by Fronetics | May 2, 2019 | Blog, Content Marketing, Logistics, Manufacturing & Distribution, Marketing, Strategy, Supply Chain

As automation technologies become increasingly sophisticated, companies throughout the supply chain are realizing the beneficial impact of automation on materials handling.

Highlights:

- Manufacturers of automation technologies are predicted to grow significantly over the next 5 years.

- Automating the “first mile” of the supply chain helps reduce labor challenges and leads to increased productivity.

- Robotics technologies offer greater capacity for data collection, facilitating informed process decisions.

While the impact of automation on the “last mile” of the supply chain is often the subject of public interest, automation in the “first mile” deserves just as much attention. Advanced robotics are increasingly ensuring accuracy — while minimizing or even eliminating human involvement in various processes — at every stage of the supply chain. Industry experts are predicting an ever-growing impact of automation on materials handling, with companies reaping the benefits up and down the supply chain.

Particularly in the materials-handling sector, human capital is increasingly difficult to recruit and maintain. Additionally, labor costs in global markets such as India and China are rising. Naturally, companies are increasingly inclined to replace or redeploy human labor, with the help of automated material-handling systems.

Not to mention, the increasing sophistication of machine-learning capabilities or AI within available automation technologies allows for even greater productivity. And there’s strong reason to believe that we’re only seeing the beginning of what automation can do. Vendors who create these technologies are investing heavily in R&D, aggressively attempting to expand their product offerings to meet specific industry demands while complying with the complex standards and regulations in place.

Quantifying the costs and impact of automation on materials handling

The robust growth in the robotics-equipment-manufacturing sector demonstrates that the materials-handling industry is investing in automation. Thanks to the demand for high-performance robotics systems, New Equipment Digest (NED) predicts that within the materials-handling-equipment sector, the robotics segment will grow by over 8%, reaching $20 billion by the year 2024. The overall material-handling-equipment market is expected to surpass $190 billion by the same year, according to a growth forecast report by Global Market Insights, Inc.

“Growing automation capabilities in the manufacturing space coupled with increasing penetration of advanced technologies, such as IoT, RFID, and AI, are expected to drive the material-handling-equipment market growth,” predicts the NED. These technologies are already increasing productivity and throughput in the materials-handling sector and reducing the potential for human error. The predicted growth in the manufacturing of robotics equipment points to the increasingly positive impact of automation supply chain-wide.

Of course, automation is not without its challenges. Companies face technical issues involved in implementation, not to mention the large capital outlay required to invest in costly equipment and technologies. With increased technical sophistication and network utilization, there are threats to cybersecurity, requiring companies to invest in measures to protect their technology.

Robotics-equipment manufacturers recognize that while automation offers significant benefits for materials handling, companies need to study potential impact before making these costly investments.

Many manufacturers are offering tools for quantifying the impact of automation on materials handling. OTTO Motors, a manufacturer of self-driving-vehicles, offers an ROI calculator, allowing potential buyers the opportunity to receive an easy ROI estimate. Manufacturers are also increasingly offering simulations of materials-handling systems, allowing potential customers to determine efficacy, test designs, and study new procedures without disrupting operations.

Realizing the benefits of automation for materials handling

Beyond the well-known benefits, such as decreased costs and increased productivity, automating materials-handling processes can offer a variety of additional advantages to companies’ first-mile operations. In fact, streamlining these processes and reducing costs has its own positive repercussions throughout a company’s operations, as it allows for increased speed, productivity, and accuracy operation-wide.

Additional benefits of automating materials handling include:

- The access to real-time data provided by automated technologies allows for more complete Key Performance Indicators (KPIs).

- Labor shortages and high turnover are some of the primary challenges in materials handling – automation shields manufacturers from these challenges, while allowing human labor to be repurposed into more intricate tasks.

- Implementing technology in the materials-handling phase of the supply chain can connect to other automated processes within the factory.

- The availability of data and the ability to leverage it allows adjustments to be made in real time, meaning more flexible manufacturing.

The bottom line is that, while it can be costly at the outset, automation at the front end of the supply chain, namely materials handling, offers rich and diverse benefits sector-wide.

Related posts:

by Fronetics | May 1, 2019 | Blog, Content Marketing, Logistics, Manufacturing & Distribution, Marketing, Social Media, Supply Chain

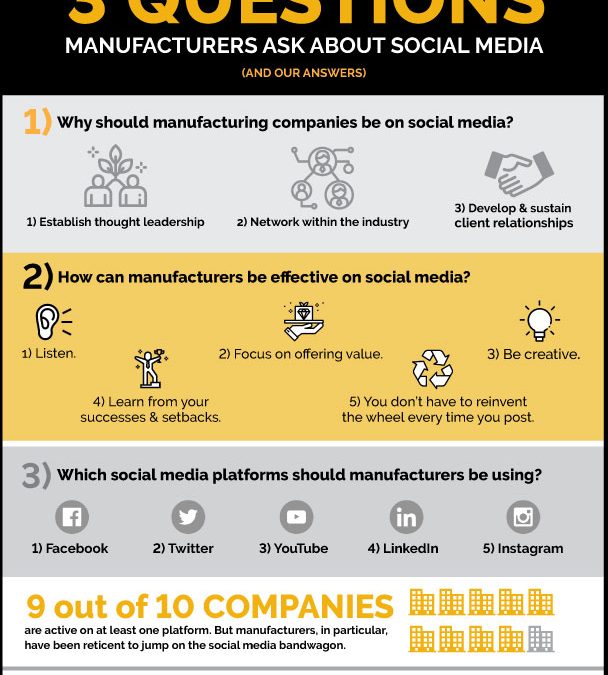

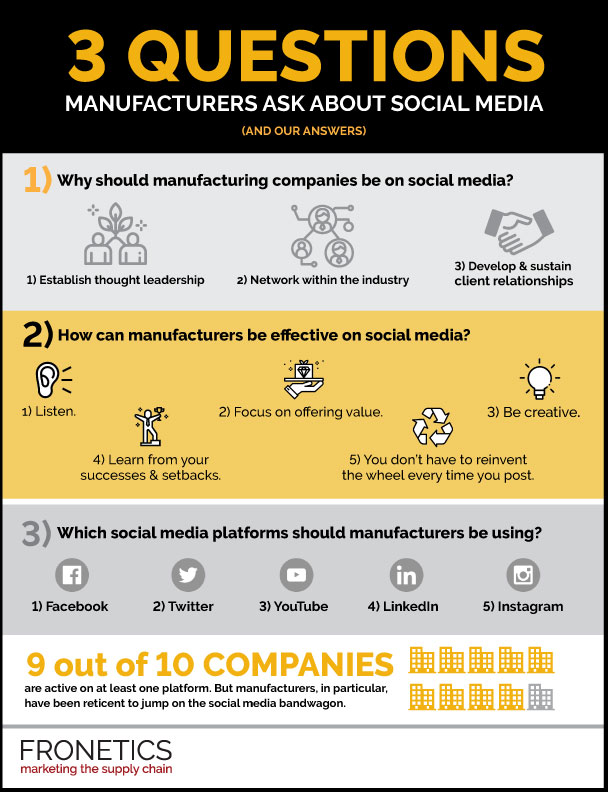

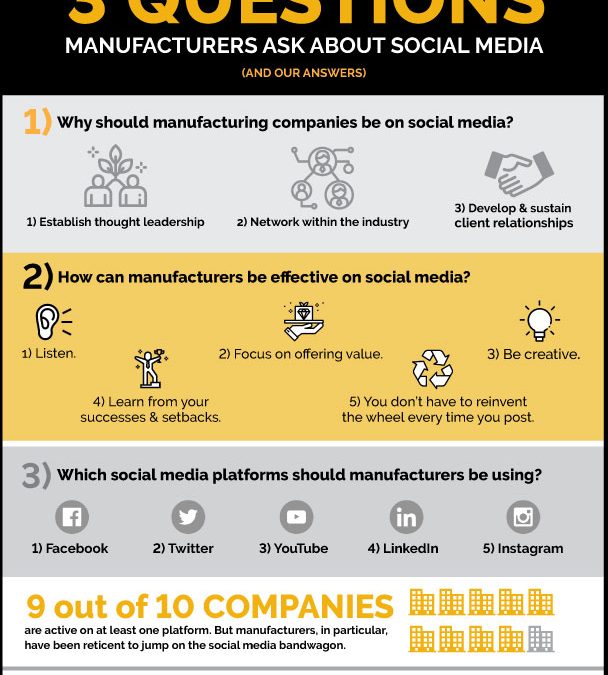

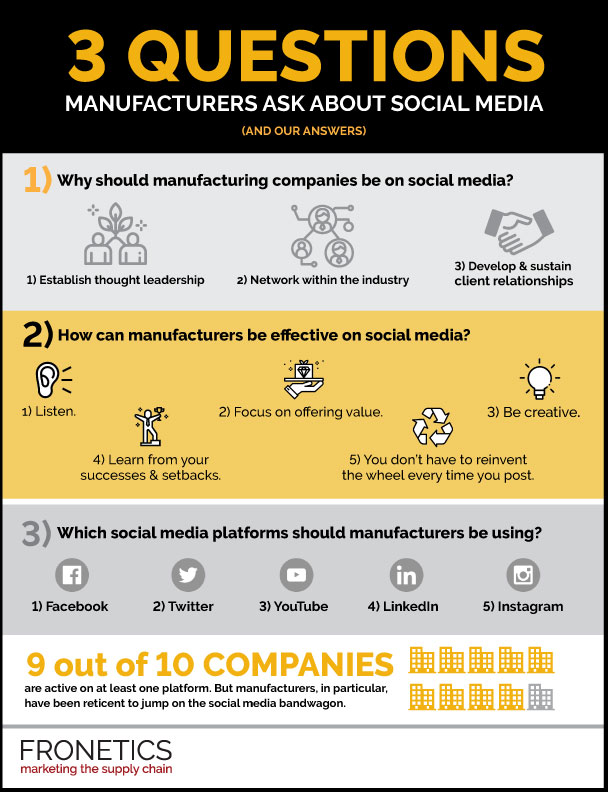

We get many queries from manufacturers about social marketing — mostly, why and how should I use it — so here are our answers to the most-popular questions manufacturers ask about social media.

Highlights:

- Facilitate networking opportunities, thought leadership, and prospect/client relationships.

- Consider using popular platforms like YouTube and Instagram to engage users and drive website traffic.

- Don’t use social media to push your products.

(Made with Canva)

B2B operations have increasingly embraced social media as a strategic marketing tool. In fact, 9 out of 10 companies are active on at least one platform. But manufacturers, in particular, have been reticent to jump on the social media bandwagon.

If your manufacturing operation isn’t making use of social media as a tool to engage with your audience, you’re missing out on big lead generation potential. Manufacturers like the Dow Chemical Company, ArcelorMittal, and CAT Products are among those that have figured out how to harness the power of social media.

To help you launch or refine your efforts, we’ve put together the following answers to the most-popular questions manufacturers ask about social media.

Why should manufacturing companies be on social media?

There are three major reasons that manufacturing brands should be all over social media:

- Establish thought leadership

- Network within the industry

- Develop and sustain client relationships

Notice that none of these involve selling products. As with content marketing in general, good social media marketing isn’t about pushing your products.

To make the most of social media as a marketing tool, abandon the idea that it’s about blatant sales pitches. Instead, approach it from the perspective that it’s an inherently social tool – that is, its value for manufacturers is in its potential to establish and expand thought leadership and to cultivate meaningful and fruitful relationships within your industry and among prospects and clients.

Which social media platforms should manufacturers be using?

Not all social media platforms are created equal. Each requires its own strategy, content format, and media. We recommend that manufacturers consider these five platforms:

1) Facebook

Facebook is an excellent place to share content with a wide segment of your audience, to promote engagement (through likes, comments, and shares), and to engage with peers and prospects. Not only that, the savviest marketers are using Facebook to understand their industry better – everything from strategies of peer brands to a fuller picture of your target buyer persona to the informational or product needs of your prospects.

2) Twitter

Twitter’s format is about brief, pithy content, used to engage with and inform your audience. This is an ideal place to let customers know what you’re planning next, to establish your corporate personality, and to let your audience in on a slice of your day-to-day operations and values.

3) YouTube

Video marketing for manufacturers is skyrocketing. With video being the most popular form of content online today, YouTube is an obvious choice for marketers. Whether it’s “how to” videos, footage of your operations, or interviews with subject-matter experts, your brand should be using YouTube to drive search traffic and educate prospects.

4) LinkedIn

B2B marketers unequivocally rank LinkedIn as the most effective network for lead generation, follower engagement, and traffic to their websites. An ideal place to engage with industry leaders, LinkedIn is also great for distributing content to a focused audience.

5) Instagram

The popularity of this highly visual platform has continued to skyrocket – it’s currently the second-most-used social media platform (up from fourth just two years ago). And believe it or not, this picture-based network is a powerhouse for B2B brands. We’ve written extensively about how brands can leverage Instagram and Instagram Stories. Suffice it to say, this is a perfect place to post your most engaging visual content and actively engage with followers.

How can manufacturers be effective on social media?

As with any content marketing effort, a well-thought-out social media strategy is a big part of success. As you create and begin to implement your strategy, start with these five tips.

1) Listen.

Before you post even a single piece of content, start by listening to your audience. In the days before social media, marketers had it much harder when it came to determining audience needs and preferences. Use these platforms to research your target prospects, as well as how competitors are engaging followers. Make note of the questions your target audience has, frustrations or challenges they express, and what types of content they engage with.

2) Focus on offering value.

You’d be surprised how many manufacturers neglect to place a premium on simply being useful with their social media content. It’s not complicated: If you post relevant, valuable content for your target audience, you’ll boost engagement, grow brand awareness, and generate and convert more leads.

3) You don’t have to reinvent the wheel every time you post.

One of the great things about social media is that it rewards not only content creation, but content curation. While you do want to be posting original content most of the time (experts recommend about 60%), a good chunk of your posting activity should include curating relevant content from third parties to share with your followers.

4) Be creative.

Separating yourself from your competitors can be a challenge, but it’s one worth striving toward. Start by asking yourself what makes your operation unique, what’s special about your process, what industry-leading expertise does your executive team have, what unusual perspective can you offer? Next, start breaking these four rules.

5) Learn from your successes and setbacks.

There are many tools out there to help you track the results of your social media efforts. Determine the right KPIs for your business and keep track of your results relentlessly. These metrics will allow you to study your impact and frequently tailor your strategy accordingly.

It’s time for manufacturers to fully embrace the marketing potential of social media. Whether you create and implement your own strategy, or decide to outsource your social media efforts, social media is a powerful set of tools that manufacturers should be harnessing.

Are there other questions manufactures ask about social media that we missed? Let me know in the comments.

Related posts:

by Fronetics | Apr 18, 2019 | Blog, Current Events, Manufacturing & Distribution, Robotics & Automation, Supply Chain

A McKinsey & Company report studied the impact of automation in manufacturing driven by rapid advances in robotics, AI, and machine learning.

Highlights:

- New robotics technologies are cheaper, faster, and smarter than before.

- 87% of hours workers spend in production could be automated with existing technologies.

- Learn what four factors to consider when making decisions about automation.

Since the industrial revolution, automation has been a major disruptor in manufacturing. Once again, a new generation of robotics and related technologies is reshaping the face of the manufacturing and distribution industries. In fact, American manufacturing has made a recent comeback, thanks in large part to the widespread use of automation and robotics.

Automation technologies that were once cost-prohibitive are now more achievable — and the return on investment is greater than ever before. The new generation of robots are not only far less expensive than their ancestors, but they are also more versatile, flexible, and able to learn new tasks, even those that were far too difficult for machines just a few short years ago.

Robots are now capable of, for example, “picking and packing irregularly spaced objects, and resolving wiring conflicts in large-scale projects in, for example, the aerospace industry,” according to a recent report from McKinsey & Company. Not only that, artificial intelligence is leveling the playing field between human and machine, and “increasing the potential for automating work activities in many industries. In one recent test, for example, computers were able to read lips far more accurately than professionals.”

Quantifying the impact of automation on manufacturing

McKinsey’s study, which covered 46 countries and about 80% of the global workforce, determined that a tremendous amount of working hours could be eliminated or repurposed by automation with technology that is already here.

The study found that “87% of the hours spent on activities performed by workers in production occupations are automatable — the most of any manufacturing occupation.”

And it doesn’t stop there. “Even among other occupations in manufacturing (for example, engineering, maintenance, materials movement, management, and administration), however, there is still significant opportunity, with approximately 45 percent of these working hours automatable as well.”

The cost and logistics of automating

In general, the study found that automation allowed wages to increase globally and profits to grow. The authors emphasize the fact that in order to capture long-term value from automation, manufacturers’ best bet is to implement technologies in phases, capturing value at each phase, allowing for future investment.

Many complex factors come into play when it comes to meeting the challenges associated with automation, deciding what to automate, and when to implement technologies to best capture long-term value. Cost is just one element, albeit an important one.

McKinsey suggests considering the following four factors when making decisions about what to automate:

- Technical feasibility

- Cost associated with developing and deploying necessary hardware and software

- Cost of labor and resultant “supply-and-demand dynamics”

- Benefits beyond labor substitution, such as increased output and quality, and fewer errors

An American manufacturing renaissance

The Association for Advancing Automation has predicted that “American manufacturing’s embrace of robotics will ensure a new manufacturing renaissance in this country.” Already, we’re seeing a steady trickle of companies reversing outsourcing trends, as it’s becoming profitable again for manufacturing to take place in the United States, rather than relying on cheap labor abroad.

As more operations embrace automation — and as we continue to witness rapid advances in robotics, AI, and machine learning — American manufacturers won’t be the only ones to reap the benefits. Many experts are predicting that automation in manufacturing will create new, better paying jobs.

Optimists include our own CEO Frank Cavallaro, who recently wrote: “From what I see now … I still feel optimistic that AI and automation will create leaner, more efficient operations that will, in turn, create new (even if different) jobs. To me, it still looks like the ones winning from the increasing technological advances in the manufacturing industry are, in fact, we humans.”

Related posts:

by Fronetics | Apr 3, 2019 | Blog, Content Marketing, Manufacturing & Distribution, Marketing, Supply Chain

Here’s why manufacturing marketers should skip the sales pitch and create content that prioritizes the needs of their target audience.

Highlights:

- Research indicates that only about half of manufacturing marketers are prioritizing their audience’s needs when creating content.

- Inbound marketing (like content marketing) is more effective than outbound marketing for B2B businesses.

- A documented strategy will help you get started creating focused, quality content.

One statistic is sticking out to me in the Content Marketing Institute’s Manufacturing Content Marketing 2019: Benchmarks, Budgets, and Trends report. According to the research, half (51%) of manufacturing marketers reported that they always or frequently prioritize their sales/promotional message over their audience’s informational needs when creating content for content marketing purposes.

Let’s think about that for a second.

A preponderance of manufacturing content marketers are, unfortunately, missing the point.

We’ve written before about why inbound marketing, like content marketing, is more effective for the supply chain than more traditional outbound marketing techniques. And while it’s true that “the supply chain is increasingly seeing the value of moving to an inbound marketing strategy,” the CMI’s research suggests that it’s taking some marketers a long time.

Why you should be putting your audience’s informational needs first

Why should you be emphasizing your audience’s informational needs over your promotional goals when creating content?

[bctt tweet=”One of the basic premises of content marketing is the recognition that, increasingly, your customers want much more from you than your product.” username=”Fronetics”]

The short answer is: because your audience prefers it. One of the basic premises of content marketing is the recognition that, increasingly, your customers want much more from you than your product. For manufacturing marketers, this means that customers want value separate from and outside of the sales funnel.

Enter content marketing. Creating effective marketing content relies on accepting that your business has much more to offer than its primary products and services. In fact, your most valuable commodity, as we’ve often said before, isn’t any material or service — it’s the knowledge, expertise, and informed, unique perspectives you have to offer.

Strategize to put customers first

To successfully adjust your content marketing efforts to put your customers’ informational needs first, the first step is having a well-defined, measurable strategy — and documenting it. This means defining precisely who you’re trying to reach and developing a complete target buyer persona(s).

Once you’ve defined exactly who you’re trying to reach, it’s time to identify the unique questions, needs, and challenges this target buyer faces. Chances are, your business has not only the products to meet those needs, but also the information to answer question and offer valuable insights.

One of the benefits of a documented strategy, with clearly stated objectives, is that it allows you to set up metrics and evaluate your successes and shortfalls. This is where you can start listening to your target buyers. You can even solicit responses from them via email and social media that will allow you to target and hone your efforts in the future.

Meeting manufacturing marketers’ challenges

The CMI’s research reinforces the fact that manufacturing marketers face unique challenges. The top reported challenge was “creating content that appeals to multi-level roles within the target audience.”

According to Achinta Mitra, founder of Tiecas, an industrial marketing consultancy, “Buying decisions are made by a committee and very rarely, if ever, by an individual. Some of these stakeholders may never interact with your content or visit your site.”

Essentially, there are various types of buyers with various needs — meaning their content needs are different. Mitra advises bringing “subject matter experts to the forefront, and letting marketing do the heavy lifting in the background.” He bases his advice on the belief that “one engineer to another is a powerful concept for earning trust, gaining credibility, and winning the mindshare of engineers and industrial professionals.”

If you’re thinking beyond downloads when creating content, and truly prioritizing quality information, your content will function broadly throughout the complex manufacturing buyer’s journey.

Related posts:

by Fronetics | Mar 21, 2019 | Blog, Content Marketing, Logistics, Manufacturing & Distribution, Marketing, Supply Chain

When it comes to growing your material handling business, digital marketing can set your company apart, capture quality leads, and keep your sales pipeline full.

Highlights:

- Material handling is extremely competitive and faces challenges like rising interest rates, trade policies that are increasingly inhospitable, and a scarcity of skilled labor, among others.

- Blog posts, e-books, tip sheets, guides, case studies, videos, and other forms of content go a long way toward attracting prospects to your digital assets.

- Arming your sales rep with targeted content to share with prospects during specific moments of the purchasing process advances their reputation as a knowledge source.

Last year, the MAPI Foundation predicted an average of 2.8% growth in manufacturing over the next three years, as well as an increase in capital equipment expenditure by over twice that. For makers of material handling equipment like conveyers, lift-trucks, and handling structures, MAPI’s forecast is good news.

As with all aspects of the supply chain industry, material handling is extremely competitive and faces challenges like rising interest rates, trade policies that are increasingly inhospitable, and a scarcity of skilled labor, among others.

For your business to participate in the forecasted global growth, your best bet is a sales funnel that’s consistently filled with quality prospects. But how do you make that happen?

Here’s where content marketing can help.

Digital marketing keeps you visible to your highest quality prospects

In the fiercely competitive material handling landscape, in which potential customers have a wide array of options, marketers face the challenge of visibility within the industry. Setting your business apart from your competition is obviously crucial to cultivating and captivating leads.

[bctt tweet=”Blog posts, e-books, tip sheets, guides, case studies, videos — all these forms of content go a long way toward attracting prospects to your digital assets, building trust, growing your reputation, and, ultimately, converting leads.” username=”Fronetics”]

Perhaps your best strategy for achieving this kind of visibility is content. Blog posts, e-books, tip sheets, guides, case studies, videos — all these forms of content go a long way toward attracting prospects to your digital assets, building trust, growing your reputation, and, ultimately, converting leads.

Generating leads with content

A content-rich site has great advantages in terms of SEO (for more on this, check out our four-part series on writing for SEO), which is key to visibility. Creating quality content and structuring your site effectively will help capture leads. As developing and sharing content attracts prospects to your site, effective calls-to-action (CTAs) drive prospects to share their contact information in exchange for information that has value for them.

Keep in mind when planning and creating your content that your goal is not to push your products — a mistake many material handling marketers make. Instead, use your content to demonstrate to prospects that you have a deep understanding of their business and the unique needs and challenges they face. Offer useful information for each stage of the buyer’s journey. Remember, the most valuable asset you have to offer is your knowledge and expertise.

Align content with sales

Keeping your sales pipeline full is your goal when it comes to competing in the material handling marketplace. Arming your sales rep with targeted content to share with prospects during specific moments of the purchasing process advances their reputation as a knowledge source. That can be the key to getting a foot in the door, advancing through the final stages of a purchasers’ decision, or closing the deal.

When digital marketing and sales work together, you’ll see the results hit your bottom line. Curating and creating great content will generate quality leads for your company. And it also empowers your sales force to build relationships with potential customers — and close the sale.

Related posts:

by Jennifer Hart Yim | Jan 15, 2019 | Blog, Consumer Electronics, Content Marketing, Logistics, Manufacturing & Distribution, Marketing, Supply Chain

It’s time for consumers to stand up to tech giants and force them to procure raw materials, used in an ethical and sustainable manner, for smart devices.

Highlights:

- Smart devices have created a dependency on batteries.

- Blockchain is being considered to track cobalt from its source in the production of lithium ion batteries.

- The number one way to decrease reliance on batteries is to reduce overall consumption of energy from batteries.

Battery technology is hot these days, no pun intended. Consumers are demanding high performance and safety from batteries as energy storage devices. Smart device manufacturers are responding by producing batteries that are smaller, safer, and store more energy; this performance comes at a cost. Increasingly rare and advanced materials are required to produce a safer and more high-performance battery for your smart device.

Cobalt is one of the key raw materials required to support the green revolution. Too bad over half of the world’s cobalt supply comes from the war-torn Democratic Republic of the Congo, where they are known to use child and slave labor in the mining of cobalt.

No one cares, however. Device manufacturers are delivering a price point and value that the consumers are willing to pay for. Supply chain reform could briefly interrupt this harmony, and peoples’ relationships with their smart devices could be jeopardized. The sad truth is that device manufacturers have pulled the wool over our eyes for too long and we have now become dependent on these batteries.

There is a solution, however.

Consumers have to stand up to tech giants such as Apple and Samsung and force them to procure raw materials used in an ethical and sustainable manner. This is happening in the “Responsible Cobalt Initiative” where blockchain is being considered to track cobalt from its source in the production of lithium ion batteries.

The blockchain method relies on adequate and honest oversight at the very site where the cobalt is being mined from the Earth in locations such as the DRC. How will honest oversight be implemented in what is known to be one of the most war-torn and corrupt regions of the world? Why wouldn’t Congolese mine owners simply lie about labor practices? In this case, the supply chain reform also requires political and cultural reform. I can’t help but think about that time when the U.S. tried to cause political and cultural reform in Iraq…

The bigger and more disturbing picture is that society is on track for over-reliance on lithium-ion batteries as energy storage devices. The number of smart devices is skyrocketing. And if electric vehicles achieve widespread adoption someday, the amount of lithium-ion batteries and cobalt required to fuel that growth will be staggering.

This is just one reason why the energy future of our planet is so uncertain. Surely the population will continue to grow. Smart device numbers will keep rising exponentially. The planet is going to need more energy and more energy storage. Hopefully, an increasing amount of energy will come from renewable and carbon-neutral sources. In order to maximize the potential of renewable energy installations, we need vast amounts of energy storage. Putting all our eggs in the lithium-ion battery basket is a very bad idea by-in-large due to the shortcomings of the cobalt supply chain.

[bctt tweet=”In order to maximize the potential of renewable energy installations, we need vast amounts of energy storage. Putting all our eggs in the lithium-ion battery basket is a bad idea due to the shortcomings of the cobalt supply chain.” username=”Fronetics”]

It is important to note that the number one, most surefire way to decrease our reliance on batteries is to reduce overall consumption of energy from batteries. Simply put, if everyone were to spend half as much time on their cell phones, we would need half as many cell phone batteries. The phone would have to be charged half as often, and the battery would last twice as long, thus requiring half as many batteries over time. Maybe we would even start talking to each other once again.

In addition to reducing consumption, humankind must pursue radical technological advances in the field of energy storage. Power-to-gas and room-temperature-superconductors are two cutting-edge technologies that have the potential to revolutionize the way we store energy. Distributed generation, smart grids, and passive heating and cooling are some more conventional ways to reduce the energy storage burden placed on large-scale renewable generating facilities.

To make a long story short, the force of corporate greed and government corruption has overpowered the force of the consumers’ desires up until now. I am sure that the vast majority of smart device users, if asked, would be opposed to the use of child and slave labor in the mining of raw materials for their smart devices. I, for example, would be willing to pay more for a device that guarantees fair and ethical trade up and down the entire supply chain. We must never forget that we the consumers have the ultimate power. If we want Apple or Samsung to change their ways, we can easily do that. Get out and vote. Make your voice heard. Stand up to corporate greed and government corruption. Take a break from your cell phone and talk to the person next to you. I promise the world will be a better place.

This article was written by Peter Chivers, an MBA student at the Peter T. Paul College of Business and Economics at the University of New Hampshire. Pete is an engineer and MBA student with a passion for innovation and the outdoors. He spends his free time with his family hiking mountains, gardening, and building ice fishing contraptions.

Related posts: