by Fronetics | Feb 14, 2017 | Blog, Current Events, Logistics, Manufacturing & Distribution, Supply Chain

Consumers will spend $18.2 billion on Valentine’s Day 2017, down from a record-high 19.7 billion in 2016, according to the National Retail Federation.

Did you purchase something sweet for your loved one to mark the special occasion this Valentine’s Day? You won’t be alone in your pursuit to find the perfect box of chocolates. According to staticsbrain.com, 47.5% of consumers celebrating Valentine’s Day 2017 will purchase chocolate or candy, and retailers will sell over 36 million heart-shaped chocolate boxes.

Connection between chocolate and Valentine’s Day

The history of the love of chocolate dates back to the Mesoamerican time, when it was viewed as a luxury item by the Mayan and Aztec upper-class elites. It wasn’t long until the popularity of the confection took over Europe and, centuries later, landed in America. Richard Cadbury created the first box of chocolates in 1868, and from there the commercialization of the treat grew. Chocolatier giants, such as Hersey and Russell Stover, have created a $98 billion industry.

Labor of love: chocolate and supply chain

When you purchase the little heart- shaped box of chocolates for Valentine’s Day this year, remember the labor of love that went into creating those delicious sweets. From the small cocoa farmers in Ghana and Côte d’Ivoire to the cocoa processors to the chocolate manufacturers and retailers, there are many hands that work together before the product reaches you, the consumer. These products — and gift-givers everywhere — rely on the logistics and supply chain industries each Valentine’s Day.

Valentine’s Day 2017 Infographic

Here’s a quick look at how U.S. consumers will spend — literally and figuratively — this Valentine’s Day.

(Made with Canva)

Related posts:

by Jennifer Hart Yim | Feb 13, 2017 | Blog, Logistics, Strategy, Supply Chain

Supply chains must accept that they cannot equal the power of Amazon’s supply chain without embracing these new trends.

This guest post comes to us from Adam Robinson, marketing manager at Cerasis, a top freight logistics company and truckload freight broker.

Amazon’s supply chain continued push deeper into new and existing markets will define additional trends in the supply chain throughout the coming year. While supply chain entities struggle to stay competitive with the e-commerce giant, more organizations will look for ways to eliminate inefficiencies and boost operations. Fortunately, these five trends may alleviate some of the strains of competition by giving supply chain partners an advantage in the global market.

Top 5 Trends to Know to Compete with Amazon’s Supply Chain

1. Robotics Will Grow More Versatile.

Amazon’s purchase of Kiva Robots changed the landscape of robotics in the supply chain. However, new companies are being created and developed to fill the void. The robotics company Starship released a robot that delivers meals and groceries to people in Euro metro markets. Meanwhile, Lowe’s has created the LoweBot, which boosts customer service, explains Dan Gilmore of Supply Chain Digest.

More companies are turning to robotics to find new ways to bridge the divide between a dwindling number of customer service representatives, including store associates, and maintaining around-the-clock operations. Across the spectrum, robotics will become more versatile and accessible. In other words, robots will gain new movements, capable of picking items from shelves in warehouses and storefronts.

Per IDC Manufacturing Insights, the use of robotics will become more platform based through robot-as-a-service, reducing costs of deployment and maintenance. Furthermore, the speed of operation of robots will increase more than 30 percent by the end of 2017. Clearly, robotics will become more important in 2017 than during any previous year.

2. Technology Will Reshape Procurement Practices.

Better procurement practices translate into better overall sales, but the role of procurement in driving sales’ statistics will change throughout 2017. Today, procurement drives up to 67 percent of sales, explains Johnathan Webb of Forbes magazine, as procurement professionals look for innovative ways to produce effective, superior products.

For example, Johnson & Johnson procurement professionals actively review market trends before making purchases. Upon identifying these trends, a correct forecast of supply demands can be generated. Thus, the role of procurement has become more focused on being physically involved in market news and research, not just signing purchase orders in an office.

3. More Businesses Will Create E-Commerce Platforms.

Amazon’s supply chain empowered the e-commerce market by giving everyone an opportunity to sell their goods online, which has made competing with Amazon difficult at best. Amazon’s supply chain expansion culminated in more companies looking to enter e-commerce without giving shares to Amazon. Companies expanded e-commerce and omnichannel solutions simultaneously as well, reports Steve Banker of Logistics Viewpoints.

For example, Walmart and Kmart redesigned their mobile e-commerce interface for consumers, making shopping and purchasing online easier and integrated with major companies. A simple search for a product on Walmart.com reveals partnered listings with Wayfair and third-party sellers, much like Amazon’s current vendor options. Moreover, customers can make purchases online and have them shipped to the store or their home. At Walmart, customers can even pick up orders without ever getting out of the car now. Ultimately, more businesses will seek out partnerships with bigger companies to stay competitive with Amazon’s bare price points and ease of use.

4. User Preferences Will Enhance Mobile Management Systems.

Traditional warehouse management systems (WMS) lacked integration with other systems. Procurement strategy was not always evident. Accessibility of systems depended on in-house IT departments, and upgrading access terminals could cause extreme delays and problems in operations. However, newer management systems, such as a comprehensive transportation management system (TMS) that integrates warehouse management with transportation management, are starting to offer more accessibility and personalization options.

In other words, accessibility and personalization allow warehouse managers and staff members to define metrics relevant to new products and current operations, test new processes, and effectively manage the flow of goods. Similarly, new mobile options, ranging from Android tablets to compact barcode scanners, will reduce inconsistencies and errors across the supply chain, explains IRMS 360. Paired with the advancements of predictive analytics and the Industrial Internet of Things (IIoT), more data will result in more efficient processes, creating a positive feedback loop throughout an organization.

5. Contingency Planning Will Become a Standard Practice.

Amazon’s supply chain has proven that not planning will result in the failure of small and medium-sized businesses. Furthermore, natural disasters reap $211 billion from the global supply chain annually. Having a larger global footprint is how Amazon’s supply chain has been able to maintain operations in the face of natural or man-made disasters. This is contingency planning.

The IIoT empowers contingency planning by giving supply chain entities real-time data from an endless number of sources, which range from online browsing data to point-of-sale data. Consequently, supply chains can react appropriately and divert resources to maintain operations. But, the key to utilizing this information lies in knowing what to do and how to do it when an event occurs. In other words, more companies will diversify distribution, supplier and storage networks throughout 2017 to prepare for what might happen in the future.

The Big Picture.

Supply chains must accept that they cannot equal the power of Amazon’s supply chain without embracing these new trends. New technologies are great, but chances are Amazon has already implemented them. Rather than falling into despair, you can use these trends to re-evaluate processes and practices in your organization, which will help you stay competitive with Amazon.

The complexities of the global supply chain rely on your willingness to take advantage of new trends and technologies today, as well as tomorrow, so do not squander this opportunity.

Related posts:

by Fronetics | Jan 30, 2017 | Blog, Content Marketing, Logistics, Marketing, Supply Chain, Transportation & Trucking

Our readers voted Morai Logistics, Women in Trucking, and the Oracle Supply Chain Management Blog as the top 3 logistics and supply chain blogs of 2017.

Every year we ask our readers to vote for the best industry blogs. The results are always interesting — there’s really a lot of great supply chain and logistics content out there, plus it’s great to see where our readers are finding value.

This year was no different. The best logistics and supply chain blogs, as named by our readers, are all new to our best blogs list. They probably couldn’t be more different, either. But all three offer consistent, high-quality content, which is key to running a successful blog.

Here are the top 3 logistics and supply chain blogs of 2017.

1) Morai Logistics

Morai Logistics Inc. is a Toronto-based third-party logistics provider representing Mode Transportation. Morai’s blog covers the most pressing issues facing the logistics industry, as well as trends to watch out for, professional tips, and career advice. The almost-weekly posts have a lot to offer, in terms of information and thought leadership, and they often include valuable (and, might we add, beautiful) visual elements like infographics.

P.S. Check out our interview with Morai Logistics’ President Kelli Saunders.

2) Women in Trucking

The Women In Trucking Association is a non-profit organization focused on encouraging the employment of women in the trucking industry, promoting their accomplishments, and minimizing obstacles. Just one vote shy of the top spot, the Women in Trucking blog — or, should we say blogs — bring to light many issues of concern to both women and men working in the trucking industry. President/CEO Ellen Voie’s blog offers thought-provoking, insight on topics from the driver shortage to recruiting women drivers. The driver’s blog — with content mostly from longtime driver and writer Sandy Long — tackles pressing day-to-day issues facing drivers, such as parking in dangerous locations, family problems stemming from job-related realities, and assimilating to trucking culture.

3) Oracle Supply Chain Management

The Oracle Supply Chain Management blog looks at how Oracle helps organizations transform their supply chains into more holistic and integrated value chains that cover the three key operational pillars: Demand, Supply, and Product. Weekly content from a number of contributors cover topics including supply chain management, events, product lifecycle management, logistics, technology, and more.

Honorable mention

These blogs received quite a few votes as well.

What blogs do you read on a regular basis? Which have the most valuable content?

Related posts:

![The State of Supply Chains: The Supply Chain Has Gone Digital [Infographic]](https://fronetics.com/wp-content/uploads/2024/10/virtual-reality.jpg)

by Jennifer Hart Yim | Jan 23, 2017 | Big Data, Blog, Data/Analytics, Logistics, Strategy, Supply Chain

2016 was the year of the digital supply chain — here’s a look at how things changed.

This guest post comes to us from Adam Robinson, director of marketing for Cerasis, a top freight logistics company and truckload freight broker.

2016 marched onward with a drive to improve the use of digital technology throughout the supply chain. In our first supply chain trends post, we surmised the previous year’s trends would continue. However, this prediction proved to only touch on how important the digital supply chain would become.

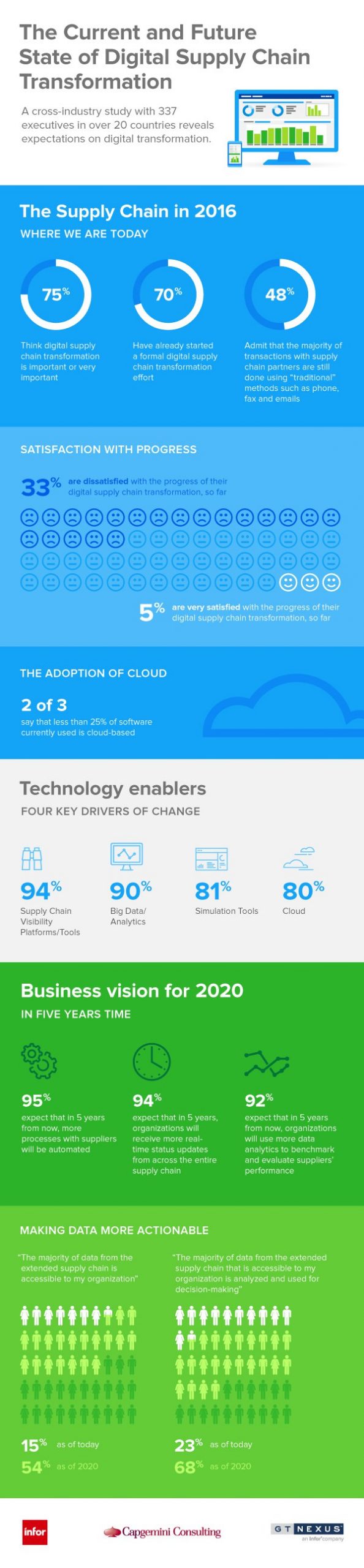

Within four months, the digital transformation had already reached most supply chain organizations. Per GT Nexus, 75% of executives surveyed recognized the digital supply chain as an important factor for the next five years. Meanwhile, 70% have also started processes to implement digital supply chain technologies throughout their companies.

Unfortunately, many supply chain entities continue to hope for a better tomorrow. In other words, the digital supply chain transformation has only been rated as very satisfying for 5% of respondents. In addition, just less than half (48%) of respondents report continued use of traditional technologies exclusively, which include the following:

- Fax machines

- Manual order entry and review

- Land-line phones, not voice over internet protocol (VoIP), which reduces overall costs and downtime

- Email, although beneficial, is susceptible to internet connectivity issues, security breaches and other problems

- Chaotic picking protocols

This infographic, created by GT Nexus, also shows other ways the digital supply chain evolved in 2016.

(Made with Canva)

Essentially, the digital supply chain is essential to gaining and maintaining competitive advantage. Digital technologies, reports Richard Howells of Forbes, including Big Data, analytics, the Internet of Things, social media, and point-of-sale reporting, enable business to know more about consumer needs and wants than ever before. Consequently, they can more accurately respond to changes in product demand across large distances and within infinitesimally small time frames.

Supply chain execs retained fundamentals throughout change.

Innovation is the driving force behind change and improvement in the modern world. Supply chains must evolve to meet an increasing number of omnichannel sales, and technologies must be integrated within existing systems to reach maximum efficiency and productive value.

As explained by Grant Marshbank of VSC Solutions, “The rate of change is not going to slow down. Technology will only delivery […] if it’s implemented with strategy and operations that adhere to best practices.”

Marshbank’s words highlighted the need to focus on fundamental concepts while responding to changes and improvements in the supply chain. For example, an optimized supply chain is good, but it opens more opportunities for errors. Simply putting all an organization’s proverbial eggs into one basket may be risky if appropriate auditing and review measures are not undertaken to ensure continued compliance and accuracy in all orders.

Change is a necessity for businesses, including the supply chain, to grow and expand. Yet many destructive forces can severely undermine a company’s progress. Bad weather, poor hiring practices or inefficient maintenance of consumers’ financial data can decimate a company. However, the response to hindrances in 2016 continued to showcase the importance of fundamental concepts, asserts Ryder, which include the following:

- Continually seeking the fastest, most cost-effective means of transporting products to consumers, including enhanced delivery optins.

- Expansion of global footprint while adhering to local, state, federal and international requirements

- Keeping companies accountable and focused on giving back to their domestic partners through reshoring or nearshoring

- Working with more outside agencies, also highlighted by Samantha Carr of Business 2 Community, including crowd-sourced logistics, warehouse optimization and outsourcing, and greater use of cloud-computing

Augmented reality found its place among consumers.

Augmented reality sounded amazing and far-fetched early in 2016, but the year has shown it to be one of the most successful product in existence. There tends to be more acceptance of technologies in the workplace once consumers can identify how they work.

For example, new hires are likely to pick up tablet-based systems more easily since they have been using them recreationally for some time. Essentially, the virtual-reality (VR), which is the precursor to augmented reality, hype of the 2016 Christmas shopping season is making more people excited about this new way to “see the world.”

While the VR hype may seem like it only emerged for Christmas, think about one of the hottest games of 2016, Pokémon Go! This app was built on augmented reality, combining the digital and physical worlds into one interactive environment. This technology, reports JOC.com, will be a key to practically eliminate extensive training courses and repair time requirements throughout the supply chain.

Ultimately, it translates into greater use of augmented reality in supply chains, which is growing by 100% annually, reports Barcoding Incorporated.

What’s next?

Clearly, technology dominated the conversation for 2016, but there are also changes in how supply chains operate that require a more in-depth discussion as well. In the next post of this series, we discuss the impact of artificial intelligence, agile processes and procurement expansion on the supply chain of 2016.

Related posts:

by Elizabeth Hines | Jan 18, 2017 | Blog, Logistics, Strategy, Supply Chain, Warehousing & Materials Handling

Having a modern, flexible supply chain is important to finding the way out of inventory dilemmas.

Imagine your irritation when you try to place an order online and are greeted by the message: “We apologize for the inconvenience, but this item is out of stock.”

However, even if the item is in stock, your mood is likely to sour if delivery will take more than a few days — and, even worse, you also have to pay for shipping. If you’re anything like me, you will quickly find an equivalent product that’s available immediately and ready to be shipped that same day.

It’s in the light of this hyper-competitive environment that the current inventory crisis should be seen. To sum it up from the perspective of warehouse owners: these are good times. Warehouse rents are hitting new highs as vacancy rates sit below five percent in many major cities.

From the viewpoint of retailers, on the other hand, it’s a significant challenge. Excess inventory is building even as consumer demand remains relatively high. Well aware of the consequences of not meeting ever-rising consumer expectations, retailers have felt compelled to stock up to — at all costs — avoid that irritating “out-of-stock” disclaimer. On the other hand, a chock-full warehouse is not necessarily good for business or speedy fulfillment.

Modernity and flexibility are key

This is when the importance of having a modern, flexible supply chain really comes into play:

- How quickly can the supply chain adjust to changes in demand?

- What’s the visibility up and down the supply chain?

- How aware is each link of what others are doing?

- How fast can inventory be refocused?

Some companies like Nordstrom have invested in cloud-based supply chain services. In Nordstrom’s case, the acquisition of a minority stake in DS Co., a supply chain software firm, which links inventory management between retailers and suppliers, was designed to facilitate direct shipments from vendors to customers, thereby circumventing the need for more inventory space. When suppliers and retailers track the inventory of one another, the risk of out-of-stock disappointments is reduced and risk is shifted up the supply chain.

Put to practice, it means that an order placed on the luxury retailer’s website is routed to the manufacturer, which then ships the item directly from its warehouse to the buyer. The Wall Street Journal noted Nordstrom’s investment comes “as retailers are racing to compete with e-commerce companies such as Amazon.com Inc. to provide convenience and speedy delivery to customers while keeping costs down.”

J.C. Penney is also shifting gears to avoid inventory gluts. The new business model essentially turns part of the store into a showroom for one of its suppliers, Ashley Furniture. Instead of keeping inventory in store or in distribution centers, all orders will be shipped straight to the consumer from Ashley Furniture.

Drones are not surprisingly part of solving the inventory dilemma. Walmart, for example, is testing the use of drones to catalog inventory, finishing in one day what it takes employees a whole month to get done. The intent is partly to make the giant retailer’s supply chain more efficient.

Clearly, traditional retailers are exploring new territory to meet consumer demand.

What do you think is key to solving the inventory crisis?

This post originally appeared at EBN Online.

Related posts:

by Fronetics | Jan 17, 2017 | Blog, Content Marketing, Logistics, Marketing

Research and firsthand knowledge show a very strong correlation between posting frequency and traffic/leads.

Clients often ask us, “How often should I blog?” It’s a great question that has no simple answer.

The reality is that the more often you blog, the more traffic and leads you’ll get. Search engines consider posting frequency in their rankings. What’s more, every time you post, you create a new opportunity to be found, to be shared, and to be linked to by other sites.

The trouble, of course, is balancing resources so that you’re publishing frequently but maintaining value and quality within your content. So while there’s no universal magic number, there may be a sweet spot for the amount of posts your organization is able to publish to maximize traffic and leads.

Let’s look at some data that makes the case for frequent blog publication.

The more you publish, the more they’ll read.

There is a high correlation between publishing frequency and web traffic/leads. This is evident in a number of recent studies:

- HubSpot’s latest benchmarking data shows that blogs that published 16+ times per month received 3.5x more traffic than those that published weekly or less often.

- From the same report, companies that published 16+ blog posts per month got about 4.5X more leads than companies that published between 0-4 monthly posts.

- Curata’s recent survey of 400+ marketers found that 90.5% of the most successful business blogs (over 10,000 views per month) publish at least once a week.

If you’re a small business, you may be thinking, “Sure. Those successful blogs are all run by big brands with endless resources!” Not so, friends.

Two-thirds of the best-in-class blogs (with 10,000+ views per month) from the Curata study were run by small companies. The Hubspot report found that increasing posting frequency had the biggest impact on smaller businesses: Companies with 10 or fewer employees that published 11+ posts per month had almost 3X more traffic than companies publishing 0-1 monthly posts, and about 2X as much traffic as those publishing 2-5 monthly posts.

Will blogging one more time per week really make a difference?

We often encourage our clients to increase their blogging cadence by just one more post per week. Though some are skeptical of the impact this will have on their traffic and lead-generation efforts, they inevitably find that such a small step can make a big difference.

Take one client of ours for example. We suggested moving from publishing one post to two posts per week. The client was unsure this would have any impact, especially for a company in the supply chain industry. But the immediate results spoke for themselves. After just one month, traffic increased by 23%, sales leads doubled, and the client landed a new customer.

How often does your company blog? Have you ever experimented with posting frequency to determine how your resources are best spent?

Related posts:

![The State of Supply Chains: The Supply Chain Has Gone Digital [Infographic]](https://fronetics.com/wp-content/uploads/2024/10/virtual-reality.jpg)