by Jennifer Hart Yim | Feb 27, 2017 | Blog, Supply Chain, Talent

Argentus Supply Chain Recruiting answers the question about what supply chain companies are looking for in new hires in terms of education.

This guest post comes to us from Argentus Supply Chain Recruiting, a boutique recruitment firm specializing in Supply Chain Management and Procurement.

This is the first installment of a new Argentus feature where we answer career questions. We’re starting this feature to help put our years of recruitment experience to good use, whether your questions are specific to our recruiting specialty of Procurement and Supply Chain or more general. You can find more questions and answers on our blog.

Drum-roll please for our first question:

Hello,

What value do you see in getting a Master’s Degree in Business/Supply Chain vs. some of the designations out there? (APICS, SCMA, etc.)?

Thanks, Vince C.

Thanks for the question, Vince. First of all, we aren’t experts in the curricula of both of these types of programs. Every university program is different, just as every professional designation is different. So we can’t speak to the specifics of various programs. However, we can speak to what companies are looking for in hiring, and how graduating from these programs builds your personal brand. We talk to lots of people in the field.

The short of it is that both an MBA and a Supply Chain designation such as APICS or SCMA can be a boon to your career, but your mileage may vary. It’s fairly common that a client looking to hire has designations as a requirement. It’s less common that they’ll ask for a particular designation (i.e. SCMA), although it’s certainly happened before. Companies are often looking to see that candidates are invested in their continued career development and education. A designation is a good way to establish that, and to pick up some valuable skills in the process.

It’s worth mentioning at this point that a designation is also often valuable for newcomers to North America who might have overseas Supply Chain Management experience, but haven’t yet secured that all-important first U.S./Canadian role in the field. A designation can be a great way to learn about local Supply Chain practices and increase your initial marketability while searching for that first role. While this option isn’t financially feasible for all newcomers, we’ve heard of candidates using it successfully in the past. A designation can provide networking opportunities, make you more marketable, and boost your income.

So is a designation the right move for your career?

One thing to keep in mind is that roles we get that “require” designations are typically at the sole contributor level — meaning below the “manager” level. Sole contributor roles can pay anywhere from 50k to 130k, so it’s not necessarily a roadblock, but it’s less common that leadership roles require designations. And while many designations offer strategic components to their curricula, we’ve had feedback from certain executives that a lot of the education offered is more transactional in nature — and that can be a limitation. For example, learning how to fill out a purchase order might make you a more immediately employable Procurement clerk at the junior end, but when looking for future leaders, executives want to hire people who have a holistic understanding of business strategy. Why are you filling out that purchase order? What’s the impact on the business? Should we be purchasing from someone else? Can we streamline our purchasing process? Should we be purchasing this at all?

The key to progressing into leadership is an understanding of strategy — so if that’s your goal, assess designations based on their strategic content.

Which brings us to MBAs — the coveted Master’s of Business Administration. It’s becoming more common for hiring managers to require Bachelor’s degrees, but it’s rare that they require an MBA. It’s also pretty new to have Supply Chain as an MBA specialization in the first place, and some people have used them to good effect to boost their careers.

The perception is that an MBA is going to be strategic. That they’re polished. That they have enhanced presentation ability. All of these are leadership qualities, and that’s why MBAs are seen as future leaders, even if the degree isn’t an absolute requirement to advance into business leadership — especially within Supply Chain.

However, there’s also the perception that an MBA isn’t going to be hands-on. From our perspective, an MBA isn’t going to work as a replacement for solid work experience. There’s a reason why people often work for 5-10 years in the field before pursuing an MBA: it’s going to augment your leadership potential, but it’s not going to give you leadership potential if you don’t have a variety of experience beforehand.

MBA programs encourage their students to think ambitiously, but it’s important not to let an MBA “go to your head.” We sometimes hear from recent MBA grads who expect to earn 150k+ on the merits of their degree rather than their experience, and they often find themselves in a 70k job a few years after graduating. If you’re prepared for this possibility, an MBA can be valuable, and it can help make you more marketable as a business leader.

So if you’re looking to slot into a Sole Contributor role, a designation might get you there faster. But if you’re looking to eventually climb into a Director, VP or CPO or CSCO role, an MBA might help you more. But don’t expect immediate dividends.

Again, we hope our advice is helpful! And every case is different, so take it with a grain of salt.

Oh, and send us more questions by visiting our blog and filling out a brief form. It can be Procurement and Supply Chain-specific, or it can be about any career topic.

Related posts:

by Jennifer Hart Yim | Feb 13, 2017 | Blog, Logistics, Strategy, Supply Chain

Supply chains must accept that they cannot equal the power of Amazon’s supply chain without embracing these new trends.

This guest post comes to us from Adam Robinson, marketing manager at Cerasis, a top freight logistics company and truckload freight broker.

Amazon’s supply chain continued push deeper into new and existing markets will define additional trends in the supply chain throughout the coming year. While supply chain entities struggle to stay competitive with the e-commerce giant, more organizations will look for ways to eliminate inefficiencies and boost operations. Fortunately, these five trends may alleviate some of the strains of competition by giving supply chain partners an advantage in the global market.

Top 5 Trends to Know to Compete with Amazon’s Supply Chain

1. Robotics Will Grow More Versatile.

Amazon’s purchase of Kiva Robots changed the landscape of robotics in the supply chain. However, new companies are being created and developed to fill the void. The robotics company Starship released a robot that delivers meals and groceries to people in Euro metro markets. Meanwhile, Lowe’s has created the LoweBot, which boosts customer service, explains Dan Gilmore of Supply Chain Digest.

More companies are turning to robotics to find new ways to bridge the divide between a dwindling number of customer service representatives, including store associates, and maintaining around-the-clock operations. Across the spectrum, robotics will become more versatile and accessible. In other words, robots will gain new movements, capable of picking items from shelves in warehouses and storefronts.

Per IDC Manufacturing Insights, the use of robotics will become more platform based through robot-as-a-service, reducing costs of deployment and maintenance. Furthermore, the speed of operation of robots will increase more than 30 percent by the end of 2017. Clearly, robotics will become more important in 2017 than during any previous year.

2. Technology Will Reshape Procurement Practices.

Better procurement practices translate into better overall sales, but the role of procurement in driving sales’ statistics will change throughout 2017. Today, procurement drives up to 67 percent of sales, explains Johnathan Webb of Forbes magazine, as procurement professionals look for innovative ways to produce effective, superior products.

For example, Johnson & Johnson procurement professionals actively review market trends before making purchases. Upon identifying these trends, a correct forecast of supply demands can be generated. Thus, the role of procurement has become more focused on being physically involved in market news and research, not just signing purchase orders in an office.

3. More Businesses Will Create E-Commerce Platforms.

Amazon’s supply chain empowered the e-commerce market by giving everyone an opportunity to sell their goods online, which has made competing with Amazon difficult at best. Amazon’s supply chain expansion culminated in more companies looking to enter e-commerce without giving shares to Amazon. Companies expanded e-commerce and omnichannel solutions simultaneously as well, reports Steve Banker of Logistics Viewpoints.

For example, Walmart and Kmart redesigned their mobile e-commerce interface for consumers, making shopping and purchasing online easier and integrated with major companies. A simple search for a product on Walmart.com reveals partnered listings with Wayfair and third-party sellers, much like Amazon’s current vendor options. Moreover, customers can make purchases online and have them shipped to the store or their home. At Walmart, customers can even pick up orders without ever getting out of the car now. Ultimately, more businesses will seek out partnerships with bigger companies to stay competitive with Amazon’s bare price points and ease of use.

4. User Preferences Will Enhance Mobile Management Systems.

Traditional warehouse management systems (WMS) lacked integration with other systems. Procurement strategy was not always evident. Accessibility of systems depended on in-house IT departments, and upgrading access terminals could cause extreme delays and problems in operations. However, newer management systems, such as a comprehensive transportation management system (TMS) that integrates warehouse management with transportation management, are starting to offer more accessibility and personalization options.

In other words, accessibility and personalization allow warehouse managers and staff members to define metrics relevant to new products and current operations, test new processes, and effectively manage the flow of goods. Similarly, new mobile options, ranging from Android tablets to compact barcode scanners, will reduce inconsistencies and errors across the supply chain, explains IRMS 360. Paired with the advancements of predictive analytics and the Industrial Internet of Things (IIoT), more data will result in more efficient processes, creating a positive feedback loop throughout an organization.

5. Contingency Planning Will Become a Standard Practice.

Amazon’s supply chain has proven that not planning will result in the failure of small and medium-sized businesses. Furthermore, natural disasters reap $211 billion from the global supply chain annually. Having a larger global footprint is how Amazon’s supply chain has been able to maintain operations in the face of natural or man-made disasters. This is contingency planning.

The IIoT empowers contingency planning by giving supply chain entities real-time data from an endless number of sources, which range from online browsing data to point-of-sale data. Consequently, supply chains can react appropriately and divert resources to maintain operations. But, the key to utilizing this information lies in knowing what to do and how to do it when an event occurs. In other words, more companies will diversify distribution, supplier and storage networks throughout 2017 to prepare for what might happen in the future.

The Big Picture.

Supply chains must accept that they cannot equal the power of Amazon’s supply chain without embracing these new trends. New technologies are great, but chances are Amazon has already implemented them. Rather than falling into despair, you can use these trends to re-evaluate processes and practices in your organization, which will help you stay competitive with Amazon.

The complexities of the global supply chain rely on your willingness to take advantage of new trends and technologies today, as well as tomorrow, so do not squander this opportunity.

Related posts:

by Jennifer Hart Yim | Jan 31, 2017 | Blog, Content Marketing, Marketing, Social Media, Strategy

Rival IQ’s Danica Benson discusses the importance of social benchmarking and offers three steps for getting started.

This guest post comes to us from Danica Benson, marketing communications manager at Rival IQ.

Imagine you’re on a little league baseball team. You’re up to bat. You swing and hit, sending the ball far over the second baseman’s head. You take off to first, see the outfielders running to the fences, fly past second base and onto third. The center fielder overthrows the ball as you sprint toward home, kicking dirt into sky behind you. Everyone is screaming, clapping and shouting! A home run! You feel on top of the world!

No matter which league you play in, be it little league or the MLB, a home run is successful. But, what if the pitcher walked you? In little league nobody claps, screams, or cheers. The next batter comes up, and you feel bummed out. But, not necessarily in the MLB. A walk is a strategic move. You’re on base. It’s only one base hit away from scoring position. A walk has the potential to be a game-changer and is considered a success. How is this so?

The benchmark determining success is different in the MLB than in little league. It’s the same performance in both cases, but a different interpretation of success. The same idea applies when measuring your social media activity — what is considered a successful engagement rate, number of followers, or content in one industry isn’t the same as the next.

Benchmarks require context

Benchmarks are key when interpreting data. Organizations of all kinds — large corporations, small privately owned business, nonprofits, and even sports teams — need to measure their performance to see if they’re efforts are leading to success.

Key performance indicators (KPIs) like Net Promoter Score (NPS) at a company, number of clicks on a social post, or a player’s batting average tells someone a lot about what is happening as a result of their activities. But it tells them nothing in terms of whether their efforts are successful, failing, or where to focus to close up those gaps. Why? Because benchmarks are relative.

3 steps to successful social benchmarking

Establishing benchmarks relative to your top competitors, like audience size and engagement rate, are meaningful because you are comparing to others like you who are fighting for the attention of the same audience. Without context, your metrics are what we call a “so what?” metric. We have 1,500 followers on Facebook… so what? Do we need more? Is that a good amount? These numbers only mean something if you have a benchmark for comparison.

At Rival IQ, measuring digital marketing performance begins with setting competitive benchmarks. To develop an effective social media strategy, you need contextual data. Analytics are great, but not if you don’t have context to compare your data. There are a couple of ways to do this: by comparing your organization’s metrics to itself, or by keeping tabs on your competitors. Using these methods, you can compare apples to apples and see growth in your organization, as well as how well you’re doing compared to your competitors.

Step #1: Know YOUR organization’s internal benchmarks

First and foremost, get to know your numbers. Identify your metrics and compare them to how you did last month (MoM) or last year (YoY). You always want to outperform yourself, so these benchmarks give you a base to start from and allow you to see if your activities are resulting in growth. Benchmarks can help you understand where your performance has been in the past, and help you create realistic expectations for the future.

But, what do you do if you don’t have any historical data to work with because you’re just starting up your analytics? I recommend looking at industry benchmarks, which you can find on websites such as Kissmetrics and MailChimp.

Step #2: Know your competitive benchmarks

Measuring your performance against your competitors gives you business intelligence you can use to make better decisions — especially if you’re struggling to earn social media attention. It’s too easy to think that we can just type, “What’s a good engagement rate for Instagram?” in a Google search to find a benchmark that means anything. What you will find are general figures calculated using everyone who uses the platform, which is great if your target audience is everyone who uses Instagram (not likely).

Go deeper than your industry by building your social benchmarks from scratch. Hand-select your direct competitors and look at metrics, such as:

- Which social channels do they use?

- How does the content differ between channels?

- When and how often are they posting on social media?

- What type of content are they sharing? Are they posting updates, photos, videos, live video, .gifs?

- What do their engagement rates look like?

- How many followers do they have?

Setting your social marketing strategy using your own landscape of competitors will give you a realistic, attainable goal. Accurate, relevant benchmarks are the first step in paving the way toward gaining a competitive advantage.

Step #3: Track, test & tweak

Now that you’ve reviewed your organization’s performance and can measure if it’s trending upward (or not), and you have established your benchmarks relative to your competitors, you track, test and tweak.

Track performance

By tracking your performance over time, you will be able to see if your audience is getting bored with your usual posts and may need to change your tactics. By monitoring your competitors, you can learn what content works well and take advantage of opportunities they may be missing.

Never stop testing

Social media is a great place to test things out, like new ads, campaigns, copy, contests, surveys, images, etc. Secondly, they give you feedback, fast! Find out what your audience likes on social first, then learn from your wins and failures. Take what you learn about your audience on social media and apply it to other marketing activities.

Tweak for optimization

This goes hand-in-hand with testing. Once you’ve tested a few things and have identified what’s working, tweak it and test it again to optimize it. Find the sweet spot. Social media is always changing, so there will always be more work to do.

Just as with all good strategies, you have to continually measure success and adjust based on real-world results. Competitive analytics is a great way to set social media benchmarks by basing them on companies you aspire to beat. If you aren’t beating the competition, it might be time to go back to the drawing board.

Originally from the Portland Metro Area, Danica Benson migrated north to work as a marketer in the startup arena. As the marketing communications manager at Rival IQ, she’s bringing her passion to the tech world. Outside of the office, Danica spends her free time on outdoor adventures and exploring the great city of Seattle.

Related posts:

by Jennifer Hart Yim | Jan 26, 2017 | Blog, Strategy, Talent

The “Right to Disconnect” is combating round-the-clock email culture, but can better work/life balance help boost employees’ productivity?

This guest post comes to us from Argentus Supply Chain Recruiting, a boutique recruitment firm specializing in Supply Chain Management and Procurement.

Here’s a new frontier in work-life balance: For the past several years, work-life balance has been one of the biggest topics in employer and HR circles. Companies are recognizing the productivity benefits of flex time, childcare assistance, on-site stress workshops, and other initiatives designed to make employees happier. They’re also using work-life balance to help attract and retain the best candidates. Read any (good) modern job description, and you’ll see lots of language from companies recognizing the importance of having a life outside of work.

But anyone who’s worked at a few different companies knows that every company has a different track record in terms of actually implementing work-life balance initiatives, and not just paying lip-service to them.

The Right to Disconnect

So here’s an interesting solution from abroad: As of January 1, a new law in France affords workers the “Right to Disconnect” from their emails after hours. In France, a country long-associated with the development of rights, companies with more than 50 employees must now negotiate a new protocol with employees to make sure that their work obligations — like email — don’t carry over to after-work hours.

Europe has long been characterized in North America as laissez-faire when it comes to working hours, mandating more weeks of vacation than Canada (where 3 weeks is the standard) and the U.S. (which typically affords a stingy 2 weeks of vacation). There’s always been a stronger cultural attachment to leisure hours in Europe, where 35-hour workweeks are common, so it isn’t surprising that such a law comes from France.

It’s also not surprising that the idea of completely banning after-work emails has been ridiculed in North America, where many employees work long hours, take lunch at their desks, and answer emails around the clock to prove their value. But outlets like Time magazine have reported on how round-the-clock email culture has taken over France as well, which is part of what’s led to these guidelines.

Work/life balance = productivity?

The idea behind a “right to disconnect” is to restore some of the ever-blurrier boundary between work and life brought about by smartphones with email access. But the idea isn’t just to give workers a break — it’s that if you make sure people can turn off their phones when they leave the office, they’ll likely be more effective in the morning. In other words, a stronger boundary between work and life improves not only life, but work as well.

One interesting piece of Time’s reporting is that checking emails after hours isn’t always company mandated. It’s something that we all often know first-hand: In many cases, checking emails after hours is something we often bring upon ourselves — either out of a desire to get ahead, to be seen as busy and highly responsive, or, let’s admit it, out of boredom. But email begets email, and when everyone’s replying on an email chain after hours, suddenly you come into the office and you’re swamped. Time reports on how companies themselves are tackling the issue of after-work emails. Some companies are building time restrictions into their email clients. Others are formally discouraging using “reply all” to limit the number of unnecessary emails. Others are outright telling their employees not to email after hours.

So does the tendency to email around the clock begin with us, or our employers?

It’s a tough question. For our part, our policy as recruiters is that we should be responding to emails after work hours only for highly time-sensitive issues. We recognize the importance of downtime, even if it’s hard to mandate.

But what do you think? It’s unlikely that a law like this would catch on in the U.S., but is our after-hours emailing obsession making workplaces more productive, or is an always-on mentality leading to burnout and distraction?

Related posts:

![The State of Supply Chains: The Supply Chain Has Gone Digital [Infographic]](https://fronetics.com/wp-content/uploads/2024/10/virtual-reality.jpg)

by Jennifer Hart Yim | Jan 23, 2017 | Big Data, Blog, Data/Analytics, Logistics, Strategy, Supply Chain

2016 was the year of the digital supply chain — here’s a look at how things changed.

This guest post comes to us from Adam Robinson, director of marketing for Cerasis, a top freight logistics company and truckload freight broker.

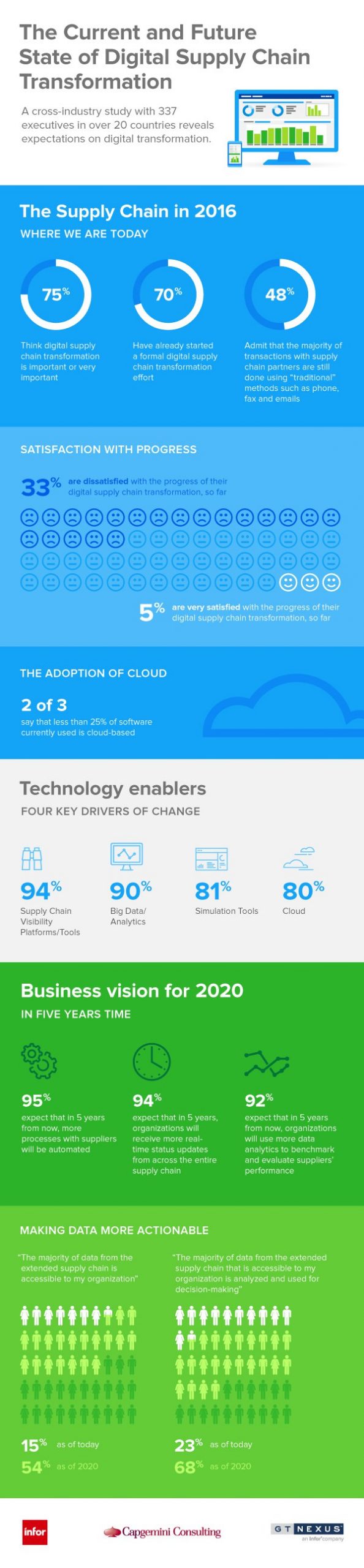

2016 marched onward with a drive to improve the use of digital technology throughout the supply chain. In our first supply chain trends post, we surmised the previous year’s trends would continue. However, this prediction proved to only touch on how important the digital supply chain would become.

Within four months, the digital transformation had already reached most supply chain organizations. Per GT Nexus, 75% of executives surveyed recognized the digital supply chain as an important factor for the next five years. Meanwhile, 70% have also started processes to implement digital supply chain technologies throughout their companies.

Unfortunately, many supply chain entities continue to hope for a better tomorrow. In other words, the digital supply chain transformation has only been rated as very satisfying for 5% of respondents. In addition, just less than half (48%) of respondents report continued use of traditional technologies exclusively, which include the following:

- Fax machines

- Manual order entry and review

- Land-line phones, not voice over internet protocol (VoIP), which reduces overall costs and downtime

- Email, although beneficial, is susceptible to internet connectivity issues, security breaches and other problems

- Chaotic picking protocols

This infographic, created by GT Nexus, also shows other ways the digital supply chain evolved in 2016.

(Made with Canva)

Essentially, the digital supply chain is essential to gaining and maintaining competitive advantage. Digital technologies, reports Richard Howells of Forbes, including Big Data, analytics, the Internet of Things, social media, and point-of-sale reporting, enable business to know more about consumer needs and wants than ever before. Consequently, they can more accurately respond to changes in product demand across large distances and within infinitesimally small time frames.

Supply chain execs retained fundamentals throughout change.

Innovation is the driving force behind change and improvement in the modern world. Supply chains must evolve to meet an increasing number of omnichannel sales, and technologies must be integrated within existing systems to reach maximum efficiency and productive value.

As explained by Grant Marshbank of VSC Solutions, “The rate of change is not going to slow down. Technology will only delivery […] if it’s implemented with strategy and operations that adhere to best practices.”

Marshbank’s words highlighted the need to focus on fundamental concepts while responding to changes and improvements in the supply chain. For example, an optimized supply chain is good, but it opens more opportunities for errors. Simply putting all an organization’s proverbial eggs into one basket may be risky if appropriate auditing and review measures are not undertaken to ensure continued compliance and accuracy in all orders.

Change is a necessity for businesses, including the supply chain, to grow and expand. Yet many destructive forces can severely undermine a company’s progress. Bad weather, poor hiring practices or inefficient maintenance of consumers’ financial data can decimate a company. However, the response to hindrances in 2016 continued to showcase the importance of fundamental concepts, asserts Ryder, which include the following:

- Continually seeking the fastest, most cost-effective means of transporting products to consumers, including enhanced delivery optins.

- Expansion of global footprint while adhering to local, state, federal and international requirements

- Keeping companies accountable and focused on giving back to their domestic partners through reshoring or nearshoring

- Working with more outside agencies, also highlighted by Samantha Carr of Business 2 Community, including crowd-sourced logistics, warehouse optimization and outsourcing, and greater use of cloud-computing

Augmented reality found its place among consumers.

Augmented reality sounded amazing and far-fetched early in 2016, but the year has shown it to be one of the most successful product in existence. There tends to be more acceptance of technologies in the workplace once consumers can identify how they work.

For example, new hires are likely to pick up tablet-based systems more easily since they have been using them recreationally for some time. Essentially, the virtual-reality (VR), which is the precursor to augmented reality, hype of the 2016 Christmas shopping season is making more people excited about this new way to “see the world.”

While the VR hype may seem like it only emerged for Christmas, think about one of the hottest games of 2016, Pokémon Go! This app was built on augmented reality, combining the digital and physical worlds into one interactive environment. This technology, reports JOC.com, will be a key to practically eliminate extensive training courses and repair time requirements throughout the supply chain.

Ultimately, it translates into greater use of augmented reality in supply chains, which is growing by 100% annually, reports Barcoding Incorporated.

What’s next?

Clearly, technology dominated the conversation for 2016, but there are also changes in how supply chains operate that require a more in-depth discussion as well. In the next post of this series, we discuss the impact of artificial intelligence, agile processes and procurement expansion on the supply chain of 2016.

Related posts:

![The State of Supply Chains: The Supply Chain Has Gone Digital [Infographic]](https://fronetics.com/wp-content/uploads/2024/10/virtual-reality.jpg)