by Fronetics | Feb 11, 2016 | Blog, Strategy, Supply Chain

Supply chain management is more than just a series of transactions; it is a valuable, strategic business process.

Change is inevitable, and, in healthcare supply chain, it is crucial. The most progressive healthcare organizations across the country now acknowledge that supply chain management is more than just a series of transactions; it is a valuable, strategic business process.

These organizations have researched this expanding avenue to improve their services and cut costs, leading to new supply chain strategies for the coming year. But many in this industry hesitate to accept the evolving role of healthcare’s supply chain and the value it holds. They fail to utilize the data or act upon it, and this carries a cost for both the organization and their patients.

And costs are a rising concern. It is estimated that healthcare costs nationwide will reach $4.8 trillion by 2021, according to the Centers for Medicare & Medicaid Services. Supply chain inefficiencies could be a contributing factor, but optimizing logistics provides a remedy.

The Force of Data Awakens

It is a pretty simple concept: The more you know, the better your decisions. As the healthcare industry continues to evolve, data has been crucial in helping organizations pinpoint ways to cut costs, improve patient care, and end wasteful methodology. And according to a Supply Chain Digital report, the vast majority of healthcare organizations have yet to tap into the full potential of the complex data available to them.

The power to improve efficiencies in a healthcare organization can be found through:

- Recognizing the supply chain is a powerful force of change: Supply chain management and analytics are no longer after-thoughts. Once their value across an organization is realized, those focused on strategy and cost-effective measures will consider tomorrow’s supply chain of great importance.

- Seeking more data with greater detail and complexity: As organizations gather more data — and that data becomes more granular, down to patients and their outcomes — in-depth analysis will achieve an unprecedented understanding of where real value is hidden throughout all departments.

- Allowing the supply chain to guide consistency in care: Everyone benefits from standardization and consistent care, especially the patients. Tapping into the valuable data from the supply chain and using it to determine the best pricing and treatment strategies for the best outcomes for patients is a key component. All of this will encourage inefficient and wasteful processes be eliminated, saving time and money.

- Implementation of product scanning, electronic ordering, order accuracy controls: Healthcare providers, distributors, and manufacturers have been challenged by an unacceptable amount of errors in the procurement of medical devices and treatment supplies, according to Inbound Logistics. Old systems requiring a manual ordering process can result in ordering errors, product shortages, or the delivery of products that are incorrect or even expired. Improving efficiency in the healthcare supply chain facilitates the elimination of costly errors and supports higher standards of patient care.

- Aligning physicians with the value of supply chain data: A partnership must be formed between the supply chain and physicians to target more efficient processes for their patients and to seek supply chain guidance regarding product price points, alternatives, and outcomes.

- Utilizing analytics to improve service and reliability: Healthcare supply chain data will be leveraged for predictive analytics. Essentially, supply chain professionals will use data to better predict and respond to products needed with greater speed and less instances of delays in service. Knowing these inventory challenges ahead of time also enables providers to seek alternatives if a product is discontinued or backordered.

There is an awakening in the healthcare industry as more organizations realize that their strategic business plans can be guided and improved by a myriad of complex supply chain data available. Across the healthcare continuum, there is a demand to look at business from a new perspective, seeking innovative methods to reduce costs and improve patient care.

This is achievable when healthcare organizations and their supply chain providers form an alliance, based on mutual goals and incentives, to leverage more analytical data to improve both patient care and operational efficiencies.

by Fronetics | Feb 4, 2016 | Blog, Leadership, Strategy, Supply Chain

When it comes to leading during difficult times in the supply chain, planning is critical. So is flexibility.

Winter storm Jonas is estimated to have cost $1 billion USD, although some believe the cost could go as high as $3 billion USD, as it paralyzed a large swath of the mid-Atlantic and Northeast. Some 30 inches of snow touched down on several East Coast cities, which cancelled over 12,000 flights and kept people out of work for days.

When difficult times strike, having a plan is critical. For example, with electricity still working, business doesn’t need to come to a close for days on end. Researchers who did a study at Chinese company C-trip encourage people to work from home during storms: “We encourage companies to do a trial the next time an opportunity presents itself — like bad weather, traffic congestion from major construction, or a disruptive event (such as a city hosting the Olympics or the World Cup) — to experiment for a week or two. We think working from home can be a positive experience, both for the company and its employees, as our research with C-trip showed. More firms ought to try it.”

The supply chain can be disrupted in many ways: natural disaster, terrorism, fluctuation in materials. When the problem hits, it’s good to have a plan, but one can’t always be prepared for every scenario. According to the president of global public affairs for UPS, Laura Lane, who had her share of difficult times when she was a young foreign officer in Rwanda during the genocide in 1994, “You have to make decisions that will result in the greatest good — and from that perspective, every decision becomes crystal clear.”

Lane shared her thoughts about how to handle difficult situations in the supply chain with The Wall Street Journal recently.

Look for leaders everywhere

Lane believes that it’s not only C-suite managers who can handle disaster. Being open to ideas and letting specialists rise from the ranks could be a game-changer in critical situations. “Don’t judge people based on their years of experience. Greatness can emerge from anyone on your team — people with decades of experience, or those just starting out.”

Don’t let fear stop you

When you are ultimately responsible for a huge decision involving lots of people and money, fear can infiltrate the mind and body quickly. Remember that you’re in the position you hold for a reason. Don’t let self-doubt or uncertainty about how things will play out delay your decision making. See boundaries and obstacles are new opportunities to find alternatives. Lane says, “Challenge how things are done, and rewrite the rules, if needed,” she says.

Think of the larger vision

Remember what the goals of the company are, and that people have been put in specific roles for reasons. Remember that your situation most likely involves teamwork, and that you can rely on the support, ideas, and voices of others, especially when the vision of the company becomes foggy in the stress of the moment. “Delivering on your promises and grounding your actions in your values is what is needed to be a great leader. You have to believe in the greater good of what you’re doing and then bring others along with you in realizing the bigger vision.”

You may also like:

by Fronetics | Feb 2, 2016 | Blog, Logistics, Strategy, Supply Chain

Amazon’s ever-expanding foray into the logistics space could turn the industry on its head.

You can have bánh mì delivered in Chicago, toilet paper in Bangalore, and, pretty soon, packages under 5 pounds via drone in Tel Aviv. Students at the University of Pennsylvania don’t even have to leave campus to return an order.

Amazon’s continued expansion into the logistics market seems to be seeping into all corners of the world, making more and more products available with a single click. Inversely, the time frame for delivery keeps dwindling, from two days to the forthcoming 30-minutes-or-less drone-delivery service Prime Air. And more options in less time happy customers make.

Amazon’s commitment to getting packages into the hands of customers as quickly as possible could be the driving force behind its recent foray into the logistics space.

Planes, freights, and automobiles

The retailer still relies on trucking partners and a longstanding partnership with UPS. But the 2014 debut of the first sortation center in Kent and purchase of thousands of truck trailers in December 2015 suggested an effort to take more control of shipping. This is particularly true for the last mile of delivery — presumably to circumvent issues like the 2013 holiday fiasco.

But then came the news that Amazon China had registered to operate as an ocean freight forwarder in the United States. That means the company can deliver products from China on its own ships. Is this a first step toward entering the $350 billion ocean freight market?

Additionally, reports surfaced in early 2016 that Amazon is in talks with several cargo-aircraft lessors regarding a number of Boeing 767 jets, which can accommodate up to nineteen 88-by-125-inch pallets a piece. The Seattle Times speculates this move is an expansion of an existing trial operation out of Wilmington, Ohio, to determine whether Amazon should pursue a larger air-cargo operation.

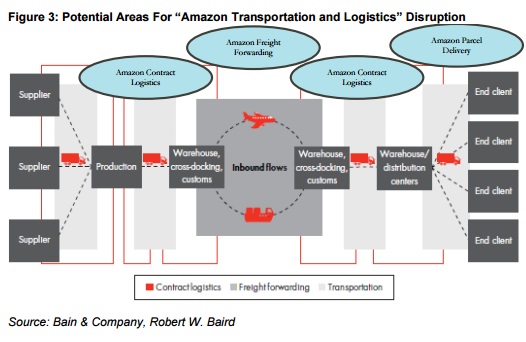

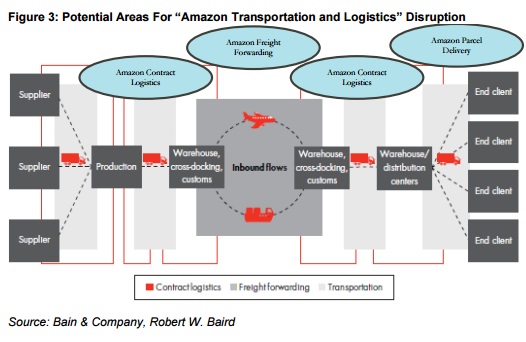

Ocean freight and air cargo suggest an interest in controlling operations well beyond the last mile. Could this be the development of a full-scale, in-house logistics department that could independently manage Amazon’s fulfillment process? Or, perhaps, are these steps to manage something beyond the company’s own shipping and delivery?

Amazon hinted at such in a securities filing last Friday, referring to itself as a “transportation service provider” and “companies that provide fulfillment and transportation services for themselves or for third parties” as competition for the first time ever.

Amazon as a 3PL

For some time now, the media has been speculating about Amazon‘s intentions to enter the transportation and logistics market as a third-party provider. That would certainly fit the existing pattern: 1) begin operations to better support core retail business, 2) grow and leverage that infrastructure to sell to other businesses.

A prescient October 2015 analysis by Baird Equity Research Analyst Colin Sebastian notes the “powerhouse potential” that Amazon has in the market should it “extend its increasingly complex and technology-centric logistics and delivery platform as a third-party offering.” The report cites the growth of Amazon Web Services (AWS) and Marketplace as templates for the expansion of logistics services to external clients.

Sebastian says the highly competitive global logistics market has yet to fully capitalize on web-based technologies to address supply chain inefficiencies — and Amazon’s wildly successful cloud computing platform, paired with its complex delivery network, may be the answer. The result would be a disruption of incumbent businesses, such as UPS and DHL. “We believe Amazon may be the only company with the fulfillment/distribution density and scale to compete effectively with global providers,” the report says.

Amazon is already moonlighting as a 3PL through its Fulfillment by Amazon (FBA) business, which debuted in 2006. The company recently revealed that FBA delivered more than 1 billion packages to customers in 2015. And Friday’s fourth quarter earnings report revealed Amazon’s sales, as a whole, were up 22% to $35.7 billion. You could say they’re doing something right.

The Baird report estimates the global fulfillment market as a $400-450 billion incremental market opportunity. Is this where Amazon has set its sights next?

Related articles:

by Fronetics | Feb 1, 2016 | Blog, Strategy, Supply Chain

Reverse logistics presents unique challenges and opportunities. To meet these challenges and take advantage of these opportunities, companies need to be both prepared and flexible.

Ikea, a company known for innovation, is facing the enigma of reverse logistics head on. As part of the company’s sustainability strategy, Ikea is challenging the perception that its products are disposable by creating opportunities to recycle and reuse products.

In a recent interview with Fast Company, Chief Sustainability Officer Steve Howard outlined several of the company’s initiatives. They include programs that allow consumers to return plastics, batteries, furniture, compact fluorescent light bulbs, mattress, and textiles to the store. These items are then sold “as-is” or recycled.

These programs have proven successful. For example, in just a few months, over 6 tons of batteries were collected in Moscow, and 25 tons of used textiles were collected in Norwegian stores last year.

Ikea is looking at other ways it can provide end-to-end supply chain solutions. One idea is to take returned products and recycle them into other products. In his interview with Fast Company, Howard shares: “We would basically be taking old bookshelves, old furniture, or an old door that’s finished its first life and sending it into new products. You’ll have a kitchen that used to be a bookshelf, without seeing any visible difference in them. It’s not a revolution, but you have to actually fundamentally change your supply chain to do that.”

Ikea has recognized that old, broken, and unwanted products are an opportunity. Through these innovative reverse logistics initiatives, Ikea is not only acting in a more sustainable manner and reducing the company’s environmental footprint, it is also increasing engagement with consumers and creating positive economic opportunities for the company.

Similar articles:

by Fronetics | Jan 28, 2016 | Blog, Logistics, Supply Chain

Fronetics names the best of the best blogs in the logistics and supply chain industries.

The logistics and supply chain industries are catching on to how successful a blog can be as part of an inbound marketing strategy. Companies are creating content that not only fuels conversation about industry best practices, trends, and issues, but also helps drive business to their websites.

Fronetics Strategic Advisors conducted a survey in January 2016 to determine the top logistics and supply chain blogs in the industry. Here are the results:

Dallas, TX-based Transplace is a 3PL and technology provider serving manufacturers, retailers, and consumer and chemical packaged goods companies. Logistically Speaking is the company’s thought leadership blog. It tells “the latest and the greatest supply chain and transportation stories” through Infographics, interviews with logistics executives, and informative articles offering information and advice.

Readers love: the weekly “TIP list,” or Transportation Industry’s Progression, which curates a short list of articles concerning trending topics and advancements in the industry

Transplace’s CEO Tom Sanderson shares information, opinions, and analysis of factors affecting the supply chain — including company economic data, freight transportation regulation and legislation, and carrier and 3PL financial performance. The blog is rich with charts and graphs that offer big-picture insight on what’s going within the industry.

Transplace’s CEO Tom Sanderson shares information, opinions, and analysis of factors affecting the supply chain — including company economic data, freight transportation regulation and legislation, and carrier and 3PL financial performance. The blog is rich with charts and graphs that offer big-picture insight on what’s going within the industry.

Readers love: Sanderson’s no-nonsense breakdown of the most pressing issues facing the supply chain

Jennifer Cortez, Director, Marketing Communications, is thrilled with Transplace being recognized by Fronetics and the industry:

“We are thrilled to be recognized as the top logistics and supply chain blogs in 2015. At Transplace, we pride ourselves on providing timely and relevant content to our customers and the industry. Our goal this year is to further connect Transplace and our thought leaders with emerging industry trends.”

Procurious is a UK-based online business network with news, education, discussion forums, and events for procurement and supply chain professionals. The blog goes beyond industry insights — it’s a savvy guide to career advancement and skill development. Articles are written for the modern-day professional, in sync with Procurious’s forward-thinking brand.

Readers love: original series like Life & Style and #firstmovers, which cover interesting, relevant topics in the procurement world.

Thank you to all who took our survey to find the top logistics and supply chain blogs!

Fronetics Strategic Advisors is a management consulting firm with a focus on inbound marketing. We create and execute successful strategies for growth and value creation. Unlike other firms, our approach is data driven. We know ROI is important, so we track and measure results to drive success. Read about our approach to inbound marketing, or get in touch.

by Fronetics | Jan 25, 2016 | Blog, Manufacturing & Distribution, Strategy, Supply Chain, Talent

We know that diversity in the workplace has value beyond enriching company culture. A McKinsey & Company report found that diverse companies financially outperform companies that are not diverse by 15%. And in terms of gender diversity, specifically, research shows that when women are in positions of leadership, companies perform better — much better.

We know that diversity in the workplace has value beyond enriching company culture. A McKinsey & Company report found that diverse companies financially outperform companies that are not diverse by 15%. And in terms of gender diversity, specifically, research shows that when women are in positions of leadership, companies perform better — much better.

Data shows that gender equality has improved in recent decades, such as the 15% increase of women working full time in the workforce since 1979. But there is still much progress to be made. As a recent UN Working Group mission to the US to explore discrimination against women found: “In the US, women fall behind international standards as regards [to] their public and political representation, their economic and social rights, and their health and safety protections.”

Women in manufacturing and the supply chain

We see that women in manufacturing and the supply chain haven’t been faring as well as their counterparts in other sectors. The number of women working in manufacturing is the lowest it has been since 1971. In the supply chain, men hold between 70-80% of the jobs, and we see even more disparity at the higher levels — only 5% of women hold Fortune 500 supply chain top-level positions.

Beth Ford, executive vice president and chief supply chain and operations officer at Land O’Lakes, sees the positive in these numbers: “The representation of women in this area is not where it needs to be. At the same time, it could be viewed as tremendously exciting. The opportunities are there for women.”

Where opportunity lies

So what can be done to make changes that will benefit everyone, and the bottom line?

According to a Fronetics Strategic Advisors report on women in the supply chain, “it has been put forth that women are better suited for roles in supply chain management than men. Research conducted by SCM World found that the majority of men (63%) and women (75%) believe that the natural skill sets of women differ from those of men and that these differences are advantageous for supply chain management.”

One of the biggest ways is diversify entry into the profession and a pathway to leadership. The typical trajectory to the top roles in the supply chain starts on the shop floor. These jobs tend to be more male-dominated trade work. For the supply chain to seek new talent, especially women, they must look beyond their four walls.

Since there is a lack of talent being funneled into the supply chain, companies should look more closely at universities that offer supply chain management programs. Many of these programs recruit and attract women.

There are several women (and men) working in the supply chain who are cheering for other women to join. According to an interview with Bravo Solution VP Mickey North Rizza, “While business has traditionally been a man’s world, more and more women are now in businesses. Most women by nature have been relationship-builders. They encourage, collaborate and innovate with others for the best outcome. It is only natural that these tendencies gravitate to the business world, and most importantly into supply chain.”