by Fronetics | Mar 21, 2019 | Blog, Content Marketing, Logistics, Manufacturing & Distribution, Marketing, Supply Chain

When it comes to growing your material handling business, digital marketing can set your company apart, capture quality leads, and keep your sales pipeline full.

Highlights:

- Material handling is extremely competitive and faces challenges like rising interest rates, trade policies that are increasingly inhospitable, and a scarcity of skilled labor, among others.

- Blog posts, e-books, tip sheets, guides, case studies, videos, and other forms of content go a long way toward attracting prospects to your digital assets.

- Arming your sales rep with targeted content to share with prospects during specific moments of the purchasing process advances their reputation as a knowledge source.

Last year, the MAPI Foundation predicted an average of 2.8% growth in manufacturing over the next three years, as well as an increase in capital equipment expenditure by over twice that. For makers of material handling equipment like conveyers, lift-trucks, and handling structures, MAPI’s forecast is good news.

As with all aspects of the supply chain industry, material handling is extremely competitive and faces challenges like rising interest rates, trade policies that are increasingly inhospitable, and a scarcity of skilled labor, among others.

For your business to participate in the forecasted global growth, your best bet is a sales funnel that’s consistently filled with quality prospects. But how do you make that happen?

Here’s where content marketing can help.

Digital marketing keeps you visible to your highest quality prospects

In the fiercely competitive material handling landscape, in which potential customers have a wide array of options, marketers face the challenge of visibility within the industry. Setting your business apart from your competition is obviously crucial to cultivating and captivating leads.

[bctt tweet=”Blog posts, e-books, tip sheets, guides, case studies, videos — all these forms of content go a long way toward attracting prospects to your digital assets, building trust, growing your reputation, and, ultimately, converting leads.” username=”Fronetics”]

Perhaps your best strategy for achieving this kind of visibility is content. Blog posts, e-books, tip sheets, guides, case studies, videos — all these forms of content go a long way toward attracting prospects to your digital assets, building trust, growing your reputation, and, ultimately, converting leads.

Generating leads with content

A content-rich site has great advantages in terms of SEO (for more on this, check out our four-part series on writing for SEO), which is key to visibility. Creating quality content and structuring your site effectively will help capture leads. As developing and sharing content attracts prospects to your site, effective calls-to-action (CTAs) drive prospects to share their contact information in exchange for information that has value for them.

Keep in mind when planning and creating your content that your goal is not to push your products — a mistake many material handling marketers make. Instead, use your content to demonstrate to prospects that you have a deep understanding of their business and the unique needs and challenges they face. Offer useful information for each stage of the buyer’s journey. Remember, the most valuable asset you have to offer is your knowledge and expertise.

Align content with sales

Keeping your sales pipeline full is your goal when it comes to competing in the material handling marketplace. Arming your sales rep with targeted content to share with prospects during specific moments of the purchasing process advances their reputation as a knowledge source. That can be the key to getting a foot in the door, advancing through the final stages of a purchasers’ decision, or closing the deal.

When digital marketing and sales work together, you’ll see the results hit your bottom line. Curating and creating great content will generate quality leads for your company. And it also empowers your sales force to build relationships with potential customers — and close the sale.

Related posts:

by Elizabeth Hines | Mar 20, 2019 | Blog, Logistics, Robotics & Automation, Supply Chain

With the power to drastically increase efficiency in all areas of the supply chain, it’s important brands are exploring the benefits of AI. Here are four examples of how AI can benefit your supply chain.

Highlights:

- It’s estimated that supply chain firms could gain $1.3 to $2 trillion a year from using AI.

- Machine learning has the ability to quickly discover patterns in supply chain data by relying on algorithms and constraint-based modeling to find the most influential factors.

- The increasing popularity of chatbots is making it harder to ignore how AI is helping shape not just the daily logistics but also the B2B marketing landscape and operational procurement for supply chain industries.

Artificial intelligence is not simply affecting supply chain management, it is revolutionizing it.

With the power to drastically increase efficiency in all areas of the supply chain, McKinsey estimates that firms could gain $1.3 trillion to $2 trillion a year from using AI in supply chain and manufacturing.

Here are 4 examples of AI and how it’s changing supply chain management for the better.

1. Autonomous transport

There’s nothing more exciting than the field of autonomous transport for SCM. We’ve all known for many years that driverless trucks have major potential to affect supply chain management and logisitics.

We aren’t there yet – and “anyone employed as a driver today will be able to retire as a driver” — but if autonomous trucking can be developed to its potential, the technology would effectively double the output of the U.S. transportation network at 25 percent of the cost.

The conversation is no longer simply talking about vehicles on the road either. Google and Rolls-Royce recently partnered to build autonomous ships too.

2. Final-mile delivery route efficiency

One doesn’t have to have a driverless vehicle, however, to use AI to optimize delivery logistics.

For example, in the “devilishly complex” task of delivering 25 packages by van, the number of possible routes adds up to around 15 septillion (that’s a trillion trillion).

That’s where route optimization software and AI-powered GPS tools like ORION — which UPS uses to create the most efficient routes for its fleet — are making their mark. With ORION, customers, drivers and vehicles submit data to the machine, which then uses algorithms to creates the most up-to-date optimal routes depending on road conditions and other factors.

And there are also other autonomous entities out there besides cars, trucks, and ships. Robots using LIDAR technology are now being used to deliver items in crowded city environments. For example, Marble’s robots deliver medicine, groceries, and packages, and they also track their routes and the condition in order to continuously improve delivery for the next time. Additionally, last-mile solutions with drones continue to be explored due to their ability to move quickly and bypass almost all ground-level obstacles.

3. Demand forecasting, particularly for warehouse management and SCM strategy

Machine learning has the ability to quickly discover patterns in supply chain data by relying on algorithms and constraint-based modeling to find the most influential factors. This ability to find data patterns without human intervention has applications in EVERY aspect of SCM, but demand forecasting is a particularly influential component beneficiary.

Warehouse management and SCM strategy rely heavily on correct supply, demand, and inventory-based management. Forecasting engines with machine learning offer an entirely new level of intelligence and predictive analysis of big data sets that provides an endless (and constantly self-improving) loop of forecasting, overhauling the way we manage inventory and the way we create new strategies for our industries.

4. Chatbots for marketing and operational procurement

The increasing popularity of chatbots is making it harder to ignore how AI is helping shape not just the daily logistics but also the B2B marketing landscape and operational procurement for supply chain industries.

A chatbot is a computer program that simulates human conversation using auditory or textual methods. It communicates with your customer inside a messaging app, like Facebook Messenger, and is similar to email marketing without landing in an inbox. Mimicking a human conversation, chatbots currently allow for increased customer engagement through messaging app technology that isn’t yet saturated with marketing. They are just one of the many ways to integrate AI and marketing.

There’s so much more than these 4 examples to consider when discussing AI and the supply chain: prediction of delivery arrival times to the warehouse and to the customer, cargo sensors, automated purchasing, financial applications…the list literally may be endless.

Choosing what to focus on for this article, and more importantly, for all supply chain and logistics businesses, is a tough decision, but one thing is clear: in the “arms race” to leverage AI in SCM, some will come out on top and some will be left behind.

This post originally appeared on EBN Online.

Related posts:

by Fronetics | Mar 6, 2019 | Blog, Content Marketing, Current Events, Logistics, Marketing, Supply Chain, Talent

Increasingly, women are pursuing careers in the supply chain. But they continue to face a salary gap — and the higher they climb, the wider it gets.

Highlights:

- Men in the supply chain industry earned an average of 29% more than women in 2017.

- Women perform at the same levels as men with the same job titles and expectations but may not be given the same opportunities to advance their careers.

It’s no secret that the supply chain and logistics sector is largely male-dominated. Over the past decade, women have increasingly pursued supply chain careers and assumed leadership roles. But according to a recent article in the Wall Street Journal, women in the industry continue to face a pay gap, and that pay gap widens as they rise through the ranks.

[bctt tweet=”According to a recent study by the Institute for Supply Management, which surveyed 3,000 supply chain professionals, men in the industry earned an average of 29% more than women in 2017.” username=”Fronetics”]

According to a recent study by the Institute for Supply Management, which surveyed 3,000 supply chain professionals, men in the industry earned an average of 29% more than women in 2017. Interestingly, in higher level positions, where there are still relatively few women, the pay gap was even wider — and it was wider still between workers with the highest levels of experience. Among those who had been in the supply chain for 15 to 19 years, the study found that men earned 48% more than women with identical experience levels.

Progress?

In her article, Wall Street Journal supply chain and logistics reporter Jennifer Smith points out that there has been some progress. “The gap has narrowed slightly since 2016,” she writes, “when the disparity in salaries was 31 percentage points.” But she goes on to detail the ways in which the industry lags behind when it comes to pay equity.

Smith quotes Cory Ann Holst, senior director of data and performance management for the global business services division of snack-food giant Mondelez International Inc. “Women haven’t made near the progress that the industry wants us to think we have,” says Holst. “We all know there is a glass ceiling.”

Echoing this sobering reality-check, a compensation survey by supply chain organization APICS found an overall pay disparity, albeit smaller, with women earning an average of 16% less than their male counterparts. Abe Eshkenazi, chief executive of APICS, told Smith that “women perform at the same levels as men with the same job titles and expectations but may not be given the same opportunities to advance their careers.”

Why the gap?

While the pay disparity in the supply chain is generally in-line with that of the broader U.S. labor force, it’s still striking. So, what causes the pay gap to persist? And why does it go from a gap to a gulf at higher-level positions and greater experience levels? “Experts say a range of factors play into the gender pay gap,” writes Smith, “including discrimination and different career choices. White-collar jobs often reward people who work long hours or change positions frequently, for instance, steps some women with families may be less likely to take.”

Smith points to the career trajectory of Sana Raheem, now head of operations at the Farmer’s Dog, a subscription-based healthy pet food company in New York City. Raheem worked her way up in logistics at Kraft Heinz Co and was a senior manager of logistics and supply chain at Mondelez International. It wasn’t an easy road. “Getting there meant taking jobs in remote manufacturing facilities with a mostly-male labor force and few female role models,” writes Smith.

“I had many moments early in my career where I was told to slow down, be less aggressive, and pay my dues,” said Raheem. “I saw a lot of women around me accept similar feedback and spend years making less than their male counterparts.”

According to Robert Handfield, professor of supply chain management and executive director of the Supply Chain Resource Cooperative at North Carolina State University’s Poole College of Management, “the industry is increasingly well suited for women. It involves identifying opportunities, thinking strategically, and working collaboratively.”

By every measure, the supply chain needs more women at all levels. It’s time to compensate them fairly.

Related posts:

by Fronetics | Feb 20, 2019 | Blog, Content Marketing, Logistics, Marketing, Supply Chain

These 6 robotics blogs are our favorite reads for gathering information, analyzing issues, and staying current in an industry that is rapidly changing.

Highlights:

- Follow these 6 blogs for the latest on the robotics industry

- Featuring a variety of expert perspectives analyzing issues and trends

- Get everything from the big headlines to niche opinion pieces

It’s not easy keeping pace with the latest developments in robotics, an industry where changes are happening swiftly and often. Not only that, sorting through masses of media sites and conversations to find informed, up-to-date coverage of these changes can be utterly overwhelming.

Why Following Robotics Blogs Matters

The robotics field is experiencing unprecedented growth and innovation. From collaborative robots revolutionizing manufacturing to AI-driven autonomous systems reshaping transportation, the pace of change is staggering. These carefully selected blogs offer a curated lens into this dynamic landscape, helping you:

- Navigate complex technical developments

- Understand market trends and investment opportunities

- Gain insights from leading thinkers and practitioners

Luckily, there are places where you can find the kind of information and analysis you need. These 6 robotics blogs are on our reading list — and we think they should be on yours, too. Here, you’ll find blogs that focus completely on covering news, trends, and issues within the robotics industry.

Top 6 robotics blogs for industry news, trends, and insights

1. Robohub

What you’ll find:

- Global community perspective

- Frequent, in-depth content

- Covers research, startups, business, and education

Robohub remains a cornerstone of robotics news and analysis. Its diverse contributor base ensures a well-rounded view of the industry.

2. IEEE Spectrum Robotics

What you’ll find:

- Technical depth from a trusted engineering authority

- Cutting-edge research and breakthroughs

- Explores ethical and societal implications

IEEE Spectrum’s robotics channel offers unparalleled insight into the technical frontiers of the field.

3. TechCrunch Robotics

What you’ll find:

- Startup and investment focus

- Breaking news on product launches and funding rounds

- Interviews with industry leaders

For those interested in the business side of robotics, TechCrunch’s dedicated robotics section is invaluable.

4. The Robotics Report

What you’ll find:

- Comprehensive industry coverage

- Market analysis and investment trends

- Curated by robotics expert Frank Tobe

The Robot Report continues to be a go-to source for business-focused robotics news and analysis.

5. Robotics Business Review

What you’ll find:

- In-depth industry analysis

- Focus on robotics applications across sectors

- Paid membership for full access

While some content remains behind a paywall, RBR offers high-quality insights for serious industry professionals.

6. MIT Technology Review: Robotics

What you’ll find:

- Academic perspective on breakthrough technologies

- Long-form articles exploring future implications

- Balances technical and accessibility

MIT’s renowned publication offers a forward-looking view of robotics and its impact on society.

Staying Informed in a Fast-Paced Field

Following these blogs will provide a comprehensive view of the robotics landscape. However, the field is vast, and new sources of information emerge regularly. We recommend:

- Setting up RSS feeds or email subscriptions to stay current

- Engaging with robotics communities on social media

- Attending industry conferences and webinars for deeper insights

The robotics industry continues to push boundaries, reshape industries, and create new possibilities. By following these top blogs, you’ll have the knowledge and insights needed to navigate this exciting field, whether you’re a researcher, entrepreneur, investor, or simply an enthusiast.

Which robotics blogs are you following?

Related posts:

by Jennifer Hart Yim | Feb 14, 2019 | Blog, Content Marketing, Internet of Things, Logistics, Marketing, Supply Chain

Rogue Ales believes that their “Ground to Glass, Grow your Own Revolution” is a key tenet to their success. The company leverages the Internet of Things (IoT) to ensure that their supply chain is able to deliver the highest-quality ingredients to their breweries just in time.

Highlights:

- Consumer desire for freshness and high quality is influencing the beer brewing industry.

- Rogue Ales owns Rogue Farms giving the brewery a unique advantage in being able to produce specialty ingredients.

- The Internet of Things has enabled Rogue to capture and act on the data surrounding their supply chains.

Rogue Ales, headquartered in Newport, OR, is an alcoholic beverage company founded in 1988 that produces beer, wine, cider, and distilled spirits. Their ales have won over 1,800 awards at various brewing competitions.

Rogue’s brewing operation is unique in that the company’s subsidiary, Rogue Farms (founded in 2008), grows all of the ingredients used. The company believes that their “Ground to Glass, Grow your Own Revolution” is a key tenet to their success. Rogue Ales leverages the Internet of Things (IoT) to ensure that their supply chain is able to deliver the highest-quality ingredients to their breweries just in time.

The trend toward freshness

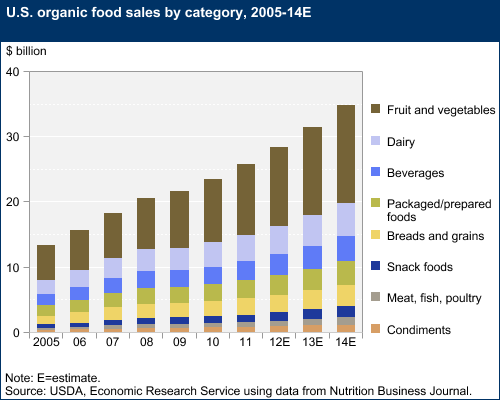

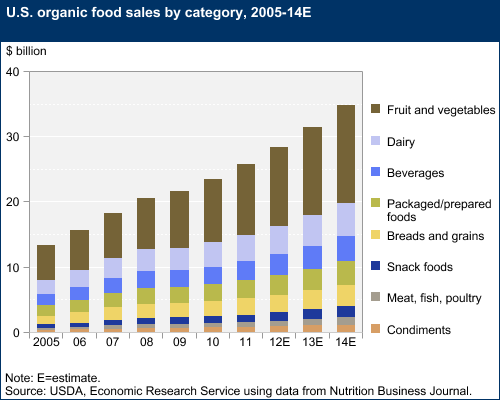

According to AT Kearney, 93% of consumers consider freshness to be the most important criterion when purchasing foods. According to the USDA, the sale of organic foods in the U.S. has more than tripled from approximately $12B in 2005 to over $35B in 2015 (data for 2016-2018 was not immediately available).

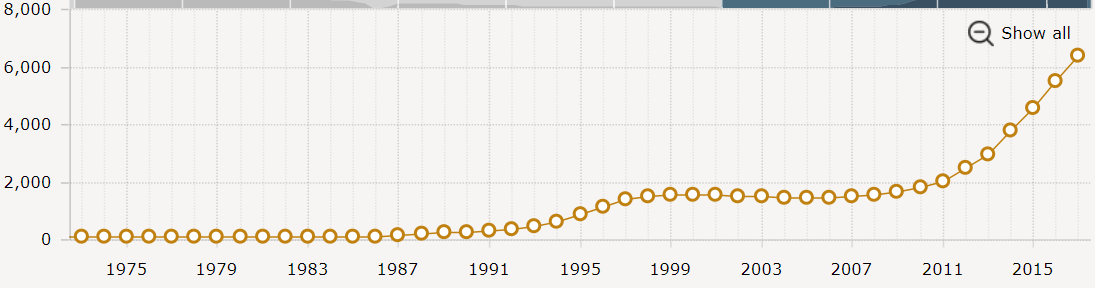

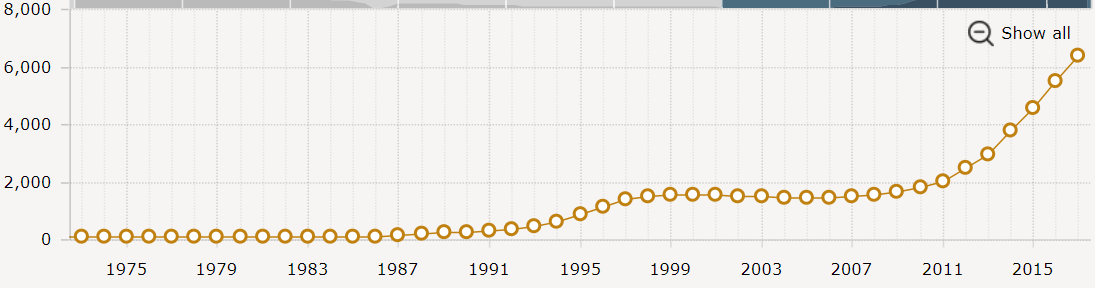

Consumer desire for freshness and high quality is influencing the beer brewing industry. According to the American Brewers Association, the number of craft breweries in the United States has increased from 122 in 1973 to over 6,300 in 2017.

As the competition between breweries intensifies, brewers are constantly looking for key ways to differentiate their beers from their competitors in this $111.4B market. Most beer sales are through microbreweries (defined as a brewery producing less than 15,000 barrels per year and at least 75% of beer sold off-site via distributors or wholesalers). Rogue Ales has made freshness a key value-add differentiator for its brand, selling over 325,000 gallons in 2016. In a Market Watch article, Rogue’s president, Brett Joyce, says:

What it means is that we have to get better all the way around. The quality has to go up. Just having products isn’t enough. You better have a strategic plan to go to market, retailer support, good follow-up and good sales people. It’s a real business now.

With the establishment of Rogue Farms in 2008, Rogue began producing their own ingredients, breaking tradition with most breweries, who acquire ingredients from traditional wholesalers. Rogue has a 52-acre hop farm, located approximately two hours from the brewery, where it produces its entire hop supply. Rogue states that:

Growing hops is an expensive and time-consuming endeavor, but it also helps to guarantee our supply and quality while allowing us to keep our Brewmaster, John ‘More Hops’ Maier, happy with unique, aromatic hops.

The control Rogue Ales has over Rogue Farms gives the brewery a unique advantage in being able to produce specialty ingredients for its core and specialty beers. At Rogue Farms, Rogue grows or produces:

- 10 varieties of hops

- Two varieties of malting barley

- Rye

- Pumpkins

- Marionberries

- Jalapeños

- Honey

The challenges of using fresh “wet” hops in beer

A basic beer recipe only has four ingredients: malted barley, water, hops, and yeast. Of these ingredients, hops are the most difficult to source, store, and transport due to their perishability. Most brewers use pelletized, dried, hop pellets. Rogue uses fresh (or “wet”) hops in their ales, harvested from Rogue Farms. Fresh hops give their beer a fresher taste, as the hops’ aromatic qualities are not damaged by drying and pelletization.

Fresh hops, once harvested, must land in a brew vat within 12 hours and cannot be exposed to excessive heat, air, or humidity during transport or their volatile aroma compounds will degrade and produce aromas of “skunk” and “compost”. To ensure the highest quality of hops, Rogue has turned to technology to ensure that its supply chain is delivering the freshest possible hops to the brewery.

Using the Internet of Things to build quality into Rogue’s supply chain

The vertical integration of Rogue Ales and Rogue Farms gives Rogue a unique advantage in being able to leverage new technologies to ensure it sources the highest quality ingredients possible directly from their farm to their brewery. Rogue Ales uses Intel’s Connected Logistics Platform to manage its hops supply chain. Intel’s platform is a logistics management solution that couples Internet of things (IoT) devices with a cloud-based data analytics system. These IoT devices are one-time-use sensor tags that attach to shipments and collect data (e.g. temperature, humidity, location, etc.). This data is sent over a proprietary wireless protocol to a central server where the data is aggregated and analyzed in real time.

[bctt tweet=”The Internet of Things has enabled companies like Rogue to capture and act on the data surrounding their supply chains. Companies are able to make smart decisions that bring cost savings and flow directly to their bottom line.” username=”Fronetics”]

The system tracks shipments and collects data during every facet of the supply chain, ensuring that quality thresholds are maintained and any problems with the shipped goods can be immediately corrected (for example, if one of the trucks runs into traffic, the others can be intelligently rerouted). It is estimated that 30% of all perishable products shipped in the United States become spoiled during their journey from the farm.

After the wet hops are picked, Rogue attaches three trackers to each shipment: at the top, middle, and bottom of the bale of hops. These trackers measure temperature, humidity, and location. Rogue can ensure that the hops have been kept in the proper environment and that they have not spent too much time in transit.

If a shipment does not meet quality standards, it can be discarded before it is used in a beer batch, reducing waste and ensuring that Rogue does not waste its precious brewing capacity brewing beer that will later need to be dumped for quality reasons. The location of the shipment is updated every ten minutes, and once the hops have reached the halfway point, Rogue starts the brewing process. This ensures that the hops arrive just in time and go directly from the truck into the brewing kettle.

The Internet of Things has enabled companies like Rogue to capture and, more importantly, act on the data surrounding their supply chains. Companies are able to make smart decisions that bring cost savings and flow directly to their bottom line.

This article was written by Zachary Richards, an MBA student at the Peter T. Paul College of Business and Economics at the University of New Hampshire. Zach is a Software Engineer at Pegasystems, Inc., where he specializes in back-end Java development, data structures, and agile development practices. He graduated from Worcester Polytechnic Institute in 2016 with a B.S. in Computer Science.

Related posts:

by Fronetics | Feb 7, 2019 | Blog, Content Marketing, Logistics, Marketing, Social Media, Supply Chain

Looking to boost followers on Instagram? These tips will help supply chain marketers grow their following, build brand awareness, and nurture a loyal audience base.

Highlights

- Instagram has over 500 million daily users.

- Fake accounts won’t help in the long run.

- Growing authentic followers requires commitment and strategy.

While it’s true that Facebook is a favorite for B2B marketing, don’t overlook Instagram. Over 500 million users browse the app daily — some of the most engaged audiences on the web. This is absolutely a powerful resource for supply chain marketers, and if you aren’t already, it’s time you start tapping into it.

But as with all social media platforms, there’s a right and a wrong way to go about using it. When it comes to Instagram, getting the most out of the platform has a lot to do with boosting followership.

Keep in mind that recent studies have shown that roughly 48 million Instagram users are fake. Inflating your audience with fake followers won’t serve you well.

Boosting engagement and growing your following takes time and strategy. The 10 tips in our infographic below will help you get the most out of Instagram, building an authentic, engaged audience.

10 tips to boost followers on Instagram

(Made with Canva)

1) Optimize your account

Before we get to anything fancy, take a step back and make sure your Instagram account is fully optimized. This means you need:

- a bio with a link to marketing or product pages related to a specific keyword or hashtag

- image captions, which can reference the link in your bio

- a search-friendly username

- a compelling profile image that reflects your brand

2) Use the right hashtags

One of the most effective ways to grow your Instagram following is to use hashtags effectively. Since Instagram gives users the ability to follow hashtags that interest them, and they function as links to other relevant content, choosing the right hashtags is the ideal way to reach and engage your target audience.

Keep an eye on accounts of peer brands to stay up to date with the best hashtags to be using. The most effective hashtags are short, memorable, and easy to read. You can also use a free online tool like InconoSquare or Websta to find relevant hashtags for the supply chain and logistics industries.

3) Keep your content consistent

Posting on a consistent timetable is crucial to maintaining an active following. Posting irregularly means you risk your followers forgetting about you. And posting all at once can annoy and drive followers away. Ideally, brands should post 2-3 times a day. For more, check out our guide to when to post on social media.

4) Use the right filters

We all know that playing with filters is fun. These lighting and color presets offered by Instagram have the potential to create mood and style in your image content. According to Iconosquare, these 10 filters are currently the most popular on Instagram. And it turns out that the filters you choose really do have an impact on engagement.

- Normal (No Filter)

- Clarendon

- Juno

- Lark

- Ludwig

- Gingham

- Valencia

- X-Pro II

- Lo-fi

- Amaro

5) Get your competitors’ followers

Maybe it sounds like a dirty trick, but hear us out! Users who have already shown an interest in similar brands to yours are an ideal audience base. Engaging with them is a great way to grow your own following. Identify a peer brand with a healthy Instagram following; follow a segment of their audience; and like or comment on their photos. Keep track of how many users follow your brand back.

6) Have other accounts post your content

Operating on the principle that followers of similar accounts to yours are an ideal audience base, getting these accounts to post your content is a great way to boost your followership. One way to do this is to sponsor user-generated content to get your brand in customers’ feeds. For example, hold a photo contest related to your brand, encouraging followers to post and caption your content.

7) Invest in sponsored posts and product reviews

Optimizing your account and following Instagram best practices will go a long way toward getting authentic followers. But to really boost your followers on Instagram, it pays to take advantage of influencer marketing on Instagram. Create a list of large accounts in your industry, follow them, reach out to their marketing team, and ask about sponsored post pricing. Be on the lookout for influencers with a high engagement rate relative to number of followers.

8) Put your Stories in Highlights

In addition to its Stories feature, Instagram now lets users create a featured group of “Highlights” in various categories on their profile. Stories have only a 24-hour lifespan, so featuring your most effective Stories clips in Highlights gives them a second life and a chance to engage future followers. One of the best features of Stories and Highlights is that they allow brands to view and analyze how users have viewed and interacted with their content.

9) Post content your followers actually want to see

This one may sound painfully obvious, but it’s harder than it looks. Because brands need to publish content consistently to maintain an active Instagram following, it can be extremely difficult to generate fresh, interesting content consistently. There’s no easy trick to this one. Keep an eye on peer brands, and make use of Instagram analytics tools to track, analyze, and benchmark Instagram content.

10) Start a conversation

It’s easy to forget that the fundamental benefit of social media is that it’s social. Users want to be part of a conversation. Encourage your followers to interact with you on all your social media platforms, including Instagram. This means responding to comments and brand mentions, as well as engaging with your followers’ content.

Final thoughts

Instagram is an extremely effective tool for supply chain marketers. These 10 tips to boost followers on Instagram will help you create and nurture a loyal, engaged audience base. In turn, an effective Instagram presence has the potential to grow brand awareness, improve your reputation, and generate qualified leads.

Related posts: