by Elizabeth Hines | Mar 10, 2016 | Blog, Manufacturing & Distribution, Strategy, Supply Chain, Talent

Manufacturing could offer a career with upward potential for STEM students at low-profile colleges.

The college graduates of 2015 were the most indebted ever — until the next round of grads wave their diplomas in the spring. But is sinking deep into debt really the ticket to a great career? If you have the means (and brains) to invest in an Ivy League degree, all stats seem to indicate you get ample payback for the $200,000-plus expense.

But among those high school grads who may not qualify for generous financial aid packages and at the same time cannot afford — or even want — an Ivy League degree, there are still lucrative options, especially if they study science, technology, engineering, and math (STEM).

The skills gap in U.S. manufacturing, for example, is well known. While as many as 60% to 70% of executives say their current employees lack sufficient skills in technology, computer, and math, the problem is exacerbated by the lack of qualified job prospects — an expected 2 million manufacturing jobs will go unfilled due to the talent gap during the next decade, according to a Deloitte study.

As I’ve said before, herein lies opportunity. There is no reason seeking a career in manufacturing should break the bank if students weigh their choices wisely. Picking a low-profile school may “pay off big both in terms of getting a good job and salary,”according to John Walsik, a Forbes contributor and author of The Debt-Free Degree.

The opportunity is best illustrated by Business Insider’s recent list of underrated colleges in America in which the US News and World Report’s rankings of the best universities was compared with PayScale’s 2015-2016 College Salary Report. Rather than pursuing degrees from the highest rated schools, high school grads should also consider schools that, although ranked relatively low on the US News list, yield high mid-career salaries.

Interestingly, Missouri University of Science and Technology, New Jersey Institute of Technology, and University of Massachusetts at Lowell, known for their science and engineering programs, all ranked in the top 5 (Pace University in New York City topped the list), with mid-career median salaries ranging from $94,700 to $102,000. Within six months of graduation, for example, 80% of New Jersey Institute of Technology graduates were either employed — top employers include IBM and ExxonMobil — or enrolled in graduate programs.

A college degree from a prestigious school means little unless your earnings quickly make it worthwhile. If only manufacturing could shake its lackluster reputation, a growing number of students may discover it holds the key to a career with a lot of upward potential — without necessarily going into big debt.

What is your take on the cost of college versus the payoff?

A version of this post previously appeared at EBN Online.

by Elizabeth Hines | Feb 29, 2016 | Blog, Manufacturing & Distribution, Strategy, Supply Chain

As companies “tiptoe” back to the United States from overseas, the “Made in USA” label should grow more common. However, ambiguous rules are costing some manufacturers hundreds of thousands of dollars in penalties and legal fees. So what’s the problem? The coveted “Made in USA” does not always mean the same thing to companies as to the Federal Trade Commission.

Although most cases stem from California, where every single component must be sourced domestically to earn the right to be advertised as American-made, the ambiguity of FTC’s rules is likely to bring more lawsuits nationwide. FTC rules state the “Made in USA” label can only go on goods that are “all or virtually all” made in the United States. But how should companies interpret “virtually?”

The latest to be slapped with a list of reprimands by the FTC is none other than Walmart, which recently was asked to not only remove “Made in USA” logos from all product listings, but also the country-of-origin information from all product specifications (unless required by law) and U.S.-origin claims that appear in product descriptions or titles. Walmart is also required to clear advertisement copy submitted by suppliers of any USA-origin claims.

A giant like Walmart can certainly handle adjustments to its Investing in America Jobs Program — redesigned logos will now disclose the percentage of U.S. content in the product — and transparency is obviously fundamentally important in sourcing and product advertisements. But the fact still remains: Companies can only guess what qualifies as U.S.-made. As reported by Supply Chain Digest, some have taken it upon themselves to include 70 percent of domestically made components before making any “Made in USA” claims.

The dysfunction is perhaps best illustrated by the case of Lifetime Products, whose basketball hoops ended up in the spotlight last fall when two consumer lawsuits claimed they were falsely labeled. Although the hoops are, to quote the Wall Street Journal, “made of parts that are almost entirely cut, shaped, painted and assembled” at the company’s sprawling Utah factory, some bolts and the net were imported from China. The costs were staggering, with the legal fees alone adding up to $535,000, and the plaintiff’s attorney’s receiving $485,000.

Sourcing every single component domestically is no easy feat, especially for companies that just returned production from overseas and want to capitalize on the move with the “Made in USA” label. After so many years of outsourcing, it will take time to rebuild the U.S. supplier base as well as upgrading aging manufacturing equipment to meet today’s demand for speed and agility.

Lasko Products Inc., a family-owned company based in West Chester, Pa., is one example of a producer that can no longer find domestic suppliers of small electric motors. The company’s electric fans are sold at Walmart, which has discovered the effort to buy more U.S.-made products has proved particularly difficult when it comes to electrical devices.

Let’s hope the FTC can at least clarify the rules.

What do you think is a reasonable definition of “Made in USA?”

A version of this article was previously published on EBN Online.

by Fronetics | Feb 18, 2016 | Blog, Strategy, Supply Chain

The health care supply chain could cut billions of dollars in cost by adopting practices well established in other industries.

Take the case of a typical Asian laptop manufacturer, for example. As a result of a top-notch supply chain, a European customer can place an order and receive a pallet of freshly assembled computers in just over a week. Ask a pharmaceutical manufacturer for a delivery, on the other hand, and the lead time stretches to 75 days.

The case is further illustrated by the difference in operational metrics between the health care supply chain and the supply chain for fast-moving consumer goods (FMCG). Whether you look at days in inventory, obsolescence, or manufacturing lead time, the FMCG is invariably so efficient that the health care supply chain looks sluggish in comparison.

But such a significant performance gap also means even minor efficiency gains could have a big impact, according to a McKinsey report. An industry that spends in the excess of $340 billion annually on pharmaceuticals and medical devices would benefit from examining every part of its supply chain to not only speed up lead time and boost ROI, but also provide safer and more affordable products to end customers around the world, the consulting firm argues.

The shortcomings so far stem from an inability to tackle challenges that today add substantial cost to the health care supply chain. Big-ticket challenges include:

- Increased regulatory scrutiny

- Expanding product portfolios

- Drug recalls

- Drug shortages

- Counterfeiting

- Supply-chain security breaches

- Medication errors in the developed world

Although transforming a supply chain is an incredibly complex undertaking, McKinsey notes:

“…if the sector adopted straightforward advances well established in other industries, we estimate that total costs (from the supply chain and external areas, such as patient care) could fall by $130 billion.”

Industry research does indeed show every member of the value chain – from pharmaceuticals and medical suppliers to pharmacies and hospitals – that embraces opportunities to optimize the health care supply chain reaps the rewards in increased profitability. In most cases, the impact on profits ranged from 10 to 20 percent.

So which area of the supply chain offers the greatest opportunity for improvement?

Senior supply chain executives in the pharmaceutical and medical device industries overwhelmingly place improved collaboration at the top of the list. To overcome cultural barriers and make transactional relationships more productive, McKinsey suggests the following approach:

“…six essential steps can make the difference between a productive collaboration and a frustrating one: companies must collaborate in areas where they have a solid footing; agree on sophisticated benefit-sharing models; select partners for the potential value of the collaboration, as well as their capabilities and willingness to act as a team; dedicate resources to the collaboration and involve senior leadership in it; jointly manage performance and measure impact; and start out with a long-term perspective.”

Collaboration is still only a small piece in the supply chain puzzle that also includes better market, product, and customer segmentation; greater agility; improved benchmarking and measurements; and the establishment of global standards for data exchange. To put it all together, it is imperative for the health care supply chain to follow the lead of high performing industries.

You may also like: Improving Efficiency in the Healthcare Supply Chain

by Fronetics | Feb 17, 2016 | Blog, Content Marketing, Manufacturing & Distribution, Marketing, Social Media, Supply Chain

The US manufacturing index is at its lowest level since 2009. This is sobering news for the industry and for the economy. Within the industry, it is clear that the road ahead is not flat, straight, or even smooth. For companies to not just survive, but to also succeed, action needs to be taken.

The US manufacturing index is at its lowest level since 2009. This is sobering news for the industry and for the economy. Within the industry, it is clear that the road ahead is not flat, straight, or even smooth. For companies to not just survive, but to also succeed, action needs to be taken.

In August 2015 Bruce McDuffee, Principal at Knowledge Marketing for Industry, released the second edition of the Manufacturer’s Growth Manifesto. If you haven’t read this, you need to do so – today. In the Manifesto, McDuffee spells out how manufacturers can achieve growth rates of 10%, 20%, and even 30%.

The key to attaining a double digit growth rate is changing your marketing strategy and adapting to buyers’ new habits. Specifically:

- Stop pitching products and start helping people.

- Start educating your audience utilizing your particular experts and expertise for FREE.

- Stop advertising product features and benefits of a product.

- Start promoting your useful, helpful papers, webinars, seminars, videos, etc. (not product information) to foster meaningful engagement.

- Admit to yourself and your team that your products are perceived as a commodity and it will take more than product revisions, releases and enhancements to gain the attention of your target audience.

McDuffee concedes that for those who have not previously embraced and engaged in this approach to marketing, “You may be thinking, WTF?”

It may seem counterintuitive, but the results are real. Your company will be able to achieve those double digit growth rates and realize these benefits:

- Reciprocity, credibility and trust in the minds of the people in your target audience.

- Top-of-Mind Awareness (T.O.M.A.) in the minds of your prospective customers so they remember your firm first when the day comes around and they need to buy.

- Higher prices, more sales, more market share, and higher growth rates.

Success, however, depends on believing in this approach and incorporating it into your overall business strategy.

Research conducted by the Content Marketing Institute (CMI) found that while 82% of manufacturers use content marketing, only 26% say that their efforts are successful. A lack of buy-in/vision from higher ups is one of the key challenges identified by CMI. Another challenge that was reported was creating and executing a strategy; only 20% of respondents reported that they had a documented strategy. Notable though, is that 58% of the most effective companies reported that they have a documented strategy.

This approach is not relevant only to manufacturing. Companies across industries and verticals should take notice. Cerasis, a top North American third party logistics company offering logistics solutions with a strong focus on LTL freight management, shifted their marketing strategy and realized positive results. Within 25 months Cerasis realized a 14% increase in revenue. This increase was directly attributable to inbound marketing. In addition to this stream of revenue, the company’s sales team was able to generate revenue totaling $20 million during this period – more than double the previous two years combined.

Those numbers are not small potatoes. If you haven’t checked out the Manufacturer’s Growth Manifesto, make the time.

You may also like:

This was originally published on Electronics Purchasing Strategies.

by Fronetics | Feb 16, 2016 | Blog, Logistics, Strategy, Supply Chain

Interim management is an opportunity.

These days there may be no such thing as “business as usual.” People no longer work for one company for decades and then retire with a pension. Most will work an average of 10 jobs before the age of 40, according to Bureau of Labor Statistics, and that number is predicted to increase over time. Given this fact, it makes sense that, even at the high levels, job consistency is not a given for any one person or any company.

Interim management is an opportunity for companies to handle transition in an optimal way. There are numerous benefits that are cost-effective and efficient.

Organizational continuity

A company can hire someone to come in and specify exactly how they would like to progress in the interim. Demanding status quo, in many ways, may be what the company needs until assessments and next steps are made. The interim manager’s experience can help stabilize public image and alleviate some employee fears.

Choose for specific needs

If continuity isn’t the desired route, the benefit of interim management is that a company can seek specific needs in interim management that fill the holes and address the challenges of outgoing management. If a change is needed, that is possible, too.

Independent thought & experience

Interim management companies work to benefit you and you alone. Of course they gain in some ways, but they are independent from allegiance to other companies and are hired to keep your best interests in mind. It benefits them, in the long run, to serve your specific needs. You can be assured that they aren’t in for a long-term position.

Flexible assignments

A company can hire interim management for however long is necessary. The flexibility of the engagement works well for everyone. Interim management are prepared to work themselves out of the job, genuinely equipped to find the best people for the support role positions and/or an executive replacement. An interim professional can also help navigate unique challenges, act as a board advisor, or offer expertise on special projects and initiatives. They provide effective and efficient talent for the necessary amount of time.

Time to search for candidate

Time, if nothing else, is to be gained here. If an executive becomes ill or leaves unexpectedly, interim management can come in swiftly and deftly take over, allowing for time and space to search for the best replacement candidate.

In a Forbes article about interim executive models in modern management, the author writes, “[G]iven all these benefits, I think companies should be a bit more creative about the way they move people into and out of executive roles.” Interim management is smart. It’s the way of the future in a fast-paced job market.

Fronetics offers management and leadership solutions to organizations within the supply chain and logistics industries during times of transition. Our Fronetics Interim Retained Management Service (FIRMS) is designed to provide specific executive, management, sales or operational expertise when and where you need it, for exactly as long as you need it. By using FIRMS for your interim management needs, you will be able to fill organizational knowledge gaps, minimize disruption, and create positive change for your organization during times of transition.

Related

by Fronetics | Feb 12, 2016 | Blog, Strategy, Supply Chain

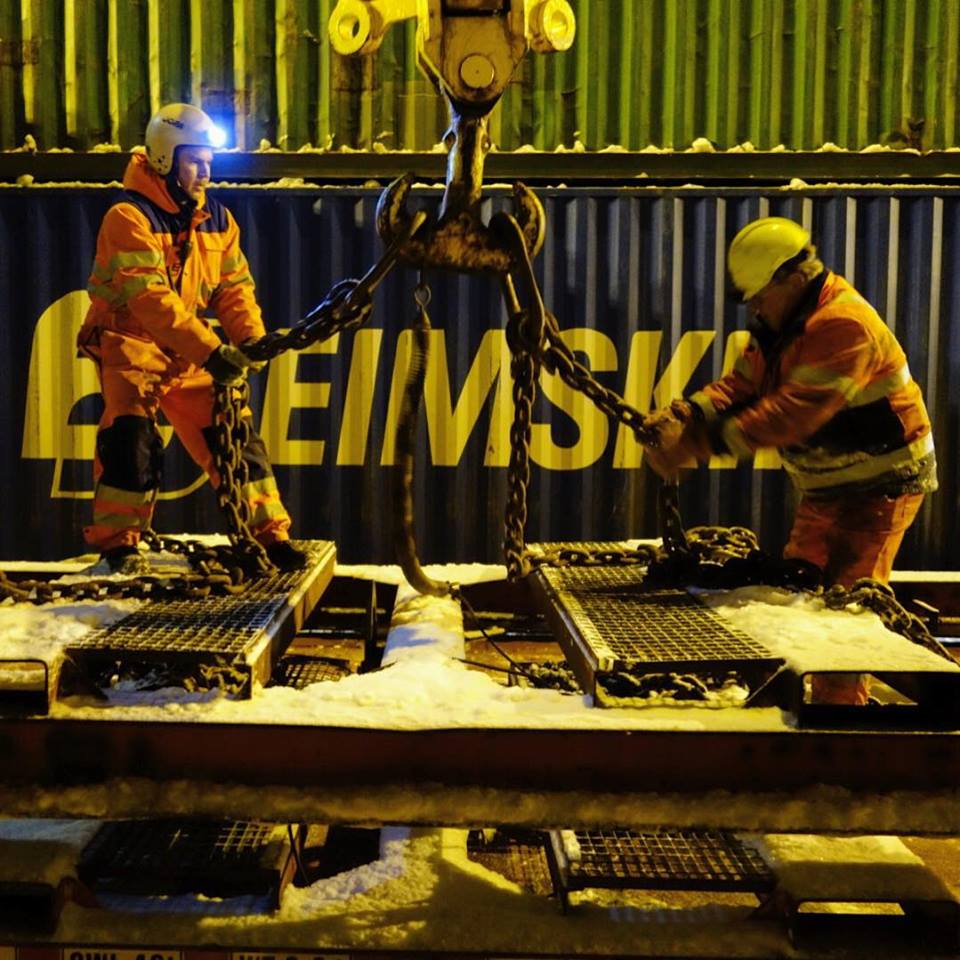

In 2013, Iceland’s oldest shipping company, Eimskip, moved the company’s North American port of call from Norfolk, Virginia, to Portland, Maine.

“Eimskip’s move to Portland was driven by the state’s commitment to investing in intermodal infrastructure and the cultural similarities between Maine and Iceland,” states Larus Isfeld, managing director at Eimskip USA Inc. and Eimskip Logistics Inc.

Culture is not rhetoric for Eimskip. This key player in worldwide reefer logistics has placed a high value on culture since it was founded in 1914. “When identifying where we operate,” says Isfeld, “we look to smaller communities where there are cultural similarities and where we can make connections and be involved.”

Eimskip makes great effort to integrate itself into all aspects of the communities in which it operates, and strives to foster connections across its operational reach. One of the ways the company has traditionally done this is through art.

For many years, Eimskip operated mixed passenger and cargo vessels and would allow artists to pay their way with their work. Over the years, Eimskip amassed a large collection of art.

When asked about this initiative, Isfeld describes the value the company places on artists and their work: “Artists make life more interesting. They also relay certain messages in a much better way than an ad.”

Interestingly, the move to Maine has reignited Eimskip’s investment in artists.

In September 2015, Maine artist Justin Levesque traveled from Portland to Reykjavik aboard Eimskip’s MV Selfoss. His multimedia project ICELANDX207 documented the nine-day journey and captured both stories and profiles of crew members.

Currently aboard the Selfoss are Jonathan Laurence and his business partner, Anneli Skaar. Laurence, a multi-artist and Maine native, is the creative director for the Center for Maine Contemporary Art (CMCA) in Rockland, Maine. Skaar is a Norwegian-American artist, graphic designer, and writer. Laurence and Skaar are also co-founders of TIMBER + ICE, which serves as a creative liaison for organizations that wish to create cultural content to enhance their involvement in the emerging, and quickly evolving, relationship between Maine and the North Atlantic countries.

In keeping with tradition, both Laurence and Skaar will create a piece of art during their passage and donate it to the Eimskip collection. Going forward, TIMBER + ICE will continue to work with Eimskip as cultural liaisons. (You can follow their passage on the Selfoss via TIMBER + ICE’s Instagram and Facebook page.)

Further, TIMBER + ICE plans to create an art installation in Portland to coincide with the U.S. State Department’s Arctic Assembly being held October 4-6, 2016. About 250 delegates are expected to attend the meeting, including scientists, business leaders, and senior government officials from eight Arctic nations. U.S. Secretary of State John Kerry and the heads of state of Arctic nations may also attend.

The installation will utilize shipping containers as exhibition space, and will connect Icelandic and Maine artists in order to highlight, spotlight, and educate — through creative means — the opportunities and challenges related to Arctic issues.

In just three years, Eimskip’s relocation to Portland has fostered a meaningful connection between the two communities — and enriched both with its investment in local artists and their art. It’s exactly what Iceland’s oldest shipping company is all about.

“We believe that businesses can connect; people need to connect,” says Isfeld. “This building of trust and understanding of values is what enables successful relationships.”