by Jennifer Hart Yim | Aug 24, 2016 | Blog, Manufacturing & Distribution, Strategy, Supply Chain, Talent

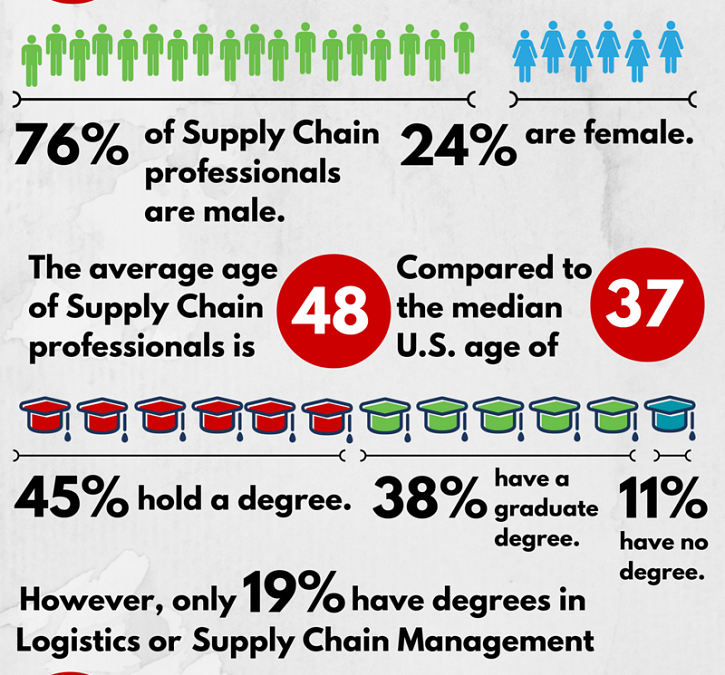

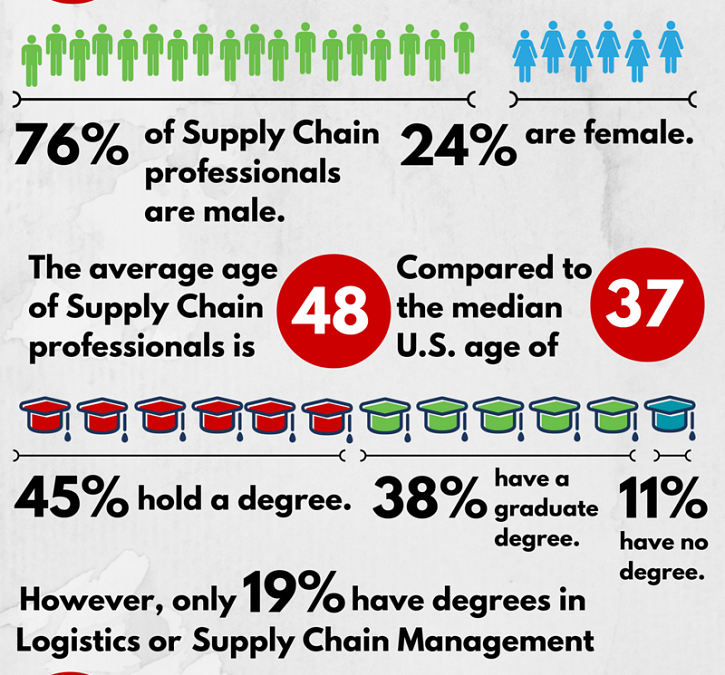

The Supply Chain industry is changing, while it’s becoming harder for companies to hire at the same time. These supply chain demographics provide a picture of the industry today.

This guest post comes to us from Argentus Supply Chain Recruiting, a boutique recruitment firm specializing in Supply Chain Management and Procurement.

Everyone knows the Supply Chain field is changing. Recently, one of the best Supply Chain publications out of the U.S., Supply Chain 24/7, released a report that examines the demographic trends underlying the industry. The report, titled “A Portrait of the Supply Chain Manager,” used research survey data from Peerless Research Group and APICS to present a picture of the typical individual working in Supply Chain. The survey asked a number of Supply Chain and talent-related questions, such as:

- What percentage of Supply Chain professionals received a raise last year?

- What percentage of Supply Chain managers hold a degree?

- What percentage of companies are willing to pay above-market compensation for the right people?

And more. These issues are sure to be of interest, whether you’re looking to hire in Supply Chain or just to get a holistic picture of the field. So we put together this spiffy infographic that highlights the answers to these questions and some other interesting datapoints from the report. Check out the infographic below!

We hope you found the supply chain demographics infographic informative, and we encourage you to dig into the full report for even more insights about where Supply Chain professionals stand and where the field is going. And (as always) stay tuned for more info and perspective about Supply Chain and talent from Argentus in the coming days and weeks!

Related posts:

by Elizabeth Hines | Aug 22, 2016 | Blog, Logistics, Manufacturing & Distribution, Strategy, Supply Chain

Improve your company’s financial performance by implementing a risk-management strategy that plans for everyday events and disruptions.

Supply chain disruptions can have a significant impact on business and financial performance. A recent PwC and the MIT Forum for Supply Chain Innovation survey found a strong correlation between the maturity of businesses’ risk-management processes and reduced decline in operational performance indicators in the face of disruption.

A supply chain company’s need for a well-developed risk-management strategy is clear. That means planning for disruptions beyond the big-impact events, like environmental catastrophes, cyber attacks, and geopolitical instability. Companies need to be better prepared to handle day-to-day bumps in the road.

Managing everyday risks

Managers will often consider cataclysmic events but ignore the smaller risks that create friction in the supply chain. Dealing with these smaller factors in a reactive and piecemeal fashion is inefficient and ineffective and can significantly hurt your company.

Consider the following tips when developing an effective risk-management strategy that focuses on the everyday risks:

1) Employ a robust strategy that is always evolving.

Consider all of the factors that currently influence your supply chain, and be vigilant in terms of new technologies or emerging risks that could impact operations in the future.

2) Put a leader in charge.

Choose someone experienced in crisis management, negotiation, and critical problem-solving. This leader should be skilled in diplomacy and remaining calm under pressure.

3) Make sure the strategy is flexible.

A strategy that it uncompromising and rigid can exacerbate issues.

4) Define your comprehensive process.

Develop a clearly defined process to mitigate events such as cash-flow issues, inventory risk, competitor interruptions, client credit risk and default, data backup and recovery, key client attrition, employee satisfaction and retention, social media use and abuse, and reputation recovery.

5) Include human resources in the strategy.

Consider moving employees into new roles as a solution. Moving an employee into a new role permanently (or for a specified period to deal with an event) can help mitigate issues.

6) Don’t hide the issue.

If there is a problem, be sure that the clients hear about the problem from you. Be clear, concise, and honest when you contact clients. Explain what the issue is and what you are doing to address it.

7) Get everyone on board.

Take the time to make sure everyone is educated about the strategy and who is in charge. If just one person knows the strategy, it will not be effective.

Related posts:

by Fronetics | Jun 16, 2016 | Blog, Content Marketing, Manufacturing & Distribution, Marketing, Strategy, Supply Chain

A recent report produced by the Content Marketing Institute and MarketingProfs, and sponsored by Brightcove, found that 81% percent of B2B manufacturers in the United States use content marketing. The same report found that the majority of manufacturers do not believe their organization is effective at content marketing.

What are organizations who are not effective missing out on? A lot.

An effective content marketing strategy can:

- Build brand awareness

- Position your company as a thought leader within the industry

- Increase engagement with customers, partners, and stakeholders

- Educate and inform customers, partners, and stakeholders

- Build trust

- Allow you to manage your reputation

- Generate leads

How can your organization realize these benefits?

The first step is documenting your strategy. The report found that organizations with a documented strategy in place were 3x more likely to report that their content marketing strategy was effective than organizations without a documented strategy.

Define your goals

Why does your company want to create content? Do you want to shorten your sales cycle? Increase leads? Build brand awareness? You don’t want your content to be just stuff. You don’t want content to be ineffective. Therefore it is important to define what it is you want your content to do for your company.

Define your audience

Who is your target audience? What are their needs? What are their goals? What are their pain points? What do they value most? Where do they go for information? Take your time. Be honest. If you identify and define your audience correctly you will be more likely to reach your target audience and engage them than if you get this step wrong.

Define your metrics

Determine how you are going to track and measure success. Define the metrics that you will track on a daily, weekly, monthly, and yearly basis.

Identify the right distribution channels

When it comes to content, distribution is essential – your content will not reach your target audience and will not be read unless it is distributed. Take the time to identify the distribution channels that are right fit for your company, your content, and your goals.

Create a publishing calendar

A publishing or editorial calendar provides you with a framework to create and distribute content. It helps you create content that is consistent, that is quality, and is tailored to your company’s goals. It is also helpful in terms of managing workflows, meeting deadlines, and managing writer’s block.

Create content

Valuable and relevant content is not a sales pitch. It is not content that pushes your products and services. Rather, it is content that communicates valuable information to customers and prospects so that they have the knowledge to make better informed decisions. Moreover, it is content that establishes your business as a reliable source of knowledge – as the thought-leader within the industry. Be thoughtful when you create content.

Curate content

Content will help you grow your business; by creating and distributing valuable and relevant content in a strategic and consistent manner you can drive profitable customer action. But, it’s not all about you. It’s not all about the content you and/or your business creates. Here’s why content curation is an essential component of a successful content strategy. The internet is a fire hose stream of content. Being able to navigate the deluge of content and identify the content that is valuable to your customers and to your business is essential. The process of identifying and sharing this content is content curation. By consistently being able to identify, make sense of, and share content that is important and relevant to your customers and to your industry you will establish your business as a thought leader and a trusted resource.

Distribute content

Distribute your content via your target distribution channels. Distribute the content consistently over time and at the right time.

Engage with customers and prospects

Once your content has been distributed, engage with your audience. Respond to comments, respond to questions, and provide clarification. Make your content more than words – make it a relationship.

Track and analyze metrics

Track and analyze your metrics on a daily, weekly, monthly, and annual basis. Take a look at what is working and what is not. By tracking and analyzing your metrics you can see, for example, what type of content is most effective and which distribution channels are helping you achieve your goals.

Make adjustments as needed

Your strategy should not be set in stone. Your strategy should be flexible. Look at your metrics, look at the feedback you are getting through your engagement with customers and prospects – make adjustments to your strategy as needed. Remember that when it comes to content it is important to think marathon not sprint. An effective content strategy requires patience and determination. Many companies make the mistake of giving up on a content strategy too early; make a long-term commitment to your strategy.

This post originally appeared on Electronics Purchasing Strategies.

You may also like:

by Elizabeth Hines | Mar 10, 2016 | Blog, Manufacturing & Distribution, Strategy, Supply Chain, Talent

Manufacturing could offer a career with upward potential for STEM students at low-profile colleges.

The college graduates of 2015 were the most indebted ever — until the next round of grads wave their diplomas in the spring. But is sinking deep into debt really the ticket to a great career? If you have the means (and brains) to invest in an Ivy League degree, all stats seem to indicate you get ample payback for the $200,000-plus expense.

But among those high school grads who may not qualify for generous financial aid packages and at the same time cannot afford — or even want — an Ivy League degree, there are still lucrative options, especially if they study science, technology, engineering, and math (STEM).

The skills gap in U.S. manufacturing, for example, is well known. While as many as 60% to 70% of executives say their current employees lack sufficient skills in technology, computer, and math, the problem is exacerbated by the lack of qualified job prospects — an expected 2 million manufacturing jobs will go unfilled due to the talent gap during the next decade, according to a Deloitte study.

As I’ve said before, herein lies opportunity. There is no reason seeking a career in manufacturing should break the bank if students weigh their choices wisely. Picking a low-profile school may “pay off big both in terms of getting a good job and salary,”according to John Walsik, a Forbes contributor and author of The Debt-Free Degree.

The opportunity is best illustrated by Business Insider’s recent list of underrated colleges in America in which the US News and World Report’s rankings of the best universities was compared with PayScale’s 2015-2016 College Salary Report. Rather than pursuing degrees from the highest rated schools, high school grads should also consider schools that, although ranked relatively low on the US News list, yield high mid-career salaries.

Interestingly, Missouri University of Science and Technology, New Jersey Institute of Technology, and University of Massachusetts at Lowell, known for their science and engineering programs, all ranked in the top 5 (Pace University in New York City topped the list), with mid-career median salaries ranging from $94,700 to $102,000. Within six months of graduation, for example, 80% of New Jersey Institute of Technology graduates were either employed — top employers include IBM and ExxonMobil — or enrolled in graduate programs.

A college degree from a prestigious school means little unless your earnings quickly make it worthwhile. If only manufacturing could shake its lackluster reputation, a growing number of students may discover it holds the key to a career with a lot of upward potential — without necessarily going into big debt.

What is your take on the cost of college versus the payoff?

A version of this post previously appeared at EBN Online.

by Elizabeth Hines | Feb 29, 2016 | Blog, Manufacturing & Distribution, Strategy, Supply Chain

As companies “tiptoe” back to the United States from overseas, the “Made in USA” label should grow more common. However, ambiguous rules are costing some manufacturers hundreds of thousands of dollars in penalties and legal fees. So what’s the problem? The coveted “Made in USA” does not always mean the same thing to companies as to the Federal Trade Commission.

Although most cases stem from California, where every single component must be sourced domestically to earn the right to be advertised as American-made, the ambiguity of FTC’s rules is likely to bring more lawsuits nationwide. FTC rules state the “Made in USA” label can only go on goods that are “all or virtually all” made in the United States. But how should companies interpret “virtually?”

The latest to be slapped with a list of reprimands by the FTC is none other than Walmart, which recently was asked to not only remove “Made in USA” logos from all product listings, but also the country-of-origin information from all product specifications (unless required by law) and U.S.-origin claims that appear in product descriptions or titles. Walmart is also required to clear advertisement copy submitted by suppliers of any USA-origin claims.

A giant like Walmart can certainly handle adjustments to its Investing in America Jobs Program — redesigned logos will now disclose the percentage of U.S. content in the product — and transparency is obviously fundamentally important in sourcing and product advertisements. But the fact still remains: Companies can only guess what qualifies as U.S.-made. As reported by Supply Chain Digest, some have taken it upon themselves to include 70 percent of domestically made components before making any “Made in USA” claims.

The dysfunction is perhaps best illustrated by the case of Lifetime Products, whose basketball hoops ended up in the spotlight last fall when two consumer lawsuits claimed they were falsely labeled. Although the hoops are, to quote the Wall Street Journal, “made of parts that are almost entirely cut, shaped, painted and assembled” at the company’s sprawling Utah factory, some bolts and the net were imported from China. The costs were staggering, with the legal fees alone adding up to $535,000, and the plaintiff’s attorney’s receiving $485,000.

Sourcing every single component domestically is no easy feat, especially for companies that just returned production from overseas and want to capitalize on the move with the “Made in USA” label. After so many years of outsourcing, it will take time to rebuild the U.S. supplier base as well as upgrading aging manufacturing equipment to meet today’s demand for speed and agility.

Lasko Products Inc., a family-owned company based in West Chester, Pa., is one example of a producer that can no longer find domestic suppliers of small electric motors. The company’s electric fans are sold at Walmart, which has discovered the effort to buy more U.S.-made products has proved particularly difficult when it comes to electrical devices.

Let’s hope the FTC can at least clarify the rules.

What do you think is a reasonable definition of “Made in USA?”

A version of this article was previously published on EBN Online.

by Fronetics | Feb 17, 2016 | Blog, Content Marketing, Manufacturing & Distribution, Marketing, Social Media, Supply Chain

The US manufacturing index is at its lowest level since 2009. This is sobering news for the industry and for the economy. Within the industry, it is clear that the road ahead is not flat, straight, or even smooth. For companies to not just survive, but to also succeed, action needs to be taken.

The US manufacturing index is at its lowest level since 2009. This is sobering news for the industry and for the economy. Within the industry, it is clear that the road ahead is not flat, straight, or even smooth. For companies to not just survive, but to also succeed, action needs to be taken.

In August 2015 Bruce McDuffee, Principal at Knowledge Marketing for Industry, released the second edition of the Manufacturer’s Growth Manifesto. If you haven’t read this, you need to do so – today. In the Manifesto, McDuffee spells out how manufacturers can achieve growth rates of 10%, 20%, and even 30%.

The key to attaining a double digit growth rate is changing your marketing strategy and adapting to buyers’ new habits. Specifically:

- Stop pitching products and start helping people.

- Start educating your audience utilizing your particular experts and expertise for FREE.

- Stop advertising product features and benefits of a product.

- Start promoting your useful, helpful papers, webinars, seminars, videos, etc. (not product information) to foster meaningful engagement.

- Admit to yourself and your team that your products are perceived as a commodity and it will take more than product revisions, releases and enhancements to gain the attention of your target audience.

McDuffee concedes that for those who have not previously embraced and engaged in this approach to marketing, “You may be thinking, WTF?”

It may seem counterintuitive, but the results are real. Your company will be able to achieve those double digit growth rates and realize these benefits:

- Reciprocity, credibility and trust in the minds of the people in your target audience.

- Top-of-Mind Awareness (T.O.M.A.) in the minds of your prospective customers so they remember your firm first when the day comes around and they need to buy.

- Higher prices, more sales, more market share, and higher growth rates.

Success, however, depends on believing in this approach and incorporating it into your overall business strategy.

Research conducted by the Content Marketing Institute (CMI) found that while 82% of manufacturers use content marketing, only 26% say that their efforts are successful. A lack of buy-in/vision from higher ups is one of the key challenges identified by CMI. Another challenge that was reported was creating and executing a strategy; only 20% of respondents reported that they had a documented strategy. Notable though, is that 58% of the most effective companies reported that they have a documented strategy.

This approach is not relevant only to manufacturing. Companies across industries and verticals should take notice. Cerasis, a top North American third party logistics company offering logistics solutions with a strong focus on LTL freight management, shifted their marketing strategy and realized positive results. Within 25 months Cerasis realized a 14% increase in revenue. This increase was directly attributable to inbound marketing. In addition to this stream of revenue, the company’s sales team was able to generate revenue totaling $20 million during this period – more than double the previous two years combined.

Those numbers are not small potatoes. If you haven’t checked out the Manufacturer’s Growth Manifesto, make the time.

You may also like:

This was originally published on Electronics Purchasing Strategies.