by Fronetics | Mar 2, 2016 | Blog, Internet of Things, Strategy

B2B sales must recognize and accommodate buyers at various levels of self-sufficiency in the purchasing process.

Widespread access to the Internet has changed life as we know it. Not only are once-token errands like trips to the supermarket and holiday gift shopping increasingly shifting online, but B2B buyer behavior is occurring most often in the digital space, as well. In fact, an Acquity Group study found that 94% of B2B buyers in the U.S. conduct research online to make purchase decisions.

An Internet search can yield thousands of results when a B2B buyer goes to research a specific product or service. What’s more, the buyer can access online sources reviewing and comparing different suppliers’ products, streamline purchasing through self-service shopping portals, and access digital training and support tools without ever talking to another human. Essentially, “buyers can take over many steps of buying that salespeople once cherished as their source of value,” says a Harvard Business Review article.

But this doesn’t eliminate the need for salespeople in B2B sales completely. Rather, the authors suggest that today’s sellers must develop new competencies that better serve customers with more access to information.

How B2B sales are changing

Information technology and digital channels create buyers at various levels of self-sufficiency. While some are able to gather all of the intel needed to make a purchasing decision, some are more overwhelmed than before and need help sifting through all the available information. Most buyers fall somewhere between the two ends of the spectrum. Additionally, customers can be at different levels at different times and for different products.

Therefore, salespeople need to be able to recognize where customers fall on the self-sufficiency scale and match their selling approach to the customers’ needs.

Salespeople must also be competent in various technologies that help manage customer information and outreach. CRM systems, analytics, and various infrastructures are just a few examples of digital tools sales teams have at their disposal.

New platforms like social media and email also supplant the need for traditional face-to-face selling but require an all-together different skill set. Video conferencing, podcasts, and webinars — these are also tools that sellers can use to accommodate buyer preferences and level of knowledge, should the seller be fluent in these technologies.

And with so many options to adapt to customers at various levels of self-sufficiency, salespeople must be able to coordinate communications across multiple channels. “Salespeople need competencies as orchestrators who can ensure an effective and efficient connection,” the authors suggest.

Salesforces, too, must adapt to the information age in terms of structure, training, compensation, and more.

How has your business adapted to B2B selling in the information age?

Related articles:

by Fronetics | Sep 17, 2015 | Blog, Internet of Things, Marketing, Social Media

As of January 2015 nearly half (3.01 billion) of the world’s population (7.21 billion) were active internet users. Population growth from the previous year was up 1.6%, active internet users were up 21%, and social media users were up 12%. These are big leaps, and continued growth is predicted. These numbers are a good thing, not only for people like Mark Zuckerberg, but also for business.

Here are 8 reasons why your business needs to harness the power of the internet:

by Fronetics | Jul 6, 2015 | Big Data, Blog, Data/Analytics, Internet of Things, Logistics, Marketing, Strategy, Supply Chain

The battle for competitiveness in the cloud.

In this age of radical transformation for supply chains, top companies are tying together prevailing concepts, like big data and the Internet of Things (IoT), with cloud-based computing. Supply chains are being reimagined as digital networks that track not only physical goods, but also people, data, and money. As such, global technology giants continue to invest heavily in cloud computing.

The Chinese e-commerce company Alibaba Group Holding, Ltd. recently announced that it is launching its first international venture – a cloud computing hub in Silicon Valley, proving the fierce competition for market share is stiffening both globally and on the home turf. Notably, all five top-ranked companies listed by the 2013 Strategy & Global Information, Communications and Technology 50 study bet their future on cloud technologies. The companies (IBM, Microsoft, SAP, Oracle, and Cisco Systems) could not, until recently, be perceived as direct competitors, and now they all wield cloud-based portfolios as their competitive weapon of choice.

Analysts note:

The industry leaders are seeking dominant positions, wanting to become the kings of the cloud. As a group, they are putting distance between themselves and the second tier of followers.

For further proof data analytics is driving competition for cloud customers, we can look to a new report by Market & Research that shows data analytics and cloud computing are expected to record a combined growth of 26% annually over the next five years. The implication is that demand is hardly going to lessen as an increasing number of organizations need cloud solutions to manage and store the huge amounts of data that they use to transform manufacturing processes, fine-tune supply chains, forecast customer behavior, and optimize inventories – to name a fraction of potential applications.

And cloud-based computing is even moving the needle of interest in industries that seem inherently averse to making data and information more easily accessible. For example, concerns about data encryption, auditing controls, and transparency have stymied the adoption of cloud-based computing in the financial industry. According to a report by the Cloud Security Alliance, only 28% of American financial institutions have a cloud-based strategy in place, but as a sponsor of the report, Dr. Chenxi Wang, vice president of Cloud Security and Strategy at CipherCloud points out:

Cloud has made solid inroads in this industry with many firms looking to harnessing the power of cloud. There’s plenty of room for growth, particularly for providers who can fill the void for the auditing and data protection controls that are at the top of respondents’ cloud wish list.

Meanwhile, the public cloud services market alone could grow into a $100 billion industry by 2017, according to researcher IDC. Is your business prepared to leverage cloud computing for its supply chain activities? It’s coming, ready or not.

Fronetics Strategic Advisors is a leading management consulting firm. Our firm works with companies to identify and execute strategies for growth and value creation.

Whether it is a wholesale food distributor seeking guidance on how to define and execute corporate strategy; a telematics firm needing high quality content on a consistent basis; a real estate firm looking for a marketing partner; or a supply chain firm in need of interim management, our clients rely on Fronetics to help them navigate through critical junctures, meet their toughest challenges, and take advantage of opportunities. We deliver high-impact results.

We advise and work with companies on their most critical issues and opportunities: strategy, marketing, organization, talent acquisition, performance management, and M&A support.

We have deep expertise and a proven track record in a broad range of industries including: supply chain, real estate, software, and logistics.

by Fronetics | Jun 25, 2015 | Big Data, Blog, Data/Analytics, Internet of Things, Marketing

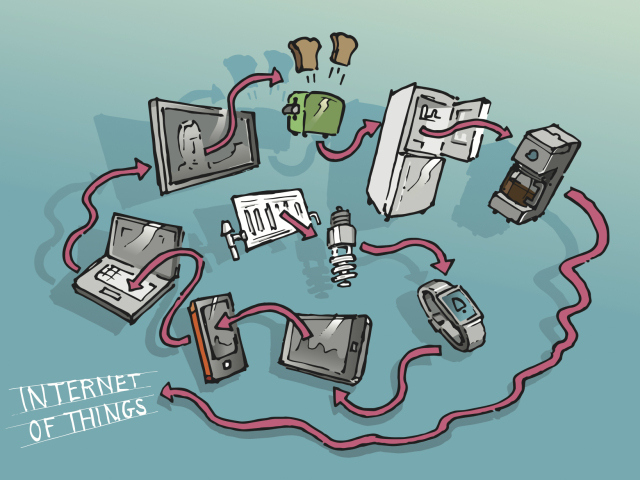

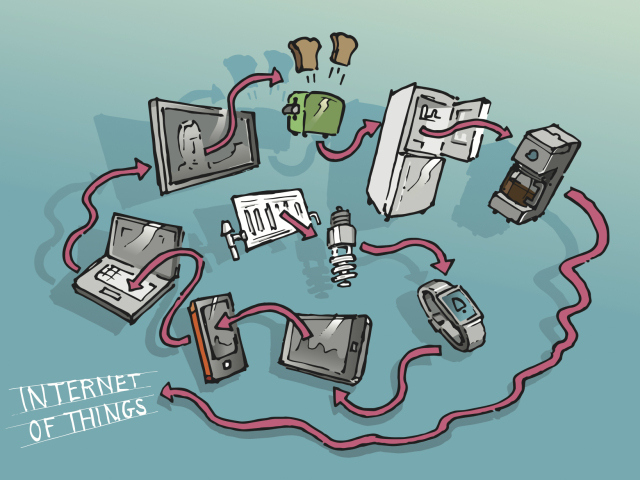

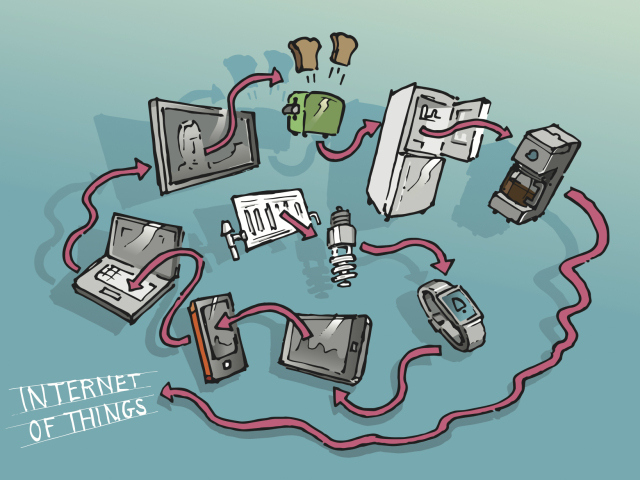

From coffee makers to urban design, the Internet of Things (IoT) is affecting change in virtually all aspects of daily life. And even though the IoT is still at the early-adopter stage, in just five years 50 billion devices are projected to be connected to the Internet, generating an estimated $2 trillion to $14 trillion in value. Expectations are running high, so high, in fact, that Gartner ranked IoT at the top of its 2014 Hype Cycle for Emerging Technologies.

Companies are naturally eager to get a piece of the action with as many as three out of four exploring how IoT technologies could fit into their business operations. Too many times, however, companies end up with mountains of data and no actionable information. Entry into the IoT should come with warnings: analyze the data or prepare to be disappointed. Or, data without analytics is nothing but noise.

But unless businesses turn the focus away from pure data collection to data analysis, investments in IoT technologies are doomed to produce disappointing results. To be truly useful, the data should do more than “look pretty on a dashboard,” as Steven Sarracino, founder of Activant Capital Group, LLC, in Greenwich, Conn., pointed out.

Vendors of sensor technologies would simultaneously be wise to take their services beyond singing the virtues of amassing data to showing their clients how to make sensor-driven decisions. In fact, the need for more guidance was underscored in a fleet report by Tracking Automotive Technology: TU Automotive (previously Telematics Update). Vendors should, according to the report, present the data in a digestible format to assist overwhelmed end-users. While purely monitoring the performance of a forklift, for example, provides value, it is not until the data is analyzed and acted upon that maximum ROI is achieved. In the case of a forklift fleet, it might entail optimizing routes in the warehouse or performing preventive maintenance. As another example, the retail sector can apply analytics to data collected by security cameras and Wi-Fi beacons to help retailers understand what types of displays catch customers’ attention.

The adoption of IoT technologies will likely come easier to industries such as manufacturing and supply chain which already connect machinery and fleets with Internet-enabled sensors or devices. Smart grid technologies also hold a lot of promise for public utilities based on current industry trends, connecting countless data points for continuous monitoring and proactive management of the power supply. However, until companies are able to adequately apply analytics to squeeze value out of their investments, it may be a while before IoT technologies reach critical mass.

by Fronetics | Jun 17, 2015 | Blog, Internet of Things, Strategy, Supply Chain

Software Advice, a Gartner Company, provides detailed reviews and research on thousands of software applications. The company works with buyers to identify supply chain systems that will meet their needs; therefore, making the buying process a little less murky and arduous.

Software Advice recently released the report: Supply Chain Management Software, BuyerView. The report is based on findings from discussions with supply chain management (SCM) professionals across industry verticals who are seeking to deploy new software solutions.

We talked with Forrest Burnson, Market Research Associate at Software Advice, about the report and its findings:

What were the biggest take aways from the research?

Businesses both large and small are investing heavily into supply chain management software. They’re realizing the power of big data within their organizations and they’re looking for specialized software solutions to help increase visibility into their supply chain. All too often many of these businesses are being hindered by outdated systems and processes.

Where there any surprises? If so, what were they.

Nothing too surprising, though I was definitely a little surprised by the budget estimates the prospective buyers were providing. It makes sense though: Prospective buyers of SCM software tend to be quite savvy, so sticker shock doesn’t affect them as much—they know have an idea of what they’re looking for and they’re willing to fork the money over because they realize the benefits this software can have on their organization.

Do your findings point to any trends (current or future) within the industry?

Software is becoming increasingly important in supply chain management, and more and more smaller businesses are catching on to that trend. Even five years ago there weren’t as many solutions available for SMBs that there are now.

Only 6% of small businesses use commercial SCM software. Why is this?

Many of the smaller businesses got by without commercial SCM software for years, but it’s just not possible for them to continue with their old methods. This also presents a huge opportunity for SCM software vendors, as the SMB market has been historically underserved.

How does it compare to the percentage of larger businesses?

Twenty-one percent of large businesses we spoke with were currently using SCM software.

Small businesses are budgeting more for SCM software. Why is this?

A couple reasons—there are more solutions available to them at a lower price point, and economic pressures are forcing many SMBs to adapt and evolve. That they’re budgeting more tells us that they recognize not only the cost but the return on investment it can potentially have.

Are large businesses also budgeting more?

Yes, we found they are budgeting approximately $171,000 for new SCM software.

To learn more, access the entire report.

by Fronetics | Apr 1, 2015 | Blog, Internet of Things, Supply Chain

During his TED talk on the Internet of Things (IoT) technologist, Dr. John Barrett, described how every thing: appliances, furniture, vehicles, equipment, soil, food, animals and humans can become connected, identified, monitored, managed, and controlled. By 2032 he predicts that each person could come in contact with 3,000 to 5,000 connected things each day. IBM sees the Internet of Things as the planet’s new central nervous system.

The Internet of Things is already here and developing—monitoring our footsteps, heartbeats, lighting, home temperature and environment— and it will continue to grow at a rapid rate: “The growth in IoT will far exceed that of other connected devices. By 2020, the number of smartphones, tablets, and PCs in use will reach about 7.3 billion units,” said Peter Middleton, research director at Gartner. “In contrast, the IoT will have expanded at a much faster rate, resulting in a population of about 26 billion units at that time.”

The IoT and the Supply Chain

This will have a huge impact on the supply chain as we currently know it. In his talk, Dr. Barrett describes how a food processing company waiting for a delivery of shellfish will be able to not only “know where the food delivery is, but its entire storage and shipping history since the moment it came on board” the boat. Already, some vendors are able to remotely monitor their vending machines and access data about temperature, supply, and theft. In the future vending machines will be able to recognize a customer, recall their past preferences, and “even refuse to vend a certain product based on a shopper’s age, medical record, dietary requirements or purchase history.”

How else will we see IoT inform end-to-end transactions within the supply chain? Transparency in the supply chain is already growing with the swell of ERP and SCM, and with its growth it brings collaboration, clarity, and trust. With the increased use of Radio Frequency Identification (RFID) computer chips can talk to each other, and gather and deliver more detailed information than ever. Visibility in the chain will continue to expand and improve operations. The IoT will impact the supply chain in many ways including the following:

- Stock management

- Preventative maintenance

- User insight

- Manufacturing flow management

- Product stability

- Operational efficiency

- Improved fleet management

An Example of Success

Many companies are already employing the IoT, and as a result they are seeing improvements while working out the kinks of this new technology. UPS has increased single carrier deliveries with the use of sensors. According to David Barnes, the company’s chief information officer, more than 200 measurements can be tracked on a delivery truck from “how fast the vehicle is traveling, how aggressively it’s accelerating or decelerating, the RPMs and the fuel consumption. We can hook into the engine bus environment. We also put in a GPS unit. There are sensors on the engine and on components like starter motors and seat belts.” The analysis of this data is a main focus for UPS and has resulted in improved safety management, fuel efficiency, environmental impact, and customer satisfaction. One carrier reported that his deliveries increased from 90 a day to 120 a day. UPS drivers have seen an increase in salary as the company’s revenue multiplies.

The $1 billion UPS invests in technology per year is producing results, but what are the downfalls of telematics and other advancements? The union representing UPS workers has already set forth some demands: drivers cannot be monitored without being informed and cannot be disciplined “based solely on data.” One driver noted that it “does feel like big brother.”

Issues of security, privacy, accuracy, capacity, and the growth of software substitution in the workplace are all matters that need to be examined as IoT explodes. As IoT matures, it is wise for companies, especially those in manufacturing and logistics, to pay close attention. As reported by Gartner, by 2020, “Economic value-add (which represents the aggregate benefits that businesses derive through the sale and usage of IoT technology) is forecast to be $1.9 trillion across sectors.” With the increased possibility, reach, and data of the IoT will come complex decisions and opportunities for businesses.

Fronetics’ Kate Lee has written extensively about the Internet of Things and the supply chain. Her article, How the Internet of Things will change your world, was published in the Quarter 1, 2015 edition of Supply Chain Quarterly.