by Fronetics | Aug 16, 2018 | Blog, Content Marketing, Data/Analytics, Logistics, Marketing, Social Media, Supply Chain

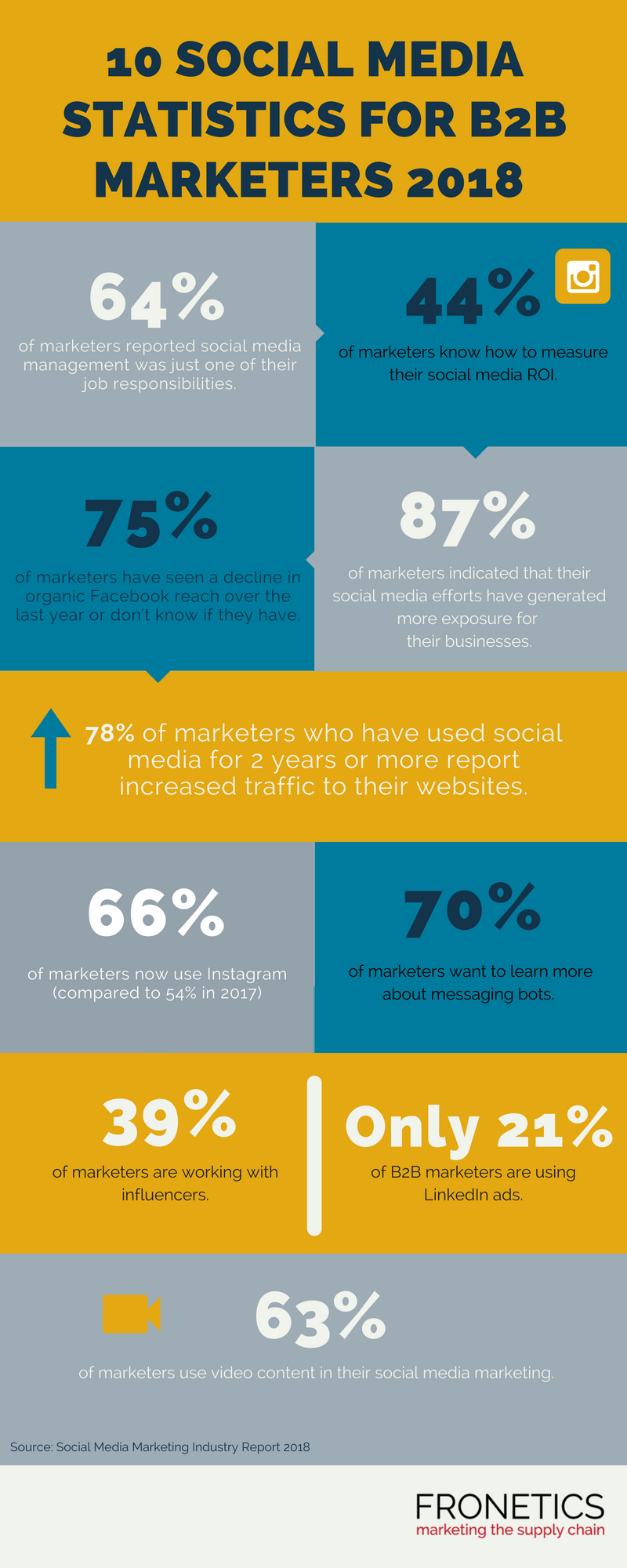

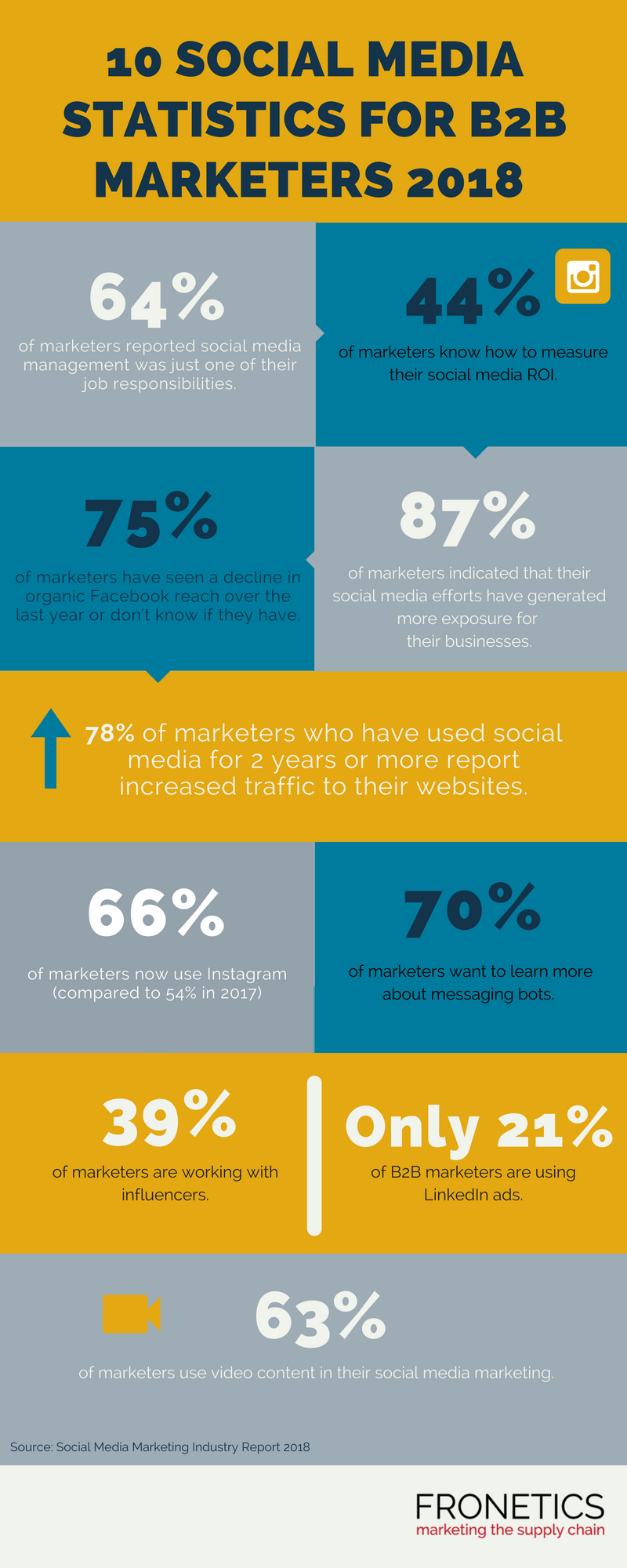

The latest social media statistics show growth of Instagram, more metrics for ROI, social messaging bots, and video content.

One thing that always holds true with social media platforms: they are constantly changing. Platforms like Facebook, Instagram, and Twitter have used 2018 to continue this trend of continual growth and improvement.

[bctt tweet=”One thing that always holds true with social media platforms: they are constantly changing. Platforms like Facebook, Instagram, and Twitter have used 2018 to continue this trend of continual growth and improvement.” username=”Fronetics”]

It’s important with all the changes to take a pause and analyze where these changes are taking us. Simple data can point us to the latest trends and show us where social media is heading.

Social Media Examiner’s 10th annual study, 2018 Social Media Marketing Industry Report, surveyed more than 5,700 marketers from across the world in a variety of industries to see how social media is changing. It offers a really comprehensive view of what’s going on in social media in our industry and beyond.

“This industry report also shows you how marketers’ organic activities have changed and what their future plans are with organic and paid social media,” write the report’s authors.

Here are 10 social media statistics from the report that reflect where social media is headed and what B2B marketers need to be paying attention to.

Infographic: 10 social media statistics for B2B marketers 2018

(Made with Canva)

Still want more?

I really recommend reading the 44-page report in its entirety from Social Media Examiner. There are pages and pages of interesting social media statistics that offer valuable insight into how marketers from all industries are using social media.

The report also shows how social media has changed in the last few years and even more rapidly in the past few months. With messaging bots and video content on the horizon, it’s hard not to wonder where social media will take us next.

What social media statistics are most interesting to you?

Related posts:

by Fronetics | Aug 15, 2018 | Blog, Customer Service, Data Security, Data/Analytics, Logistics, Strategy, Supply Chain

Data breaches are all over the news lately, but data analytics may be the key to tighter security — and better customer service.

A growing number of high-profile organizations have been in the news recently for data breaches that put customers at risk, and the trend shows no signs of stopping. Collecting data about customers allows organizations the advantage of personalizing their services, but safeguarding that data comes with major security concerns.

[bctt tweet=”Collecting data about customers allows organizations the advantage of personalizing their services, but safeguarding that data comes with major security concerns.” username=”Fronetics”]

Data analytics, or the way organizations process the information they collect to learn about their customers, is becoming increasingly effective at de-anonymizing large amounts of data and tying it back to specific individuals. While personalized data is a goldmine in terms of marketing and services, it’s also exactly what cyber-criminals target.

But information expert Sam Ransbotham, in the MIT Sloan Management Review, says that de-anonymizing people through data analytics coud be a powerful security tool itself, and can even improve customer service along with way.

How data analytics plays into security

Ransbotham points out that authenticating identity is one of the most important parts of keeping data secure. Whether online or over the telephone, authenticating your identity usually means answering a string of questions first to identify your account and then to affirm that you are who you say you are.

Data analytics, however, offer a better way of authenticating identity. A number of companies in the banking sector have already begun to use speech processing to identify a caller’s voice based on recordings of previous telephone calls. These “voiceprints” can confirm identity almost instantly and reduce the chance of someone stealing a personal identification number (PIN).

Using an automated system of voice-data analysis gives banks the added benefit of being able to adjust their security protocols for all customer service interactions at once. This allows for faster responses to updated assessments of security threats, rather than having to re-train customer service representatives.

Customer service advantages

Instead of making callers identify themselves by answering “security challenge questions,” data analytics allows the security process to take place behind the scenes. Customers experience a more streamlined calling experience that immediately addresses their needs. They save time and are spared the hassle of answering questions to identify themselves.

Security challenge questions are, Ransbotham says, “adversarial by design. … This authentication process must begin with the assumption that the caller is a malefactor impersonating the real customer.” By performing the authentication process behind the scenes, voiceprints help re-define the customer service experience as helpful instead of combative.

Organizations, in turn, can save time on employee training. They can focus on training employees for service rather than security.

Data analytics does not have to involve a trade-off between security and service. Techniques like collecting and analyzing voice data can actually start providing solutions to some of the security concerns that data collection raised in the first place.

As Ransbotham suggests, data analytics has the potential for further applications. Voice analysis can detect speech patterns that indicate if someone is being coerced or suffering from impairment, which could be adapted for security and service purposes, too.

Related posts:

by Elizabeth Hines | Jul 24, 2018 | Blog, Current Events, Data/Analytics, Internet of Things, Logistics, Manufacturing & Distribution, Supply Chain

Automation in manufacturing can help create more, better paying jobs. But two leading economists have examined real-world data and concluded that the robots may be winning after all. Is it true?

Last year I wrote about artificial intelligence (AI) and the potential loss of American jobs. At the time, I thought; “Yes, people will lose jobs — that is inevitable. Automation, however, will create many more.”

Automation would create leaner, more efficient operations. Efficiency facilitates new market opportunities and business growth, which in turn would allow for expansion and job creation.

It felt like a good argument! And I wasn’t alone. If one looks at media coverage from last year, one can find plenty of references to “beating the robots.”

There was a palpable feeling, an energizing hope, that automation would, in fact, ultimately create more, better paying jobs. And these new jobs wouldn’t be the low-skill positions of their pre-automation predecessors, but rather higher-paying opportunities operating new technology and supervising automated processes.

In a paper last year, two of the most respected researchers on the subject said it was likely that increased automation would create new, better jobs, so employment and wages would eventually return to their previous levels.

It all seemed positive.

This year’s news

But wait. The same researchers — Daron Acemoglu of M.I.T. and Pascual Restrepo of Boston University — published an updated study that has gained a tremendous amount of attention. It was covered in-depth by the New York Times, with the title: Evidence That Robots are Winning the Race for American Jobs.

Sadly, their study appeared to be the first “to quantify large, direct, negative effects of robots.”

In referencing the difference in prognosis from last year to this year, the NYT article noted that the older paper was “a conceptual exercise” and the new study “uses real-world data — and suggests a more pessimistic future.”

I thought, I’m going to have to write a new article. It was tentatively titled, “I Take It Back: The Data Says the Robots May Be Winning.”

But as I sat down to write, something just didn’t add up. How did all this jive with the latest employment news? Only days ago, unemployment rates hit 3.9%, a rare low, mimicking rates we haven’t seen since 2000.

Taking in the whole picture

As I looked further into the study, I found that it covered 1990-2007, a lengthy but rather unique time in our economic history. The years from 1990 to 2007 saw a dotcom boom and burst. (Just for reference, unemployment rates rose sharply in 2009 and 2010, but have been on a steady decline since then.)

The robot vs. man study said that robots were to blame for up to 670,000 lost manufacturing jobs between 1990 and 2007. I’m not arguing with the study.

But they then go on to conclude the following: The numbers will rise because industrial robots are expected to quadruple. And from where I sit in 2018, I simply don’t see the facts to support that assumption.

Let’s look at manufacturing specifically. Are machines and automation blowing up the manufacturing sector? Well, yes and no.

Certainly manufacturing jobs have had a sharp decline over the last 20 years; that’s undeniable.

But since 2000, their percentage of the overall job market has held generally stable between 8 and 9%. And current employment statistics for 2018 show increases in the manufacturing sector.

Now, I’m not suggesting manufacturing jobs are “roaring back” by any stretch. But a positive trend line is … well … positive. The prognosis of a “pessimistic future” just doesn’t seem widely supported yet by the facts. Time, as always, will tell.

Of course, economists warn that employment rates aren’t the whole picture. While they may mimic that of 2000, they warn that the economy isn’t the same and that it is concerning that wages have been slow to rise even though unemployment has fallen.

From what I see now, however, I still feel optimistic that AI and automation will create leaner, more efficient operations that will, in turn, create new (even if different) jobs. To me, it still looks like the ones winning from the increasing technological advances in the manufacturing industry are, in fact, we humans.

This post originally appeared on EBN Online.

Related posts:

by Jennifer Hart Yim | Jun 5, 2018 | Blog, Content Marketing, Data/Analytics, Internet of Things, Logistics, Manufacturing & Distribution, Marketing, Strategy, Supply Chain

The Internet of Things is revolutionizing manufacturing and supply chain. Is your organization prepared?

This article is part of a series of articles written by MBA students and graduates from the University of New Hampshire Peter T. Paul College of Business and Economics.

“If you think that the internet has changed your life, think again. The Internet of Things (IoT) is about to change it all over again!”

This famous quote from co-founder of Aria Systems, Brendan O’Brien, sums up the significant role that the Internet of Things is playing now, and also its unlimited potential in the near future. The technology can be defined as the networked connection of physical objects.

[bctt tweet=”More than 1.2 trillion items on earth now have the potential to join the IoT network, but less than one percent of them are connected to the internet.” username=”Fronetics”]

Since 2014, Internet of Things is no longer a new term for most companies. However, this is just the beginning of the IoT revolution. More than 1.2 trillion items on earth now have the potential to join the IoT network, but less than one percent of them are connected to the internet.

And if we look at estimated worldwide spending on IoT through 2020, manufacturing, logistics and utilities are the industries that will spend the most money on this technology. This is partially due to their reliance on supply chain management. In addition, their supply chain networks are usually much more complex then companies from other industries.

The real value of Internet of Things is the data captured during the process, instead of the devices themselves. Nowadays customers are expecting higher quality products delivered in the shortest amount of time. That trend requires companies to have a more efficient supply chain in order to fulfill the demand. Brand matters less as it did a decade ago.

How to move products from the factory to consumers’ hands more efficiently becomes the new challenge for all players across all industries. Meanwhile, saving cost, adding asset velocity through enhanced transparency, as well as visibility are also the potential benefits by embracing the Internet of Things.

There are a number of IoT practices in supply chain:

Operational efficiency

Warehouses always play a vital role in a supply chain. It is also an area where IoT technology shows its magic by providing competitive advantages through data acquired from sensor networks. And generally, it can be improved from four aspects:

- Manufacturing maintenance – Sensors and robots linked to the internet increase up-times, reduce operational costs, and improve overall service quality. By visualizing and collecting data — such as temperature and equipment malfunction — managers are able to see and control operations on the floor in a real-time manner. Data collected in the IoT process can also be used in setting alerts for predictive maintenance. It works like HP Instant Ink, which will automatically order new ink when you the printer is about to run out of the old one.

- Inventory forecasting – As Vice President of IT at DHL Supply Chain Javier Esplugas said: managers no longer have to wait for weeks or months to get a report to have an understanding what happened during the last quarter. Instead, managers can make decisions on things that are happening now. Even companies using a 3PL can closely monitor the distribution centers and warehouses so that they can avoid prolonged cycle times and receive warnings in advance.

- Asset tracking – In a warehouse, scales and visual sensors can alert workers about fulfillment needs. The IoT also reduces human error for inbound and outbound records, requiring less human capital for one warehouse.

- Freight transportation – Logistics also holds a great potential for IoT networks. Today, sensors can track and monitor a container in a freighter in the middle of the sea or on a cargo flight. In the future, IoT will also be used to provide a more secure freight transportation environment. In 2016, around $3.7 million worth of consumable goods was stolen in cargo thefts in the U.S. The number of incidents reported in 2016 was 692. Through IoT technology, owners will have access to real-time information on the movement of goods.

Real-world examples

We’ve already seen leading car manufacturer BMW using IoT to improve its product lines efficiency. That is the most basic level of optimization within a warehouse.

A more thorough example would come from DHL. This global company actively involves IoT in different stages of its logistics process.

The journey of a package at DHL starts at the time it’s received by a carrier. By scanning the bar code or QR code on the package, it is formally recorded in the company’s system.

When the package arrives at the warehouse, basic information such as height, weight, and goods type will be collected as it enters the gate, providing accurate inventory control for workers. Sensors in the facility will be constantly monitoring the condition, as well as location of the items, giving workers a visual graph on the computer. When the package leaves the warehouse or sorting center, sensors built in the gate will collect information again for outbound items. Cameras attached to the gateways could also be used for damage detection.

They call the warehouse with all those systems the Smart Warehouse. And now they are testing the solution in multiple locations.

Due to the fact that DHL has been focusing on global logistics, its activities always include freight transportation. To reduce the inventory delays as well as the cost of stolen goods, DHL expects to set up location and condition monitoring through IoT. Ultimately, transport visibility and security functions will be enhanced.

What’s more, DHL’s Supply Chain segment is developing a software that gives clients a way to manage global supply chain risk by providing alternatives. The tool can find other optimized solutions by leveraging data collected from connected objectives.

Last-mile delivery

It makes a lot of sense to introduce IoT to warehouse management or freight transportation. However, for last-mile delivery, it can be a very different story. This final part is highly dependent on labor.

Carriers use data collected from vehicles for road condition in order to optimize the route. Before delivery, they would send notification to the end-customer, who has the choice to either accept the scheduled delivery time or re-schedule the delivery.

The future

By the year of 2020, the number of devices connected to the IoT will be over 50 billion. But that’s still just 3 percent of the number of all things on earth.

JDA’s Intelligent Manufacturing Survey discovered that 57 percent of manufacturers were going to incorporate IoT into their digital supply chain strategy. However, according to an Accenture report, up until the beginning of 2017, 88 percent of manufacturing executives were not prepared to adopt the technology. This is going to benefit companies that are willing to be the first movers and create barriers for the rest to catch up.

So, is your company ready for the digital revolution?

About the author

Xiaoxue Liu, originally from China, is a current MBA student at University of New Hampshire, with a huge interest in supply chain digitalization.

Related posts:

by Elizabeth Hines | May 29, 2018 | Blog, Content Marketing, Current Events, Data Security, Data/Analytics, Manufacturing & Distribution, Marketing, Strategy, Supply Chain

While information-heavy companies employ entire teams dedicated to cyberattacks, American factories have quietly been growing more and more susceptible.

It’s been eight years since the widely publicized Stuxnet virus was released to wreak havoc on its unsuspecting victims. Are we in a better place now to deal with a highly sophisticated next-generation Stuxnet-style attack?

[bctt tweet=”Information heavy companies have entire teams dedicated to cyber defense, while American factories have been left more and more susceptible.” username=”Fronetics”]

Most experts say no. In fact, studies suggest that manufacturers, in particular, are increasingly vulnerable to cyberattacks. While information-heavy companies have grown to employ entire teams dedicated cyber defense, American factories have quietly been growing more and more susceptible.

Time to Pay Attention

Ransomware attacks, in which hackers use malware to encrypt data, systems, or networks until a ransom is paid, are alarmingly common. According to a recent report from Radware, 42% of global companies have dealt with this kind of attack. That number has been steadily rising. The number of companies reporting financially motivated attacks has doubled in the last two years.

Manufacturers — if you haven’t been paying attention yet, it’s time. This summer, about half of the organizations targeted by the sweeping Petya ransomware cyberattack were manufacturers. The recent WannaCry virus actually forced a Honda plant in Japan to halt production.

And there’s a bit more: The Wall Street Journal recently reported on what they call a new type of cyberattack that targets factory safety systems. Hackers who attacked a petrochemical plant in Saudi Arabia last year specifically focused on a safety shut-off system.

Is the WSJ right? Is this a new trend? Will hackers begin targeting control-system computers that manage American factory floors, chemical plants, and utilities on a more regular basis? Maybe.

There are plenty of theories that even the most crippling ransomware attacks like Petya and WannaCry are, at their core, motivated by something other than money, namely sheer pleasure in chaos and disruption. The potential damage to factory production and safety systems is growing. Now is the time to wake up and pay attention.

Factories Growing More Susceptible

Factories and manufacturers are at a heightened risk for a few coinciding reasons.

The complexity of our supply chains is a liability. With parts and materials from diverse and sometimes changing sources, as well as networks that can span all phases of production, our supply chains are large and constantly adapting and, because of this, extremely vulnerable.

The intensity of the manufacturing schedule raises a second issue. Many manufacturing facilities run around the clock, and halting factory production for testing is often cumbersome and costly.

The third reason is, of course, the byproduct of a manufacturing sector that has become steadily more data-driven and dependent on information technology. As manufacturing has steadily merged with technology to create the Industrial Internet of Things, we too have unknowingly created a space in which hackers see the potential for massive amounts of under-protected data, equipment, networks, and intellectual property.

How Can We Prepare

We’ve all heard the mantra, “The first step to solving any problem is admitting you have one.” A core concern has been the manufacturing sector’s inability or unwillingness to face this growing threat.

A report summary issued through a joint venture between MForesight and the Computing Community Consortium warned, “There’s a widespread failure to reckon with the risks.” The report recognizes that solving the issue will be long-term and complicated, but offers a few suggestions, including wide-reaching efforts to increase awareness, collaboration with trusted third-party partners, and cybersecurity research and development.

In the shorter term, maybe this can help. Last year the National Institute of Standards and Technology (NIST) released a Cybersecurity Framework Manufacturing Profile that provides a roadmap to managing cybersecurity and reducing risk to your manufacturing systems.

But I think Sridhar Kota, professor of engineering at the University of Michigan, hit the nail on the head in his article entitled A Plan for Defending U.S. Manufacturers from Cyberattacks, when he wrote: “Cybersecurity needs to become a deeply ingrained part of every manufacturing company’s culture — embedded in management decisions, workforce training, and investment calculations.”

The risks to manufacturers are growing from all-too-common ransomware attacks to sophisticated Stuxnet-style assaults targeting our safety systems. Its’s time that we in the manufacturing sector think of cybersecurity, and cyber defense, in absolutely every decision we make. To do otherwise is reckless.

Related posts:

by Fronetics | May 17, 2018 | Blog, Content Marketing, Data/Analytics, Logistics, Marketing, Social Media, Supply Chain

These metrics to benchmark marketing performance will give you insight into how your brand stacks up against your competition.

A few months ago, the winter Olympics were in full swing, and Mikayla Shiffrin became the youngest slalom champion in Olympic alpine skiing history. Shiffrin achieved this incredible record, not only working to beat her best personal performance, but also that of her biggest competitors. After all, you don’t become a two-time Olympic gold medalist without the knowledge — and drive — to beat out the world’s best athletes.

You have to know how your competitors are performing to be the very best at what you do. That goes for Olympic athletes and supply chain companies alike.

We call this benchmarking performance. For we marketers, it’s important, albeit difficult, to find metrics to benchmark marketing performance. We tend to turn inward to focus on key performance indicators (KPIs), like website traffic, social engagement and conversion rates. But it’s time to start looking outward, as well.

[bctt tweet=”Competitive benchmarking gives brands the ability to benchmark their marketing performance against that of their competitors, giving you the knowledge and drive you need to improve your performance and chance of success.” username=”Fronetics”]

Competitive benchmarking gives brands the ability to compare themselves against a number of competitors using a set collection of metrics. These metrics allow you to benchmark marketing performance against that of your competitors. This will give you the knowledge and drive you need to improve your performance and chance of success.

Here are four metrics to benchmark marketing performance against your competitors.

4 metrics to benchmark marketing performance against your competitors

1. Content

Benchmarking your content allows you to compare the differences and similarities between you and your competitors’ types and relevancy of content. Are they focusing on video content or blog posts? Are they creating infographics? How often are they posting content?

2. Social activity

Knowing what social media platforms your competitors are using is critical in today’s digital marketing world. Are they having success on a specific platform? Are you using the same platforms? And how often are they posting on social media? How do you compare? Knowing when and where to post on social media can help get you in front of your target audience.

3. Social engagement

You’re posting and tweeting, but are audiences interacting with your content? Benchmarking your social engagement against your competitors lets you see if and how audiences are interacting with your posts and videos. How many likes and shares are you receiving? And how many are you competitors?

4. Keywords and topics

We talk a lot about the importance of keywords and topics. After all, that’s how audiences are searching for — and finding! — your brand and your competitors. Using online tools like SERPS, you can easily determine how you and your competitors rank for specific keywords and topics.

Analyze and adjust

Use these metrics to benchmark marketing performance. Once you have collected data, you can start analyzing your results. How does your marketing strategy stack up against your competitors and industry leaders?

Benchmarking allows you to see strategic opportunities — what you’re doing well and what you need to improve. You’ll gain valuable insight into what your competitors are doing better than you. Use this knowledge to improve your strategy. After all, action is key!

Which metrics to benchmark marketing performance do you use?

Related posts: