- User insight

- Manufacturing flow management

- Product stability

- Operational efficiency

- Improved fleet management

An Example of Success

Many companies are already employing the IoT, and as a result they are seeing improvements while working out the kinks of this new technology. UPS has increased single carrier deliveries with the use of sensors. According to David Barnes, the company’s chief information officer, more than 200 measurements can be tracked on a delivery truck from “how fast the vehicle is traveling, how aggressively it’s accelerating or decelerating, the RPMs and the fuel consumption. We can hook into the engine bus environment. We also put in a GPS unit. There are sensors on the engine and on components like starter motors and seat belts.” The analysis of this data is a main focus for UPS and has resulted in improved safety management, fuel efficiency, environmental impact, and customer satisfaction. One carrier reported that his deliveries increased from 90 a day to 120 a day. UPS drivers have seen an increase in salary as the company’s revenue multiplies.

The $1 billion UPS invests in technology per year is producing results, but what are the downfalls of telematics and other advancements? The union representing UPS workers has already set forth some demands: drivers cannot be monitored without being informed and cannot be disciplined “based solely on data.” One driver noted that it “does feel like big brother.”

Issues of security, privacy, accuracy, capacity, and the growth of software substitution in the workplace are all matters that need to be examined as IoT explodes. As IoT matures, it is wise for companies, especially those in manufacturing and logistics, to pay close attention. As reported by Gartner, by 2020, “Economic value-add (which represents the aggregate benefits that businesses derive through the sale and usage of IoT technology) is forecast to be $1.9 trillion across sectors.” With the increased possibility, reach, and data of the IoT will come complex decisions and opportunities for businesses.

Fronetics’ Kate Lee has written extensively about the Internet of Things and the supply chain. Her article, How the Internet of Things will change your world, was published in the Quarter 1, 2015 edition of Supply Chain Quarterly.

by Fronetics | Apr 1, 2015 | Blog, Internet of Things, Supply Chain

During his TED talk on the Internet of Things (IoT) technologist, Dr. John Barrett, described how every thing: appliances, furniture, vehicles, equipment, soil, food, animals and humans can become connected, identified, monitored, managed, and controlled. By 2032 he predicts that each person could come in contact with 3,000 to 5,000 connected things each day. IBM sees the Internet of Things as the planet’s new central nervous system.

The Internet of Things is already here and developing—monitoring our footsteps, heartbeats, lighting, home temperature and environment— and it will continue to grow at a rapid rate: “The growth in IoT will far exceed that of other connected devices. By 2020, the number of smartphones, tablets, and PCs in use will reach about 7.3 billion units,” said Peter Middleton, research director at Gartner. “In contrast, the IoT will have expanded at a much faster rate, resulting in a population of about 26 billion units at that time.”

The IoT and the Supply Chain

This will have a huge impact on the supply chain as we currently know it. In his talk, Dr. Barrett describes how a food processing company waiting for a delivery of shellfish will be able to not only “know where the food delivery is, but its entire storage and shipping history since the moment it came on board” the boat. Already, some vendors are able to remotely monitor their vending machines and access data about temperature, supply, and theft. In the future vending machines will be able to recognize a customer, recall their past preferences, and “even refuse to vend a certain product based on a shopper’s age, medical record, dietary requirements or purchase history.”

How else will we see IoT inform end-to-end transactions within the supply chain? Transparency in the supply chain is already growing with the swell of ERP and SCM, and with its growth it brings collaboration, clarity, and trust. With the increased use of Radio Frequency Identification (RFID) computer chips can talk to each other, and gather and deliver more detailed information than ever. Visibility in the chain will continue to expand and improve operations. The IoT will impact the supply chain in many ways including the following:

- Stock management

- Preventative maintenance

- User insight

- Manufacturing flow management

- Product stability

- Operational efficiency

- Improved fleet management

An Example of Success

Many companies are already employing the IoT, and as a result they are seeing improvements while working out the kinks of this new technology. UPS has increased single carrier deliveries with the use of sensors. According to David Barnes, the company’s chief information officer, more than 200 measurements can be tracked on a delivery truck from “how fast the vehicle is traveling, how aggressively it’s accelerating or decelerating, the RPMs and the fuel consumption. We can hook into the engine bus environment. We also put in a GPS unit. There are sensors on the engine and on components like starter motors and seat belts.” The analysis of this data is a main focus for UPS and has resulted in improved safety management, fuel efficiency, environmental impact, and customer satisfaction. One carrier reported that his deliveries increased from 90 a day to 120 a day. UPS drivers have seen an increase in salary as the company’s revenue multiplies.

The $1 billion UPS invests in technology per year is producing results, but what are the downfalls of telematics and other advancements? The union representing UPS workers has already set forth some demands: drivers cannot be monitored without being informed and cannot be disciplined “based solely on data.” One driver noted that it “does feel like big brother.”

Issues of security, privacy, accuracy, capacity, and the growth of software substitution in the workplace are all matters that need to be examined as IoT explodes. As IoT matures, it is wise for companies, especially those in manufacturing and logistics, to pay close attention. As reported by Gartner, by 2020, “Economic value-add (which represents the aggregate benefits that businesses derive through the sale and usage of IoT technology) is forecast to be $1.9 trillion across sectors.” With the increased possibility, reach, and data of the IoT will come complex decisions and opportunities for businesses.

Fronetics’ Kate Lee has written extensively about the Internet of Things and the supply chain. Her article, How the Internet of Things will change your world, was published in the Quarter 1, 2015 edition of Supply Chain Quarterly.

by Elizabeth Hines | Apr 1, 2015 | Big Data, Blog, Data/Analytics, Logistics, Supply Chain

A distribution center struggling with a high number of forklift truck impacts found a way to leverage big data to address a nagging, costly warehouse issue. The company had installed a telematics solution on its forklift trucks, but could not determine the cause of the impacts. The time and location of impacts were known, as well as the identity of the drivers involved, but the company still needed to pull in more data sources for an effective assessment.

Forget for a moment the potential of adopting big data analytics throughout the entire supply chain and consider instead how big data can untangle and integrate seemingly unrelated masses of data to solve small problems in a warehouse or distribution center. That’s exactly what this company did.

By analyzing the link between environmental factors inside the distribution center and the forklift impact records, the culprit was swiftly identified: fast-moving thunderstorms that caused the humidity level to rise so quickly that the dehumidifiers could not keep up, increasing the risk of drivers losing control on the slippery concrete floor. That knowledge helped the company prevent sliding accidents by using a function of the telematics solution to reduce the maximum speed of the trucks when the humidity hit a certain level.

Indeed, distribution centers and warehouses present ideal environments — microcosms — for big data applications. Modern facilities are loaded with sensors and detectors to track every pallet and every piece of material handling equipment in real-time. Managers see the benefits in increased productivity, improved inventory flow, optimized equipment usage, and more. However, for that Eureka moment, organizations should also apply big data analytics across these multiple sources of data to uncover patterns that will drive even more, and perhaps surprising, operational improvements.

Rather than looking at data in isolation, a holistic approach holds significantly more power. Managers typically keep careful track of the performance of lift trucks, batteries, and chargers. But it is not until those entities are reviewed as a single system and matched with data coming off the lift trucks that a new level of revelations can be had.

Look for big data analytics to further raise the IQ of our “smart” warehouses and DCs. Inbound Logistics sums it up this way: “Accessing the right information to make smart decisions in the warehouse is one main reason why the demand for big data has grown so much — and so rapidly — in the distribution sector.”

Do you think distribution center and warehouse managers do enough to leverage big data?

by Elizabeth Hines | Apr 1, 2015 | Big Data, Blog, Data/Analytics, Logistics, Supply Chain

A distribution center struggling with a high number of forklift truck impacts found a way to leverage big data to address a nagging, costly warehouse issue. The company had installed a telematics solution on its forklift trucks, but could not determine the cause of the impacts. The time and location of impacts were known, as well as the identity of the drivers involved, but the company still needed to pull in more data sources for an effective assessment.

Forget for a moment the potential of adopting big data analytics throughout the entire supply chain and consider instead how big data can untangle and integrate seemingly unrelated masses of data to solve small problems in a warehouse or distribution center. That’s exactly what this company did.

By analyzing the link between environmental factors inside the distribution center and the forklift impact records, the culprit was swiftly identified: fast-moving thunderstorms that caused the humidity level to rise so quickly that the dehumidifiers could not keep up, increasing the risk of drivers losing control on the slippery concrete floor. That knowledge helped the company prevent sliding accidents by using a function of the telematics solution to reduce the maximum speed of the trucks when the humidity hit a certain level.

Indeed, distribution centers and warehouses present ideal environments — microcosms — for big data applications. Modern facilities are loaded with sensors and detectors to track every pallet and every piece of material handling equipment in real-time. Managers see the benefits in increased productivity, improved inventory flow, optimized equipment usage, and more. However, for that Eureka moment, organizations should also apply big data analytics across these multiple sources of data to uncover patterns that will drive even more, and perhaps surprising, operational improvements.

Rather than looking at data in isolation, a holistic approach holds significantly more power. Managers typically keep careful track of the performance of lift trucks, batteries, and chargers. But it is not until those entities are reviewed as a single system and matched with data coming off the lift trucks that a new level of revelations can be had.

Look for big data analytics to further raise the IQ of our “smart” warehouses and DCs. Inbound Logistics sums it up this way: “Accessing the right information to make smart decisions in the warehouse is one main reason why the demand for big data has grown so much — and so rapidly — in the distribution sector.”

Do you think distribution center and warehouse managers do enough to leverage big data?

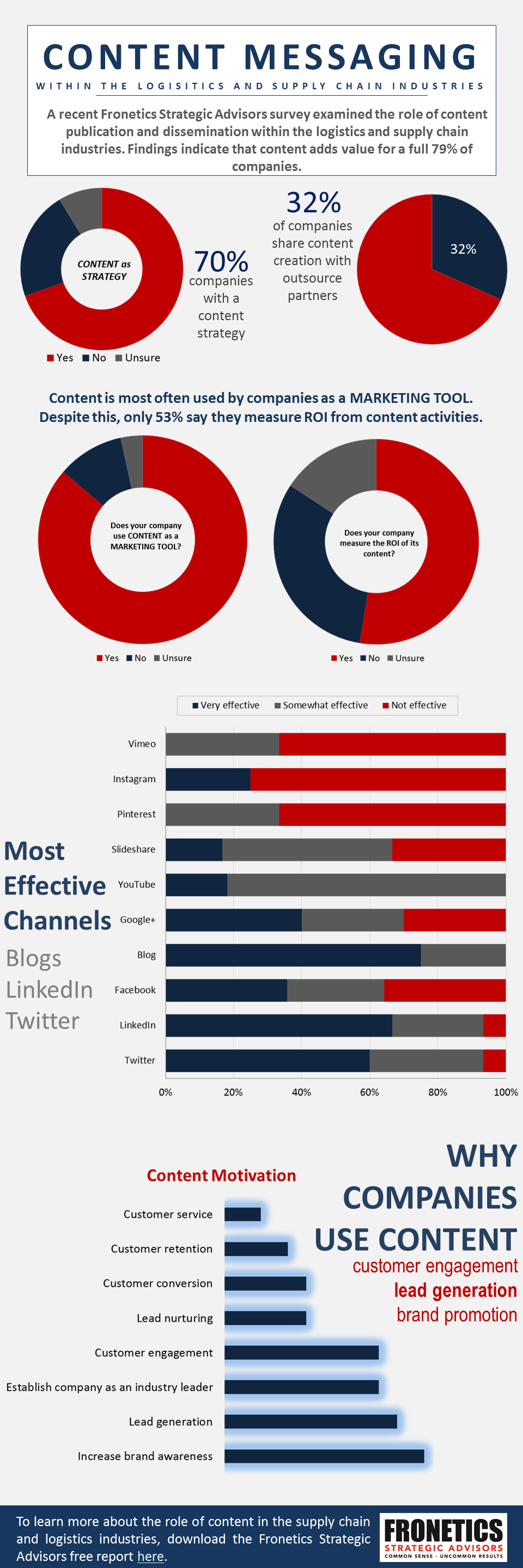

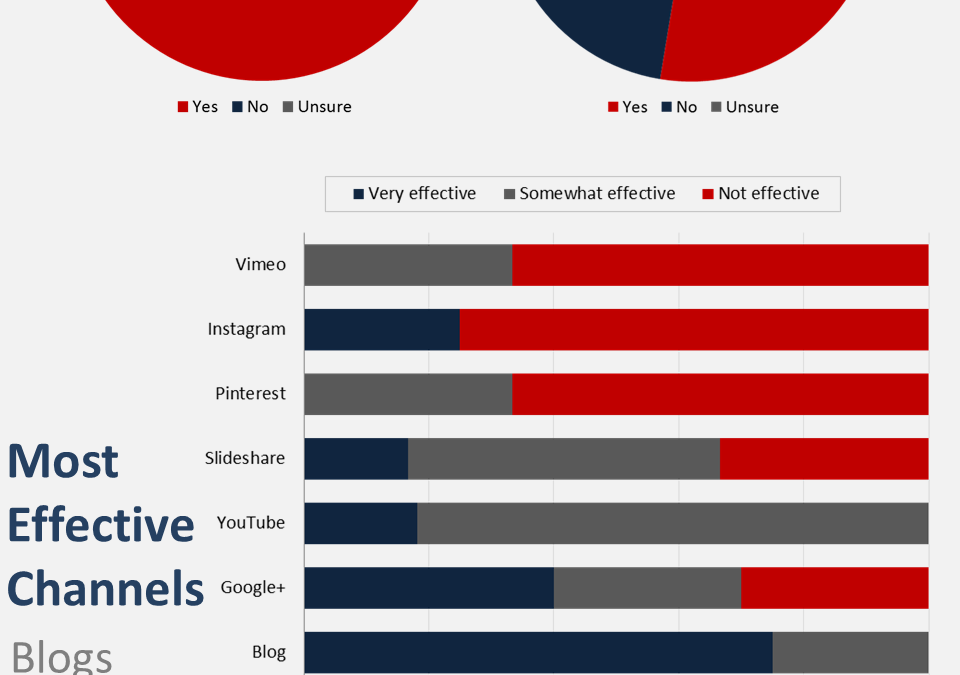

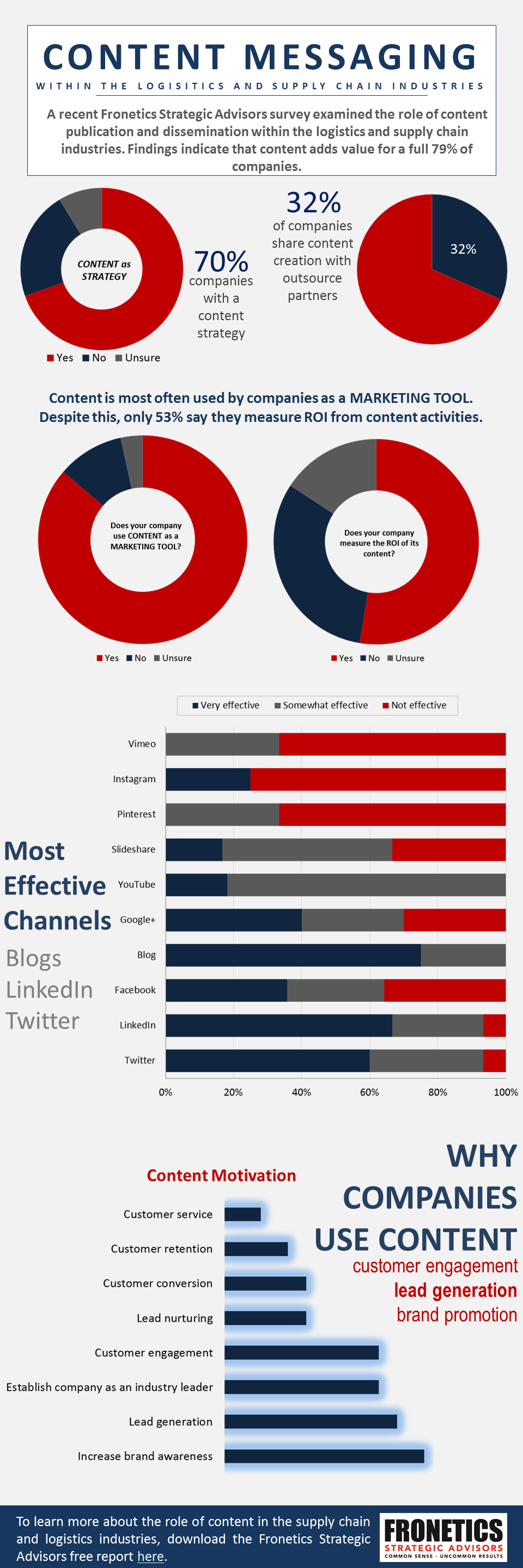

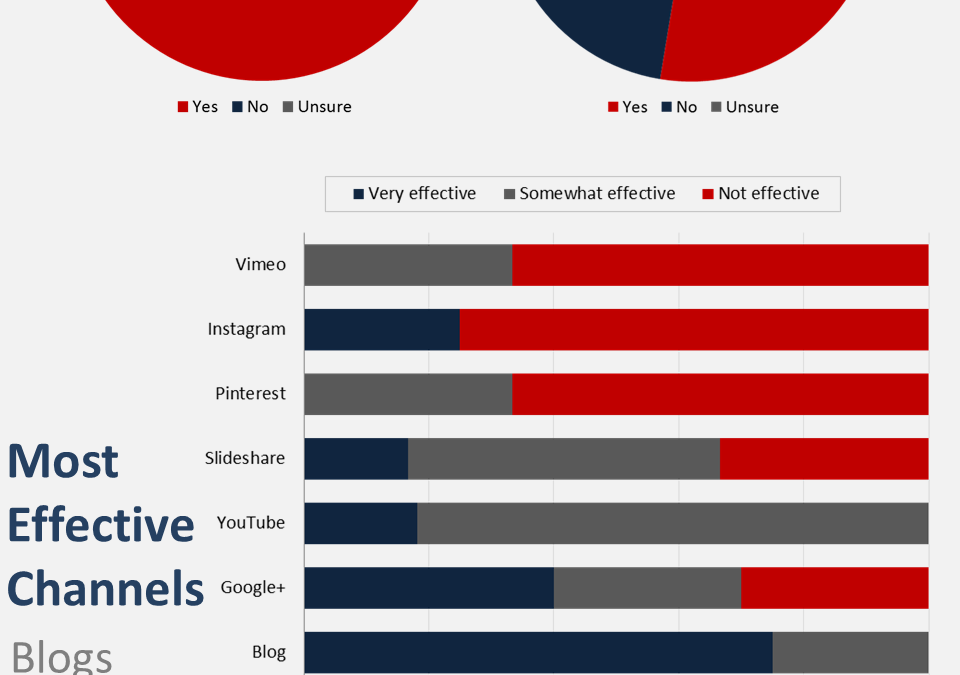

by Fronetics | Mar 31, 2015 | Blog, Content Marketing, Logistics, Marketing, Strategy, Supply Chain

Chief among the determinants of success and failure of companies around the world is the ability to effectively communicate ideas and information. Both internal and external communication play critical roles in advancing business objectives. To be sure, connecting with audiences to convey messaging is a central component of building a solid business strategy. Recent cultural shifts and advances in digital technology have pushed aside traditional methods of communication and given way to the rise of a new type of communication strategy– one that puts content at the very center.

Fronetics Strategic Advisors conducted a survey to better understand the role and use of content within the logistics and supply chain industries.

The survey found that companies within the logistics and supply chain industries are using content as a marketing tool and are realizing benefits.

Survey respondents were asked to identify the goals of their company’s content strategy. The top three goals identified were:

- Increasing brand awareness

- Lead generation

- Establishing the company as an industry leader.

To learn more, check out our infographic, or download the report.