by Jennifer Hart Yim | Oct 24, 2016 | Blog, Strategy, Supply Chain, Talent

Millennials have a reputation for being lazy and feeling entitled — but what if we got it all wrong?

This guest post comes to us from Argentus Supply Chain Recruiting, a boutique recruitment firm specializing in Supply Chain Management and Procurement.

For the past few years, there’s been a glut of articles about the millennial generation in the workforce. These articles originally focused on how millennials’ perceived laziness and entitlement kept them from securing long-term employment. Coincidentally (or maybe not) these articles first started popping up around 2009-2010, when the great recession made for the toughest jobs climate in decades, especially for young people trying to find their first good jobs out of university — a difficult task for most grads even in a boom economy. Over time (as the economy improved and millennials’ ranks in the workforce began to swell), these millennial-focused articles shifted to discussions of what makes millennials “difficult” to work with. There are a few negative stereotypes that tended to come out of this analysis:

- Millennials ask for raises and promotions constantly.

- Millennials hop around from job to job with little loyalty to their employers.

- Millennials always want to take more vacation time than their superiors.

Of course these stereotypes (like most stereotypes) don’t actually hold up to scrutiny. And in the past couple years it seems as if the business press has finally caught on to the fact that millennials are fitting in and thriving in working culture. Now, companies recognize that this generation offers unique advantages to employers. Millennial-focused analysis has shifted to talking about millennials’ good qualities, including being creative, highly proficient with technology, and excellent multi-taskers.

What millennials aren’t doing

What it comes down to is that companies are now fighting over millennial talent. They’re trying to do all they can to get the star performers to the table. On this topic, we read an interesting piece in the Toronto Star recently — just the latest in the long history of millennial thinkpieces — that bats down one of the nastiest stereotypes about millennial workers. It discusses how new research shows that millennials actually take less vacation than other employees, and tries to tease out the implications of how a seemingly-more “casual” working environment can lead to a chained-to-your-desk working culture.

Interesting stuff.

The article, titled “Millennials Can’t Afford to Keep Skipping Vacation,” discusses the phenomenon of millennial “work martyrs” — people who are afraid to take time off, even if that time off is paid vacation mandated by employment contracts. It cites research from the non-profit U.S. Travel Association that millennials take much, much less time off than stereotypes would dictate. (We should mention that, over the past 15 years, the use of paid vacation days has fallen off a cliff among a lot of different age groups). At Argentus, we try to stay abreast of whatever’s happening in the world of work, so it’s interesting to us think through issues like this.

So what are the implications of this trend?

The article echoes a lot of anxieties about 21st-century white-collar working culture more generally: that in our hyper-connected world, employees are expected to be always working, even when they’re not in the office. Companies reward people based on time commitment rather than productivity. Vacation time might be generously apportioned, or even unlimited, but workers don’t necessarily feel like they can take vacation. The Star article cites an interesting case: in 2015, Kickstarter began offering unlimited paid vacation, but the result was that actual time off taken went down. It appears that workers, especially millennials who are often working more junior, more precarious jobs, won’t take time off unless you tell them to.

Whether this plays out in every company, anxieties about these changes in the workplace are real: They illustrate the importance of work/life balance, which, despite being a buzzword, is also a real concept that pays dividends for employers. Employees who take vacations are not only happier, they’re more productive.

The solution? Maybe companies should start enforcing paid time off instead of rewarding workers who adopt a “work martyr” mentality.

Related posts:

by Jennifer Hart Yim | Sep 27, 2016 | Blog, Strategy, Supply Chain, Talent

The supply chain talent deficit is real — but what about the experienced people who can’t find a job?

This guest post comes to us from Argentus Supply Chain Recruiting, a boutique recruitment firm specializing in Supply Chain Management and Procurement.

It’s no secret that we write a lot about the Supply Chain talent deficit — the growing industry consensus about a looming shortage of talent needed to fill Supply Chain, Procurement, and Logistics jobs as those roles grow in prominence and the baby boomers retire. It’s an important issue to the field that we recruit in, and we’re interested to see how companies, educational institutions and other industry players respond as it plays out. But today we wanted to comment on an interesting side note of the whole issue:

Every time we write about the Supply Chain talent deficit, on the Argentus blog or elsewhere, we see comments from experienced professionals in the field who aren’t able to find work. We’re always sure to say that the Supply Chain talent deficit is a big-picture trend, and doesn’t mean that everyone in the field is going to be able to get a job easily. But it’s interesting that we hear from quite a few people who are having difficulty finding work, despite the fact that companies are having more difficulty hiring in the field than perhaps ever before.

A comment by 3PL executive Valerie Kucherenko on one of our recent LinkedIn Publisher posts pointed out this disconnect, and got us thinking. First of all, here’s the relevant part of the comment:

“Frankly speaking there are so many articles, including the ones by Argentus Supply Chain Recruiting, indicating a shortage of qualified candidates in the Supply Chain field that I am torn between this feeling of high demand for Supply Chain professionals and the fact that many experienced ones can not find a job. Where is the confusion coming from?”

Let’s try to answer this question.

If there is a Supply Chain talent deficit, why are so many people in the field having trouble finding work?

First of all, the talent deficit in Supply Chain isn’t just buzz. Experts throughout the industry are talking about it, but it’s also something we’re hearing about daily from our clients looking to hire in the field, and from executives we speak to. We’re on the front lines of the talent war in this industry, and we can observe it directly. So it’s not that the difficulty of hiring in Supply Chain is made up.

Of course, the trouble that certain experienced people are having looking for work isn’t made up either. So we started thinking about big-picture reasons for this disconnect, based on our experience as people who have been recruiting in Supply Chain for over a decade. Here they are:

A certain amount of churn in employment is inevitable, and even a productive fact of the economy. There’s a reason why under economists’ definitions of “full employment,” there’s still about 5% of the workforce that’s unemployed. Structural factors such as geographic shifts and technological change mean that there will always be a certain number of unemployed people, independent of other factors like economic downturns, etc. This means that no matter the demand for Supply Chain talent, there will always be a certain number of people in between jobs — people who haven’t yet found work because it takes some time to get the right opportunity in front of the right people.

But that doesn’t tell the whole story. The other thing that helps explain this disconnect is the fact that the deficit of talent isn’t, strictly speaking, a numbers game. What matters isn’t necessarily the raw number of experienced candidates vs. positions (e.g. 10,000 candidates and 50,000 positions) so much as the kind of experience companies are looking for. This is one of the things that comes up over and over again in our conversations with executives.

Supply Chain’s role in companies is expanding. Instead of just being about putting product in the right place at the right time, Supply Chain now uses data, innovation, and supplier relationships to provide companies with a strategic edge. It interfaces with sales to plan and predict demand, etc. And while the function’s scope is increasing, companies are becoming more specific in their experience requirements. For example, more companies are looking for specific category experience (like Real Estate or IT) in Procurement. It’s possible that certain experienced professionals don’t have the right experience in the most high-demand niches (such as Demand Planning, S&OP), making it harder for them to find work than if “Supply Chain” was a more monolithic category. The nature of the experience required is changing — for example companies requiring specific software experience — and much of the deficit of talent exists on this cutting edge of skills requirements, rather than for more general, classic Supply Chain roles.

The solution to this issue? We think it’s two-fold: companies need to be more open-minded in their hiring, recognizing that strong business acumen can be as important to Supply Chain success as niche experience. And on the other side, candidates need to constantly work to adapt and diversify their skillsets, expanding their knowledge to follow the niches that are in highest demand among companies.

Hopefully that sheds some light on why it can be tough for certain Supply Chain professionals to find work even though there’s a deficit of Supply Chain talent more broadly. As F. Scott Fitzgerald once said, “the test of a first-rate intelligence is the ability to hold two opposed ideas in the mind at the same time, and still retain the ability to function.”

Which is true (in our experience), but we get that it doesn’t make it any easier for those Supply Chain workers who are having trouble finding that next role! Feel free to reach out to us for help.

Related posts:

by Jennifer Hart Yim | Aug 24, 2016 | Blog, Manufacturing & Distribution, Strategy, Supply Chain, Talent

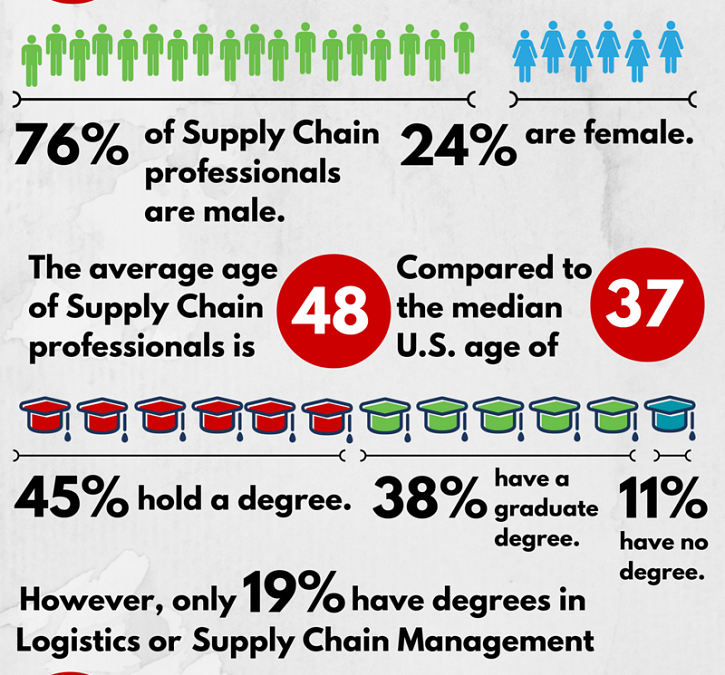

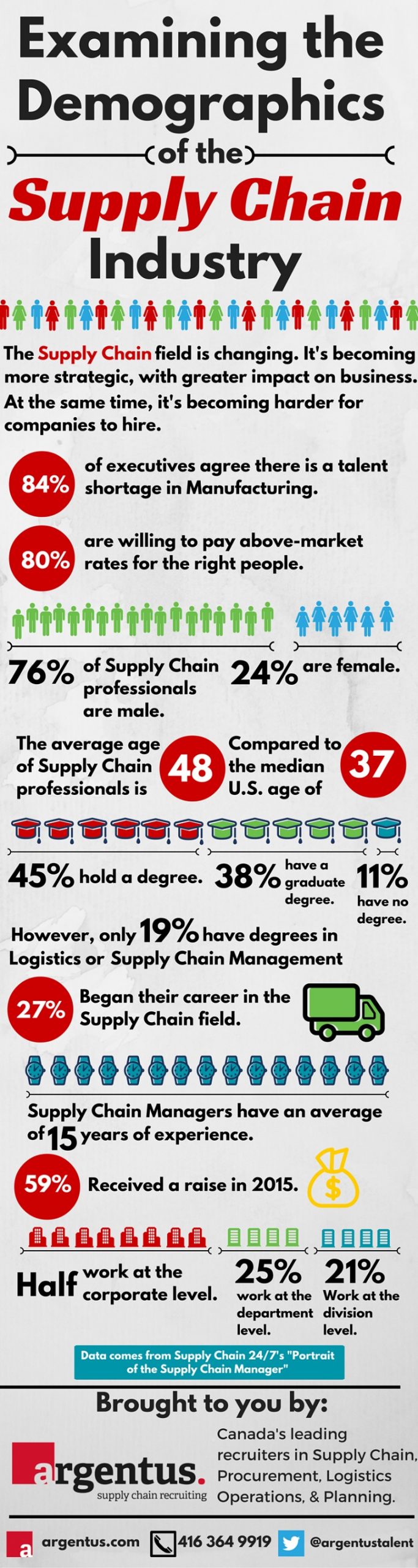

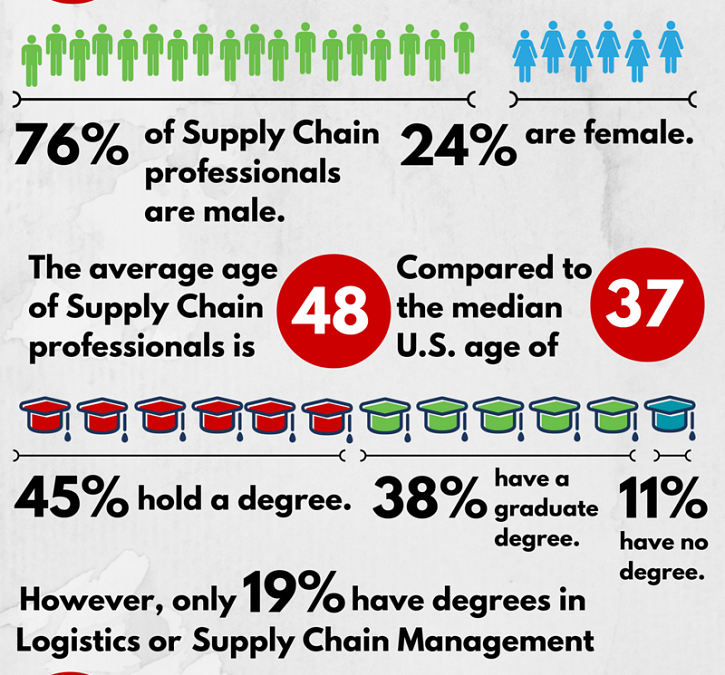

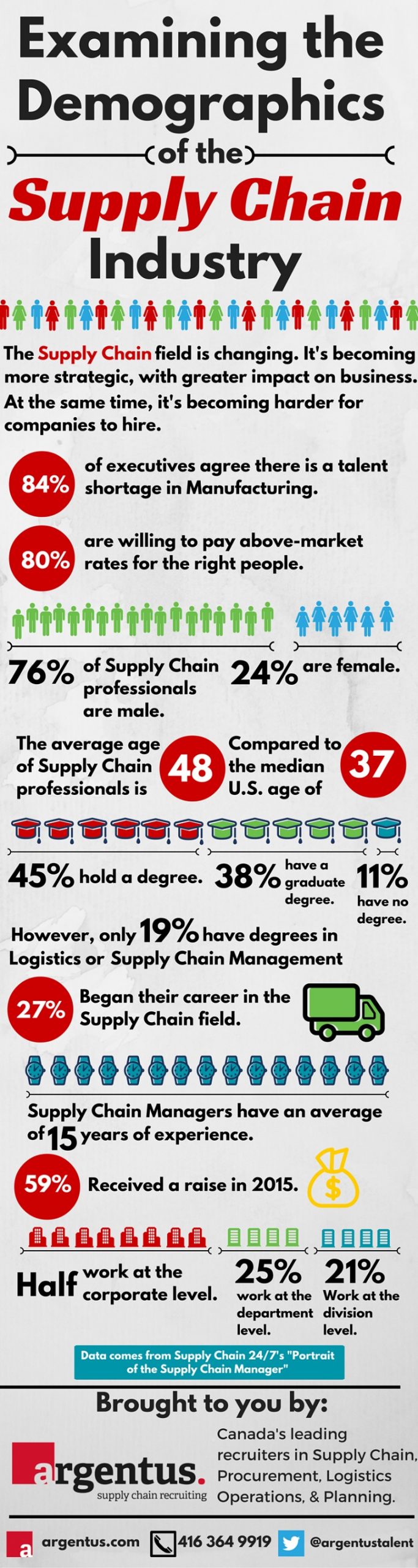

The Supply Chain industry is changing, while it’s becoming harder for companies to hire at the same time. These supply chain demographics provide a picture of the industry today.

This guest post comes to us from Argentus Supply Chain Recruiting, a boutique recruitment firm specializing in Supply Chain Management and Procurement.

Everyone knows the Supply Chain field is changing. Recently, one of the best Supply Chain publications out of the U.S., Supply Chain 24/7, released a report that examines the demographic trends underlying the industry. The report, titled “A Portrait of the Supply Chain Manager,” used research survey data from Peerless Research Group and APICS to present a picture of the typical individual working in Supply Chain. The survey asked a number of Supply Chain and talent-related questions, such as:

- What percentage of Supply Chain professionals received a raise last year?

- What percentage of Supply Chain managers hold a degree?

- What percentage of companies are willing to pay above-market compensation for the right people?

And more. These issues are sure to be of interest, whether you’re looking to hire in Supply Chain or just to get a holistic picture of the field. So we put together this spiffy infographic that highlights the answers to these questions and some other interesting datapoints from the report. Check out the infographic below!

We hope you found the supply chain demographics infographic informative, and we encourage you to dig into the full report for even more insights about where Supply Chain professionals stand and where the field is going. And (as always) stay tuned for more info and perspective about Supply Chain and talent from Argentus in the coming days and weeks!

Related posts:

by Jennifer Hart Yim | Mar 23, 2016 | Blog, Content Marketing, Marketing

Editor’s note: This is a guest post by Jennifer Cortez, Director, Marketing Communications, Transplace. Transplace is a North American non-asset-based provider offering manufacturers, retailers, chemical and consumer packaged goods companies the optimal blend of logistics technology and transportation management services.

Content has become a critical component of the modern marketing mix, but companies have to walk a fine line when it comes to the information that is being pushed out to the market. Too little and your audience will become bored and uninterested, and unfortunately, may look elsewhere for information (i.e., your competition). Too much and your audience may not know where to start (especially if it’s poorly organized). And if churning out too much content leads to a decline in quality, your audience may be left with dull, unremarkable content that, most importantly, is lacking in value to the industry.

When we’re creating content here at Transplace, (and I encourage others to keep this in mind) we ask ourselves this question: “Why should my customer care?” If you can’t answer that question, then it’s time to rethink your strategy. If you’re creating content just for the sake of it or because it’s something you know you need to do, you are most likely headed down the wrong path.

If you’re new to content marketing, first figure out what you want your content to solve before getting started. Do you want to increase brand awareness or drive more traffic to your website? Or maybe you’re focused on converting more leads into customers? Whatever it might be, each of your marketing goals will influence your content marketing strategy and therefore help you understand the audience you’re writing for, what channels you’ll share the content on, and how you’ll communicate key messages.

3 Key Content Considerations

Content is an extremely important part of our marketing and communications strategy and helps us continue to grow our brand awareness and thought leadership in the logistics and transportation industry. Our main objectives focus on three things: creating quality content that is relevant and helpful to the people in our industry, easy to understand and comes in a variety of formats. Let’s dig into these three areas a little further.

1. Producing helpful content

It’s easy to produce self-serving content such as sales pitches or a 1-pager on ‘Why you should pick our company,’ but let’s face it – tooting your own horn isn’t going to do much in terms of moving the needle closer to any of those marketing goals we mentioned previously. And most likely, these types of content pieces aren’t going to be searched for or probably even read by your target audience. One of two things occurs with standard sales slicks these days – they get deleted or physically thrown in the trash.

What is going to be helpful is producing content that becomes a useful resource for people in their day-to-day job. We want to keep them updated on trends, but it’s also important for us to keep in mind what we should be talking about that others aren’t. What are we foreseeing based on our unique position in the market that we can relay through content so our network is more prepared? If we can do a better job of talking to the buyer and figuring out what they want to hear about, then our content is only going to prove that much more valuable.

2. Content readability is key

Sometimes the topics in our industry can be complicated and it’s our job as the subject matter experts to make these complex topics understandable. It’s also important to not talk above your audience. You’ve probably heard of the Flesch readability score before, which indicates how difficult a reading passage is to understand. Content readability is powerful and your content marketing, website and SEO are dependent on it. Search engines like Bing and Google prefer readable content so when it comes to writing – keep it readable, compelling and easy to understand.

3. Content variety keeps things fresh

What I mean by this is have some fun with the types of content being created or reused for additional purposes. Did you conduct a survey and now have some great data points to share? Instead of housing this valuable information in a long article or whitepaper, you could highlight the research in an animated infographic. At Transplace, we’ve had great success at creating a variety of content pieces – from videos and podcasts to our TIP List and Q&As – we change up the types of content we’re creating to keep our audience coming back for more. You can also leverage existing content to create “new” types of thought leadership to push out. Nowadays there are several different ways people prefer to digest news and information, and we don’t have a crystal ball to show us these preferences, so you do typically need content in multiple forms in several different places whether that be print, online or social media. The permutations of content creation are endless if you tap into your creativity and keep things fresh!

Today, there is so much content out there that it’s become all too important for companies to truly create value in the information that they’re pushing out to the market. And when it comes to valuable content, keeping these three tips in mind will have you well on your way to creating content that is helpful to your audience and keeps them coming back for more!

by Jennifer Hart Yim | Mar 17, 2016 | Blog, Leadership, Marketing, Social Media, Strategy, Supply Chain

Source: Library of Congress

This is a guest post written by Tania Seary, founder of Procurious. Procurious, the world’s first online social network for supply chain and procurement professionals, has acquired more than 12,000 members in less than two years.

I’m trying to use a baseball analogy here, but appreciate that my headline does have other connotations!

Another analogy might be to say that we’re “getting the flywheel spinning” here at Procurious – the world’s first online network for supply chain and procurement professionals.

Now, for those of you who aren’t familiar with the flywheel analogy, it is a metaphor created by author Jim Collins in his famous business manifesto, “From Good to Great,” to explain one of the key drivers for creating long-term success in business.

A flywheel is a heavy disk on an axle used to smooth a machine’s operation to generate momentum and maintain a constant rotational speed.

It takes much effort and persistence to get the metaphorical flywheel to move, but consistent energy in one direction over time helps build momentum and ultimately leads to a breakthrough. In the case of Procurious, as with Collins’ companies, there has been no specific event, decision, action, or lucky moment that single-handedly helped us to successfully break through the “beta” stage, to where we are today.

Over the last two years, we have remained committed to building something truly special for the procurement profession. Step by step we have stayed focused on our goal of building a very credible and content-rich community for our members.

Now with more than 12,000 members in 135 countries, Procurious has cemented its position as the secret weapon for professionals wanting to be part of the movement toward creating the new face of procurement.

Getting back to our headline analogy with baseball, I wanted to share some of the key decisions we have made along our journey to date to build Procurious.

Agreeing on the MVP

Just to confirm, we are talking about Minimum Viable Product here, not the Most Valuable Player. In the early days of designing this business, everything was up for grabs. Among a long list, we considered building a procurement news aggregator, a pure-play training repository called Procurious TV, and a procurement lifestyle magazine.

What we ended up with was a community platform that included a community feed, member profiles, discussions, eLearning, a worldwide calendar of procurement events, twice-daily blog, and private groups.

The end result was a powerful combination of career advancement, skill development, and professional networking opportunities to help propel today’s procurement professionals forward.

To have open or closed membership?

Once we had agreed on the core features and functionality of Procurious, we had a lot of heated debates over whether we should have an open or closed network. That is, should it be closed exclusively to highly pre-qualified procurement professionals, or open for the whole world to join?

Luckily my team convinced me to keep our network open… and it’s been an important part of our success story to date.

Of course, the major advantage to our members is that on Procurious, they gain access to a wide range of thought leaders and industry experts which then exposes them to diverse opinions on the hot topics in procurement.

Finding our fans

Every club, or community, needs a strong support base. We have been very fortunate to have a number of “early adopters” from around the globe support the building of the Procurious community. And, of course, we now have our “poster child” — Siddarth Sharma — who was surprised to learn he was our 10,000th member. Siddarth is representative of so many of the exciting procurement professionals around the globe — an MBA working for KPMG managing a small team of indirects buyers in India.

Securing our sponsors

Like a baseball club, we needed some big-brand sponsors to keep our operations humming. We have been fortunate to create partnerships with the profession’s leading institutes, associations, analysts, and technology companies. The Hackett Group has supported Procurious from the start, and The Institute for Supply Management (ISM) has joined the team this year. These relationships enrich Procurious in many ways and, most importantly, provide our members with access to world-leading research and resources.

Fielding a winning team

Lisa Malone, Euan Granger, and Jack Slade have been a powerhouse behind building this community, covering all the bases, and getting runs on the board.

Handling the curveballs

The biggest threat to our success is the introduction of a fierce competitor. But we are fortunate that we now have a loyal community that has been built on a substantial foundation of trust and commitment. This will be difficult to shake.

Our next biggest hurdle to success is to overcome the procurement profession’s hesitancy to create social media networks.

Despite the well-publicized benefits, we still meet procurement professionals that tell us “they don’t believe in networking” and don’t accept LinkedIn invitations from people they don’t know. We need to convince the profession of the multiple benefits of using social media, and then provide them with the skills to leverage the opportunity.

One base at a time

Our plan is to continue building Procurious based on our members’ needs, one base at a time.

We will be hosting our Big Ideas conference in London on Thursday, 21 April, for which you can register as a digital delegate on www.bigideassummit.com.

We are also currently beta-testing our new app, which can be downloaded from the Apple App store.

We are asking as many procurement professionals as possible to sign up to the network at www.procurious.com to join this new era and — as we like to say — get involved and get ahead!

Tania is the Founding Chairman of three companies specializing in the development of the procurement profession – The Faculty, The Source and Procurious.

The Faculty is recognized as one of Australia’s leading advisors on procurement development. Established twelve years ago, The Faculty works with leading organizations to transform and elevate the role of procurement, build high performance procurement teams and create professional knowledge networks.

Under Tania’s leadership, The Faculty has instigated a number of “firsts” for the procurement profession in Australia, including the development of a Procurement Executive Program through Melbourne Business School, the establishment of a Procurement Roundtable which includes many of Australia’s leading organizations, creation of an annual Chief Procurement Officer (CPO) Forum and attracting leading global procurement thought leaders to teach in Australia. She also initiated the Corporate Board for Social Procurement, which has created a foundation for leading corporations to dedicate appropriate areas of spend toward social enterprises.

Four years ago, Tania founded The Source, a specialist recruitment firm for the procurement profession. In 2013 she moved to London and founded Procurious, the world’s first online community for procurement professionals to connect, share and learn.

Tania’s fascination and commitment to procurement development started around fifteen years ago in the United States. After finishing her MBA at Pennsylvania State University, Tania became one of Alcoa’s first global commodity managers.

Prior to moving to the USA, Tania’s career was focused on marketing roles within Alcoa and Rowland in Australia, and the Walt Disney Company in the UK. Tania has an MBA and a Bachelor of Business.