by Fronetics | May 28, 2015 | Blog, Leadership, Strategy, Supply Chain, Talent

Cathy Morris, senior vice president and chief strategy officer for Arrow Electronics, Inc., talks women in the supply chain and offers up career advice

Cathy Morris, senior vice president and chief strategy officer for Arrow Electronics, Inc., talks women in the supply chain and offers up career advice

Men hold 95% of top level supply chain positions within Fortune 500 companies. Outside the corner office things aren’t much better; between 70% and 80% of positions within the supply chain industry are held by men. Cathy Morris, senior vice president and chief strategy officer for Arrow Electronics, Inc., defies these statistics. Morris discusses her career and the gender gap in an interview:

Only a small percentage of top level positions in Fortune 500 companies are held by women. Within the supply chain industry this percentage is even smaller. How did you get to where you are today?

I’d like to say that I chose the supply chain, but the reality is that I stumbled into it. I was working in finance as a corporate controller when the company for whom I was working was purchased by Arrow. My position was eliminated; however, an individual within Arrow came to me and suggested that I stay with the company albeit in a different department. He suggested that I take my practical experience in finance and my expertise in making businesses better and “do something different.” I did do something different – I went from being a corporate controller to running a series of warehouses.

Products can be made, money can be invested, ideas can be brought to fruition, but without the supply chain everything stops. The supply chain provides routes to market; everything hinges on an effective supply chain.

I decided I need to identify what I needed to know so that I could sit at the table. I invested between 12 and 18 months in roles, from logistics to sales, throughout the company. When I started each role I identified what I could learn from the role, what I could contribute, and what milestone I could attain.

As one of the few women in the supply chain and one of the few women in an executive position what challenges have you experienced?

While I have had incredible mentors few have been women. There are, as you said, not a lot of women at the table. I would say that 90% of the time I am the only woman in the room.

What can women who are in the supply chain do to support each other and how can the supply chain attract more women to the field?

It is the responsibility of women to invest in each other and to help each other. This is important in building a better organization. A better organization is not about the numerical statistics related to diversity. A better organization is about better decision-making. Diversity is essential for companies; diversity enables better decision making and diminishes group think.

Change starts from the top down. If you are interviewing for a position and everyone is of the same gender and race, be bold – ask if inclusion is a top priority for the company. Ask what the company is doing to increase diversity.

The supply chain needs to be rebranded. The perception is that when you work within the supply chain you are a second class citizen. The reality is that in the absence of an effective supply chain the entire value proposition of a Company falls apart. This is what we need to get out there.

What career advice can you offer?

Every career decision you make needs to reflect your personal goals; focus on the culture of company and how the position will enable you in your career.

When you leave a job it needs to be for a purpose. You should never leave a job because you don’t like it, rather you should leave a job because you have achieved what you set out to do within that job.

If you don’t like your job, sit back and assess why you don’t like. When you determine this, change what you don’t like about the job.

One of the most common reasons people leave their job is because they don’t like their boss. This is not a reason to leave. Bad bosses provide more learning than good bosses. With bad bosses you learn what not to do – this is invaluable.

You manage your own career. As long as you continue to manage your career you will be happy. Once you stop managing it, you’ll be unhappy.

Cathy Morris is the senior vice president and chief strategy officer for Arrow Electronics, Inc.. Morris leads strategic initiatives for Arrow, including global merger and acquisition activity. She brings nearly 30 years of experience in the computer products and electronic components distribution industry, having previously served as president of Arrow’s enterprise computing solutions segment after holding senior positions in support service, finance and corporate development.

Prior to joining Arrow in 1994, Morris held financial leadership roles in the banking and manufacturing industries. She is a board member and chairs the audit committee for Graftech International, and she is a member of the Global Leadership Council at Colorado State University and the YWCA’s Society of Women Achievers.

In March 2015 Cathy Morris, was named to the National Diversity Council’s 2015 “Top 50 Most Powerful Women in Technology.” This is the second consecutive year Morris has been honored with this distinction.

by Fronetics | May 28, 2015 | Blog, Leadership, Strategy, Supply Chain, Talent

Cathy Morris, senior vice president and chief strategy officer for Arrow Electronics, Inc., talks women in the supply chain and offers up career advice

Cathy Morris, senior vice president and chief strategy officer for Arrow Electronics, Inc., talks women in the supply chain and offers up career advice

Men hold 95% of top level supply chain positions within Fortune 500 companies. Outside the corner office things aren’t much better; between 70% and 80% of positions within the supply chain industry are held by men. Cathy Morris, senior vice president and chief strategy officer for Arrow Electronics, Inc., defies these statistics. Morris discusses her career and the gender gap in an interview:

Only a small percentage of top level positions in Fortune 500 companies are held by women. Within the supply chain industry this percentage is even smaller. How did you get to where you are today?

I’d like to say that I chose the supply chain, but the reality is that I stumbled into it. I was working in finance as a corporate controller when the company for whom I was working was purchased by Arrow. My position was eliminated; however, an individual within Arrow came to me and suggested that I stay with the company albeit in a different department. He suggested that I take my practical experience in finance and my expertise in making businesses better and “do something different.” I did do something different – I went from being a corporate controller to running a series of warehouses.

Products can be made, money can be invested, ideas can be brought to fruition, but without the supply chain everything stops. The supply chain provides routes to market; everything hinges on an effective supply chain.

I decided I need to identify what I needed to know so that I could sit at the table. I invested between 12 and 18 months in roles, from logistics to sales, throughout the company. When I started each role I identified what I could learn from the role, what I could contribute, and what milestone I could attain.

As one of the few women in the supply chain and one of the few women in an executive position what challenges have you experienced?

While I have had incredible mentors few have been women. There are, as you said, not a lot of women at the table. I would say that 90% of the time I am the only woman in the room.

What can women who are in the supply chain do to support each other and how can the supply chain attract more women to the field?

It is the responsibility of women to invest in each other and to help each other. This is important in building a better organization. A better organization is not about the numerical statistics related to diversity. A better organization is about better decision-making. Diversity is essential for companies; diversity enables better decision making and diminishes group think.

Change starts from the top down. If you are interviewing for a position and everyone is of the same gender and race, be bold – ask if inclusion is a top priority for the company. Ask what the company is doing to increase diversity.

The supply chain needs to be rebranded. The perception is that when you work within the supply chain you are a second class citizen. The reality is that in the absence of an effective supply chain the entire value proposition of a Company falls apart. This is what we need to get out there.

What career advice can you offer?

Every career decision you make needs to reflect your personal goals; focus on the culture of company and how the position will enable you in your career.

When you leave a job it needs to be for a purpose. You should never leave a job because you don’t like it, rather you should leave a job because you have achieved what you set out to do within that job.

If you don’t like your job, sit back and assess why you don’t like. When you determine this, change what you don’t like about the job.

One of the most common reasons people leave their job is because they don’t like their boss. This is not a reason to leave. Bad bosses provide more learning than good bosses. With bad bosses you learn what not to do – this is invaluable.

You manage your own career. As long as you continue to manage your career you will be happy. Once you stop managing it, you’ll be unhappy.

Cathy Morris is the senior vice president and chief strategy officer for Arrow Electronics, Inc.. Morris leads strategic initiatives for Arrow, including global merger and acquisition activity. She brings nearly 30 years of experience in the computer products and electronic components distribution industry, having previously served as president of Arrow’s enterprise computing solutions segment after holding senior positions in support service, finance and corporate development.

Prior to joining Arrow in 1994, Morris held financial leadership roles in the banking and manufacturing industries. She is a board member and chairs the audit committee for Graftech International, and she is a member of the Global Leadership Council at Colorado State University and the YWCA’s Society of Women Achievers.

In March 2015 Cathy Morris, was named to the National Diversity Council’s 2015 “Top 50 Most Powerful Women in Technology.” This is the second consecutive year Morris has been honored with this distinction.

by Jennifer Hart Yim | May 13, 2015 | Blog, Leadership, Strategy, Supply Chain

This article is part of a series of articles written by MBA students and graduates from the University of New Hampshire Peter T. Paul College of Business and Economics.

Corey Ducharme is Green Belt Certified in Six Sigma. He has a BA in Business and is currently in the MBA program at the University of New Hampshire. He has consulted at major corporations including Johnson & Johnson, Universal Studios, Sony Pictures, Oklahoma Oil & Gas, and Suncor as a management consultant at D&A Management. He can be reached via e-mail.

We all use Six Sigma problem solving whether we know it or not

How do humans tend to solve problems? Consciously or unconsciously humans use a four-step method that is defined as:

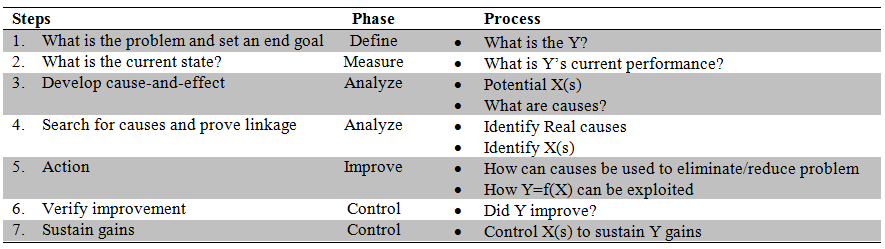

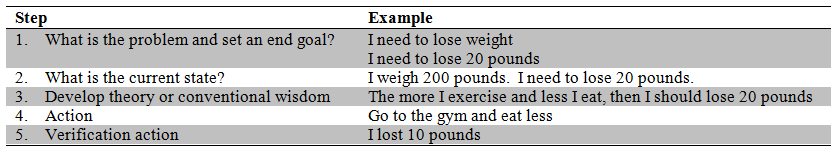

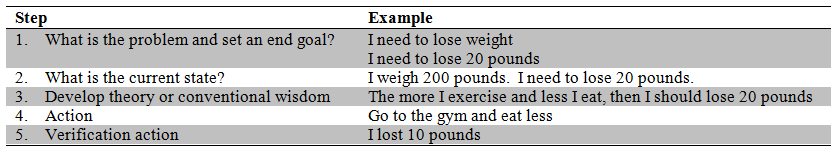

Table 1: Traditional Problem Solving Process

In the above example, the root cause is identified – exercise and eating less equals losing weight – and verified. The conventional wisdom is proven true and there is little need to consider a more robust or analytical method. Most humans solve their day-to-day issues in this manner whether consciously or unconsciously. My root-cause analysis in this case (I exercise and eat less) is verified by the fact that I lost ten pounds and sustainable until my goal is achieved. (Losing 20 pounds).

Six Sigma Problem Solving

What if the root-cause lies outside of conventional wisdom or is difficult to determine?

These needle-in-a-haystack problems – due to limited business resources – cause businesses to lose revenue and lead to process failures, poor quality, and poor customer service. These types of problems are at the heart of Six Sigma Problem Solving and are a way to find the needle-in-the-haystack.

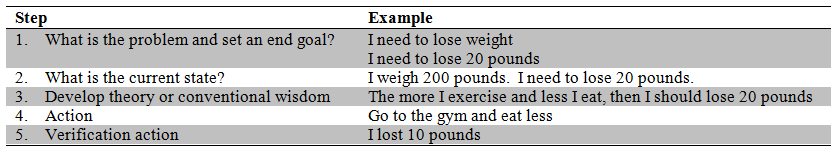

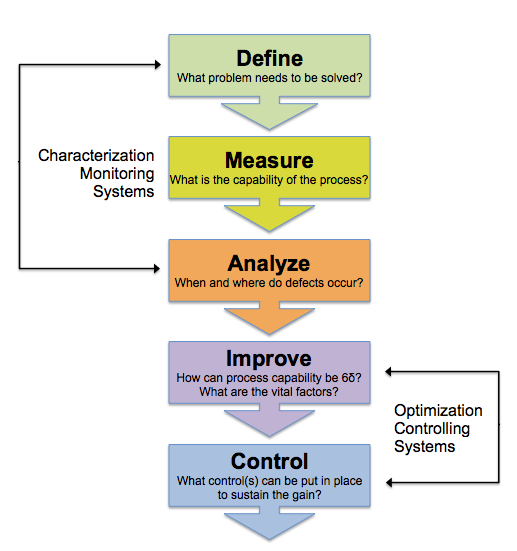

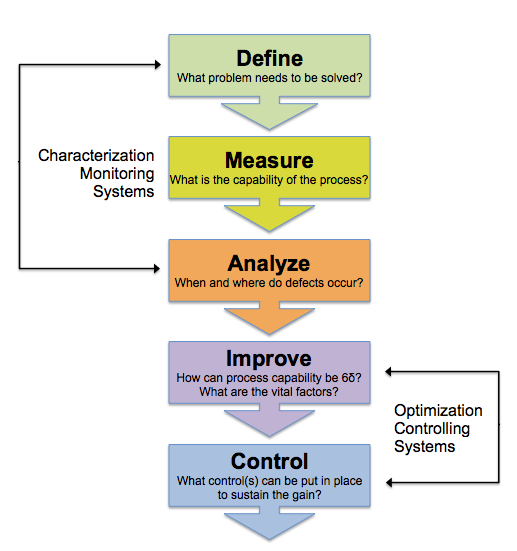

The Six Sigma methodology is based on the DMAIC process and using our weight loss example we begin to see the similarities between the two methods.

- Define Phase: What is the problem and set the end goal.

- Measure Phase: What is the current state?

- Analyze Phase: 1. Develop cause-and-effect analysis of problem. What are the real causes and prove cause and effect links.

- Improve Phase: Action

- Control Phase: 1. Verify improvement and 2. Sustainability

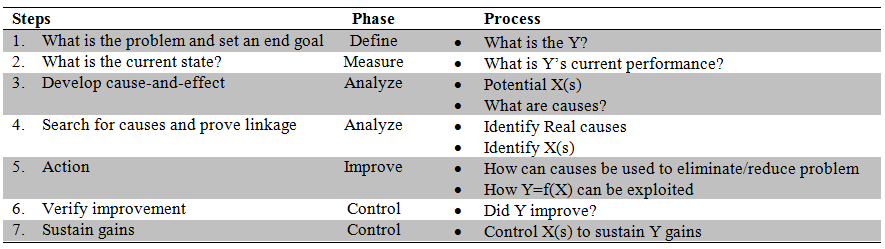

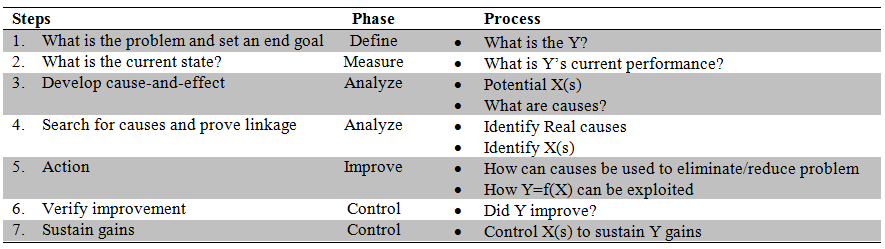

What differs between the phases of conventional and Six Sigma problem solving begins in the Analyze Phase. Six Sigma methodology demands the proof of cause be determined before a clear course of action is taken. The proof of cause must be data-driven as root-cause analysis is at the core of Six Sigma problem solving. It is also the reason that the Analyze phase is divided into the development of cause-effects and proof of cause-effect links.

The second difference is in the fifth phase. In the Traditional problem-solving methodology, verification comes in the form of losing weight. I can prove it by weighing myself. In Six Sigma problem solving, a two-step process is needed. Verification is essential (Did I improve?) and if so, a plan to sustain our gains is created. This is not necessary in a Traditional methodology because our cause-effect is proven (exercise/eat less = weight loss); however, in the Six Sigma methodology our cause-effect must be tested and verified.

The Linguistics of Six Sigma: Y=f(X)

To speak in the language of Six Sigma, we need to change ‘problem’ with ‘Y’ and ‘cause’ with ‘X’. The Y is the output and the X(s) are any inputs that are involved in producing the output. In other words, the Y = 100% customer satisfaction and X(s) are the variables that affect the level of customer satisfaction. For more, click the following link: Y=f(X).

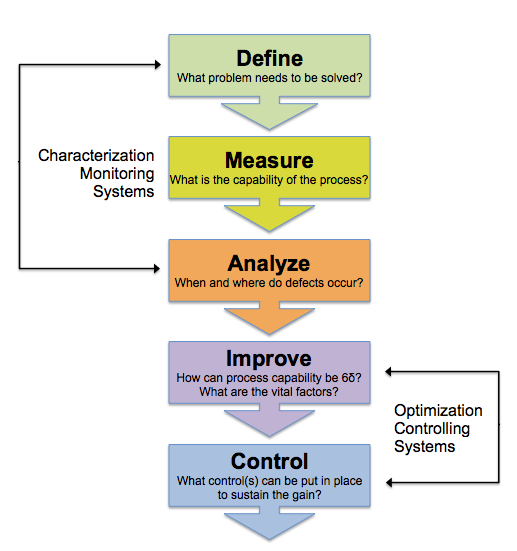

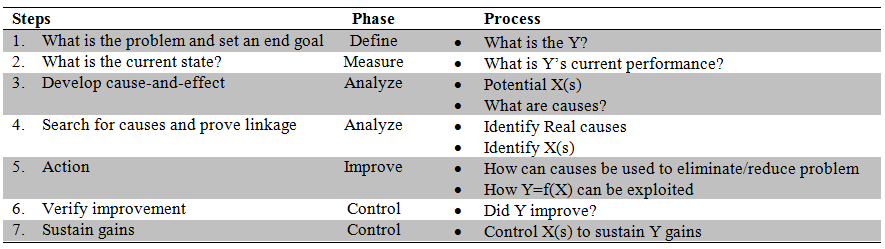

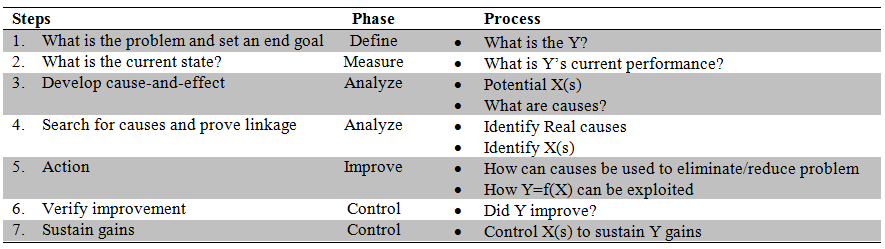

Using Six Sigma linguistics and the DMAIC process, we can combine the Traditional problem solving steps in Table 1 and we see that our four-step process has become a more robust seven-step process. We can now use DMAIC to ask ourselves the most essential question:

If our root-cause analysis is discovered and proven true, then can the problem be solved or reduced by controlling or removing the cause(s)?

Table 2: DMAIC Problem Solving

Real World Example: Boeing

Boeing’s Six Sigma team in Everett, WA discovered that root cause analysis is often like finding a needle-in-a-haystack, especially for the maker of the world’s largest commercial twin-engine airplane with millions of components. (To read the entire story, click the following link: Problem-solving approach helps team pinpoint solution). Boeing discovered that recirculating air fans were being rejected during production, costing Boeing money in waste, removal, testing, and cost of replacing the component.

Boeing assembled a cross-functional ‘detective squad’ that included employees from Engineering, Quality, Manufacturing, Supply Management, Procurement, and their supplier Hamilton Sundstrand who began the problem-solving techniques of the DMAIC process by examining data from the fans and beginning root-cause analysis.

This analysis determined that Foreign Object Debris (FOD) damaged the fans and the test tools. Job done, right? Not according to Kent Kuiper, Six Sigma expert at Boeing, the team had to dig deeper. “For example,” he said, “when we found that FOD was a problem and determined the source for it, removing the FOD and replacing the fan wasn’t going to get us where we needed to go. We had to figure out a way to keep the FOD from happening again.”

Further inspection led the team to discover failures in ductwork caps and plastic sheeting – two items ironically intended to prevent FOD damage and two electrical issues. One failure of improperly modified test equipment and the second issue related to crimping procedures in manufacturing process that improved connections in the fans. The results? Although the FOD in the fans was the main X, the results were clear. “After 18 fan failures in two years, we went four and a half months without a rejection,” said Max Limb, a supplier field service representative. “We haven’t completely eliminated the rejections, but we’re close.”

“Our team has become well-versed in the concept of Six Sigma,” said Valerie Feiberti, Supply Management and Procurement Director of the Lean Promotion Team. “We feel very strongly that it provides a way to correct production-related problems and proactively design-in quality.”

Summary

The DMAIC methodology is essentially a series of common sense questions to determine root-cause analysis, identification of X(s), elimination of problems, and maintaining of gains. The DMAIC process asks the following questions:

- Define: What is the Y that is performing poorly?

- Measure: What is Y’s current performance?

- Analyze: What are the X(s)? Are they real?

- Improve: How can X(s) be controlled/eliminated?

- Control: How can X(s) be controlled to sustain gains in Y?

Six Sigma problem solving is the data-driven representation of the conscious or unconscious thinking we use to solve problems in our lives and can be used to solve may needle-in-a-haystack problems that vex businesses.

by Jennifer Hart Yim | May 13, 2015 | Blog, Leadership, Strategy, Supply Chain

This article is part of a series of articles written by MBA students and graduates from the University of New Hampshire Peter T. Paul College of Business and Economics.

Corey Ducharme is Green Belt Certified in Six Sigma. He has a BA in Business and is currently in the MBA program at the University of New Hampshire. He has consulted at major corporations including Johnson & Johnson, Universal Studios, Sony Pictures, Oklahoma Oil & Gas, and Suncor as a management consultant at D&A Management. He can be reached via e-mail.

We all use Six Sigma problem solving whether we know it or not

How do humans tend to solve problems? Consciously or unconsciously humans use a four-step method that is defined as:

Table 1: Traditional Problem Solving Process

In the above example, the root cause is identified – exercise and eating less equals losing weight – and verified. The conventional wisdom is proven true and there is little need to consider a more robust or analytical method. Most humans solve their day-to-day issues in this manner whether consciously or unconsciously. My root-cause analysis in this case (I exercise and eat less) is verified by the fact that I lost ten pounds and sustainable until my goal is achieved. (Losing 20 pounds).

Six Sigma Problem Solving

What if the root-cause lies outside of conventional wisdom or is difficult to determine?

These needle-in-a-haystack problems – due to limited business resources – cause businesses to lose revenue and lead to process failures, poor quality, and poor customer service. These types of problems are at the heart of Six Sigma Problem Solving and are a way to find the needle-in-the-haystack.

The Six Sigma methodology is based on the DMAIC process and using our weight loss example we begin to see the similarities between the two methods.

- Define Phase: What is the problem and set the end goal.

- Measure Phase: What is the current state?

- Analyze Phase: 1. Develop cause-and-effect analysis of problem. What are the real causes and prove cause and effect links.

- Improve Phase: Action

- Control Phase: 1. Verify improvement and 2. Sustainability

What differs between the phases of conventional and Six Sigma problem solving begins in the Analyze Phase. Six Sigma methodology demands the proof of cause be determined before a clear course of action is taken. The proof of cause must be data-driven as root-cause analysis is at the core of Six Sigma problem solving. It is also the reason that the Analyze phase is divided into the development of cause-effects and proof of cause-effect links.

The second difference is in the fifth phase. In the Traditional problem-solving methodology, verification comes in the form of losing weight. I can prove it by weighing myself. In Six Sigma problem solving, a two-step process is needed. Verification is essential (Did I improve?) and if so, a plan to sustain our gains is created. This is not necessary in a Traditional methodology because our cause-effect is proven (exercise/eat less = weight loss); however, in the Six Sigma methodology our cause-effect must be tested and verified.

The Linguistics of Six Sigma: Y=f(X)

To speak in the language of Six Sigma, we need to change ‘problem’ with ‘Y’ and ‘cause’ with ‘X’. The Y is the output and the X(s) are any inputs that are involved in producing the output. In other words, the Y = 100% customer satisfaction and X(s) are the variables that affect the level of customer satisfaction. For more, click the following link: Y=f(X).

Using Six Sigma linguistics and the DMAIC process, we can combine the Traditional problem solving steps in Table 1 and we see that our four-step process has become a more robust seven-step process. We can now use DMAIC to ask ourselves the most essential question:

If our root-cause analysis is discovered and proven true, then can the problem be solved or reduced by controlling or removing the cause(s)?

Table 2: DMAIC Problem Solving

Real World Example: Boeing

Boeing’s Six Sigma team in Everett, WA discovered that root cause analysis is often like finding a needle-in-a-haystack, especially for the maker of the world’s largest commercial twin-engine airplane with millions of components. (To read the entire story, click the following link: Problem-solving approach helps team pinpoint solution). Boeing discovered that recirculating air fans were being rejected during production, costing Boeing money in waste, removal, testing, and cost of replacing the component.

Boeing assembled a cross-functional ‘detective squad’ that included employees from Engineering, Quality, Manufacturing, Supply Management, Procurement, and their supplier Hamilton Sundstrand who began the problem-solving techniques of the DMAIC process by examining data from the fans and beginning root-cause analysis.

This analysis determined that Foreign Object Debris (FOD) damaged the fans and the test tools. Job done, right? Not according to Kent Kuiper, Six Sigma expert at Boeing, the team had to dig deeper. “For example,” he said, “when we found that FOD was a problem and determined the source for it, removing the FOD and replacing the fan wasn’t going to get us where we needed to go. We had to figure out a way to keep the FOD from happening again.”

Further inspection led the team to discover failures in ductwork caps and plastic sheeting – two items ironically intended to prevent FOD damage and two electrical issues. One failure of improperly modified test equipment and the second issue related to crimping procedures in manufacturing process that improved connections in the fans. The results? Although the FOD in the fans was the main X, the results were clear. “After 18 fan failures in two years, we went four and a half months without a rejection,” said Max Limb, a supplier field service representative. “We haven’t completely eliminated the rejections, but we’re close.”

“Our team has become well-versed in the concept of Six Sigma,” said Valerie Feiberti, Supply Management and Procurement Director of the Lean Promotion Team. “We feel very strongly that it provides a way to correct production-related problems and proactively design-in quality.”

Summary

The DMAIC methodology is essentially a series of common sense questions to determine root-cause analysis, identification of X(s), elimination of problems, and maintaining of gains. The DMAIC process asks the following questions:

- Define: What is the Y that is performing poorly?

- Measure: What is Y’s current performance?

- Analyze: What are the X(s)? Are they real?

- Improve: How can X(s) be controlled/eliminated?

- Control: How can X(s) be controlled to sustain gains in Y?

Six Sigma problem solving is the data-driven representation of the conscious or unconscious thinking we use to solve problems in our lives and can be used to solve may needle-in-a-haystack problems that vex businesses.

by Fronetics | May 6, 2015 | Blog, Leadership, Marketing, Social Media, Strategy

There’s a great deal of buzz about social media in the business world – and for good reason. Marketing and communications professionals have made it de rigueur to tap into the popularity of social media networks to extend their brands into the digital world. But when it comes to executive use of social media, the field seems much more divided. Domo and CEO.com estimated that of the 500 leaders of the biggest companies in the US, 68% have no social media presence whatsoever. By leaving the social media management to marketers, these leaders are missing opportunities to connect with followers and expand their influence.

There’s a great deal of buzz about social media in the business world – and for good reason. Marketing and communications professionals have made it de rigueur to tap into the popularity of social media networks to extend their brands into the digital world. But when it comes to executive use of social media, the field seems much more divided. Domo and CEO.com estimated that of the 500 leaders of the biggest companies in the US, 68% have no social media presence whatsoever. By leaving the social media management to marketers, these leaders are missing opportunities to connect with followers and expand their influence.

Here’s why social media should be part of the game plan when it comes to matters of leadership.

Social media expands perspective.

Social media isn’t simply a mechanism for broadcasting company news or personal opinion. Many individual perspectives coalesce to create a social network. Asking questions of followers and participating in online discussions helps leaders gain new perspectives. Executives who do utilize social media tend to stick to LinkedIn at a rate greater than the general public, but increasing social participation beyond one network brings more heterogeneous insight and connects leaders to diverse groups.

Social media allows you to keep a finger on the pulse of industry trends and new research.

Participating digitally with like-minded professionals ties a leader into a broad network of resource-sharing. Having consistent access to relevant, curated articles about market and industry trends keeps leaders far ahead of peers who rely on just a few media outlets.

Social media connects your team.

Online social business tool Basecamp promises to help “wrangle people with different roles, responsibilities, and objectives toward to common goal.” Hosted in the cloud, Basecamp is a project management tool that helps managers and employees see exactly what’s happening with a given project. Its dashboard provides a snapshot of tasks and gives users – managers and employees – an opportunity to interact directly on the site. In addition to the real-time accountability it builds in, it also allows for real-time communication about projects, a concept that all but eliminates the need for private emails.

Social media inspires and motivates.

Hadyn Shaughnessy writes about top social media influencers in his contributing posts on Forbes.com. He believes stellar leadership is built firmly on relationships and that day-to-day operations of a business rely on a leader’s ability to connect, inspire, and mobilize employees. Leveraging social media is one way leaders are achieving that. But, he contends, passive consumers of social media – regardless of the number of followers – cannot be considered top influencers. Leaders who inspire are those who actively participate.

Social media builds relationships.

Among executives active on social media, the top benefit of maintaining “socialbility” is the direct access it provides to employees, media outlets, and the public. “Relationship building is one of the strongest skills sets related to leadership effectiveness,” says Jean Leslie, a researcher at the Center for Creative Leadership. Tying into social media networks allows leaders to establish connections with employees, building individual and collaborative relationships.

Leaders who embrace social media technologies are more agile and innovative; their companies are more likely to attract and retain top talent; and they tap more deeply into the ideas of their employees. It’s clear that there is value in social media, and for leaders looking to build the strongest brand for their company, it might not be just an option anymore.

by Fronetics | May 6, 2015 | Blog, Leadership, Marketing, Social Media, Strategy

There’s a great deal of buzz about social media in the business world – and for good reason. Marketing and communications professionals have made it de rigueur to tap into the popularity of social media networks to extend their brands into the digital world. But when it comes to executive use of social media, the field seems much more divided. Domo and CEO.com estimated that of the 500 leaders of the biggest companies in the US, 68% have no social media presence whatsoever. By leaving the social media management to marketers, these leaders are missing opportunities to connect with followers and expand their influence.

There’s a great deal of buzz about social media in the business world – and for good reason. Marketing and communications professionals have made it de rigueur to tap into the popularity of social media networks to extend their brands into the digital world. But when it comes to executive use of social media, the field seems much more divided. Domo and CEO.com estimated that of the 500 leaders of the biggest companies in the US, 68% have no social media presence whatsoever. By leaving the social media management to marketers, these leaders are missing opportunities to connect with followers and expand their influence.

Here’s why social media should be part of the game plan when it comes to matters of leadership.

Social media expands perspective.

Social media isn’t simply a mechanism for broadcasting company news or personal opinion. Many individual perspectives coalesce to create a social network. Asking questions of followers and participating in online discussions helps leaders gain new perspectives. Executives who do utilize social media tend to stick to LinkedIn at a rate greater than the general public, but increasing social participation beyond one network brings more heterogeneous insight and connects leaders to diverse groups.

Social media allows you to keep a finger on the pulse of industry trends and new research.

Participating digitally with like-minded professionals ties a leader into a broad network of resource-sharing. Having consistent access to relevant, curated articles about market and industry trends keeps leaders far ahead of peers who rely on just a few media outlets.

Social media connects your team.

Online social business tool Basecamp promises to help “wrangle people with different roles, responsibilities, and objectives toward to common goal.” Hosted in the cloud, Basecamp is a project management tool that helps managers and employees see exactly what’s happening with a given project. Its dashboard provides a snapshot of tasks and gives users – managers and employees – an opportunity to interact directly on the site. In addition to the real-time accountability it builds in, it also allows for real-time communication about projects, a concept that all but eliminates the need for private emails.

Social media inspires and motivates.

Hadyn Shaughnessy writes about top social media influencers in his contributing posts on Forbes.com. He believes stellar leadership is built firmly on relationships and that day-to-day operations of a business rely on a leader’s ability to connect, inspire, and mobilize employees. Leveraging social media is one way leaders are achieving that. But, he contends, passive consumers of social media – regardless of the number of followers – cannot be considered top influencers. Leaders who inspire are those who actively participate.

Social media builds relationships.

Among executives active on social media, the top benefit of maintaining “socialbility” is the direct access it provides to employees, media outlets, and the public. “Relationship building is one of the strongest skills sets related to leadership effectiveness,” says Jean Leslie, a researcher at the Center for Creative Leadership. Tying into social media networks allows leaders to establish connections with employees, building individual and collaborative relationships.

Leaders who embrace social media technologies are more agile and innovative; their companies are more likely to attract and retain top talent; and they tap more deeply into the ideas of their employees. It’s clear that there is value in social media, and for leaders looking to build the strongest brand for their company, it might not be just an option anymore.

Cathy Morris, senior vice president and chief strategy officer for Arrow Electronics, Inc., talks women in the supply chain and offers up career advice

Cathy Morris, senior vice president and chief strategy officer for Arrow Electronics, Inc., talks women in the supply chain and offers up career advice