by Fronetics | Oct 20, 2015 | Blog, Leadership, Logistics, Strategy, Supply Chain, Talent

It’s common to think of the people who work for a company as “employees”, but reframing language and thinking could be critical to your supply chain. Start considering your employees as “talent”. The word employee has the connotation of working for someone or under someone. It implies being one of many, whereas the word talent has a positive connotation, implying that a person has depth, value, and potential. The term talent empowers both employees and companies to be the best and seek the best in their work and their search for other skilled people.

Reframing is an important step, but it doesn’t fix common problems that plague supply chain managers and human resource departments. It’s important to think about hiring processes as a long undertaking that extends beyond an ad, job interview, and offer letter. Companies should always be thinking about retention and promotion. This is called succession planning.

According to a study conducted by supply chain management researchers at Auburn University and Central Michigan University, 37.5% of surveyed companies had no engagement in succession planning, 27% had just started to work on planning, 23% engaged in informal planning, while only 12.5% engaged in formal succession planning.

Acquire

The supply chain is notorious for having a dearth of talent. The area is growing and more talent will need to be acquired for businesses to compete. As job titles expand and shift, due to the rapid changes in supply chain management and technological requirements, many people won’t be qualified for their own job title. Looking towards universities who are teaching supply chain management, and looking to other business sectors could be critical to find the right, flexible kind of talent the supply chain will need. Considering women for these traditionally male-dominant roles will also be important as women tend to be strong in many of the soft skills needed for the future of SCM. According to Shanton J. Wilcox, vice president, North America, and lead for logistics and fulfillment at Capgemini, “many so-called tactical jobs will be replaced by positions requiring more interpersonal and relationship management skills.”

Develop

As more and more money floods into the supply chain, it will be important to avoid the Silicon Valley problem of poaching, or talent leaving for larger and larger salaries elsewhere. Investing in current employees in a meaningful, attentive way, could make all the difference. Think about their future and next steps within your company. They probably have a plan for their future, and you should as well. Make sure those plans align and be open to assisting their journey to meet their goals.

Instead of conducting exit interviews, try conducting “stay” interviews. Ask specific questions about what it takes to create the environment that would help encourage your talents’ best performance. Ask what works, and also ask what doesn’t work. Be specific and ask what causes your talent anxiety or stress. You may find a trend and be able to fix it before people leave, rather than after. Investment is a big part of development. It helps talent feel like part of a bigger picture. If you invest in them they will invest in you.

Advance

Consider talent from within. According to a Forbes article, many companies are getting it wrong in trying to hire from outside. Internal candidates may not seem as appealing or exciting as the unknown, external candidate, but companies need to be clear-minded in these decisions. “Internal successors are in many ways lower risk than outsiders, yet surprisingly few promotions are awarded internally. That appears to be because boards often prefer the devil they don’t know to the devil they do. Also, some find it difficult to imagine someone at the top after seeing him operate in a lesser role for years.”

Internal talent may not appear to be ready for the next level if the position they’re seeking is a promotion, whereas an external candidate going for the same job may be making a lateral move and appear more “ready”. One thing to consider is the knowledge the internal candidate holds and brings to the job. Getting external talent up to speed can take months if not years.

Don’t sit back and assume your employees are willing to be passive about their careers. See your employees as assets. Have a strategy. Be part of their team, and make them part of yours. See their talent and invest in them, otherwise they’ll find another supply chain company who will.

You may also like:

Fronetics Strategic Advisors is a leading management consulting firm. Our firm works with companies to identify and execute strategies for growth and value creation.

We advise and work with companies on their most critical issues and opportunities: strategy, marketing, organization, talent acquisition, performance management, and M&A support.

by Fronetics | Oct 15, 2015 | Blog, Consumer Electronics, Logistics, Marketing, Social Media, Strategy, Supply Chain

Consumers are using social media to help them make purchase decisions. An infographic by Invesp provides key details including that:

- 4 in 10 social media users have purchased an item online or in-store after sharing it or marking it as a favorite on Twitter, Facebook or Pinterest.

- 50% of those purchases take place within a week; 80% take place within 3 weeks.

- 71% of consumers are more likely to make a purchase based on social media referrals.

- Twitter is the most influential for tech purchases, and the least influential for gardening and decor.

- The top 2 ways Twitter helps solidify purchase decisions are: purchase location identification and product discovery.

A Consumer Electronics Association (CEA) study found similar results. CEA found that 24 percent of consumers who use social media say that they always or almost always refer to social media websites before they make a consumer electronics purchase. For high engagement users (13.5 or more hours per week) this increases to 65 percent.

Here’s how companies can use this information to reduce returns.

Inform

Use social media to give consumers the basic facts about your company and your product.

Educate

Use social media to educate consumers about your product. Specifically, social media can be used to educate the consumer about how the product can be used, the benefits that can be realized by the use of the product, and the ROI of the product.

Engage

Use social media to engage with consumers.

If a consumer is considering the product, use social media to answer questions the consumer has, or to address concerns. Similarly, if the customer has already purchased your product, you can use social media to answer questions the consumer has, or to address concerns.

Through the use of social media you can enable consumers to make more informed purchase decisions. Additionally, you can use social media to answer questions and better educate consumers on how to use your product thereby reduce no fault found returns.

This was originally published on Electronics Purchasing Strategies.

by Elizabeth Hines | Oct 12, 2015 | Blog, Logistics, Strategy, Supply Chain

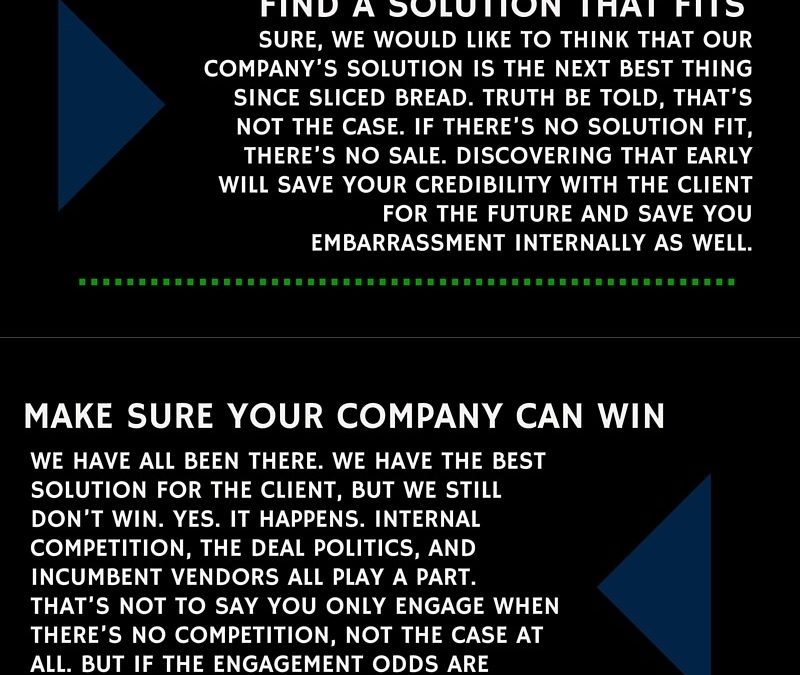

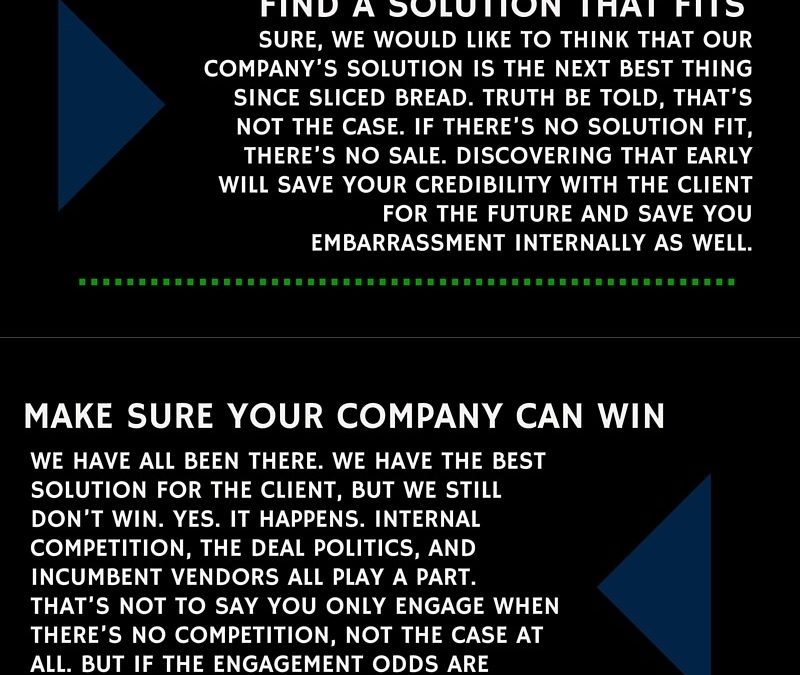

There are organizations that sell products and there are organizations that sell solutions. To be sure, both can be successful as long as products are being sold as products and solutions like solutions. The difference is that the product sale is really a commodity sale. Commodities come with an “each” price or a “per pound” pricing matrix, etc. It usually is a short or shortened sales cycle and negotiations revolve around the total price and your typical supplier performance metrics. The solution sale is much different. This sale is one that requires client discovery, isolation of unique client pain points (that only your solution can address effectively), and being able to drive distinct value for the client, and in turn, for your organization. This sales effort is highly specialized and requires selling time (sales cycle) that is much more detailed than a product sale. That being the case, you need to be sure that your close rates are high enough to justify the work load and sales cycle needed. You also need to be sure that the deals you close have a deal size that reflect the sales effort and cycle time (said another way, is the deal worth winning?)

If your sales team thrives on creating value for their customers far beyond ‘supplying’ their ‘product’ at the best price, check out our other solution selling tips below.

Fronetics Strategic Advisors is a leading management consulting firm. Our firm works with companies to identify and execute strategies for growth and value creation.

We advise and work with companies on their most critical issues and opportunities: strategy, marketing, organization, talent acquisition, performance management, and M&A support.

We have deep expertise and a proven track record in a broad range of industries including: supply chain, real estate, software, and logistics.

by Fronetics | Oct 5, 2015 | Blog, Logistics, Strategy, Supply Chain, Transportation & Trucking

On October 1st the 735-foot cargo ship El Faro issued a distress call, and then vanished in the eye of Hurricane Joaquin. The search for the ship, captain, and crew has thrust the shipping industry into the spotlight.

There is a common misconception that the majority of goods we purchase arrive via plane, or are transported via road. The reality is that 90% of everything we buy comes by ship – and it’s not likely that this number is going to decrease any time soon.

The advent of the megaship

In the last 50 years cargo-carrying capacity has increased by 1,200%. In the past 10 years cargo-carrying capacity has increased by 80%. Today’s bohemyths including the CSCL Globe, MSC Oscar, and MSC Zoe will soon be surpassed by ships that can carry more, and more. In June the major Chinese shipping group Cosco announced that it has ordered nine 20,000-TEU capacity ships, with an option for four additional identical vessels.

Larger ships are about efficiency and about narrowing the cost advantage. Not only do larger ships carry more containers, they also consume as little as 50% of the fuel per container moved as older ships, while also more than halving insurance and staffing costs.

The race for efficiency and cost advantage is competitive. The Globe held the record for largest carrying capacity for just 53 days, and then had to relinquish the title to The Oscar. The Oscar has a capacity of 19,224 TEUs, 124 more TEUs than The Globe.

Congestion

The increase in the size and volume of ships is putting pressure on ports. At least 7 out of the 10 busiest US ports by container volume are grappling with regular congestion. Early this year, congestion crippled West Coast ports grinding activities to a halt. Although operations have resumed, it won’t be smooth sailing going forward. It is projected that congestion will only get worse as ships continue to grow in size and volume. A 2013 Department of Transportation study projects that between 2010 and 2040 the volume of the US’s container trade with Northeast Asia—which accounts for the majority of the US’s overall container trade— will more than triple.

In a recent Wall Street Journal article, Frank Layo, retail strategist at consulting firm Kurt Salmon, points to the economic costs of the congestion. He forecasts that the cumulative costs of shipping delays could reach $7 billion this year and climb as high as $37 billion in 2016. Additionally, he expects some retailers to divert shipments from Asia to more-expensive routes to avoid congested West Coast ports. This could impact consumers in the form of stock-outs and price increases.

Loss

According to a recent survey by the World Shipping Council, an average of 1,679 containers are lost overboard every year. The loss of these containers cause significant economic losses for carriers and their customers, have the potential for harming the environment and marine life, and are a hazard to those on the water (floating containers pose an off-shore danger).

The majority of time ships don’t lose their entire load overboard. Rather, a number of containers are lost. But what happens when an entire load is lost, or even worse, when an entire ship is lost?

AGCS experts believe that the industry should prepare for a loss of $1 billon or more in the future. Captain Rahul Khanna, Global Head of Marine Risk Consulting, AGCS, believes that a $2 billion container ship loss scenario is not out of the realm of possibility.

El Faro is not a megaship. Nonetheless, El Faro and her crew of 33 play a significant role in the global economy. As Hurricane Joaquin moves out of the Bahamas we can hope that El Faro, her captain, crew, and cargo will be found – safe.

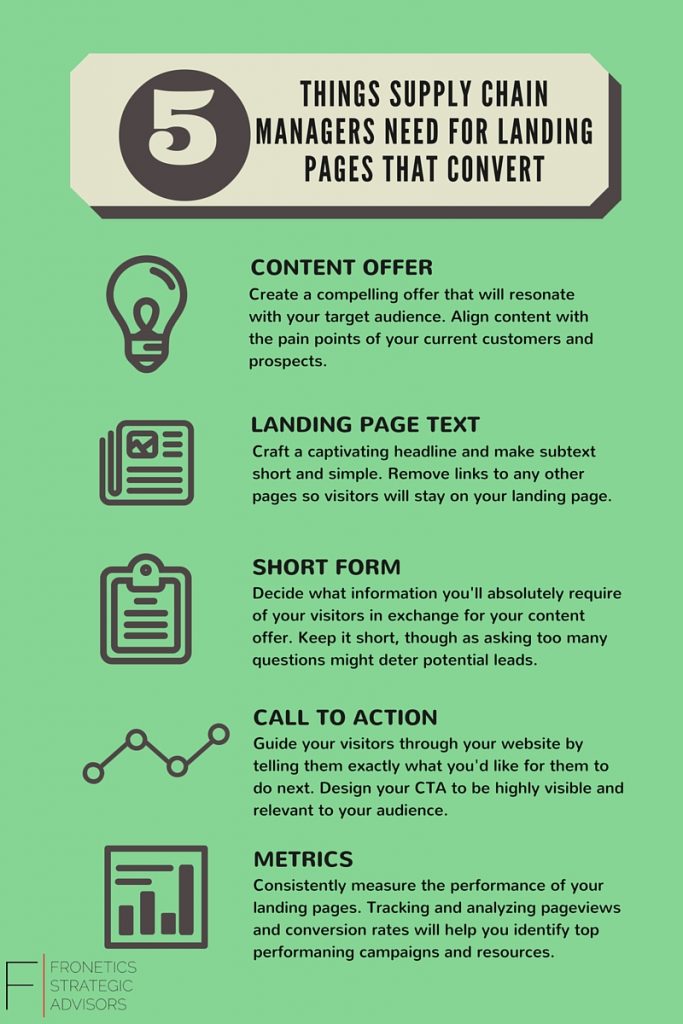

![5 Tips Supply Chain Managers Need to Build Landing Pages That Convert [Infographic]](https://fronetics.com/wp-content/uploads/2024/10/landing-pages-that-convert.jpg)

by Fronetics | Sep 28, 2015 | Blog, Logistics, Marketing, Supply Chain, Talent

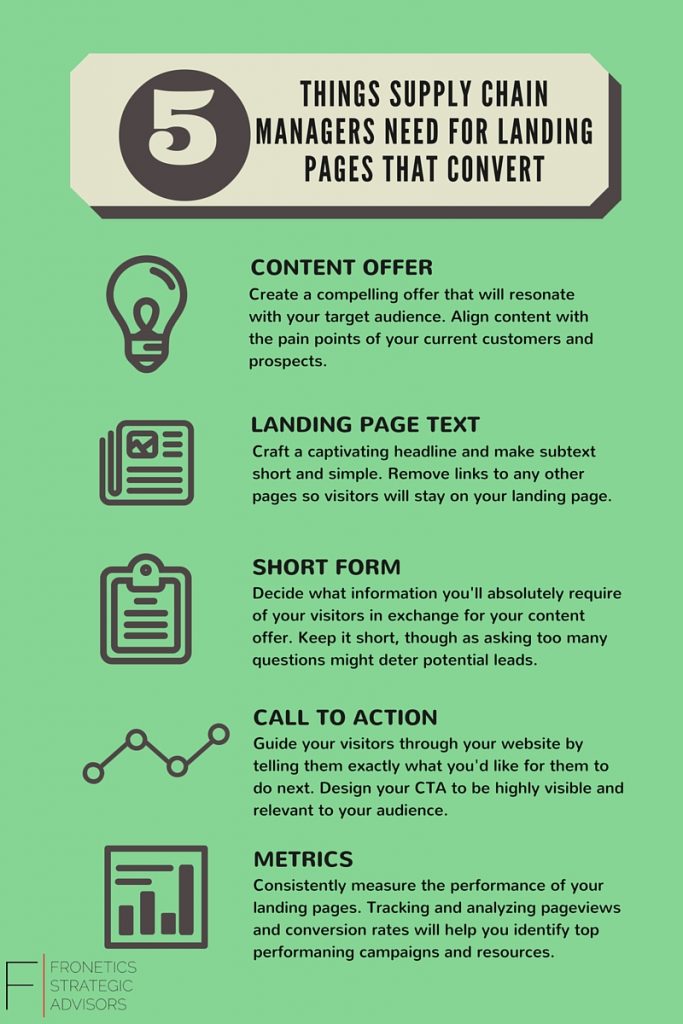

Landing pages are a fundamental tool in converting website visitors into leads. They’re what convince your visitors that they absolutely must download your fabulous resource offer. Yet often times they’re treated as the annoying little sibling to high-value content pieces – tagging along almost as if an after-thought. In reality, landing pages have just as much, and possibly even more importance than the content offer. Besides, what good is your best resource if it’s landing page stinks?

Here are five tips supply chain managers need to build landing pages that are sure to convert visitors into leads.

by Fronetics | Sep 23, 2015 | Blog, Logistics, Strategy, Supply Chain

Logistics is logistics is logistics– right? Wrong. The direction the product is moving in the supply chain – forward or backward – makes a difference.

Forward logistics, or the forward supply chain, is all about getting the product to market. In contrast, reverse logistics, or the aftermarket supply chain, is inclusive of events that move the product at least one step back in the supply chain. That is, reverse logistics is inclusive of activities that move goods from the consumer to the distributor or the manufacturer, and is inclusive of operations related to the reuse of products and materials.

The direction in which the product is moving matters. Companies that attempt to employ the same strategy for their reverse logistics process as they do for their forward logistics process do so at their peril.

The forward supply chain has its challenges. The forward supply chain has risks and it has surprises. However, the forward supply chain is more predictable and more certain than the aftermarket supply chain.

There is a greater level of uncertainty and predictability in reverse logistics. Because of this, when it comes to reverse logistics, flexibility needs to be a key component of your strategy.

Specifically, in forward logistics the product itself, the quality of the product, and the volume of the product are known and are relatively easy to forecast. Likewise, rules and regulations are fairly straightforward and uniform, and the value of the product is known.

When it comes to reverse logistics there are many unknowns. The product, the volume of the product, the quality of the product, and the value of the product are difficult to forecast. Rules, regulations, and restrictions are constantly evolving and vary by state, country and region. Moreover, the visibility and speed at which it is necessary for the aftermarket supply chain to move is vastly different than that of the forward supply chain.

It is important to remember that when it comes to the supply chain one size does not fit all. Incorporating flexibility into your aftermarket supply chain strategy is essential to your success.

This post originally appeared on Electronics Purchasing Strategies.

![5 Tips Supply Chain Managers Need to Build Landing Pages That Convert [Infographic]](https://fronetics.com/wp-content/uploads/2024/10/landing-pages-that-convert.jpg)